Retaining wall with your own hands. Wall Configuration

When we buy a building plot, the question arises: to choose a flat or sloping site. Often offered places with difficult terrain - mounds, depressions, and even with small ravines are much cheaper. Typically, such sites are located either close to natural reservoirs or in primary development, in places that are environmentally friendly, but not yet leveled and ennobled by previous owners. In skillful hands, a place with a difficult terrain can become not a problem, but a godsend. A retaining wall on a sloping site will help to strengthen the soil and give additional charm to a country estate. But if you are going to use most of the land for a garden, choose the most even sunny land allotment.

Even if you do not build a retaining wall yourself, it would be useful to have an idea about its structure.

A section with a rugged relief, containing slopes and hills, is conveniently divided into horizontal platforms located at different levels. Gentle slopes can be strengthened with grasses, shrubs or trees with strong roots.

If the slope is steep or its strengthening with the help of vegetation does not fit into the design concept, a retaining wall is placed at the boundaries of the platforms and ledges. Its main purpose:

- Artificial formation of a well-fortified horizontal plane.

- Prevention of soil collapses.

- Soil erosion prevention.

- The division of the household into plots.

- Territory decoration.

With skillful planning and arrangement of sites and retaining walls, a site on a slope can become more interesting and convenient than a flat one.

Retaining walls are decorative, designed to decorate the site or reinforce the unevenness of the relief, preventing their destruction. This does not mean that reinforcing retaining walls should look ugly, they are made as attractive as possible without reducing their functional properties.

Few people are lucky enough to become the owner of a completely flat piece of land. On a flat surface, it's easy...

advance planning

Before proceeding with the construction of retaining walls, it is necessary to think over some points, to carry out preliminary planning. Even if you are going to strengthen the slope on your own, at this stage it is better to involve a specialist or a person with experience in arranging gentle areas.

Retaining walls should fit into the design of the site, be in harmony with the architecture of the house, courtyard buildings and the external fence. Before you make a granite block parapet in a small area, think about whether it should look like a massive structure and attract attention. Bulky structures hide space, which is not always in place even in large areas. But if your site is designed, for example, in the Victorian style, a massive natural stone structure that attracts attention will be more than appropriate.

Be sure to plan in advance the height of the retaining structure, the area of the terrace above it, the thickness of the earth layer on the terrace. After all, if you lay a thin layer of soil, then you will not be able to plant large tree groups, and for a lawn or garden of succulent plants, a layer of fertile soil of one and a half meters is not needed at all. So even if you do not have a detailed dendrological plan, you need to imagine at least in general terms what kind of plants will be placed there.

Another important point is that you will not jump from terrace to terrace, even if they are not very high. Between them, as well as with the rest of the site, it is necessary to connect them with ladders and paths. It is possible that on one of the ledges there will be a bench or a small gazebo for relaxation. All this should be taken into account at the planning stage, and not changed during the work process.

DIY manufacturing technology

To design soil-reinforcing retaining walls, it is better to call an experienced specialist, but if this is not possible, and you yourself have the necessary knowledge, you can do the calculations yourself. The following points must be taken into account:

- A retaining wall can only be placed on solid ground.

- The ground in this place should not freeze more than 1.5 m.

- It is necessary that groundwater lies more than a meter from the surface.

- You can not independently put a retaining wall higher than 1.4 m.

Retaining wall components:

- base;

- parapet;

- drainage.

Foundation

When the retaining wall is higher than 30 cm, it must certainly stand on the foundation. The foundation is the underground base of the retaining wall, it is pressed by the weight of the retained soil. You can't just dig a moat and fill it with concrete. The configuration of the foundation should be such that the retaining wall does not change its position and slope under the pressure of the soil. In our case, it is an inverted pyramid with a cut top and various slopes of the faces.

The foundation is set on a thick layer of gravel, reinforced with reinforcement. Concrete is poured in one go - this is the only way we get a monolithic base. The more unreliable the soil under the supporting wall, the deeper the foundation is needed:

- Dense soil. The ratio of the depth of the foundation to the height of the retaining wall is 1:4.

- Medium loose soil. The ratio of the depth of the foundation to the height of the retaining wall is 1:3.

- Loose soil. The ratio of the depth of the foundation to the height of the retaining wall is 1:2.

Retaining wall

Directly the retaining wall with its inner part is in contact with the retained soil and outlines the elevation with its contour. Its outer part is clearly visible and should seem picturesque.

The retaining wall does not have to be a perfectly flat structure. Need a slope of more than 5-10 degrees, directed upwards and towards the slope. When constructing a concrete wall, the slope is taken into account during the installation of the formwork and reinforcement cage. The wall of other materials is also constructed obliquely.

Water disposal and drainage

Water will accumulate between the retaining wall of any material and the soil. It will get there with watering and rains. It is imperative to ensure its outflow, if, of course, you want the structure to stand for a long time and effectively protect the soil from collapse.

Drainage helps keep the soil adjacent to the wall dry. It does not allow the soil near the foundation to turn into dirt. It is made in the standard way - a drainage pipe is laid between the wall and the soil of the high part of the site, then it is covered with gravel, which is covered with a geotextile fabric. The drainage pipe is directed down the slope.

Keep in mind that fertile soil will be located on top of the drainage layer - leave room for it.

Nature does not have bad reliefs, everything is harmonious and original in it. It is believed that if you got a plot with…

Global retaining wall

Global retaining walls, mounted on the slopes of large ravines, are rarely needed in household plots. But if you have vast lands with a ravine, the slope of which needs to be strengthened, do not even try to do the work yourself. Invite a specialist who will competently make the necessary calculations and do the work.

If you think that you can manage the construction of a global retaining wall on your own, read this chapter to the end, then make your final decision. The retaining structure must be very reliable, so that it cannot be destroyed and the soil does not slip. Below we list the factors on which the strength and durability of the retaining wall depends. They must be taken into account when designing:

If you think that you can manage the construction of a global retaining wall on your own, read this chapter to the end, then make your final decision. The retaining structure must be very reliable, so that it cannot be destroyed and the soil does not slip. Below we list the factors on which the strength and durability of the retaining wall depends. They must be taken into account when designing:

- The weight of the elevated section of the retaining wall;

- Width, wall height;

- Grip with the soil;

- Vibration level (in case there is a highway, metro, railway or airport nearby);

- Seismic characteristics of the region;

- The level of precipitation during the year;

- Winter expansion of the soil;

- Depth of groundwater;

- Wind strength, wind rose throughout the year;

- Type, mechanical properties of the soil.

Construction materials

Of great importance is the material from which the retaining wall is made. Most often for their construction use:

- tree;

- stones;

- brick;

- concrete.

Each material has its own characteristics, which will be discussed below.

You will need gravel, reinforcement, concrete for the foundation, material for the actual supporting structure, gravel, sand, pipes, waterproofing for the drainage device.

wooden retaining wall

The advantage of a retaining wall made of wood can be considered its relative cheapness, but its main disadvantage is that it is the most short-lived. Immediately make a reservation that the wood is smooth and of good quality. The best for the construction of retaining walls is round timber with a diameter of 12-18 cm. When calculating its length, it must be taken into account that at least 50 cm will be underground.

We carefully lubricate the logs with used machine oil, let them dry for a couple of hours, and lubricate them again. This will protect them from rotting, especially the part that is underground and constantly in contact with wet ground.

- To build a simplified wooden supporting wall, we position the round timber in a ditch at least half a meter deep vertically, fitting the logs to each other very tightly. Then we fix them at the top with a wire, connect them with nails. The ditch in which the round timber was installed is filled with concrete.

- Retaining wall "Fence". Logs of larger and smaller diameters are used. Larger ones are installed in a ditch at a set distance, a gap is made between them, into which a round timber of a smaller diameter is very tightly installed. As in the example described above, we fill the moat with concrete.

Retaining wall made of stone

The most expensive, both financially and physically, as well as the most attractive, is a retaining wall made of natural stone. It will be appropriate in the design, made in any style. In addition, special pockets for planting plants can be formed in it in advance, which will only increase its aesthetics.

You can use basalt, granite, shell rock, syenite. It is important that the thickness of the stone wall is at least 30 cm, otherwise it will turn out to be unstable and may soon collapse. Let's look at the stages of building a stone retaining wall using an example. We will assume that our soil is dense, and we are building a wall 1 meter high.

- We choose a place, make markings - we drive in pegs and pull a strong cord.

- We dig a ditch 40 centimeters deep.

- Level and tamp the bottom of the trench.

- Pour at least 3/4 of the foundation with a concrete mixture consisting of 6 parts of gravel and sand and 1 part of concrete. (In our case, we assumed that the soil is dense. With loose soil, a wooden fence is made, and the depth of the foundation is increased according to the looseness of the soil).

- Let the concrete pad sit for about 3 days.

- We prepare a lime mixture: for 1 part of quicklime we take 4 parts of sand. We take 300 g of water per kilogram of the mixture. Add water gradually to avoid lumps. In 7 parts of the mixture diluted with water, add 1 part of cement. We lay a lime layer of at least 3 cm on the foundation.

- We lay the stones. Remember what we talked about above. It is necessary to lay stones with a bevel towards the earthen wall of about 10 degrees. We lay the stones so that the largest and even ones fall on the edge of the wall, and if the wall configuration provides for a hall, then at the corner. Small stones should be in the middle of the structure. Choose your stones carefully. They need to be secure. When the first row is laid out, lay out a 1-1.5 cm layer of lime-cement mortar. Do not make a large seam - it quickly collapses. When laying each next row, make sure that the side edges of the stones are not located one above the other - such a design will not be stable. It is necessary that the side faces of the stones of different rows touch in a checkerboard pattern. From afar, such masonry will resemble brick.

- After laying each row of stones, we fill the holes between the stones and the soil with crushed stone, gravel and a rammer (carefully so as not to knock down the stones).

- After laying the second row of stones, we lay the drainage pipe.

- When the stone supporting wall is ready, we erase the traces of the bonding solution.

Retaining wall made of concrete

The strongest and most solid is considered a concrete retaining wall. We dig a moat along the border of the wall, fill it with a layer of gravel and rubble, on which we lay the reinforcement. Now we are constructing formwork from lumber with a thickness of 25 to 45 mm, fixing it with ties or nails. Every one and a half meters we hammer metal rods so that the screed does not bend under the weight of concrete.

We pour concrete. After a few days it will harden, the formwork can be removed. Let's level all defects by means of plaster. So that the concrete wall does not look dull and does not spoil the appearance of land ownership, it is faced. Facing material should be harmoniously included in the design of the site.

Brick retaining wall

A brick wall less than a meter high is laid out in half a brick, if a meter or higher - in a brick. The laying of a retaining wall is the same as ordinary brickwork in the construction of any other object. The foundation for brickwork of a meter height should be 20-30 cm wider than the brickwork itself.

Clean air, green spaces, lack of city noise are the reasons why the construction of suburban housing has recently become increasingly popular. However, not everyone gets flat plots for individual development. What to do for those owners who received plots in areas with fairly large elevation changes? In this case, a concrete retaining wall will help, the construction technology of which has been worked out for more than a decade. Such structures are also widely used in urban development, as cities grow and there are not enough flat areas for the construction of new buildings.

Purpose of retaining walls

By appointment, retaining walls are divided into two main classes:

- Decorative. The main purpose of such buildings is to give the landscape a site with a slight slope of a more attractive aesthetic appearance.

- Fortifying. Such walls withstand significant soil pressure and are designed to prevent it from sliding down the slope and washing away the fertile layer from the surface of the site.

Varieties of concrete retaining walls

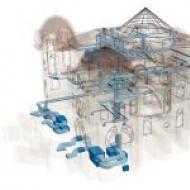

Reinforcing retaining walls made of monolithic reinforced concrete are divided into three types:

- massive;

- combined;

- thin-walled.

The first category of supporting walls holds the ground pressure only due to its large mass (strength also depends on the depth of penetration). Due to the fact that the manufacture of such walls requires a large amount of building material, for individual construction they can be recommended for the construction of low retaining structures (height above the soil level of 0.5 ÷ 0.7 m) in areas with a small angle of inclination. Then the recommended depth (⅓ of the height) will be 0.17÷0.24 m, and the thickness (¼÷½ of the height) will be 0.25÷0.35 m.

Combined products have less weight than massive ones. To increase their stability, a foundation of a wider size is used than the base of the wall itself (the soil pressing on the protruding elements of the foundation partially reduces the load and thereby increases stability).

Thin-walled concrete retaining walls are made in L- or T-shape. Since the width of the "sole" of such products is commensurate with their height, the vertical pressure of the soil on the support significantly reduces horizontal loads and increases the wall's resistance to overturning.

Such products can be purchased in the form of finished sections made in the factory.

Homemade retaining concrete wall

If the slope of the surface of your site is not too large, then it will not be difficult to make a concrete retaining wall with your own hands. For example: you need to build a retaining wall 1.2 m high (above ground level). In order to save building material (reinforcing bars and concrete mortar), we recommend choosing a thin-walled corner retaining wall with a T-shaped base. How to make a retaining wall out of concrete (three main steps):

Preparatory stage

First, we prepare a sketch, a drawing and a reinforcement scheme.

Then we proceed to earthworks. We make markings with the help of pegs and construction cord. We dig a trench of the required width (slightly more than the width of the support, taking into account the formwork) and depth (taking into account the thickness of the support and the cushion of sand and gravel). We store the earth from the trench in a free area (later it will be needed for backfilling on both sides of the wall). We fill the bottom of the trench with sand (layer thickness of about 0.2 m) and ram it (periodically wetting it with water). Then we fill up the same layer of crushed stone and also ram it (with a vibrating plate or manual rammer). We lay geofabric on top of the equipped pillow.

Formwork and grouting

Now let's start creating a reinforcing frame. The reinforcing bars of the "soles" and "body" of the wall must be interconnected.

We build formwork. First, we make it only for the foundation of the wall. After that, we pour the concrete solution along the entire length of the foundation, compact it with a vibrator. After the mortar has set, we proceed to the installation of the formwork of the supporting wall itself. The formwork manufacturing technology and the materials used for its manufacture are similar to the arrangement of the strip foundation.

Important! In the process of arranging the formwork, it is necessary to lay transverse plastic or asbestos-cement pipes in it to drain groundwater and precipitation penetrating the soil (the lower edge of the pipes should be slightly above the ground level on the outside of the supporting wall). This will significantly reduce the loads on the inside of the vertical slab. Distance between transverse drainage pipes - 1.0÷1.5 m.

Then we proceed to pour the concrete retaining wall.

Attention! To prevent the formwork from collapsing or deforming during pouring, this process is best done in stages. First pour the solution into⅓ height along the entire length of the wall. Then we perform vibration compaction of the poured solution. Next, fill the formwork with a solution for another third and so on.

To ensure the greatest strength and uniformity, it is desirable to pour the entire structure in one day. After the solution is poured to the upper edge of the wall and completely tamped, the surface is leveled and covered with plastic wrap and left for final drying. To prevent the rapid evaporation of water from the solution (which can adversely affect the strength) in hot weather, the surface of the solution is periodically wetted.

Waterproofing and arrangement of the drainage system

After 7÷9 days, we proceed to the dismantling of the formwork. To ensure durability, we cover the concrete surfaces of the wall with a waterproofing material (for example, a special compound based on liquid rubber).

- Along the entire length of the wall from the inside (that is, from the side of the slope), we lay a perforated pipe (always wrapped in a permeable geofabric).

- Then we fill this pipe with rubble.

- We lay geotextiles on top of the crushed stone (to keep the free space not filled with soil between the individual particles of crushed stone).

- The free end of the pipe (on one or both sides of the wall) is brought out into the drainage ditch (or well) or the nearest water collector.

At the final stage, we fill the free space around the wall with soil.

Important! We start backfilling the soil only after the concrete retaining wall gains its final strength and can withstand significant loads from the side of the slope, that is, not earlier than in a month.

Retaining wall made of concrete blocks

For the device of decorative retaining walls, blocks of lightweight porous concrete are successfully used. Reinforcing retaining walls made of concrete blocks are made of FBS (solid foundation blocks), at least 400 mm wide (by the way, this value will be the wall thickness). They are made in the factory. High strength and density (2000÷2300 kg/m³) of the material determine their wide application in the construction of massive retaining walls.

Algorithm for arranging a retaining wall made of concrete blocks:

- We make markings, earthworks and arrangement of a cushion of sand and gravel (all works are similar to the construction of a reinforced concrete wall).

- After that, we proceed to laying the blocks, which we fasten together with a sand-cement mortar.

- We lay the rows of blocks "in a row" (that is, we equip each subsequent row with a shift by the floor of the block in relation to the previous one).

- To increase the bearing capacity and strength of the wall, we place reinforcing elements (metal mesh or reinforcement bars) in horizontal mortar joints.

Attention! Standard block weight with dimensions 800x 400 x580 mm is 470 kg, therefore, to equip a retaining wall from such products, you will need to use lifting equipment.

In custody

The choice of retaining wall design depends on its purpose (decorative or reinforcing) and the characteristics of a particular site: elevation difference, soil characteristics, groundwater level, and so on. A properly designed and equipped retaining wall will last for decades without repair.

In summer cottages and urban areas, where a complex terrain with hilly or ravine places creates many problems regarding gardening and planning a beautiful yard, I want to put things in order. Usually, in this case, it is convenient to divide the territory of the site into terraces, which are located at different levels. The retaining wall plays a key role in such cases.

Terracing a site is the process of artificially forming a fortified horizontal plane - a terrace or ledge.

The retaining wall is built on the boundaries between such planes, which helps prevent the occurrence of collapses and landslides, as well as the washing out of fertile layers of the earth.

Unfortunately, it is true that not all land owners can say that they have a flat terrain. So the conclusion suggests itself that the retaining wall is an indispensable part of the site. It will not only decorate your garden, but this structure will also divide it into special zones.

Making a retaining wall yourself is not at all difficult. During the process itself, a wide variety of plans related to landscape design are implemented. Next, we will consider the main features of the construction of retaining walls with our own hands.

Retaining wall: device and functions

There are different designs of retaining walls. It all depends on the function that this building should perform. The retaining wall can be both decorative and fortifying. For each of the two types, there must be a certain degree of impact. But the "backbone" always consists of the following main components:

Retaining walls have the following features:

What affects the stability of retaining walls

Maximum stability, resistance to high pressure are very important qualities that a well-made retaining wall should have. Otherwise, the structure can easily collapse, and the soil can slide. Therefore, it is necessary to take into account every factor on which the strength of retaining walls depends.

So, we need to figure out what still acts on retaining walls? The influence of the own weight of the building, the forces of adhesion and friction with the ground, the pressure of the soil, the additional weight of the components that may be on it - all this is of tremendous importance.

What can affect the design of the building:

- soil swelling in winter;

- wind strength (if the retaining wall is higher than 2 m);

- vibration level (for example, if there is a railway nearby);

- any seismic event (each region has its own characteristics);

- washing with rainwater.

An additional factor affecting the level of stability of the building is the thickness of the wall. It is determined by the type of soil and the height of the structure itself. If the ground is soft and the support is high, then it is natural that the width of the protective “shield” should be greater. This is logical.

How to set up a retaining wall. Basic moments

The retaining wall is a rather complex engineering structure, therefore, before constructing it, it is necessary to take into account certain factors that affect the level of strength, reliability and service life of the wall. Of course, when real specialists are involved in this business, everything is done strictly according to the rules. And this is very good. But having certain specific skills and taking into account the circumstances under which you can build a support, you can build such a structure yourself without any problems.

How to make an underground part. Which foundation to choose

Retaining walls with a height of more than 30 cm must necessarily be with a reliable foundation. The main principle that should not be forgotten when laying the foundation is that if the soil is soft and unstable, then the depth of the foundation should be increased.

If you want to level your site and you will learn how to do it.

The depth of the foundation and the height of the support, taking into account the friability of the soil

- If the soil is quite dense, then the depth of the foundation and the height of the upper part of the support (above the ground) should be related as 1:4.

- In the presence of soil with medium friability, the depth of the foundation should be 1/3 of the height of the support.

- If the soil is loose, soft, the depth of the foundation should be 1/2 of its height.

- Concrete, crushed stone, gravel, compacted with heavy clay or cement, should form the foundation.

Use of drainage, drainage and waterproofing for the construction of retaining walls

For the equipment of the support, it is necessary not only to lay a high-quality foundation and build a supporting wall on it. The design needs to be protected on the other hand from moisture, which adversely affects it.

The organization of drainage, drainage and, if necessary, waterproofing the inside of the wall are all necessary measures, regardless of what material is used, and what size and shape the retaining wall has. The most important thing is that this prevents the accumulation of moisture and water, which, for obvious reasons, act destructively on the structure.

The drainage of retaining walls can be transverse, longitudinal, and also combined.

With a transverse organization of drainage, special holes are installed in every second or third rows of masonry (their diameter should not exceed 10 cm) or tubes at an angle. Then the water will immediately leave the territory of the site, which is what we wanted.

For longitudinal (underground) drainage along the retaining walls (underground at the level of the foundation), corrugated, ceramic or asbestos-cement pipes (their diameter is about 10-15 cm) are laid, wrapped in geotextile materials that absorb water, since it enters the pipe through small holes and assigned to the site.

Also, special visors or eaves blocks with a slope are made so that atmospheric water does not enter the masonry, because at low temperatures this will lead to the destruction of the retaining walls. And this cannot be allowed.

Drainage layers between wall and ground

When the wall is assembled and has stood for a couple of days, the space between it and the slope must be filled. Coarse-grained soil (for example, with gravel, coarse sand and pebbles) is suitable for this task. We'll have to stock up on small pieces of brick and other waste material. Regardless of the fact that the gravel presses on the support, this is an additional drainage layer.

Each layer of drainage mixtures and soil is poured separately in order to compact these layers. Here it is preferable to deal with coarse soil and sandy loamy sands.

The use of vegetable soil is necessary for the upper ball of laying materials. When the tamping of the last layer of the retaining wall is finished, the wall is left in this state for a couple of weeks without additional load. Such a measure will lead to the fact that reinforcing materials will acquire all the necessary properties. It is also necessary to remove a layer of soil in advance with a sufficient amount of humus and put it on top. Having done all these manipulations, you can move on to the equipment of the site with peace of mind.

Use of waterproofing

To increase the service life of a retaining brick, wooden, metal or concrete wall, it is necessary to waterproof it from the ground. For this important event, roofing material or roofing felt applied in two layers is used. If the soil is dry, you can use bitumen or mastic to apply to the inner surface.

What material are retaining walls made of?

First you need to decide on the purpose of the retaining wall, and then select the material for it. It has already been said before that retaining walls can be fortifying and decorative.

To build a reinforcing element of steep slopes, natural stone or concrete should be used. There are areas located near the railway, which regularly give in to ground vibration. And because of such constant powerful pressure, the more brittle material will soon lose its properties, which will negatively affect the level of wall reliability.

If you plan to build a retaining wall as a decorative element, then the use of wood, brick or gabion is already acceptable.

Retaining wall made of wood

The installation of this type of retaining wall is considered cheap, but the construction process itself will not be as easy and fast as it might seem at first. Creating and installing a wall will immediately require smooth, high-quality wood. A more simplified construction method is to place the logs vertically, fitting them tightly together. Logs with a diameter of 12-18 cm are considered the most suitable for building a retaining wall. The height of the logs must be calculated depending on what height of the supporting wall we are planning. Calculating each step in advance, do not forget that when installing the wall, somewhere around 50-60 cm of the structure will be buried in the ground. And this is at least.

Each log is placed vertically and close to other logs. At the top, they are tightly wrapped with wire. And to prevent displacement, the logs are connected with nails. For maximum stability, after the logs have been fixed, the trench must be completely filled with concrete.

To avoid rotting wood, which is partially underground, it is lubricated with engine oil. This is a very effective remedy for this situation.

Would you like to use the next method called "fence"? This will be more difficult when building, since here each vertical log must be established at a certain interval. It is necessary to make a special hole in which a log of a smaller diameter will be installed quite tightly.

Here you can’t do without high-quality and even logs, because because of rotten wood, everything can completely deteriorate. And we certainly don’t need this, otherwise it will turn out that all efforts and labors will go down the drain. This method is often used: logs are taken, arranged strictly vertically, tightly docking with each other. The diameter is taken here, as in the previous method. But the parts that remain underground are about 40-50 cm. This length will be quite sufficient for the structure to stand straight in the spring and not move when the soil begins to absorb moisture many times more. The reliability of the design must be ensured in the first place.

Retaining wall made of concrete

This is the most durable and solid construction. Its construction begins like this: a trench breaks out, which will have exactly the same perimeter as the wall itself. It is worth considering the fact that the height of the wall affects the depth of the trench.

At the bottom of the trench, a mixture with gravel and crushed stone is laid, after which reinforcement is laid, which is fixed with a bonded wire. Only after that the formwork is removed. The formwork is made of boards with a thickness of at least 25 mm and not more than 45 mm. Nails or ties give the structure a fortress. In the future, it will not crumble, deform concrete. Due to the pressure of the mixture, the side walls of the formwork may begin to buckle. To prevent possible further destruction, it is necessary to score metal rods at intervals of 1.5 meters.

At the end of the preparatory work to strengthen the retaining wall, concrete is evenly poured. You have to wait a couple of days for the wall to form. Then the formwork is removed. And if there are any irregularities, they are leveled with plaster.

Then you can proceed to facing work, in the implementation of which each owner can choose the necessary materials at his own discretion. Here you can already give preference to whatever your heart desires.

Construction of a brick pillar

The brick wall is laid in exactly the same way as during conventional construction. The only thing that needs to be emphasized is that here the thickness should be made smaller. If the wall is less than a meter high, it must be laid out with a half brick. If the wall is higher, then a whole brick is used. Facing materials for a brick structure are the same as for concrete.

For this structure, a foundation of that depth is needed, which will be affected by the final height of the wall, the composition of the soil and the degree of its freezing. If we talk about the width, then it is often 20-30 cm larger than the retaining wall itself.

During the construction of the wall, the main thing is not to forget to follow the ratio of length and thickness of 1: 3. The special design of the retaining brick wall has always distinguished it from similar structures made of other materials. The installation of such a wall is not considered too simple, but at the same time it is not very difficult. The main thing is to carefully follow each paragraph of the instructions.

Retaining walls made of natural stone

The construction of stone walls is more significant material and physical costs. But the game is worth the candle, because the beauty and aesthetics of such a support cannot be compared with anything. Indeed, if you look closely at such a structure, you cannot fail to note this special style and appearance that natural stone gives to the entire building.

A stone retaining wall has a considerable advantage: plants are planted in pre-formed earthen pockets. Natural stone is the most attractive material from which a retaining wall is manually created. Often, granite, basalt and syenite are used in construction. These are the most common natural stones. Sandstone or lime will help give the retaining wall an antique look. They can quickly absorb moisture, moss appears on the treated areas. Because of this, the design has a touch of an old building. And this decision looks very romantic. The foundation is laid in such a way that its width is more than 30 cm. Without following these rules, you can end up with an unstable wall, which may soon collapse.

Retaining stone wall, the height of which is 1 meter, with a longitudinal drainage system.

1) You need to mark the site.

A suitable place for support is selected in advance (with a slope at the terrace, which is located higher than ground level). Stakes are driven in along the edges of the selected area and a cord is pulled.

2) Prepare the trench.

With the help of a garden knife, the soil is cut along the markings. And with the help of a shovel, a thin layer of earth is removed. This will be followed by digging the trench itself, the depth of which will be 40 cm.

3) Laying the foundation.

The bottom of the trench is well leveled and compacted. Then a layer of concrete is poured with a depth of at least 30 cm. The concrete mixture for the foundation consists of one part of concrete, 6 parts of sand and gravel. That should be the proportion.

If the soil is loose, then before pouring the concrete mixture, a wooden fence should be made. Let the concrete pad dry completely, which will take about three days.

4) Creation of a lime layer.

When the foundation is completely dry, before laying the stone, it is necessary to smear it with a lime mixture in layers of 2-3 cm. The composition of the mixture includes sand, water, cement and lime. For one part of quicklime, 3-4 parts of sand are needed. For each kilogram of such a mixture, 300 ml of water is required. To avoid lumps, water is added gradually. Then you can add cement. We get the ratio: 1 part of cement to 7 parts of the mixture.

5) We lay the stone.

The stones are carefully cleaned of dirt and wetted with water. You can not put a stone one on top of the other. Otherwise, the building will fall apart due to the slightest external influence. The junction of two stones is located in the center of the stone located in the previous row. A larger stone with regular shapes is always placed along the edge. For the middle, a smaller stone is suitable. We must try to find stable positions for all stones.

For the next row of walls, the same principle is used with lime mortar. The mixture should be with a minimum thickness of 1-1.5 cm, otherwise too large seams will be quickly destroyed. For the stability and strength of the structure, the side that is behind is made with a certain slope towards the retained soil (approximately 5-10 degrees).

A broken curvilinear retaining wall configuration is stronger and more reliable, since such wall lines are characterized by a reduced span length. There is no huge load on them, and thanks to the rough surface of the back wall, there is a closer contact with the soil.

6) Use of drainage and drainage.

Each installed row of support between the soil and the wall requires falling asleep a layer of crushed stone with gravel or small pebbles with gravel. After that, everything is neatly rammed. When laying the second row of support, you will need a drainage pipe.

When the retaining wall is in place, traces of lime mortar are removed with water, a sponge and a brush.

Retaining wall in landscape design

Immediately it should be said that each site has its own individual shape, size, relief features. Therefore, in the process of building retaining walls, their own special approaches are used, taking into account the personal preferences of the owner, his tastes, the style of the house itself, the territory of the garden and everything related to it. For example, if this landscape has a pronounced relief, then it is worth using a vertical layout. This move would be really appropriate. To do this, the site is divided into horizontal levels, which are fixed with supports.

For a small land area, the height of the wall being erected reaches 60 cm. Bushes grow well along such structures. While too high a wall creates an unpleasant impression of heaviness. If, however, such buildings are planned in advance on the site, then they are “diluted” with the help of various interesting architectural elements (for example, a bench, niches, steps, and the like).

The chosen material for the construction of retaining walls should be explained by specific design decisions. It would be logical. After all, relief, textured material is used to “elevate” the monumentality of the support. Also in this case, the installation of large granite stones, laid with a large seam, is welcome. And here it is appropriate to use a powerful log. To create a more refined, somewhat inconspicuous, but on the other hand elegant relief, wall cladding is done using small stones and plaster.

Today, any project can be realized. It is important not to violate the construction technology.

Video How to make a retaining wall

During the construction of various kinds of buildings on terrain with complex terrain (beams, ravines, etc.), a need often arises for a retaining structure. Such a reinforcing structure has one main task - to prevent the collapse of soil masses. The article will discuss the construction of retaining walls.

- Decorative- effectively hide small differences of soil in the adjacent territory. If the levels differ slightly and, accordingly, the height of the wall is low (up to half a meter), then its installation is carried out with a slight depth of up to 30 cm.

- Fortifying perform the main function - restrain the soil masses from slipping. Such structures are erected when the slope of the hill exceeds 8 °. With their help, the organization of horizontal platforms is carried out, thereby expanding the usable space.

Retaining wall photo

Retaining wall design

Regardless of the purpose, the retaining wall has 4 elements:

- foundation;

- body;

- drainage system;

- drainage system.

The underground part of the wall, drainage and drainage serve to implement technical standards, and the body - aesthetic purposes. In height, they can be low (up to 1 meter), medium (not higher than 2 meters) and high (over 2 meters).

The back wall of the structure can be with the following slope:

- steep (with direct or reverse slope);

- sloping;

- recumbent.

The profiles of the fortification walls are varied, mainly rectangular and trapezoidal. The latest designs, in turn, can have a different slope of the faces.

Acting loads on retaining walls

When choosing a material, and, accordingly, a foundation for lifting walls, they are guided by the determination of the loads that act on the structure.

Vertical Forces:

- own weight;

- top load, that is, the weight pressing on the top of the structure;

- backfill force acting both on the wall itself and on part of the foundation.

Horizontal forces:

- soil pressure directly behind the wall;

- friction force in the places of adhesion of the foundation to the ground.

In addition to the main forces, there are also periodic loads, these include:

- wind strength, this is especially true when the height of the structure is over 2 m;

- seismic loads (in seismic hazard zones);

- vibrational forces act in places where a road or railroad tracks passes;

- water flows, in particular in the lowlands;

- swelling of the soil in winter, etc.

Retaining wall stability

The construction of low retaining walls is carried out to a greater extent for decorative purposes, they do not need a careful calculation of stability. An increase in this property is indicative of retaining engineering structures.

You can prevent wall shifting or tipping over by applying the following measures:

- significantly reduces ground pressure on the back face slight slope designed towards the hill;

- the side facing the ground is roughened. Protrusions are made in stone, brick, block masonry, and chips are made in monolithic retaining walls;

- a properly organized drainage system prevents the structure from being washed away;

- the presence of a console in front of the wall provides additional stability, as it distributes part of the soil load;

- lateral (vertical) pressure is reduced by backfilling hollow materials (expanded clay) between the back wall and the existing soil;

- foundation walls are required for solid walls made of heavy materials. For clay soil, it is advisable to use a tape-type base, weak soil (sandy, especially quicksand) - a pile foundation.

Retaining wall construction

As for the material, its choice is based on many criteria, such as the height of the structure, water resistance, resistance to aggressive environments, durability, availability of building material and the possibility of mechanizing the installation process.

brick retaining wall

- When calculating retaining walls made of bricks, the presence of a reinforced foundation is provided. Decorative qualities can be enhanced by using bricks that differ in size or color from the elements of the main masonry. A low wall (up to 1 meter) is laid out independently. In cases where an increased load is implied, you should resort to the services of professionals.

- For work, ordinary red burnt brick or clinker with a high coefficient of strength and moisture resistance is used. As a rule, a strip foundation is required for the construction of retaining walls.

- The width of the ditch under the base is equal to the triple width of the wall, that is, if it is planned to build in one brick (25 cm), then this parameter will be equal to 75 cm. The depth should be at least 1 m. But the bottom is covered with a 20-30 cm layer of gravel or crushed stone , then a layer (10-15 cm) of sand, each filling of the material is rammed.

- The formwork is knocked down, its upper part should be 15-20 cm below ground level. For reinforcement, reinforcement bars are used, which are laid on broken brick or rubble stone. In any case, they should not just lie on a sand and gravel pad. Next, concrete grade 150 or 200 is poured.

- The clinker is placed in the dressing on the solution. The second row provides for the laying of drainage pipes Ø50 mm. During installation, the slope of the pipes to the front of the face is observed, the recommended distance between them is 1 meter. It is important to monitor the displacement of the seams. To prevent this from happening, you can use brick halves.

- It is worth noting that laying in one brick is possible for building a wall up to 60 cm, for higher structures it is recommended to build in one and a half, two bricks, with the expansion of the lower part of the wall. Thus, a construction resembling a console is obtained.

Stone retaining wall

- Natural stone, like its artificial counterpart, has high aesthetic properties. In addition, the appearance of the finished wall allows you to harmoniously fit into the surrounding landscape, creating a single ensemble with nature.

- Both dry and wet laying methods can be used here. The first option is more time-consuming and requires some skill, since it is necessary to fit the stone in size, ensuring optimal fit to each other.

- The base for a stone retaining wall is made in the same way as for a brick. A strip foundation is being carried out, followed by the laying of stone. If the construction of the wall is carried out without the use of mortar, then the seams are filled with planting material or garden soil. Later, plants with a fibrous root system are planted between the stones. As they develop, they will significantly strengthen the structural elements.

- In this case, you can organize the drainage system in a simplified way - leave gaps of 5 cm in the first row between each 4th and 5th stone.

- Walls made of stones are recommended for the construction of structures no higher than 1.5 m.

Retaining walls made of concrete

- Such a construction of a monolithic type is carried out using wooden formwork or bored piles.

- Factory retaining reinforced concrete wall

- Installation of a factory-made plate is carried out using lifting equipment. It can be console or buttress. For the installation of finished products, a foundation with dense soil is not needed. It is enough to dig a trench with a width slightly larger than the size of the sole of the slab or console.

Prefabricated retaining walls photo

- Gravel (crushed stone) and sand are laid at the bottom in layers of 15-20 cm. Thorough tamping is ensured by abundant watering. Reinforced concrete slabs are installed strictly vertically. They are connected to each other by welding reinforcing embedded elements. Further, a longitudinal drainage system is installed and the space is backfilled with soil.

- Reinforced concrete support wall on piles is recommended on weak (unstable) soils. The distance between the piles depends on the length of the slab, they can be located every 1.5, 2 or 3 meters. The pile diameter is usually between 300 and 500 mm.

Do-it-yourself concrete retaining wall

- The console, made with a slope (10°-15°) towards the embankment, gives greater stability to the wall. If we take a wall 2.5 meters high as an example, then the height of the underground part of the structure will be 0.8-0.9 m, and the width of the body will be 0.4 m.

- For the formwork, a trench 1.2 m wide is pulled out (here an allowance of 30 cm is provided on the front side and 50 cm for the rear face) and a depth of 1.3 m (taking into account the organization of the sand and gravel cushion). The required slope is carried out by manually excavating the soil, this parameter is checked both when installing the formwork and when pouring it with concrete. If necessary, the slope is adjusted.

- The base must be reinforced both in the longitudinal and vertical directions. The height of the rods sticking out of the concrete should be at least half a meter. Allow the sole to gain strength; for concrete, this period is about a month. It is not recommended to carry out any work on the sole before this time.

- For the convenience of building formwork for the wall body, moisture-resistant plywood of a standard size of 2440x1220x150 mm is taken. For one blank, you will need 3 sheets, 2 of which will go to full faces, and one plywood should be cut to the appropriate width for 2 sides.

- In subsequent works, one sidewall is not used, since it is the wall of the previous part of the structure. It is possible to prevent the divergence of the seam between the elements by means of reinforcement. In this case, after pouring the material, holes are drilled in the side part and metal bars are inserted. They can be placed in a checkerboard pattern 40-50 cm apart with an exit from the body of the wall by 30-40 cm.

- To connect the edges of the frame, metal corners are used, since the weight of the concrete intended for pouring is high. An additional reinforcement will be bars 50x50 mm, which are nailed along the perimeter of the formwork. For reliability, spacers should be set on three sides.

- If desired, the concrete surface can be decorated with natural or artificial stone.

- Blocks made of foam concrete, expanded clay concrete, gas or cinder blocks greatly facilitate work and reduce construction costs. But the strength characteristics of such a wall will be an order of magnitude lower. In addition, masonry made of such material does not differ in an attractive appearance.

wooden retaining wall

From the point of view of landscape design, wood is optimally suited for these purposes, but a long service life is not its strongest strong point. To increase resistance to aggressive media, considerable efforts will have to be made for repeated treatment with impregnating agents.

In the design of a retaining wall, logs can be located both horizontally and vertically. There is no big difference in terms of strength characteristics here. Such material is used for the construction of walls with a height not exceeding 1.5 m. To prevent rotting of the buried part of the log, it is necessary to burn it or process it with liquid bitumen.

Vertical arrangement of logs in a retaining wall

- The length of the logs can be different, it all depends on the height difference. For stability, they are buried to a depth equal to 1/3 of the total length of the beam, so if this parameter is 2 m, then the part to be dug in will be 60-70 cm.

- Installation of calibrated wood is carried out in a previously dug trench. At the bottom, a 15 cm layer of rubble is poured and compacted. The logs are placed in a solid wall, close to each other, strictly observing the vertical. Fasteners are made using wire or nails driven in at an angle.

- The maximum stability of the log wall is achieved by filling the trench with a sand-cement mixture. The back side of a kind of tyna is covered with a sealing material (roofing material, roofing felt, etc.), after which the soil is backfilled.

Horizontal arrangement of logs in a retaining wall

- Support pillars are dug in every 1.5-2 or 3 m, the more often they are located, the stronger the retaining wall will be. The wood used is necessarily treated with antiseptic agents.

Horizontal fastening can be carried out in several ways:

- longitudinal grooves are pre-cut on the pillars from two opposite sides, into which horizontal elements will be tightly inserted. In this case, the diameter of the supporting logs should be larger than the beams intended for the transverse position;

- the second option involves fastening logs from the back of the pillars. In this case, the first beam is laid on the ground, so it is recommended to lay the waterproofing material in advance. The connection of horizontally located logs to the supports is carried out with wire and / or nails.

Gabion retaining wall

- To install mesh structures, it is enough to level the surface and have coarse crushed stone (up to 150 mm) or small river boulders available to fill the sections. The main advantages of gabions are their flexibility and water permeability, which eliminates the need for a drainage system.

- Such wire boxes are simply assembled, then installed on flat ground and covered with river or quarry stones. The following blocks are mounted in the same way. Between themselves, the sections are fastened with a wire with an anti-corrosion coating. This is a convenient method when you want to create many corner retaining walls.

- If soil is poured between the stones and sown with plant seeds, then in a few years the wall will acquire an attractive appearance and organically fit into the surrounding landscape.

Retaining wall calculation

Before you make a retaining wall, it is important to carefully consider all the nuances. Otherwise, illiterate calculation and negligent attitude to building standards can lead to collapse.

Such walls with a height of not more than 1.5 meters are allowed to be erected on their own. For the size of the sole, a coefficient of 0.5-0.7 multiplied by the height of the wall is taken. Calculate the ratio of wall thickness to its height, you can be guided by the type of soil:

- dense soil (limestone, quartz, spar, etc.) - 1: 4;

- medium-density soil (shale, sandstone) - 1:3;

- soft soil (sandy-clay particles) - 1:2.

If the height of the wall is large and the construction is planned on weak soils, then you should contact the services of specialized organizations. Calculations will be made in accordance with the requirements of SNiP.

In this case, many factors will be taken into account and, based on the limit state of the retaining walls, the following calculations will be made:

- stability of the position of the wall itself;

- soil strength, its possible deformation;

- the strength of the wall structure, the crack resistance of its elements.

Calculations for passive, active and seismic ground pressure will also be performed; clutch accounting; groundwater pressure and so on. The calculation is carried out taking into account the maximum loads and covers the operational, construction and repair periods of the wall.

Of course, it will be possible to use online calculators specially designed for this purpose. But you need to know that such calculations will be advisory in nature. The absolute accuracy of the calculations is not guaranteed.

Drainage system for retaining wall

The organization of drainage and drainage requires special attention. The system provides collection and drainage of ground, melt and storm water, thereby preventing flooding and erosion of the structure. It can be longitudinal, transverse or combined.

- Transverse drainage provides for holes Ø100 mm per meter of wall.

- The longitudinal option involves the placement of a pipe located on the foundation along the entire length of the wall. For these purposes, corrugated pipes are used, due to their flexibility they allow them to be installed in difficult terrain. On straight sections, ceramic or asbestos-cement pipes are used, having holes in the upper part.

Retaining walls perform important tasks. Their construction should be entrusted to specialists, or at least consult with them on this issue. The slightest mistake in the calculations can have very sad consequences.

During the construction of various kinds of buildings in areas with complex terrain (ravines, beams, etc.), there is often a need for a retaining structure. This reinforcing structure carries one main task - to prevent the collapse of soil masses.

Retaining walls conditionally are divided into two types:

- Fortifying, perform the main function - they delay soil masses from slipping. These structures are constructed if the slope of the hill is not more than 9 °. With their help, horizontal platforms are being built, thereby increasing the usable area.

- Decorative - quite effectively mask small differences in the ground in the adjacent area. When the levels differ slightly and, naturally, the height of the wall is small (up to one and a half meters), then its installation takes place with a small recess up to 45 cm.

Retaining wall design

Regardless of the purpose, a retaining wall is usually has four elements:

- body;

- foundation;

- drainage system;

- drainage system.

Drainage, underground part and drainage of the wall are required for the implementation of technical standards, and the body itself is necessary for aesthetic purposes. In height, these structures can be small (up to one meter), medium (no more than two meters) and high (more than two meters).

Rear wall of the structure happens with such a bias:

- recumbent;

- sloping;

- steep (with a reverse or straight slope).

Retaining wall profiles vary, but are generally trapezoidal and rectangular. In turn, the former may have a different slope of the faces.

Acting forces on the retaining walls

During the choice of material, and, of course, the foundation for retaining walls, they are guided by the calculation of loads acting on the entire structure.

Vertical loads:

- backfill force, which acts both directly on the wall and on part of the foundation;

- upper load, namely, the weight that presses on the upper part of the structure;

- own weight of the retaining wall.

Horizontal forces:

- friction force in the areas of adhesion of the soil to the foundation;

- earth pressure directly behind the retaining wall.

In addition to the main forces, periodic loads also act, these include:

- seismic loads;

- wind strength, all the more so when the height of the structure is more than 2 meters;

- water streams, especially in the lowlands;

- vibrational forces act on the sections where the railway track or road route passes;

- swelling of the soil in winter, etc.

Stability of retaining structures

As a rule, the construction of low retaining walls is carried out for decorative purposes, they do not require careful stability calculations. An increase in this characteristic is indicative for the calculation of retaining walls of a higher structure.

Prevent rollover or the wall can be shifted using the following measures:

- the side that faces the ground is roughened. In block, brick, masonry, ledges are constructed, and in monolithic supporting walls, chips are made;

- greatly reduces the pressure of the soil on the back face a small slope made towards the hill;

- the presence of a wall in front of the console creates additional stability, since it distributes part of the load of the earth;

- a properly equipped drainage system does not allow the structure to be washed away;

- for capital retaining walls made of heavy building materials, a foundation is needed. For clay soil, it is advisable to use a strip foundation, for weak soil - a pile foundation;

- lateral pressure is reduced by backfilling hollow materials (eg expanded clay) between the existing soil and the back wall.

Retaining wall construction

As for the material, its choice is made on several criteria, these are water resistance, structure height, durability, resistance to aggressive environments, the possibility of mechanizing the installation process and availability of building materials.

During the calculation of brick retaining walls, the arrangement of a reinforced foundation is provided. Decorative indicators can be enhanced by using bricks that differ in color or size from the elements of the main masonry. A small wall (up to one meter) is made independently. In cases where an increased load is expected, it is advisable to use the services of specialists.

For work, the usual burnt red brick or clinker with an increased coefficient of moisture resistance and strength. Most often, a strip foundation is required for the construction of retaining walls.

The width of the foundation pit is equal to three times the width of the wall, so when a one-brick construction (25 centimeters) is planned, this parameter is 75 centimeters. The depth is at least one meter. A 25-35 cm layer of crushed stone or gravel is poured onto the bottom, after a layer (12-18 cm) of sand, all backfills of the material are carefully compacted.

A formwork is being constructed, its upper part must be 18-25 cm less than the ground level. For reinforcement, reinforcement bars are used, they are laid on a rubble stone or broken brick. Then, concrete grade 200 or 150 is poured.

It should be noted that laying in one brick can be done for building a wall up to 70 cm, for higher walls it is best to build 1.5-2 bricks, with an increase in the bottom of the wall. So, it turns out a design that resembles a console.

stone retaining wall

Natural and artificial stone have excellent aesthetic properties. At the same time, the appearance of the finished structure makes it possible to harmoniously fit into any landscape.

In this case, both wet and dry laying of the material can be used. The latter method is more complicated and will require some skill, since the stone needs to be adjusted in size.

The base for a stone wall is the same as for a brick. A strip foundation is being constructed with further stone laying. If the construction is carried out without the use of concrete, then the seams are filled with garden soil or planting material. Stone walls are recommended for the construction of structures no more than 1.6 meters.

Concrete retaining walls

This monolithic structure is carried out using bored piles from wooden formwork. Installation of a factory-made plate is done using lifting equipment. It can be buttress or cantilever. For the installation of finished products, a foundation with dense soil is not required. You can just make a trench slightly larger than the width of the sole of the console or slab.

This monolithic structure is carried out using bored piles from wooden formwork. Installation of a factory-made plate is done using lifting equipment. It can be buttress or cantilever. For the installation of finished products, a foundation with dense soil is not required. You can just make a trench slightly larger than the width of the sole of the console or slab.

At the bottom, sand and gravel are poured in layers of 18-25 cm. Ramming is done using abundant watering. Concrete slabs are placed clearly vertically. They are connected to each other by welding from reinforcing elements. After that, a longitudinal drainage system is installed and the space is backfilled with soil. A concrete retaining wall is best suited for soft soils.

Do-it-yourself concrete retaining wall

Good stability of the wall is given by a console made with an inclination (12°-17°) towards the embankment. If we take as an example a wall 2.5 meters high, then the size of the underground part will be 0.9-1 m, and body width is 0.5m.

For formwork, a trench is made 1.3 meters wide and 1.4 meters deep. The necessary inclination is made by manual excavation, this parameter is checked both during the installation of the formwork and during pouring it with concrete.

The base is certainly reinforced both in the vertical and in the longitudinal position. The height of the rods that stick out of the concrete must be at least 1.5 m. The sole must be allowed to gain strength, for concrete this time is approximately a month.

If desired, the concrete surface can be decorated with artificial or natural stone.

Foam concrete blocks greatly facilitate work and reduce construction costs. However, the strength indicators of this wall will be much lower. At the same time, masonry from this material is not distinguished by its attractiveness.

Retaining wall made of wood

In terms of landscape design, wood is the most suitable for this purpose, but the operation of this material is not very long. In order to increase the resistance to aggressive media, it will be necessary to make great efforts for constant treatment with special impregnating substances.

In the construction of the wall logs can be installed both vertically and horizontally. There is no particular difference in terms of strength indicators in this case. This material is used for the construction of walls with a height of not more than 1.6 m.

Vertical installation of logs

The size of the logs can be different, it depends on the height difference. For better durability dig in to a depth of 1/3 the overall size of the beam.

The size of the logs can be different, it depends on the height difference. For better durability dig in to a depth of 1/3 the overall size of the beam.

Laying of calibrated wood is carried out in a previously dug trench. A layer of crushed stone 18 cm is poured and rammed at the bottom. The logs are installed as a solid wall, close to each other, clearly observing the vertical. Fasteners are made with nails or wire.

The maximum resistance of a wooden wall is achieved by filling the trench with a cement mixture. The reverse side of a kind of tyna is treated with a sealing material (roofing paper, roofing felt, etc.), then backfilled with soil.

Horizontal installation of logs

Support logs are buried every two or three meters the more often they are, the stronger the wall will be. Installed wood is certainly treated with antiseptic substances.

Horizontal fastening can be done in the following ways:

- On two opposite sides, longitudinal grooves are preliminarily made on the pillars, where the horizontal parts will be inserted. Moreover, the diameter of the logs must be larger than the beams that are used for the transverse position;

- The next option involves attaching logs to the back of the pillars. In this option, the first beam is placed on the ground, so you need to lay the waterproofing material in advance. The logs are connected to the supports with nails or wire.

Before you make a retaining wall, you need to carefully calculate all the nuances. Otherwise, negligence and incorrect calculation can lead to the collapse of the wall.

Before you make a retaining wall, you need to carefully calculate all the nuances. Otherwise, negligence and incorrect calculation can lead to the collapse of the wall.

Such high walls no more than 1.6 meters possibly build with your own hands. For the width of the sole, a coefficient of 0.6-0.8 multiplied by the height of the wall is used. You can find out the ratio of the size of the wall to its height, taking into account the type of soil:

- soft ground - 1: 2;

- medium soil - 1: 3;

- dense soil - 1: 4.

If the height is large and the construction is planned on weak soil, then it is advisable to turn to the services of professionals. Calculations will take place in accordance with the rules of SNiP.

In this case, many factors are taken into account and on this basis will be the following calculations were made:

- structural strength, resistance to cracks;

- soil strength, its probable deformation;

- stability of the position of the wall itself.

Calculations are also performed for seismic, active and passive ground pressure, groundwater pressure, adhesion, etc. The calculation is made taking into account maximum loads and covers the repair, construction and operational periods of the wall.

Naturally, you can also use an online calculator, which is specially designed for this purpose. But keep in mind that these calculations are only advisory in nature.

The drainage and drainage system needs special attention. The system provides for the collection and removal of storm, melt and groundwater, thereby preventing erosion and flooding of the structure. It can be transverse, longitudinal or combined.

The drainage and drainage system needs special attention. The system provides for the collection and removal of storm, melt and groundwater, thereby preventing erosion and flooding of the structure. It can be transverse, longitudinal or combined.

The transverse option implies the presence of holes diameter 10 cm one meter wall.

Longitudinal drainage involves the placement of a pipe located on the foundation along the entire length of the wall.

Retaining walls have a very important task. Their construction is best entrusted to professionals, or at least consult with them on this issue. Even a small error in the calculation of the retaining wall can have rather disastrous consequences.