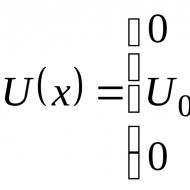

Calculation of cable core thickness depending on power. How to calculate the required wire cross-section based on load power? Permissible current for cables and wires

The table shows power, current and cross sections of cables and wires, For calculations and selection of cables and wires, cable materials and electrical equipment.

The calculation used data from the PUE tables and active power formulas for single-phase and three-phase symmetrical loads.

Below are tables for cables and wires with copper and aluminum wire cores.

| Copper conductors of wires and cables | ||||

| Voltage, 220 V | Voltage, 380 V | current, A | power, kWt | current, A | power, kWt |

| 1,5 | 19 | 4,1 | 16 | 10,5 |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 46 | 10,1 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33,0 |

| 16 | 85 | 18,7 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 135 | 29,7 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 260 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66,0 | 260 | 171,6 |

| Cross-section of current-carrying conductor, mm 2 | Aluminum conductors of wires and cables | |||

| Voltage, 220 V | Voltage, 380 V | current, A | power, kWt | current, A | power, kWt |

| 2,5 | 20 | 4,4 | 19 | 12,5 |

| 4 | 28 | 6,1 | 23 | 15,1 |

| 6 | 36 | 7,9 | 30 | 19,8 |

| 10 | 50 | 11,0 | 39 | 25,7 |

| 16 | 60 | 13,2 | 55 | 36,3 |

| 25 | 85 | 18,7 | 70 | 46,2 |

| 35 | 100 | 22,0 | 85 | 56,1 |

| 50 | 135 | 29,7 | 110 | 72,6 |

| 70 | 165 | 36,3 | 140 | 92,4 |

| 95 | 200 | 44,0 | 170 | 112,2 |

| 120 | 230 | 50,6 | 200 | 132,0 |

Example of cable cross-section calculation

Task: to power the heating element with a power of W=4.75 kW with copper wire in the cable channel.

Current calculation: I = W/U. We know the voltage: 220 volts. According to the formula, the flowing current I = 4750/220 = 21.6 amperes.

We focus on copper wire, so we take the value of the diameter of the copper core from the table. In the 220V - copper conductors column we find a current value exceeding 21.6 amperes, this is a line with a value of 27 amperes. From the same line we take the cross-section of the conductive core equal to 2.5 squares.

Calculation of the required cable cross-section based on the type of cable or wire

| № | Number of veins section mm. Cables (wires) | Outer diameter mm. | Pipe diameter mm. | Acceptable long current (A) for wires and cables when laying: | Permissible continuous current for rectangular copper bars sections (A) PUE |

|||||||||||

| VVG | VVGng | KVVG | KVVGE | NYM | PV1 | PV3 | PVC (HDPE) | Met.tr. Du | in the air | in the ground | Section, tires mm | Number of buses per phase | ||||

| 1 | 1x0.75 | 2,7 | 16 | 20 | 15 | 15 | 1 | 2 | 3 | |||||||

| 2 | 1x1 | 2,8 | 16 | 20 | 17 | 17 | 15x3 | 210 | ||||||||

| 3 | 1x1.5 | 5,4 | 5,4 | 3 | 3,2 | 16 | 20 | 23 | 33 | 20x3 | 275 | |||||

| 4 | 1x2.5 | 5,4 | 5,7 | 3,5 | 3,6 | 16 | 20 | 30 | 44 | 25x3 | 340 | |||||

| 5 | 1x4 | 6 | 6 | 4 | 4 | 16 | 20 | 41 | 55 | 30x4 | 475 | |||||

| 6 | 1x6 | 6,5 | 6,5 | 5 | 5,5 | 16 | 20 | 50 | 70 | 40x4 | 625 | |||||

| 7 | 1x10 | 7,8 | 7,8 | 5,5 | 6,2 | 20 | 20 | 80 | 105 | 40x5 | 700 | |||||

| 8 | 1x16 | 9,9 | 9,9 | 7 | 8,2 | 20 | 20 | 100 | 135 | 50x5 | 860 | |||||

| 9 | 1x25 | 11,5 | 11,5 | 9 | 10,5 | 32 | 32 | 140 | 175 | 50x6 | 955 | |||||

| 10 | 1x35 | 12,6 | 12,6 | 10 | 11 | 32 | 32 | 170 | 210 | 60x6 | 1125 | 1740 | 2240 | |||

| 11 | 1x50 | 14,4 | 14,4 | 12,5 | 13,2 | 32 | 32 | 215 | 265 | 80x6 | 1480 | 2110 | 2720 | |||

| 12 | 1x70 | 16,4 | 16,4 | 14 | 14,8 | 40 | 40 | 270 | 320 | 100x6 | 1810 | 2470 | 3170 | |||

| 13 | 1x95 | 18,8 | 18,7 | 16 | 17 | 40 | 40 | 325 | 385 | 60x8 | 1320 | 2160 | 2790 | |||

| 14 | 1x120 | 20,4 | 20,4 | 50 | 50 | 385 | 445 | 80x8 | 1690 | 2620 | 3370 | |||||

| 15 | 1x150 | 21,1 | 21,1 | 50 | 50 | 440 | 505 | 100x8 | 2080 | 3060 | 3930 | |||||

| 16 | 1x185 | 24,7 | 24,7 | 50 | 50 | 510 | 570 | 120x8 | 2400 | 3400 | 4340 | |||||

| 17 | 1x240 | 27,4 | 27,4 | 63 | 65 | 605 | 60x10 | 1475 | 2560 | 3300 | ||||||

| 18 | 3x1.5 | 9,6 | 9,2 | 9 | 20 | 20 | 19 | 27 | 80x10 | 1900 | 3100 | 3990 | ||||

| 19 | 3x2.5 | 10,5 | 10,2 | 10,2 | 20 | 20 | 25 | 38 | 100x10 | 2310 | 3610 | 4650 | ||||

| 20 | 3x4 | 11,2 | 11,2 | 11,9 | 25 | 25 | 35 | 49 | 120x10 | 2650 | 4100 | 5200 | ||||

| 21 | 3x6 | 11,8 | 11,8 | 13 | 25 | 25 | 42 | 60 | rectangular copper bars (A) Schneider Electric IP30 |

|||||||

| 22 | 3x10 | 14,6 | 14,6 | 25 | 25 | 55 | 90 | |||||||||

| 23 | 3x16 | 16,5 | 16,5 | 32 | 32 | 75 | 115 | |||||||||

| 24 | 3x25 | 20,5 | 20,5 | 32 | 32 | 95 | 150 | |||||||||

| 25 | 3x35 | 22,4 | 22,4 | 40 | 40 | 120 | 180 | Section, tires mm | Number of buses per phase | |||||||

| 26 | 4x1 | 8 | 9,5 | 16 | 20 | 14 | 14 | 1 | 2 | 3 | ||||||

| 27 | 4x1.5 | 9,8 | 9,8 | 9,2 | 10,1 | 20 | 20 | 19 | 27 | 50x5 | 650 | 1150 | ||||

| 28 | 4x2.5 | 11,5 | 11,5 | 11,1 | 11,1 | 20 | 20 | 25 | 38 | 63x5 | 750 | 1350 | 1750 | |||

| 29 | 4x50 | 30 | 31,3 | 63 | 65 | 145 | 225 | 80x5 | 1000 | 1650 | 2150 | |||||

| 30 | 4x70 | 31,6 | 36,4 | 80 | 80 | 180 | 275 | 100x5 | 1200 | 1900 | 2550 | |||||

| 31 | 4x95 | 35,2 | 41,5 | 80 | 80 | 220 | 330 | 125x5 | 1350 | 2150 | 3200 | |||||

| 32 | 4x120 | 38,8 | 45,6 | 100 | 100 | 260 | 385 | Permissible continuous current for rectangular copper bars (A) Schneider Electric IP31 |

||||||||

| 33 | 4x150 | 42,2 | 51,1 | 100 | 100 | 305 | 435 | |||||||||

| 34 | 4x185 | 46,4 | 54,7 | 100 | 100 | 350 | 500 | |||||||||

| 35 | 5x1 | 9,5 | 10,3 | 16 | 20 | 14 | 14 | |||||||||

| 36 | 5x1.5 | 10 | 10 | 10 | 10,9 | 10,3 | 20 | 20 | 19 | 27 | Section, tires mm | Number of buses per phase | ||||

| 37 | 5x2.5 | 11 | 11 | 11,1 | 11,5 | 12 | 20 | 20 | 25 | 38 | 1 | 2 | 3 | |||

| 38 | 5x4 | 12,8 | 12,8 | 14,9 | 25 | 25 | 35 | 49 | 50x5 | 600 | 1000 | |||||

| 39 | 5x6 | 14,2 | 14,2 | 16,3 | 32 | 32 | 42 | 60 | 63x5 | 700 | 1150 | 1600 | ||||

| 40 | 5x10 | 17,5 | 17,5 | 19,6 | 40 | 40 | 55 | 90 | 80x5 | 900 | 1450 | 1900 | ||||

| 41 | 5x16 | 22 | 22 | 24,4 | 50 | 50 | 75 | 115 | 100x5 | 1050 | 1600 | 2200 | ||||

| 42 | 5x25 | 26,8 | 26,8 | 29,4 | 63 | 65 | 95 | 150 | 125x5 | 1200 | 1950 | 2800 | ||||

| 43 | 5x35 | 28,5 | 29,8 | 63 | 65 | 120 | 180 | |||||||||

| 44 | 5x50 | 32,6 | 35 | 80 | 80 | 145 | 225 | |||||||||

| 45 | 5x95 | 42,8 | 100 | 100 | 220 | 330 | ||||||||||

| 46 | 5x120 | 47,7 | 100 | 100 | 260 | 385 | ||||||||||

| 47 | 5x150 | 55,8 | 100 | 100 | 305 | 435 | ||||||||||

| 48 | 5x185 | 61,9 | 100 | 100 | 350 | 500 | ||||||||||

| 49 | 7x1 | 10 | 11 | 16 | 20 | 14 | 14 | |||||||||

| 50 | 7x1.5 | 11,3 | 11,8 | 20 | 20 | 19 | 27 | |||||||||

| 51 | 7x2.5 | 11,9 | 12,4 | 20 | 20 | 25 | 38 | |||||||||

| 52 | 10x1 | 12,9 | 13,6 | 25 | 25 | 14 | 14 | |||||||||

| 53 | 10x1.5 | 14,1 | 14,5 | 32 | 32 | 19 | 27 | |||||||||

| 54 | 10x2.5 | 15,6 | 17,1 | 32 | 32 | 25 | 38 | |||||||||

| 55 | 14x1 | 14,1 | 14,6 | 32 | 32 | 14 | 14 | |||||||||

| 56 | 14x1.5 | 15,2 | 15,7 | 32 | 32 | 19 | 27 | |||||||||

| 57 | 14x2.5 | 16,9 | 18,7 | 40 | 40 | 25 | 38 | |||||||||

| 58 | 19x1 | 15,2 | 16,9 | 40 | 40 | 14 | 14 | |||||||||

| 59 | 19x1.5 | 16,9 | 18,5 | 40 | 40 | 19 | 27 | |||||||||

| 60 | 19x2.5 | 19,2 | 20,5 | 50 | 50 | 25 | 38 | |||||||||

| 61 | 27x1 | 18 | 19,9 | 50 | 50 | 14 | 14 | |||||||||

| 62 | 27x1.5 | 19,3 | 21,5 | 50 | 50 | 19 | 27 | |||||||||

| 63 | 27x2.5 | 21,7 | 24,3 | 50 | 50 | 25 | 38 | |||||||||

| 64 | 37x1 | 19,7 | 21,9 | 50 | 50 | 14 | 14 | |||||||||

| 65 | 37x1.5 | 21,5 | 24,1 | 50 | 50 | 19 | 27 | |||||||||

| 66 | 37x2.5 | 24,7 | 28,5 | 63 | 65 | 25 | 38 | |||||||||

Cable power table required to correctly calculate the cable cross-section, if the power of the equipment is large and the cable cross-section is small, then it will heat up, which will lead to the destruction of the insulation and loss of its properties.

To calculate the conductor resistance, you can use the conductor resistance calculator.

For the transmission and distribution of electric current, the main means are cables; they ensure the normal operation of everything related to electric current, and how good this work will be depends on the right choice cable cross-section by power. A convenient table will help you make the necessary selection:

|

Current cross-section |

||||

|

Voltage 220V |

Voltage 380V |

|||

|

Current. A |

Power. kW |

Current. A |

Power, kWt |

|

|

Section Toko- |

Aluminum conductors wires and cables |

|||

|

Voltage 220V |

Voltage 380V |

|||

|

Current. A |

Power. kW |

Current. A |

Power, kWt |

|

But in order to use the table, you need to calculate the total power consumption of devices and equipment that are used in a house, apartment or other place where the cable will be laid.

Example of power calculation.

Let's say you are installing closed electrical wiring in a house using an explosive cable. You need to write down a list of equipment used on a piece of paper.

But how now find out power? You can find it on the equipment itself, where there is usually a label with the main characteristics recorded.

Power is measured in Watts (W, W) or Kilowatts (kW, KW). Now you need to write down the data and then add it up.

The resulting number is, for example, 20,000 W, which would be 20 kW. This figure shows how much energy all electrical receivers together consume. Next, you should consider how many devices will be used simultaneously over a long period of time. Let’s say it turns out to be 80%, in which case the simultaneity coefficient will be equal to 0.8. We calculate the cable cross-section based on power:

20 x 0.8 = 16 (kW)

To select a cross-section, you will need a cable power table:

|

Current cross-section |

Copper conductors of wires and cables |

|||

|

Voltage 220V |

Voltage 380V |

|||

|

Current. A |

Power. kW |

Current. A |

Power, kWt |

|

|

10 |

15.4 |

|||

If the three-phase circuit is 380 Volts, then the table will look like this:

|

Current cross-section |

Copper conductors of wires and cables |

|||

|

Voltage 220V |

Voltage 380V |

|||

|

Current. A |

Power. kW |

Current. A |

Power, kWt |

|

|

16.5 |

||||

|

10 |

15.4 |

|||

These calculations are not particularly difficult, but it is recommended to choose a wire or cable with the largest cross-section of conductors, because it may be that it will be necessary to connect some other device.

Additional cable power table.

When laying electrical wiring, you need to know what cross-section cable you will need to lay. The choice of cable cross-section can be made either by power consumption or current consumption. You also need to take into account the cable length and installation method.

Selecting the cable cross-section according to power

You can select the wire cross-section according to the power of the devices that will be connected. These devices are called load and the method can also be called “by load”. Its essence does not change from this.

Collecting data

First, find the power consumption in the passport data of household appliances and write it down on a piece of paper. If it’s easier, you can look at nameplates - metal plates or stickers attached to the body of equipment and equipment. There is basic information and, more often than not, power. The easiest way to identify it is by its units of measurement. If a product is manufactured in Russia, Belarus, or Ukraine, it is usually designated W or kW; on equipment from Europe, Asia or America, the English designation for watts is usually W, and the power consumption (this is what is needed) is designated by the abbreviation “TOT” or TOT MAX.

If this source is also unavailable (the information has become lost, for example, or you are just planning to purchase equipment, but have not yet decided on the model), you can take the average statistical data. For convenience, they are summarized in a table.

Find the equipment you plan to install and write down the power. Sometimes it is given with a wide spread, so sometimes it is difficult to understand which figure to take. In this case, it is better to take the maximum. As a result, when calculating, you will slightly overestimate the power of the equipment and will need a cable with a larger cross-section. But for calculating the cable cross-section it is good. Only cables with a smaller cross-section than necessary will burn. Routes with a large cross-section work for a long time, as they heat up less.

The essence of the method

To select the wire cross-section for the load, add up the power of the devices that will be connected to this conductor. It is important that all powers are expressed in the same units of measurement - either in watts (W) or in kilowatts (kW). If there are different values, we bring them to a single result. To convert, kilowatts are multiplied by 1000 to get watts. For example, let's convert 1.5 kW into watts. This will be 1.5 kW * 1000 = 1500 W.

If necessary, you can carry out the reverse conversion - convert watts to kilowatts. To do this, divide the figure in watts by 1000 to get kW. For example, 500 W / 1000 = 0.5 kW.

| Cable cross-section, mm2 | Conductor diameter, mm | Copper wire | Aluminum wire | ||||

| Current, A | power, kWt | Current, A | power, kWt | ||||

| 220 V | 380 V | 220 V | 380 V | ||||

| 0.5 mm2 | 0.80 mm | 6 A | 1.3 kW | 2.3 kW | |||

| 0.75 mm2 | 0.98 mm | 10 A | 2.2 kW | 3.8 kW | |||

| 1.0 mm2 | 1.13 mm | 14 A | 3.1 kW | 5.3 kW | |||

| 1.5 mm2 | 1.38 mm | 15 A | 3.3 kW | 5.7 kW | 10 A | 2.2 kW | 3.8 kW |

| 2.0 mm2 | 1.60 mm | 19 A | 4.2 kW | 7.2 kW | 14 A | 3.1 kW | 5.3 kW |

| 2.5 mm2 | 1.78 mm | 21 A | 4.6 kW | 8.0 kW | 16 A | 3.5 kW | 6.1 kW |

| 4.0 mm2 | 2.26 mm | 27 A | 5.9 kW | 10.3 kW | 21 A | 4.6 kW | 8.0 kW |

| 6.0 mm2 | 2.76 mm | 34 A | 7.5 kW | 12.9 kW | 26 A | 5.7 kW | 9.9 kW |

| 10.0 mm2 | 3.57 mm | 50 A | 11.0 kW | 19.0 kW | 38 A | 8.4 kW | 14.4 kW |

| 16.0 mm2 | 4.51 mm | 80 A | 17.6 kW | 30.4 kW | 55 A | 12.1 kW | 20.9 kW |

| 25.0 mm2 | 5.64 mm | 100 A | 22.0 kW | 38.0 kW | 65 A | 14.3 kW | 24.7 kW |

To find the required cable cross-section in the corresponding column - 220 V or 380 V - we find a figure that is equal to or slightly greater than the power we previously calculated. We select the column based on how many phases are in your network. Single-phase - 220 V, three-phase 380 V.

In the found line, look at the value in the first column. This will be the required cable cross-section for a given load (power consumption of devices). You will need to look for a cable with cores of this cross-section.

A little about whether to use copper wire or aluminum. In most cases, when using cables with copper conductors. Such cables are more expensive than aluminum ones, but they are more flexible, have a smaller cross-section, and are easier to work with. But copper cables with a large cross-section are no more flexible than aluminum ones. And under heavy loads - at the entrance to a house or apartment with a large planned power (from 10 kW or more), it is more advisable to use a cable with aluminum conductors - you can save a little.

How to calculate cable cross-section by current

You can select the cable cross-section according to the current. In this case, we carry out the same work - we collect data about the connected load, but we look for the maximum current consumption in the characteristics. Having collected all the values, we summarize them. Then we use the same table. We just look for the nearest higher value in the column labeled “Current”. In the same line we look at the wire cross-section.

For example, we need a peak current consumption of 16 A. We will lay a copper cable, so look in the corresponding column - third from the left. Since there is no value of exactly 16 A, look at line 19 A - this is the nearest greater. A suitable cross-section is 2.0 mm 2 . This will be the minimum cable cross-section for this case.

When connecting powerful household electrical appliances, a separate power supply line is pulled from them. In this case, the choice of cable cross-section is somewhat simpler - only one value of power or current is required

You cannot pay attention to a line with a slightly lower value. In this case, at maximum load, the conductor will become very hot, which can lead to the insulation melting. What could happen next? Might work if it's installed. This is the most favorable option. Household appliances may break down or a fire may start. Therefore, always select the cable cross-section according to the larger value. In this case, it will be possible to later install equipment even slightly larger in power or current consumption without altering the wiring.

Cable calculation by power and length

If the power transmission line is long - several tens or even hundreds of meters - in addition to the load or current consumed, it is necessary to take into account losses in the cable itself. Usually long distances of power lines at . Although all data must be indicated in the project, you can play it safe and check. To do this, you need to know the allocated power per house and the distance from the pole to the house. Next, using the table, you can select the wire cross-section taking into account losses along the length.

In general, when laying electrical wiring, it is always better to take some margin in the cross-section of the wires. Firstly, with a larger cross-section, the conductor will heat up less, and therefore the insulation. Secondly, more and more devices powered by electricity are appearing in our lives. And no one can guarantee that in a few years you won’t need to install a couple more new devices in addition to the old ones. If stock exists, they can simply be included. If it’s not there, you’ll have to get smart—either change the wiring (again) or make sure that powerful electrical appliances don’t turn on at the same time.

Open and closed wiring

As we all know, when current passes through a conductor, it heats up. The higher the current, the more heat generated. But, when the same current passes through conductors with different cross-sections, the amount of heat generated changes: the smaller the cross-section, the more heat is released.

In this regard, when the conductors are laid open, its cross-section may be smaller - it cools down faster, since heat is transferred to the air. In this case, the conductor cools down faster and the insulation does not deteriorate. When the gasket is closed, the situation is worse - heat is removed more slowly. Therefore, for closed installations - in pipes, in the wall - it is recommended to take a cable of a larger cross-section.

The choice of cable cross-section, taking into account the type of installation, can also be made using the table. The principle was described before, nothing changes. There's just one more factor to consider.

And finally, some practical advice. When going to the market to buy cables, take a caliper with you. Too often the stated cross-section does not coincide with reality. The difference can be 30-40%, which is a lot. What does this mean for you? Burnout of wiring with all the ensuing consequences. Therefore, it is better to check right on the spot whether a given cable actually has the required core cross-section (the diameters and corresponding cable cross-sections are in the table above). And more about determining the section The cable by its diameter can be read here.

Current values can be easily determined by knowing the rated power of consumers using the formula: I = P/220. Knowing the total current of all consumers and taking into account the ratio of the permissible current load for the wire (open wiring) per wire cross-section:

- for copper wire 10 amperes per square millimeter,

- for aluminum 8 amperes per square millimeter, you can determine whether the wire you have is suitable or whether you need to use another one.

When performing hidden power wiring (in a tube or in a wall), the given values are reduced by multiplying by a correction factor of 0.8. It should be noted that open power wiring is usually carried out with a wire with a cross-section of at least 4 square meters. mm based on sufficient mechanical strength.

The above ratios are easy to remember and provide sufficient accuracy for using wires. If you need to know with greater accuracy the long-term permissible current load for copper wires and cables, then you can use the tables below.

The following table summarizes the data on power, current and cross-section of cable and conductor materials for calculations and selection of protective equipment, cable and conductor materials and electrical equipment.

Permissible long-term current for wires with copper conductors with rubber insulation in metal protective sheaths and cables with copper conductors with rubber insulation in lead, polyvinyl chloride, nayrite or rubber sheaths, armored and unarmoured.

* Currents refer to wires and cables with and without a neutral core.

Permissible continuous current for cables with aluminum conductors with rubber or plastic insulation in lead, polyvinyl chloride and rubber sheaths, armored and non-armored.

Note. Permissible continuous currents for four-core cables with plastic insulation for voltages up to 1 kV can be selected according to this table as for three-core cables, but with a coefficient of 0.92.

Summary table of wire cross-sections, current, power and load characteristics.

The table shows data based on the PUE for selecting cross-sections of cable and wire products, as well as rated and maximum possible currents of circuit breakers for single-phase household loads most often used in everyday life.

The smallest permissible cross-sections of cables and wires of electrical networks in residential buildings.

- Copper, U = 220 V, single phase, two-wire cable

- Copper, U = 380 V, three phase, three-core cable

* cross-sectional value can be adjusted depending on the specific cable laying conditions

The smallest cross-sections of current-carrying conductors of wires and cables in electrical wiring.

|

Core cross-section, mm 2 |

||

|

Conductors |

aluminum |

|

|

Cords for connecting household electrical receivers |

||

|

Cables for connecting portable and mobile power receivers in industrial installations |

||

|

Twisted two-core wires with stranded cores for stationary installation on rollers |

||

|

Unprotected insulated wires for fixed indoor electrical wiring: |

||

|

directly on the bases, on rollers, clicks and cables |

||

|

on trays, in boxes (except for blind ones): |

||

|

single-wire |

||

|

stranded (flexible) |

||

|

on insulators |

||

|

Unprotected insulated wires in external electrical wiring: |

||

|

on walls, structures or supports on insulators; |

||

|

overhead line inputs |

||

|

under canopies on casters |

||

|

Unprotected and protected insulated wires and cables in pipes, metal sleeves and blind boxes |

||

|

Cables and protected insulated wires for stationary electrical wiring (without pipes, sleeves and blind boxes): |

||

|

for conductors connected to screw terminals |

||

|

for conductors connected by soldering: |

||

|

single-wire |

||

|

stranded (flexible) |

||

|

Protected and unprotected wires and cables laid in closed channels or monolithically (in building structures or under plaster) |

||

The issue of choosing a cable cross-section for installing electrical wiring in a house or apartment is very serious. If this indicator does not correspond to the load in the circuit, then the wire insulation will simply begin to overheat, then melt and burn. The end result is a short circuit. The thing is that the load creates a certain current density. And if the cable cross-section is small, then the current density in it will be high. Therefore, before purchasing, it is necessary to calculate the cable cross-section according to the load.

Of course, you shouldn’t just randomly choose a wire with a larger cross-section. This will primarily hit your budget. With a smaller cross-section, the cable may not withstand the load and will quickly fail. Therefore, it is best to start with the question, how to calculate the cable load? And only then, based on this indicator, select the electrical wire itself.

Power calculation

The easiest way is to calculate the total power that the house or apartment will consume. This calculation will be used to select the cross-section of the wire from the power line pole to the input circuit breaker in the cottage or from the entrance switchboard to the apartment to the first distribution box. Wires in loops or rooms are calculated in the same way. It is clear that the input cable will have the largest cross-section. And the farther you are from the first distribution box, the less this figure will decrease.

But let's get back to the calculations. So, first of all, it is necessary to determine the total power of consumers. Each of them (household appliances and lighting lamps) has this indicator marked on the body. If you can’t find it, look in your passport or instructions.

After which all powers must be added up. This is the total power of the house or apartment. Exactly the same calculation must be made for the contours. But there is one controversial point. Some experts recommend multiplying the total indicator by a reduction factor of 0.8, adhering to the rule that not all devices will be connected to the circuit at the same time. Others, on the contrary, suggest multiplying by an increasing factor of 1.2, thereby creating a certain reserve for the future, due to the fact that there is a high probability of additional household appliances appearing in the house or apartment. In our opinion, the second option is the optimal one.

Cable selection

Now, knowing the total power indicator, you can select the wiring cross-section. The PUE contains tables that make it easy to make this choice. Let's give some examples for an electric line running at 220 volts.

- If the total power is 4 kW, then the wire cross-section will be 1.5 mm².

- Power 6 kW, cross-section 2.5 mm².

- Power 10 kW – cross-section 6 mm².

There is exactly the same table for an electrical network with a voltage of 380 volts.

Current load calculation

This is the most accurate value of the calculation carried out on the current load. The formula used for this is:

I=P/U cos φ, where

- I is the current strength;

- P – total power;

- U – network voltage (in this case 220 V);

- cos φ – power factor.

There is a formula for a three-phase electrical network:

I=P/(U cos φ)*√3.

It is by the current indicator that the cable cross-section is determined according to the same tables in the PUE. Again, let's give a few examples.

- Current 19 A – cable cross-section 1.5 mm².

- 27 A – 2.5 mm².

- 46 A – 6 mm².

As in the case of determining the power cross-section, here it is also best to multiply the current indicator by a multiplying factor of 1.5.

Odds

There are certain conditions under which the current inside the wiring can increase or decrease. For example, in open electrical wiring, when the wires are laid along walls or ceilings, the current strength will be higher than in a closed circuit. This is directly related to the ambient temperature. The larger it is, the more current this cable can carry.

Attention! All of the above listed PUE tables are calculated under the condition that the wires are operated at a temperature of +25C with the temperature of the cables themselves not exceeding +65C.

That is, it turns out that if several wires are laid at once in one tray, corrugation or pipe, then the temperature inside the wiring will be increased due to the heating of the cables themselves. This leads to the fact that the permissible current load is reduced by 10-30 percent. The same applies to open wiring inside heated rooms. Therefore, we can conclude: when calculating the cable cross-section depending on the current load at elevated operating temperatures, you can choose wires of a smaller area. This is, of course, a good saving. By the way, there are also tables of reducing coefficients in the PUE.

There is one more point that concerns the length of the electrical cable used. The longer the wiring, the greater the voltage loss in the sections. Any calculations use a loss of 5%. That is, this is the maximum. If the losses are greater than this value, then the cross-section of the cable will have to be increased. By the way, it’s not difficult to independently calculate current losses if you know the wiring resistance and current load. Although the best option is to use the PUE table, which establishes the relationship between load torque and losses. In this case, the load torque is the product of the power consumption in kilowatts and the length of the cable itself in meters.

Let's look at an example in which an installed cable 30 mm long in an alternating current network with a voltage of 220 volts can withstand a load of 3 kW. In this case, the load moment will be equal to 3*30=90. We look at the PUE table, which shows that losses of 3% correspond to this moment. That is, it is less than the nominal value of 5%. What is acceptable. As mentioned above, if the calculated losses exceeded the five percent barrier, then it would be necessary to purchase and install a cable of a larger cross-section.

Attention! These losses greatly affect lighting with low-voltage lamps. Because at 220 volts 1-2 V is not reflected much, but at 12 V it is immediately visible.

Currently, aluminum wires are rarely used in wiring. But you need to know that their resistance is 1.7 times greater than that of copper ones. And that means their losses are just as many times greater.

As for three-phase networks, the load torque here is six times greater. This depends on the fact that the load itself is distributed over three phases, and this is a corresponding exponential increase in torque. Plus a double increase due to the symmetrical distribution of power consumption across phases. In this case, the current in the zero circuit must be zero. If the phase distribution is asymmetrical, and this leads to an increase in losses, then you will have to calculate the cable cross-section for the loads in each wire separately and select it according to the maximum calculated size.

Conclusion on the topic

As you can see, to calculate the cable cross-section for loads, you have to take into account various coefficients (reducing and increasing). It’s not easy to do this on your own, if you understand electrical engineering at the level of an amateur or a novice master. Therefore, my advice is to invite a highly qualified specialist, let him do all the calculations himself and draw up a competent wiring diagram. But you can do the installation yourself.