How to lay the mortar during brickwork. How to lay a brick: actions with a photo, how I lay a brick myself

When facing walls with bricks, a certain skill is required, because the masonry must be perfectly even and neat. To do this on your own, you need to study in detail how to lay facing bricks, what laying methods are, how to do the jointing correctly. Finishing with such a brick is very much appreciated for its visual appeal and durability.

Brick laying tools

| brick parameters | Hyper pressed brick | Clinker brick | silicate brick | ceramic brick |

|---|---|---|---|---|

| Compressive strength, kg/cm² | 150-300 | 300-500 | 75-200 | 100-175 |

| Frost resistance, cycle | 75-150 | 50-100 | 35-50 | 15-50 |

| Moisture absorption, % | 6-8 | Less than 6 | 6-12 | 6-8 |

| Thermal conductivity, W/m° С | 0,7-0,8 | 0,7 | 0,3-0,7 | 0,3-0,5 |

| Weight at the size 250х120х65., kg. | 4 | 3-4 | 3,8 | 3,5 |

For high-quality cladding, you need the appropriate tools:

- building level - without it, laying bricks in even rows will not work;

- trowel - a solution is applied with it, the excess is removed, the brick is trimmed during laying;

- hammer-pick - used for splitting the facing material;

- grinder with diamond discs - used for cutting bricks;

- a square metal twig with a section of 10x10 mm - to form identical seams between rows;

- round rod with a diameter of 10 mm - for jointing.

Additionally, you will need a thin construction cord or a strong thread, anchors and knitting wire for tying the masonry to the load-bearing wall.

Types of masonry

According to the location of the brick in a row, several types of masonry are distinguished:

- front (bed) - the brick is laid so that the widest side is visible;

- spoon - the long narrow side is visible from the outside;

- tychkovy - only the ends of the bricks are visible from the outside.

In addition, masonry is divided into types according to decoration:

- masonry "in half a brick" - the vertical seams of the spoon or bed masonry are shifted horizontally by half the length of the brick;

- stacked - vertical seams between bricks are located on the same line;

- Flemish - spoon and bonder masonry alternate in one row;

- "American" - spoon and bonder masonry alternate in rows.

In the absence of experience, it is better to start with a standard half-brick laying, and as your skill improves, you can try other methods. It should be noted that stacked masonry is the most unstable, therefore it is used exclusively for decorative purposes.

brick cladding technology

Step 1. Preparing the base

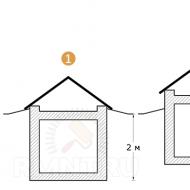

Facing must be laid on the plinth, therefore, when pouring and insulating the foundation, the plinth protrusion along the perimeter of the house is provided for the thickness of the facing masonry plus 2-3 cm for the air gap. Before starting work, you should check the base with a building level to eliminate possible distortions. If any irregularities are found, they are eliminated with cement mortar. After that, the surface must be carefully swept.

Step 2. Mixing the solution

For brick mortar is prepared from M500 cement and clean fine sand. The components are mixed in a ratio of 1: 4, water is poured in small portions. The finished mixture should be homogeneous, thick enough; if the ball rolled from the solution does not fall apart and holds its shape well, the consistency is considered correct. Water for kneading must be taken clean, with a minimum amount of salts, otherwise unaesthetic whitish spots will appear on the lining - efflorescence, which is not so easy to remove. An important point: you need to knead the solution in a small volume, since the laying process takes time, and the solution dries quickly.

Step 3. Laying the bottom row

A container with water is placed next to the workplace and bricks are soaked in it. Experienced builders recommend laying the bottom row without mortar. Since the length of the perimeter of the house is not always a multiple of the length of the brick, in certain places it will be necessary to cut the brick and choose the optimal location of the seams. If you lay the first row on the mortar, trimming will be more problematic. They start working from the corner: with the help of a level, each brick is laid on top and the seams are aligned. Between the bearing wall and the cladding, be sure to leave 2-3 centimeters of free space for ventilation.

Step 4: Laying the Corners

Now you need to lay out the corners to a height of 4-6 rows. A square rod is placed on the bottom row along the outer edge, a little solution is collected with a trowel and it is carefully applied. Having slightly leveled the solution, a brick is laid on top, knocked out with a trowel handle so that it comes into contact with the bar. Check the location with a level, if necessary, incite more. Carefully remove the rod, wipe the crumbs of the solution, and then repeat the same on the other side of this corner. When laying the following bricks, the correct dressing of the corner is monitored: the ends should alternate with long edges on both sides.

Step 5. Wall cladding

When all the corners are laid out, proceed to. A strong thread is pulled between the corner bricks of the second row, laid on top and fixed with something heavy. Now they put a bar on the edge of the first row, cover the masonry surface with mortar. The bricks intended for this row are placed vertically on the ground, a little mortar is applied to the ends with a trowel, and then placed on the mortar with gentle movements. Each of them is knocked out, guided by the thread, the bar is taken out, the row is checked with the help of a level.

Step 6 Attaching the cladding to the wall

If the brick cladding was not originally planned, it is necessary to bind to the load-bearing wall. They do this in two ways: using anchors and dowels with knitting wire. In the first version, an anchor is driven into the wall of the building up to half, leaving the second part between the rows of cladding. Anchors are best taken galvanized, with a diameter of 6 mm.

The second option: holes are drilled in the wall, dowels are inserted, a knitting wire is attached to them. The wire should lie on the brick, but not go beyond its edge. As standard, fasteners are installed in 4 vertical rows and at a distance of 70 cm horizontally. Approximately 5 fasteners are required per square meter of surface. Around the openings, the distance between the dowels is reduced by about a third.

The remaining rows are carried out according to the same scheme: they pull the thread between the corner elements at the height of the row, lay the bar, then the mortar and bricks. It should be noted that the width of the horizontal seams should be 10-15 mm, and the vertical ones should be slightly less - from 8 to 10 mm. Such a masonry will look the most attractive. Near the door and window openings, the brick is cut and fixed so that the row is not interrupted on the other side, then the masonry pattern above the opening will remain correct. Step 7. Laying slopes

For greater decorativeness, the slopes are laid out from bricks of a different color. Along the perimeter of the slopes, the cladding is done by tying; the resulting one-brick-wide columns may protrude slightly beyond the edge of the wall cladding. The slopes themselves must be strictly vertical, therefore, when laying, they control the building level.

Step 7. Stitching

Once the mortar has set, you can begin to lay out the masonry. The surface is swept, the crumbs of the solution are removed, the masonry is moistened with water. Prepare a working solution: mix equal parts cement and lime, and then add sand. The ratio of sand to cement is 10:1, so much water is added so that the mixture acquires the consistency of a paste. After that, the seams are filled with a solution and they begin to form them with the help of jointing. The vertical seams are formed first, then the horizontal seams are embroidered.

It is impossible to lay out more than 6-7 rows at a time, since the masonry can be deformed from a large load. Every 3-4 rows are checked with a level to achieve maximum verticality. It is impossible to fill the gap between the cladding and the wall of the building with anything, the air gap is necessary for the ventilation of surfaces, in addition, it also performs heat-insulating functions. Sloping can be done immediately after laying, so as not to rearrange the scaffolding twice.

Prices for building and facing bricks

Building and facing bricks

Video - How to lay a facing brick

Allows for durable construction. High-quality brickwork can only be done by professionals who have extensive experience behind them.

When laying bricks, it is necessary to monitor the thickness of the joints, the maximum thickness of which should not exceed 15 mm.

People who doubt their ability to lay brick walls are advised to first familiarize themselves with the theory and only then proceed to practice. In order to avoid mistakes in the process of building walls, it is important to follow the sequence of brick laying.

According to the method of making a seam between bricks, the following types can be distinguished:

- Wasteland. In this case, the building mixture should not flow to the outer edge of the material being laid, due to which a gap is formed. A seam of this type is recommended when the wall is intended for plastering. The plaster mixture will be able to better adhere to such a wall, flowing into the gaps.

- Undercut In this case, the mixture should fill the gap flush with the edge of the material to be laid. A similar type of seam is used in the process of laying pipes for stoves and fireplaces, so that it is possible to give smoothness to the inner base of the pipe and avoid the accumulation of soot on it.

- The convex or concave seam of the building mixture between the laid bricks has an exclusively decorative function. In its manufacture, a piece of pipe of small dimensions or a round stick is used (to obtain a concave seam). To create a convex seam in the pipe, you will need to cut off part of the base.

There are several masonry methods, on which the wall thickness will directly depend. You should be aware that the thickness of the wall can be from 12 to 64 cm.

To ensure the norms of heat saving, the walls must be 1.9 m thick or insulated if solid masonry is made of solid ceramic bricks. However, making a wall of great thickness is quite difficult and impractical from an economic point of view.

In order to reduce the total weight of the walls and the load on the concrete base, as well as reduce material consumption, the outer walls are most often made using hollow bricks or solid ones, but with the formation of voids that will be filled with insulating material in the future.

The most difficult thing in the bricklaying process is to display right vertical corners and lay the material in a straight line at the same level.

Items that will be needed to complete the job

Working with bricks requires the use of special tools. The following devices will be needed:

- Trowel. It is used for laying out the building mixture. The tool must have a wide and flat working base, which is narrowed on one side.

- To perform a beating and give the profile a suitable shape, you should use a joint that resembles an ordinary chisel with a sharp working edge in shape.

- Hammer. Used to level bricks.

- You will need to make a special device that will allow you to maintain the same thickness of the seam. It will be necessary to nail a piece of plywood 1 cm thick to a small wooden beam. The plywood should follow the contour of the letter P. The inner opening should be equal to the length and width of the brick, and the height of the legs should be the thickness of the seam. The building mixture must be laid inside the fabricated structure. Excess mixture can be removed with a trowel.

- Order. This element can also be made independently from several identical strips about 1-1.5 m long. In the strips, you need to make cuts for the cord. They should be located from each other at a distance of the height of the brick and the thickness of the masonry seam. In this case, it will be possible to transfer the cord without any problems, and the masonry will turn out to be even.

Reinforcement of brickwork is carried out using wire reinforcement, while the brickwork is significantly strengthened.

Control over the correctness and evenness of the masonry can be performed using tools such as:

- Building level. Used to control the horizontality of walls.

- Plumb. Used for vertical walls.

- Plastic or wooden ruler with serifs. Used to control the rows and the thickness of the seam between them.

- Rule. Used to monitor the accuracy of the outer edge. As a rule, you can use a metal ruler up to 2 m long.

Back to index

How to prepare a mortar for laying bricks?

The mortar for laying bricks is mixed in the required proportions from water, sand and cement.

You should know the main requirements for the building mixture for:

- plastic;

- no small stones.

The mortar can be prepared using cement, sand and water. Cement must be purchased grade M300 or higher. Sand should be used sifted, medium grain. The ratio of elements is 1 part of cement to 4 parts of sand. Some builders add clay to the masonry mortar to give the mixture plasticity and better viscosity.

If you plan to build only a few walls, then you can use dry ready-made mortars for construction, which are very convenient to work with. They contain all the necessary additives for plasticity and the necessary fluidity of the building mixture. It remains only to add to the mixture the amount of water indicated by the manufacturer of the solution, and then mix the elements thoroughly. The quality of the prepared mixture for construction can be checked in this way: you need to throw a trowel into the container with the blade down. If the tool plunges to the full length of the blade, then the mixture is cooked correctly.

Back to index

The basics of bricklaying

To control the horizontalness of the walls, you need to apply a level.

Brick is an expensive material, so you will need to carefully draw on paper each layer of the material being laid. Further, it is recommended, first of all, to lay out all the brick rows dry, without using a building mixture. If no design errors are found, and no changes will need to be made to the plan, you can begin to lay the material on the mortar. Bricks before laying will need to be moistened with water. To do this, they will need to be dipped in a bucket or large container.

The construction of a brick wall is carried out in layers, in rows. Bricks are connected to each other with a mixture of sand and cement. You will need to learn how to prepare such a mixture. Each subsequent row should be slightly shifted to the side in relation to the previous one. Thus, it will be possible to obtain a dressing, which is necessary to ensure the strength and stability of the wall.

The first row of bricks is laid on the foundation. If its base is uneven, then this deficiency can be corrected with a building mixture. Before you start laying bricks, you will need to make cut-off waterproofing. To do this, you need to lay any material that can repel water on a concrete base. Suitable materials are:

- ruberoid;

- fiberglass;

- bituminous mastic.

After that, you will need to mark the perimeter of the walls. It can be done using a marking cord and a hydraulic level. Beacon bricks must be placed in the corners, at the intersection of the walls, the nodes of the openings of doors and windows. On walls of great length, it will be necessary to set up intermediate beacons that prevent the cord from sagging. It will need to be fixed to these bricks.

First of all, it is recommended to make corners: in the appropriate places, you need to put 3-4 rows of bricks on the made base. In this case, it will be possible to transfer the cord to the level of the next row. In addition, the laying process will be greatly simplified. If you need to make a wall of great thickness, then the first row will need to be done with a poke, that is, the bricks are installed perpendicular to the direction of the wall.

Back to index

Brick laying sequence

The prepared solution is laid out on a brick in a slide, it is not necessary to smear it.

In most cases, the brick is laid as follows:

- First of all, you will need to lay and level the building mixture.

- On the end of the brick, before laying, you need to make a smear with the prepared mixture. It will be necessary to press the next brick to this place.

- You will need to monitor the coincidence of the vertical seams. This is necessary in order to prevent the need to install small pieces of bricks in the space remaining after laying the row. In this case, the aesthetics of the wall will be preserved.

- You can level the brickwork on the building mixture not only with a mallet, but also with a trowel handle.

- The mixture that will protrude beyond the edges of the installed material can be removed with a trowel and dropped onto the top of the wall or into a container with mortar.

- On the end part of the material, the prepared composition will not need to be smeared. It will need to be laid out and left in the form of a tubercle.

- It is important to ensure that during brickwork there are no gaps along the end parts of the material or along the front sides of the walls.

- To give the structure a more aesthetic appearance, you will need to perform the jointing of the seams. To do this, it is necessary to carry out a special device (joining) along the seams, which can be replaced by a piece of pipe of a suitable diameter. In this case, it will be possible to obtain strong and high-quality seams and.

However, you should be aware that you can lay out such material in various ways.

Back to index

Existing types of brick installation: masonry sequence

- Zabutka (pruning, half-up).

- Hold on.

- Butt.

When choosing a brickwork method, it is important to take into account the season, the plasticity of the building mixture, as well as the degree of moisture content of the material.

Back to index

Features of the butt method

The building mixture in this case is distributed evenly. On the sides of the structure, you will need to leave a small mass. A similar mass of building mixture is used to fill the seams that will be formed during the masonry process.

When applying the mixture for the spoon row, the distance to the wall must be observed - the maximum distance is 2.5 cm. The layout should not be more than 8 cm.

When forming a bonded row, the mass of the mixture must be applied with a layout that does not exceed 22 cm. The layer thickness in this case should be less than 3 cm. Laying side by side involves the use of several bricks, which are located at a distance of 10 cm from previously located materials. Brick is laid at an angle, flat. Bricks will need to be slowly turned and brought closer to those already laid. After that, a building mixture should be applied, which will gradually fill the vertical and horizontal seams.

Brick is a multifunctional building stone of artificial origin, with which you can build almost anything. Perhaps this is the most popular building material, without which the improvement of any suburban

Tools and equipment

When laying brickwork, it is necessary to have:

- trowels for applying mortar to bricks;

- hammer-pick, with the help of which products will be hemmed;

- additional tools, which include a cord, plumb line, level, etc.

For laying bricks, an ordinary concrete mortar is used, prepared from cement and sand in a ratio of 1 to 5-6. The solution is necessary to strengthen the masonry and glue individual bricks together. Sometimes ordinary washing powder is added there - due to this, plasticity and fluidity increase, but it is forbidden to use it for hollow products, because the solution will flow into the cracks, which will negatively affect the thermal insulation properties of the material.

To prepare the mortar, you must first mix dry cement with sand, then dilute with water as needed.

Note! It is undesirable to mix more than 50 liters at a time, since the solution is consumed slowly. It is better to take a small amount of dry mix and dilute it with water.

But if it is planned to carry out a large amount of masonry, and several builders are involved in the work at once, then it is more expedient to use. We also note that it is recommended to use cement of the “three hundredth” or “four hundredth” brand.

Prices for cement and mixture bases

Cement and mixture bases

After preparing the solution, you can start laying directly.

| Masonry size | Length, L | Width, V | Height, H | Number of bricks thickness not included mortar joint, PC. | Number of bricks taking into account the thickness mortar joint 10 mm, PC. |

|---|---|---|---|---|---|

| 1 m3 single brick laying | 250 | 120 | 65 | 512 | 394 |

| 1 m3 thickened brickwork | 250 | 120 | 88 | 378 | 302 |

| 250 | 120 | 65 | 61 | 51 | |

| 1 sq. m of masonry in half a brick (masonry thickness 120 mm) | 250 | 120 | 88 | 45 | 39 |

| 1 sq. m of masonry in one brick (masonry thickness 250 mm) | 250 | 120 | 65 | 128 | 102 |

| 250 | 120 | 65 | 189 | 153 | |

| 1 sq. m of masonry in one and a half bricks (masonry thickness 380 mm) | 250 | 120 | 88 | 140 | 117 |

| 250 | 120 | 65 | 256 | 204 | |

| 1 sq. m of laying in two bricks (masonry thickness 510 mm) | 250 | 120 | 88 | 190 | 156 |

| | 250 | 250 | 65 | 317 | 255 |

| 1 sq. m of masonry in two and a half bricks (masonry thickness 640 mm) | 250 | 250 | 88 | 235 | 195 |

How to lay corners

If you have seen how a professional bricklayer works, then you probably noticed that he starts his work by drawing corners. First, each of the corners should be drawn in turn, while their height should slightly exceed the height of the middle sections of the walls. For this purpose, beacons-benchmarks are used, through which a cord is pulled - it will indicate the height and level of the masonry. It is necessary to pull the cord as tight as possible so that it does not sag during operation. Moreover, it is necessary to periodically re-lay with beacon bricks.

To form rectangular corners, it is necessary to use the so-called ordering - a special device, which is a flat iron square. In order, you can make marks along the laying lines. The first two or three bricks must be laid using the rule, after which the order is established through the staples. To give a vertical position, use a plumb line. According to the marks made in order, a mooring cord is drawn.

Note! Experienced masons do not like to use ordering, preferring to draw angles “by eye” and considering this tool to be the lot of exclusively inexperienced craftsmen. But if you are doing bricklaying for the first time, then you cannot do without ordering.

Video - Laying corners

Types of seams

After laying out the corners in several rows, it is necessary to stretch the cord between them (the corners) and put the solution on. After that, you need to proceed to the main masonry. To understand all the nuances, you need to familiarize yourself with at least the main types of masonry joints.

There are several such seams, the most common of them are listed below.

- Pustoshovka - the solution in this case does not protrude above the surface of the bricks; there are small gaps that will be used for plastering. The plaster will flow into the gaps between the products, as a result of which it will hold well.

- Raised seams perform a purely decorative function. For their formation, a piece of a rounded pipe, cut lengthwise, is used.

- Function of concave seams also purely decorative, but an ordinary, uncut pipe is used for shaping.

- Undercut the cracks are filled completely and aligned with the surface of the bricks. Such masonry is used mainly for smooth surfaces (fireplaces, chimneys) to avoid soot accumulation, less often as a decorative one.

Main masonry

So, after removing the corners in several rows, you need to proceed to the main masonry. In the future, as the construction of the corners will rise. After the corners are formed, a layer of mortar is applied to the foundation, and a cord is pulled between them. You need to pull it extremely tight to avoid problems with the evenness of the masonry. A mortar is applied to the end of the first brick, after which it (the brick) is placed close to the corner. All subsequent bricks are laid in the same way.

Note! The cord should be pulled exclusively along the upper level of the bricks.

For a tighter fit, more mortar is placed on the walls, after which each brick is tapped with the end of the trowel and aligned with the level of the cord. The solution that came out is selected with a trowel. Of course, if you are doing the masonry for the first time, then the first few rows will have to be shifted in any case, but after two days the work will go faster.

Find out how it is made, as well as familiarize yourself with the choice of materials and styling technology, from our new article.

- After every five to six rows, a reinforcing mesh is laid.

- Bricks should be tied up, that is, the coincidence of the seams of adjacent rows should be excluded.

- Before laying, each brick is immersed in water for better adhesion of the mortar.

- If you are doing masonry for the first time, then start with primitive buildings (steps, posts, etc.). After such a training stage, it will be easier to lay out more complex structures - a summer kitchen, for example, or a brick barbecue.

- After preparing the tools and consumables, it is desirable to carry out the so-called dry laying (without the use of mortar) in order to identify possible flaws. If everything is fine, then you can start laying on the solution.

- For the first experience, the most suitable face brick (it has a smooth side) or chocolate brick (with excellent decorative properties), the dimensions of which are somewhat smaller than usual. Conversely, you can use a rough brick that looks like natural stone.

- Before proceeding directly to the laying, you need to draw up a detailed plan in which all rows of bricks will be drawn. This will avoid unnecessary costs, because brick is a very expensive material. The dimensions of the brick are as follows: 6.5x12x25 cm. When calculating, you should “throw” about 10% more over the required amount, since the battle is inevitable (especially if the laying is done for the first time).

And remember the main thing - do not rush. First, lay the brick dry, as we have already talked about, then apply the mortar and proceed with the laying, tapping each product with the end of the trowel so that it takes the desired position. The solution that protrudes out must be removed with a trowel and thrown back into the bucket.

You should not rush when working with a solution, because this is not a "Moment", which seizes in a few seconds. You will have enough time to experiment with laying, remove and put the mortar, turn the bricks in one direction or another - in a word, make it perfect. After acquiring the appropriate skills, you will be able to draw the right amount of mortar on the trowel the first time and immediately install the brick in the required place. So the laying procedure will be carried out much faster.

| Name | Average density, kg/m3 | Porosity, % | Frost resistance grade | Strength grade | Color |

|---|---|---|---|---|---|

| Brick solid | 1600-1900 | 9 | 15-50 | 75-300 | red |

| Hollow brick | 1000-1450 | 6-8 | 15-50 | 75-300 | light brown to dark red |

| Hollow brick "super efficient" | 1100-1150 | 6-10 | 15-50 | 50-150 | shades of red |

| Brick facing | 1300-1450 | 6-14 | 27-75 | 75-250 | white to brown |

| Brick facing glazed or engobed | 1300-1450 | 6-14 | 27-75 | 75-250 | any |

| brick parameters | Hyper pressed brick | Clinker brick | silicate brick | ceramic brick |

|---|---|---|---|---|

| Compressive strength, kg/cm² | 150-300 | 300-500 | 75-200 | 100-175 |

| Frost resistance, cycle | 75-150 | 50-100 | 35-50 | 15-50 |

| Moisture absorption, % | 6-8 | Less than 6 | 6-12 | 6-8 |

| Thermal conductivity, W/m° С | 0,7-0,8 | 0,7 | 0,3-0,7 | 0,3-0,5 |

| Weight at the size 250х120х65., kg. | 4 | 3-4 | 3,8 | 3,5 |

Prices for building bricks

Building brick

Find out, with step-by-step instructions, from our new article.

And as a conclusion - a thematic video.

Video - Proper bricklaying

Brick has been around for more than a century. From it they built houses in different countries and even parts of the world, having come up with many different methods and types of brickwork. And although there are a lot of secrets and features in the technology itself, you can understand everything. First you need to familiarize yourself with the basic provisions and terminology, without which it will be impossible to understand what is at stake. Then, choose the masonry technique and the type of dressing, and then begin the practical development of skills. Do-it-yourself brickwork can be done at least as well as that of professionals. The only thing in which an amateur will definitely concede is in speed. All other parameters, subject to technology, will certainly not be worse.

Basic terms

Let's start with general concepts. Everyone knows exactly what a brick looks like, that it is ceramic, and there is silicate - too. But not many are aware of how the edges of this material are correctly called. And in the description of masonry technology, they are very common.

The largest edge is called pastel", middle - lateral - " spoons", and the smallest -" poke«.

The dimensions of a brick, in principle, are standardized (250 * 125 * 66 mm - single and 250 * 125 * 88 mm - one and a half), but its production technology is such that they can differ significantly from different manufacturers: by 2-3 mm in each of faces, and this is a rather significant difference, given the number of pieces in one row. Therefore, before ordering a batch, it is advisable to measure samples from several firings in order to determine how accurately the technology is maintained.

It is also important to pay attention to the geometry: the edges must be located strictly at 90 °. Otherwise, bursting loads will occur, and the wall may crumble.

Types of masonry

Brick walls can play a different role. In some cases, this is only decoration, in some - partitions, and sometimes - load-bearing walls. Based on the purpose, as well as the required thermal conductivity of the walls, the type of brickwork is selected:

- In half a brick. Most often, this is how cladding is done. The thickness of such a wall is 125 mm. To save money, you can put the material on a spoon, then you get a wall a quarter of a brick. When arranging such (in 1/2 or 1/4) in each 4-5 row, a reinforcing mesh is laid. It is necessary to increase the rigidity of the wall and create additional bonds that increase the strength of the masonry.

- Into a brick It can already be partitions or two load-bearing walls of small buildings. Wall thickness - 250 mm.

- One and a half, two and two and a half bricks are already load-bearing walls.

Dressing and row names

Although a brick wall is made up of many small elements, it should work as a monolith. To provide increased strength, the seams, which are the weak point in this system, are made with an offset. Experts call this technique "dressing". It seems to connect different elements into a single whole, allowing you to redistribute the load on large surfaces.

To ensure the necessary displacement of the seams, the bricks are arranged in different ways:

- if they are turned to the front side by the smallest part - a poke, such a row is called tychkovy;

- if turned with a long side - a spoon - a row is called spoon.

Moreover, the first in the masonry - on the foundation - lies the bonder, they also finish the masonry. And for him it is necessary to use solid bricks.

Single row dressing

Alternate alternation of such rows gives a very good result. This type of ligation is called single-row or chain ligation. It is practiced on walls that are not planned to be finished: it looks neat. According to such a system, both external and load-bearing walls can be folded.

Wall masonry schemes

Examples of a single-row brick wall in 1.5 and 2 bricks are shown in the photo below.

Single-row dressing in the wall of 1.5 and 2 kripich

In the case of laying a wall in two bricks, two more terms appear. Two outer spoon rows are called versts - outer verst directed to the street inner verst- into the room. They use even, good material, especially carefully choosing those that are directed outward. The space between them is called backlog. Since this element is closed on all sides, you can use a lower grade material, for example, second-hand.

Please note that with this masonry, sawn bricks are also required: halves and three-quarters. Three-quarters in the diagram are crossed out crosswise, halves - with one diagonal stripe. How to make the adjunction of partitions to walls made using this technique is shown in the photo below.

Corner schemes

The laying of the corner in this case is very important. According to the method, the corners are first driven out, a cord is pulled between them, and then the wall is laid according to the scheme. But the corners are put first, on how correctly and evenly they are driven out, it depends on how even the whole building will be. The scheme of laying a corner in 1 brick with a single-row dressing is located below. Masonry begins with the installation of two 3/4 pieces, then the whole ones go.

See the video for the sequence of actions. Very detailed explanation with step by step demonstration of the procedure.

The same system, but in a wall of 1.5 bricks. In addition to whole pieces, 3/4 pieces and quarters are required. Spoon row alternately on the inside, then on the outside verst.

How this scheme is put into practice, see the video.

When laying a corner of 2 bricks in the first row, all the same two three-quarter pieces are required, and another 6 quarters or, as they say, checks. In the second one, one for 3/4 and two checks are already required.

Multi-row dressing

With multi-row dressing, several spoon rows - 6 (for a single brick) or 5 (for a one-and-a-half) - are interspersed with one bonder. The first and last are also placed with pokes. This method is also suitable for laying exterior and interior walls. Only they are usually planned for insulation or decoration.

Wall masonry schemes

So that with such a system, free-standing columns do not turn out, the spoon rows inside are also tied up. To ensure the displacement of the seams, crushed bricks are used.

Do-it-yourself brickwork: multi-row dressing scheme in 2 and 2.5 bricks

The adjunction of walls with this method also occurs with a dressing. This ensures increased strength of the abutment of the walls. Schemes - in the photo below.

Corner masonry patterns

And again about how to lay corners, but with multi-row dressing. If the wall is one brick, even and odd rows (except the first) are the same.

You will see all this in the video.

If the wall is 1.5 bricks, in the first and second rows with bonders, but located either in the outer or in the inner verst. The third and fourth rows are exclusively placed on a spoon.

The fifth row is laid similarly to the third, the sixth - to the fourth. The system then repeats. At times, not a multi-row (with 5 spoon poisons), but a three-row system is required. Then from the fifth row, the clack is repeated.

Mortar for masonry

The brick is placed on a cement-sand mortar. Cement is used not lower than M400, sand is clean, ravine. The proportions for the specified brand are 1 to 4 (for m500 - 1: 5). The batch is done manually or with a concrete mixer, but the order does not change.

First, sand is sifted, a binder is added to it, everything is mixed in a dry state until a uniform color is achieved. Then water is added. Its amount is 0.4-0.6 parts, but they look at the plasticity of the solution. It is more convenient to work with a plastic mortar than with a rigid one, but when laying a hollow brick, in this case the consumption of the mortar greatly increases: it fills the voids. In this case, it is more practical to make a hard solution.

To improve plasticity and more convenient work, lime, clay or liquid detergent are added to the composition (hand soap can be found in large flasks). The number of additives is quite small - no more than 0.1 parts, but the characteristics of the solution improve significantly: it is easier to stack, it does not delaminate for longer.

Immediately it is worth warning: do not knead large volumes at once. The batch must be used within two hours. And in the last half hour, it can be difficult to work with him: the separation of water may begin, or it may begin to seize. It depends on the weather conditions and the quality of the cement, on the thoroughness of the kneading. If do-it-yourself bricklaying is your first experience in this area, it will turn out slowly. Therefore, it is better to make portions of the solution small.

Approximate solution consumption

Often for beginners planning to lay bricks on their own, the question arises: at what temperature can you work. Without special additives, it is possible to work at positive temperatures. In the best case - not lower than + 7 ° C. This is the threshold at which the cement normally sets. At lower temperatures, the hardening process practically stops, as a result, the mortar may crumble, and the strength of the wall will be low. To lower the bar, there are special antifreeze additives, but the cost of such a solution is already high: the price of these additives is considerable.

Before use, the solution is stirred, as heavy particles can sink down, and water can rise to the top. The mixed solution is placed in buckets and transferred to the masonry site, where it is distributed. Immediately put a strip of mortar - a bed - for one row. Under the tychkovy row, the width of the bed is 200-220 mm, for the spoon row - 80-100 mm. If the seam is completely filled, about 10-15 mm recede from the edge, the mortar height is 20-25 mm, which during laying provides a seam of 10-12 mm. Before installing the brick, the mortar is leveled with a trowel.

There are three techniques for doing brickwork. On a hard low-plastic solution, the “press” technique is used. In this case, the seams are completely filled. If the solution is plastic, use the "butt" technique.

Brickwork technique "butt"

As already mentioned, this method of laying bricks is used with plastic mortar. It should be mobile, easy to apply and move. This is achieved by adding additives. You can spread the solution immediately on the entire surface of the wall: additives allow you to extend the time before setting begins.

The bed is laid with a thickness of about 20 mm, an indent of about 15-20 mm remains from the edge. Such an indentation avoids squeezing the solution onto the front surface, but at the same time, the edges of the seams often remain unfilled. This significantly reduces the strength of the wall, therefore, in regions with seismic activity, the laying of verst rows (outer and inner) by this method is prohibited.

When laying a spoon row, they take a brick, holding it with a slight slope. Bringing to the already laid, at a distance of 8-10 cm, they begin to rake up the solution with an edge (poke). When docking, it turns out that the seam is already partially filled. The brick is pressed down a little (sagging), pressing it to the bed. The excess is removed with a trowel and sent either to a bucket or to a wall.

Brick laying technique "back to back"

With this technique, it often turns out that the vertical seams are only partially filled. Therefore, this method is also called "wasteshovka". They are filled when laying the bed for the next row. If the technique is not yet very well developed, it is better to fill the seams before laying the next row: voids reduce strength and thermal insulation characteristics.

When laying the bonder row, everything is exactly the same, only the solution is raked with a spoon edge. The backing is laid, like the tying rows, and then pressed with the palm of your hand. It is necessary to ensure that all the stones are on the same level. This is done using the building level, and the verticality of the wall is checked with a plumb line every 3-4 rows.

Technique "squeeze"

When working with hollow bricks, as a rule, hard mortars are used. In this case, a brick is used with the “press” technique. In this case, you also have to work with a trowel.

The bed is laid at a distance of 10 mm from the edge, the thickness is still about 20 mm. Since such a composition does not stretch well, it is raked to the edge of the laid brick with the edge of the tool. They take a brick with their left hand and press it against the trowel, while pulling it up. At the same time, they continue to press with a brick, achieving the required thickness of the seam (10-12 mm).

Technique "end-to-end"

Excess solution is picked up with a trowel. Having laid several fragments, they take the level, checking the horizontality of the row, by tapping the handle of the trowel, straightening the position. The solution squeezed out is selected. It turns out dense masonry, but the process takes longer: more movements are required.

Butt with undercut

The average performance method - butt with cutting seams. With this method, the bed is laid out close to the edge (10 mm), as when laying, pressing it, and the laying technique is close-fitting: they raked the mortar with a brick, put it down, pressed it down, and removed the excess. If the wall is subsequently not planned to be finished with anything, after several rows it is necessary to take the jointing - a special tool and give the seams the required shape (convex, concave, flat).

As you can see, this is a kind of symbiosis. To make it more convenient to work, the solution is also made with "intermediate" plasticity. If it is too liquid, it will flow down the wall, leaving streaks, so it needs to be kneaded a little tighter than when laying back to back.

DIY brickwork: tools, order and features

Now, how to lay a brick with your own hands, you have an idea, you need to talk about the procedure as well as some technical nuances.

Let's start with the tool. You will need:

- mason's trowel - apply and level the mortar on the bricks;

- concrete mixer or container for mixing mortar;

- mortar shovel - for kneading and periodic mixing;

- two or three buckets for the solution;

- plumb - check the verticality of walls and corners,

- building level - to check the horizontal laying of the row;

- mooring cord - for beating rows;

- jointing (for forming seams);

- hammer-pick for beating undersized bricks (halves, 3/4 and checks - 1/4);

- the rule is a metal or wooden flat bar to check the plane of the wall.

Next, we talk about the features of the technology. First: it is advisable to soak the brick before use. This is especially true in hot dry weather. Then it will “pull” less moisture from the solution. If there is not enough moisture, the cement will not be able to gain the required strength, which will affect the strength of the building.

Second: the corners are driven out first. First two first. They are connected with 2-3 rows of bricks according to the chosen masonry pattern. Then the third corner is expelled. The second and third are also connected by several full rows. After the fourth corner is placed and the perimeter closes. This is how walls should be erected, bypassing them around the perimeter, and the walls will not be kicked out one by one. This is one of the most common mistakes.

Third, there are two row control technologies. The first is that nails are inserted into the seams of the corners, to which fishing line laces are tied. It must be stretched so that it marks the upper edge of the brick, and also limits the outer (and, if necessary, inner) surface of the wall.

The second way is to use wooden or metal orders. This is a flat bar or corner, on which marks are made every 77 mm - risks on wood or cuts on metal. They mark the required row thickness: brick height + seam. They are installed using flat mounting brackets that are inserted into the seam. If necessary, they are then simply removed and rearranged higher.

There is another way - a bricklayer's corner. It has a slot on one side into which the mooring is inserted. "Sits down" on the corner on the solution.

The disadvantage of this method is the same as just a nail in the seam: the height of the row must be controlled "manually" when deriving corners. With a lack of experience (and where to get it if brickwork is being done for the first time with your own hands), this is difficult. Having (having done it yourself) ordering is easier.

Fourth: preparation of incomplete bricks. As you saw, when laying, they use halves, three-quarter bricks and checks - 1/4 of the part. So that the work does not slow down, before starting the masonry, it is required to prepare them. This is done with a pickaxe. When preparing, high accuracy in size is required, otherwise the dressing will fail. To make it easier to control the length, marks of the appropriate length are made on the handle. Having attached the pen to the brick, marks are made on it on both sides of the spoon. Then, having applied the pick blade to the mark, they beat on the reverse side with a hammer, making notches. Having made notches on both spoons, the picks break the brick with a strong blow.

Brick houses are still popular due to their reliability and durability. And, although often the construction and laying of walls is entrusted to specialists, it is not difficult on your own.

Varieties of brickwork

Brickwork is not only distinguished by its strength and quality. Through this material, you can create a large number of drawings.

However, the complexity of the pattern suggests greater skill in doing the work. Consider the most common masonry options:

Do-it-yourself chain laying of bricks involves a constant series of bonder and spoon rows. Mandatory condition: the joints must match vertically.

The cross is distinguished by the dressing of the spoon masonry with horizontal seams.

Dutch masonry includes a combination of bonded and combined rows. The last of them is formed by horizontal alternation of bricks, set in a bond and spoon method.

Gothic masonry is based on mixing the basic principles of masonry.

To obtain masonry in the English style, one brick must be laid with dressing in two. Another condition is the alternation of tychkovy and two spoon rows.

Well masonry is considered the simplest and most rational. It is formed by erecting two walls in half brick and connecting them with a bridge vertically or horizontally.

For the result to be appropriate, it is worth choosing a brick laying template and following it.

How to determine the correct laying of bricks

For beginner bricklayers, laying bricks in a line at a uniform level and getting right angles are common difficulties. For the process to proceed correctly, the following must be observed:

- The first row requires special attention. They are placed at a distance of three mm. The evenness of the row is checked using a special tool.

- It is necessary to lay a brick exactly both horizontally and vertically.

Equipment

Each master has and uses the following devices for laying bricks:

- To align the products, a pickaxe hammer and a grinder are used.

- To check the evenness of the wall, the master uses a plumb line, level and tape measure.

- Trowels are used not only for applying mortar, but also for pre-fitting bricks.

- When making a corner in brickwork, rowing is necessary.

- Safety is ensured by special measures in the form of glasses.

- Since the work will require a solution, you need a container.

Solution preparation

Mixing the solution is an important part of the job. It consists of sand, cement and water. For greater plasticity, laundry powder or clay is added to it.

The laying of hollow bricks using this mortar is prohibited, because in this way their hermetic properties are violated.

To work in a small team, it will be useful to purchase a concrete mixer and buy 300 or 400 grades of cement.

Corner stacking

When choosing where to start laying bricks, pay attention to the corners. Experienced craftsmen usually bring out the corners above half the wall before working on the flat sections of the wall. This is not surprising, since half of the correctness of the design depends on the evenness of the corners.

Note!

The perimeter of the future house is determined using a tightly stretched cord. For the evenness of the angle, novice masons use ordering. It helps to fix and correctly lay the first bricks.

Experienced craftsmen can do without this tool, relying on experience. To regulate the vertical, a plumb line or level is used.

Making seams

Since each row of brickwork is interspersed with mortar, you need to know the basic principles of working with it:

When choosing an empty space, the solution should not only not be outside the wall, but also leave gaps, which will then be plastered.

Convex seams are classified as decorative. They are performed using a special tool. From improvised materials, you can use a pipe cut along.

Note!

A concave seam is not considered difficult to perform. It requires a stick or a tube.

Smooth seams are considered the most optimal, since after them it is not necessary to further level the surface. They are often used in the manufacture of chimneys and fireplaces.

Main masonry

Immediately after the removed corners, you can start laying the wall. The corners will rise with the erection of the walls. But it is important that the cord does not sag. The brick is laid tightly to the corner on the mortar applied earlier with a gap of 3 mm.

If there is a need to cut bricks, it makes sense to use a grinder. In the absence of this tool, this work can be done with a pickaxe.

To ensure the density of the masonry mortar, they take a little more than necessary, and each brick is carefully pressed down. What came out must be assembled with a trowel. Don't be discouraged if you don't get what you want right away. Sometimes it takes practice to get the job done right.

Note!

To make sure that the result obtained is correct, pay attention to the photo of the brickwork.

Strengthening masonry

Such work is necessary for those who wish to extend the life of an old house instead of building a new one. Whatever the do-it-yourself bricklaying scheme, before starting this work, it is necessary to check the reliability of the foundation. If there are cracks

or breaks, your structure will not last long.

After you are convinced of the reliability of the base, it makes sense to strengthen the wall with reinforcement and wire plaster. Other tools necessary for this work include a chain-link mesh, a special solution for plastering walls, trowels, nails and wire.

wall reinforcement technology

The first stage of work is to clean the wall. Then it is necessary to clean the seams and hammer nails with a distance of no more than 100 mm so that the height of the cap is 20 mm higher than the wall level.

Now you need to put the chain-link mesh on the prepared nails as firmly as possible. Instead of such a mesh, you can use ordinary wire. Only when forming cells should you pay special attention to the corners, avoiding holes in these places.

The next step is to plaster the wall. The composition necessarily includes cement and sand in a ratio of 1:3 or 1:4, as well as polymers to increase viscosity and plasticity.

For the basement of the wall, a cement-lime mixture, which is water resistant, can be used. To avoid lumps, the components of the composition must be sieved. The layer of plaster should be such that it covers the frame.

Conclusion

If you first decided to master the profession of a bricklayer, do not rush into the process of doing the work. Prepare materials and tools carefully.

Make a plan and calculate the number of bricks. And if you have decided on the masonry method and theoretically imagined the final result, you can begin the process.

DIY brick laying photo