How to make a homemade hot smoker. DIY cold smoked smokehouse

Smoked fish and meat are considered delicacies for a reason - smoking not only gives the product a unique taste and aroma, but also significantly extends its shelf life. Products from the store, unfortunately, cannot be called smoked - “liquid smoke” concentrate has long been used for their mass production. As a result, the taste is mediocre, and their benefits are completely questionable.

You can smoke completely different products: the usual fish, meat and lard, as well as nuts, cheeses, vegetables and even fruits and berries. Of course, they require different modes: smoke temperature and smoking duration, as well as the wood chips used for this.

- Smoking happens:

- cold, with slightly warm smoke 30-50ºС;

- hot, with a smoke temperature of 70-120ºС;

- semi-hot, at 60-70ºС.

The higher the temperature, the faster the meat and fish cook. Giving the smoke the desired temperature is a problem solved by the correct design of the smokehouse.

We give recommendations on how to install a stove in a bathhouse with an external firebox with your own hands.

We give recommendations on how to install a stove in a bathhouse with an external firebox with your own hands.

Find out the details of laying a long-burning coal-fired furnace.

We tell you how, based on the technical characteristics, you can make the right choice of a wood-burning stove.

Cold smoked

Its main difference is the extended chimney, in which the flue gases have time to completely burn out, harmful carcinogens from them are deposited on the walls of the chimney, and the products being smoked are enveloped in a light aromatic smoke. Meat after this treatment can be stored for several months, fish - from three to 12 weeks.

In the figure -, it can be installed on a site in a country house. The dimensions are arbitrary, therefore only the main structural elements are indicated in the drawing.

A cold smoked smokehouse consists of three main blocks: the firebox, the smoking chamber and the one connecting them. The firebox can be made of blocks, bricks or welded from metal. It must be equipped with an easily cleaned ash pan - the smoking time of some products is several days, and the ash must be removed during the combustion process.

The smoke output is adjustable; when igniting and at the beginning of the fire, the wood emits dark acrid smoke, which can spoil the taste of smoked meats. Therefore, the firebox is equipped with a smoke damper, directing its flow either into the chimney or out. Most often it is made in the form of a combustion chamber lid.

For smoking, you cannot use resinous ones - spruce, pine, or those that emit tar - maple, birch, firewood. The best wood is cherry, alder, oak and apple. The photo shows a cold smoked smokehouse made from a wooden barrel, equipped with removable rods.

The photo shows a cold smoked smokehouse made from a wooden barrel, equipped with removable rods.

Due to the low temperature, the smoking chamber can be made from anything, for example, metal or wood. The use of porous materials such as brick is not recommended- absorbing smoke, and after smoking, moisture, they form a sediment, which over time acquires an unpleasant rotten smell.

The simplest option is a metal or wooden barrel with a hole in the bottom into which smoke will flow. It is equipped with hooks or grates for placing products. The role of the lid is usually played by damp burlap - it traps smoke inside the chamber while absorbing excess moisture. The photo shows an example of a willow smoking chamber covered with burlap on top.

The crucial point is the installation of the chimney. It, like the smoking chamber, should not be made of brick, as it absorbs moisture and harmful substances from the smoke. Metal is better, but condensation and soot must be removed from it in a timely manner, otherwise an odor will form over time. The best option is a chimney dug in the ground. The soil not only effectively cools the smoke, but also absorbs condensation, and the microorganisms contained in the soil successfully process carcinogens from it.

The crucial point is the installation of the chimney. It, like the smoking chamber, should not be made of brick, as it absorbs moisture and harmful substances from the smoke. Metal is better, but condensation and soot must be removed from it in a timely manner, otherwise an odor will form over time. The best option is a chimney dug in the ground. The soil not only effectively cools the smoke, but also absorbs condensation, and the microorganisms contained in the soil successfully process carcinogens from it.

Making such a smokehouse with your own hands is quite simple. To do this, you need to choose an area with a slight slope that provides natural smoke draft. A firebox is placed at the bottom of the slope. A groove is being dug on the slope, which will serve as a chimney. It is covered with iron sheets on top, and a layer of soil is poured on them for better thermal insulation. The chimney leads into a smoking chamber; it can be made in different ways.

Hot smoked

Hot smoking is a fairly quick process, from 15 minutes to several hours, depending on the size of individual pieces of meat or fish. The smoke is hotter, about 100ºС, and it is obtained not from firewood, but from special wood chips, so the design of a hot smoked smokehouse has its own characteristics.

- First of all, the firebox is located directly under the smoking chamber. It is not necessary to make a firebox with wood; you can make it yourself from a gas burner or electric stove. The main thing is to heat the bottom of the smokehouse to the temperature at which the wood chips begin to smolder.

- The smoking chamber in hot smoked smokehouses is sealed. This ensures more uniform heating of all levels of the product - there can be several of them in the smokehouse, and also allows you to use the smoke completely, without allowing it to leak.

- Some smokehouse models have a lid with a water seal. This water seal is a U-shaped depression around the perimeter of the chamber into which water is poured. The edges of the lid fit into this recess, resulting in a barrier for air from the outside and smoke from the inside. The water seal not only allows you to isolate the chamber, but also reduces the amount of carcinogens in the smoke.

- Removable gratings or rods are placed at one or several levels for hanging hooks. Products are placed on them during smoking. You can use barbecue grills of a suitable size if you make supports for them from a corner with your own hands and cut off the handles with a grinder.

- Another prerequisite is a tray for collecting juice and fat.. If they drip directly to the bottom of the smoker, the fat will begin to burn and the food will acquire a bitter, unpleasant taste. For fish, due to the low combustion temperature of its fats, it is better to do it with an outflow from the chamber. The tray must also be removable and must be regularly cleaned of residual grease.

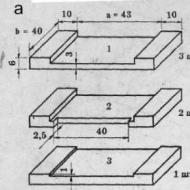

A drawing with options for making a smokehouse for hot smoking is shown below.

Portable mini-smokehouses for semi-hot smoking

The above smokehouse designs are great for a summer house or country house, but you won’t be able to take them with you on a picnic or fishing - they are too bulky. In field conditions they will be successfully replaced mini smokehouse in the form of a box with a lid, as in the drawing. You can make it yourself and use it both at the dacha and transport it in the trunk of a car to a vacation spot.

The above smokehouse designs are great for a summer house or country house, but you won’t be able to take them with you on a picnic or fishing - they are too bulky. In field conditions they will be successfully replaced mini smokehouse in the form of a box with a lid, as in the drawing. You can make it yourself and use it both at the dacha and transport it in the trunk of a car to a vacation spot.

The temperature in such a smokehouse is optimally maintained at 60-70ºС, which corresponds to the semi-hot smoking mode. The preparation of products for such smoking does not take long, and their shelf life is about three days.

The design of the mini-smokehouse is simple: a box with a lid, equipped with a grease tray and grates. The shavings are poured onto the bottom; when the smokehouse is placed on the fire, it begins to smolder. Smoke fills the chamber space and the food cooks quickly. If desired, the lid can be equipped with a water seal and a small diameter smoke outlet hole, as in the photo.

The design of the mini-smokehouse is simple: a box with a lid, equipped with a grease tray and grates. The shavings are poured onto the bottom; when the smokehouse is placed on the fire, it begins to smolder. Smoke fills the chamber space and the food cooks quickly. If desired, the lid can be equipped with a water seal and a small diameter smoke outlet hole, as in the photo.

Material for production - sheet steel, preferably stainless. The thickness should be such that when heated, the walls of the smokehouse do not move away, otherwise, due to uneven heating, it will become deformed. Typically, black steel 2-3 mm thick is used, stainless steel - from 1.5 mm. In any case, the gratings must have a stainless steel coating.

Video: how to make a mini smokehouse with your own hands.

Firewood and wood chips: how to choose the right one

The key to the taste of smoked meats is properly selected firewood. It is known that smoke from different types of wood has completely different flavors. The easiest way is to use purchased wood chips in this case, choosing the one suitable for each type of product:

- alder- universal, suitable for meat, lard, fish and vegetables;

- oak- mainly for smoking game and red meat;

- willow, birch- game with a specific taste, for example, elk or bear, as well as swamp fish;

- cherry, apple tree- cheeses, vegetables, nuts and berries.

The costs of making a smokehouse are insignificant; you can use scrap materials and leftovers. A self-made smokehouse and a properly selected smoking mode will allow you to prepare delicacies that are unique in taste and will surprise your family and guests.

Smoked dishes have a bright, memorable taste. Therefore, the idea of home smoking is very attractive to many owners. Cooking your own meals will save you a lot of money and guarantee the use of quality products.

This review is dedicated to home smokehouses and how they are designed, what points you need to pay attention to when purchasing or making them.

Design

In the photo, home smokehouses are very similar, but at the same time they have strong differences. In order to make the right choice of smokehouse, you need to familiarize yourself with their structure. Therefore, in order to decide on the right choice, you should study their design.

There are household and industrial equipment. Professional equipment is large in size and can process several hundred kilograms of products at a time.

A household smokehouse is small in size and can only cook a few servings of food. It is a metal rectangular box that closes tightly. The food being prepared is placed on a special grid in it. A special container should be placed under the grate to collect fat released during cooking.

There must be space at the bottom to accommodate the fuel that will be used to produce smoke for smoking. In addition to these basic elements, there are also additional ones, which will be discussed later.

The types and sizes of home smokehouses are determined primarily by the heating method. There are three possible heat sources for smokehouses: electricity, gas and an open charcoal fire.

The most natural way is to cook over a fire. It produces products with the most natural taste and smell. At home, using a fire is difficult, so they use either gas or electricity.

These remaining options have their advantages and disadvantages. Electrical appliances are more expensive, but have many useful features. But they consume a lot of electricity and require a special power supply.

Household gas smokers are heated directly on a household gas stove. They may look like pots or look like rectangular fire pits. A home smokehouse for a stove is usually significantly cheaper, more reliable and more compact than its electric counterparts.

Types of smoking

There are two types of smoking: hot and cold. In household appliances, only the principle of hot smoking is used. In this case, the products are processed with hot smoke, the cooking time is from 1 to 2 hours. Such products do not have a very long shelf life.

When cold smoking, products are treated with smoke at a temperature of no more than 40 degrees for several days. Food prepared this way can be stored for a long time.

Additional functions

In order to determine which smokehouse is better to choose for your home, you should consider the presence of additional functions. Not all of them can be present on any type of smokehouse, but only on either gas or electric appliances.

When choosing a gas model, you should pay attention to the presence of a hydraulic lid seal. It does not allow odors to spread throughout the room and such a device can be used in an apartment.

The presence of a thermostat in an electric smokehouse creates a uniform distribution of the desired temperature and thereby improves the quality of the prepared product.

Automatic cleaning of internal surfaces from contaminants occurs thanks to the addition of a special catalyst to the enamel with which the internal walls are painted.

Automatic cleaning of internal surfaces from contaminants occurs thanks to the addition of a special catalyst to the enamel with which the internal walls are painted.

The purchased kit must include: a lid, a grill, and a grease tray. The fire smokehouse must have devices for removal. When choosing, you should pay attention to what material it is made of and its thickness.

When purchasing stainless steel products, you should definitely check its quality. Unlike iron, stainless steel is poorly magnetic. If the magnet sticks to the smokehouse like a metal pan, then it is better not to buy such a device.

Having understood the design in general terms, it becomes clear how to use a home smokehouse. During operation, you should pay attention to several points.

Coniferous wood should not be used to create smoke. They contain a lot of resin. It is most desirable to use beech, oak or alder wood. If these materials are not available, then birch will do.

In outdoor smokehouses with combined combustion and smoking chambers, the meat should be wrapped in gauze, but this operation is not mandatory.

In smokehouses without a glass door, it is impossible to visually determine the degree of readiness. The only information is smell and time. Therefore, after acquisition, it will take some time to develop the technology. Having gained experience, you can get chic, tasty dishes at home that are in no way inferior to those on store shelves.

Photos of home smokehouses

To significantly expand your diet with quality products, you can acquire a small boiler room (both portable and stationary). But before you start working directly, you need to objectively assess your capabilities, prepare the necessary materials, only in this case a mini smokehouse with your own hands will be made with high quality and quickly.

There are many ways to create a smokehouse, but we will tell you only about the most accessible of them.

Option #1. Cold smoked design

This type of smokehouse is made from a wide variety of materials. Below is a step-by-step guide to creating a simple design using plastic film.

Step one. First you need to purchase the plastic film itself. Two meters of thick film (the kind used for greenhouses) will be more than enough. From one end, the sleeve of the purchased film is sewn up in such a way that the result is a kind of bag.

Step two. Next, you need a place where the mini-smokehouse will be located. To do this, you will need a small leveled area of 1 square meter. A two-meter stake should be driven into each corner of this site. At the top, the stakes must be connected to each other using crossbars. It is important that the structure is sufficiently stable.

Step three. Opposite stakes must be connected using diagonal slats in approximately two to three rows.

Step four. Fish, already prepared for smoking, should be hung on these slats. It is also important that the bodies of the fish do not touch each other.

Step five. The prepared plastic “bag” must be pulled over this structure to approximately half its height. After this, the site should be filled with 1/2 a bucket of hot coals, on top of which green grass should be laid.

Step six. After this, the film is already lowered to the very ground, and pressed down with something from below so that the mini smokehouse with your own hands is airtight. That's it, the design is ready and, as you have seen for yourself, the costs for it are very insignificant.

In the future, if necessary, fresh grass is added - the fact is that there should always be thick smoke inside the smokehouse. After three to four hours, the plastic “bag” is removed and the fish is ventilated. If there are fish with large carcasses, then the next day they need to be smoked again.

How to make a barbecue out of metal with your own hands

Previously, we gave detailed instructions on how to make several options for a metal barbecue yourself; in addition to this article, we advise you to read this information

Option #2. Hot smoked smokehouse

The easiest way to make a smokehouse of this type is from sheets of metal. But before you start work, you should prepare everything you need (the list is given below).

- A pair of metal sheets 2 millimeters thick and dimensions 1565x610 millimeters.

- Thin reinforcing rods.

- Bulgarian.

- Meter.

- Carpenter's corner.

- Welding machine.

After this, you can proceed directly to production. The algorithm of actions should be as follows.

Step one. First, the first metal sheet should be cut into four parts. To achieve a square smokehouse, it is important that the dimensions of all elements are the same. To cut the sheet, use a grinder with an appropriate disk.

Step two. The two sheets are welded together using drip welding, after which, using a carpenter's angle, you should make sure that the planes are connected to each other strictly at right angles. If necessary, their position is adjusted. Then the remaining sides are welded in the same way.

Step three. In order to achieve tightness, all internal seams of our structure must be carefully welded.

Step four. The bottom of the future smokehouse is cut out of another metal sheet, after which it should be carefully welded to the box made at the previous stage.

Step five. After this, you can begin making the cover of the structure. Using a grinder, you should cut out four strips of stainless steel sheet (it is important that the dimensions of these strips are slightly larger than the external dimensions of the finished box). The cover is welded. When all work is completed, the lid should be deep enough so that it can be easily placed on the box.

Step six. The product is almost ready. But to completely complete all the work, iron handles and a couple of levels of metal rods are welded to the body. Rods should be welded on top of the body to mount a tray in which fats and juices will accumulate. The upper rods are required in order to place hooks with meat or fish.

Video - Making a smokehouse (hot smoking option)

That’s it, after this you can start operating the smokehouse. In this case, the heat will be provided by an electric stove, but to get a higher temperature, it is advisable to light a fire.

Note! If desired, the dimensions of the smokehouse can be changed in one direction or another, but the main requirement must be met - we are talking about the complete tightness of the smoking chamber.

We also note that in order to make a mini smokehouse with your own hands, you should first work on drawings of the future product. In this case, it will be possible to correctly calculate the amount of required consumables.

Option #3. Bucket smokehouse

The algorithm of actions in this case should look like this.

Step one. Take a bucket and pour a one- or two-centimeter layer of sawdust into its bottom. At the bottom. Approximately ten centimeters from the bottom of the bucket, a grate is placed on which products previously prepared for the smoking procedure are placed.

Step three. When steam or smoke begins to seep out from under the lid, this means that the smoking procedure has begun successfully. It is also important that the structure itself does not overheat. At first, when the prepared product is just dried (this takes approximately the entire time that the process takes), the temperature inside the case should be about 80-90C, and during the entire remaining time, that is, directly during smoking, it should be 120C.

Step four. To determine the current temperature in the smokehouse, you need to perform just one simple action - drop water on the lid. And if it does not boil, but only evaporates without any hissing, then everything is in order with the temperature. The meat or fish will be smoked correctly, but ultimately will not be cooked.

Step five. To regulate the temperature, you need to rake out the coals or add fuel to the smokehouse. As a rule, the smoking procedure takes from 30 to 45 minutes. At first, you will have to remove the smokehouse from the fire a couple of times and, quickly removing the lid, taste the food. When you have sufficiently mastered the process, there will be no need for this manipulation.

Step six. When smoking is finished, the bucket should be removed from the fire and, as soon as it cools, remove the product and dry it a little. It is worth noting that, for example, on a hike you will not need a tray to accumulate heat.

Option number 4. Smokehouse inside the apartment

To make such a design, you must perform the following steps.

Step one. A box 0.4-0.5 meters high is made from stainless steel, and it is equipped with a lid. Next, you need to weld an iron tube into the lid, through which the smoke will be removed.

Step two. After this, a hose is put on the tube - the latter should be led out into the window. The lid is installed on the box in special sides (made in the form of the letter “L”), previously equipped from the outside.

Step three. Water is poured into the sides - this will prevent smoke from escaping from the box.

Step four. The bottom of the box is covered with a layer of alder sawdust one to two centimeters thick. The sides are welded approximately 10-12 centimeters from the bottom, and a special tray is installed on them, in which the heat will accumulate. A grate for food is placed approximately 17-20 centimeters from these sides.

Option #5. How to make a portable smoker from an old refrigerator

In most cases, old refrigerators are used by owners of suburban areas as cabinets in which all sorts of small items are stored. But few people know that it is quite possible to make a small-sized smokehouse from such a refrigerator. To do this, you should follow these steps.

Step one. First, all the “insides” of the refrigerator are removed, leaving only the door and the box itself.

Step two. A hole is made at the top for the chimney pipe.

Step three. 3 pairs of metal corners are attached to the side walls of the case at three different levels. The first two levels are covered with gratings and slats with hooks. As for the corners located below, they are needed for installing a tray in which heat will accumulate.

Step four. The product will also require a strong tray for sawdust and an electric stove. The tile should be installed at the bottom of the body, and the pallet itself should be installed on top of it.

Step five. It is important that the door closes properly - this is necessary to minimize the entry of air.

Video - Creating a smokehouse from a refrigerator

Option number 6. Making a smokehouse from an old barrel

Perhaps one of the simplest ways to make a miniature smokehouse is to use an iron barrel. First, the bottom of such a barrel is cut off, then it is equipped with a grate (or, as an option, reinforcing bars) at two different levels. A pallet is installed in the lower part, and products will be hung in the upper part (using hooks).

Note! If the fire is located directly under the body, then we are talking about a hot-smoked design.

And if the barrel is placed in a special pit and a chimney pipe from the fire is brought there (its length should be two meters), then the result will be cold smoking.

Video - Making a good smokehouse out of a barrel

Option No. 7. Making a smokehouse from a cylinder (easy way)

A mini smokehouse can also be made from an old propane cylinder. If you have such an unnecessary thing lying around in your household, and you don’t know where to “put it”, then we advise you to read the instructions below. Let’s say right away that the remodeling procedure is quite complicated, but if you have competent instructions, it is quite possible to cope with it. For everything to work out, you need to follow these steps.

Step one. First, the cylinder is taken to a remote place in order to release the remaining propane from it and cut off the valve. To check whether the cylinder is truly completely empty, you need to apply soapy water to the valve. If there are no bubbles, you can proceed to the next step.

Step three. For rinsing purposes, the empty bottle should be filled with plain water.

Step four. The washed container is taken home, after which you can begin to make the smokehouse itself.

Step five. First you need to take care of the large door through which the products will be loaded. It is important that the cuts in the cylinder are not made completely, otherwise the door will simply fall out prematurely.

Step six. The corresponding places are protected, then hinges are welded to them where the door will be located in the future. At the end of the welding procedure, the door is finally cut out. After this, you need to take care of the smokehouse stand.

Step seven. First, a strip of metal is cut out of the bottom of the cylinder, after which half of the entire bottom is sawed off. The smokehouse must also be equipped with a combustion chamber.

Step eight. Thick metal sheets are used to make the combustion chamber. After manufacturing, the firebox is welded to the cylinder so that a single solid structure is formed.

Step nine. Before starting the first smoking, the device from the cylinder is calcined using firewood.

Photos of smokehouses

As you can see, a mini smokehouse with your own hands can be made in a variety of ways, so you yourself have the right to choose which one to use.

Make a smokehouse with your own hands, smoke fish or meat, try it and feel how tasty ordinary food can be after smoking!

Products during the smoking process will receive an amazing aroma and taste, and this taste will not be similar to the taste of smoked products purchased in a store. However, first you need to understand the intricacies, and only then decide how to make a smokehouse with your own hands for hot and cold smoking.

We study the features of the smoking process

The man began to smoke food out of necessity. It was noticed that after smoking they can be stored without spoiling for a longer time. This allowed ancient man to take some of his provisions with him in smoked form, rather than relying on luck while hunting or fishing during long trips.

We smoke products at home mainly to give them a different, unique taste. To do this, you can use hot or cold smoking. And the smokehouses themselves come in two types. Their design is almost no different. It is necessary to equip a fireplace, a chamber with hooks where the products will be hung and smoked, and a device for collecting fat that will be released during the smoking process. The smoking chamber must be located in a hermetically sealed housing.

What is the difference between hot and cold smoking? After all, both processes involve the presence of products located in a limited space in smoke from smoldering sawdust or shavings. The main difference is the distance separating the chamber in which the food is smoked from the hearth. For hot smoking, the smoke temperature should be high enough, for cold smoking - 35°C. A mandatory requirement is that smoking cannot be carried out over an open fire.

Cold smoking

Cold smoking takes significantly longer than hot smoking. With this method, the products retain their appearance and acquire an amazing taste and aroma. The cold smoking process takes place at a temperature of approximately 30°C and lasts several days. You should not rush, because at this temperature bacteria multiply well and, without completing the process, you risk getting severe poisoning instead of a tasty dish. Typically, cold smoking lasts 5-7 days, but can last several weeks.

Important ! Particular attention should be paid to the sawdust or wood chips that you will use. We forget about softwood sawdust; you should not use aspen sawdust. The best choice would be:

- alder (you must first remove the bark, it produces bitterness);

- juniper;

- bird cherry and birch (should also be cleared of bark);

- maple;

- shavings and sawdust of fruit trees (cherry, apple, sea buckthorn).

DIY cold smoked smokehouse

It should be remembered that the hearth must be located away from the cold smoking chamber. A good option would be to dig a hole in the far corner of the site; you cannot use the natural height difference. A fireplace is installed in the pit, which should be connected to the chamber with a chimney. There is no need to line the fireplace with bricks; it is enough to line the walls of the fireplace.

Very important ! The length of the chimney is usually 2.5-3.0 meters. To do this, it is enough to dig a trench no more than 0.5 meters wide and 0.25-0.3 meters deep, line the walls and bottom with bricks held together with clay mortar, cover the top with a sheet of metal or slate, and sprinkle with earth. Instead of a brick chimney, you can lay a chimney in the trench. Provide a damper at the top of the fireplace to regulate the flow of air, the intensity of combustion and the removal of excess smoke. The damper can be cut from sheet metal. Make the junction of the chimney and the chamber (diameter 200 mm required) airtight using available means. You can use the same clay solution. The chimney has been built.

Another solution could be to install a “potbelly stove” stove, a chimney from a chimney pipe and install a smoking chamber above the level of the chimney laying.

We make a chamber for cold smoking from a barrel

The easiest way to make a simple smokehouse with your own hands is from a barrel. You need a barrel of 100-200 liters. The top cover is cut off, the barrel must be cleaned and washed before use. A hole for the chimney is cut in the bottom of the barrel. The barrel will be mounted on bricks or blocks, so there will be no problems with their articulation. A tray is made from a cut-off lid or other available material to collect fat that will flow out of the product during smoking. The diameter of the pan must be smaller than the diameter of the barrel to ensure the passage of smoke.

We need to make at least one grate on which the food will be smoked. This is one of the options for placing products when smoking. Or secure scraps of reinforcement to the top of the barrel. We will attach hooks to the reinforcement, and products to the hooks.

We make the grate from scrap materials. These can be willow twigs that are woven into a shape of the desired size. It is advisable to secure the cells with thin wire. You can use thin wire and weave it into a lattice, and make the rim from thicker wire. To do this, a thick wire is wrapped around the barrel to determine the desired size, slightly compressed and the rim is secured.

One grating is used or several gratings are installed at different levels. In this case, the distance between the gratings should be about 15 cm.

To install the pallet, pieces of reinforcement are welded to the walls of the barrel, which form a cross in the center of the barrel. Tip: Provide a loop on the tray so that it can be easily removed for cleaning.

To attach the grates, you can make loops and weld them to the walls of the barrel. Or screw self-tapping screws into the walls of the barrel.

The chamber cover is made from hardwood trees. It should not be massive and several small holes should be provided in it for moisture to escape. You can limit yourself to a jute bag, which is simply thrown over the barrel during smoking. Remember that the bag must be moistened with water.

We make a chamber for cold smoking from brick

The smoking chamber can be made of brick. This would be the best solution, but it makes sense to build such a chamber only when you are constantly engaged in smoking products and have achieved the required skill in this matter. Otherwise, a rarely used structure of unknown purpose will appear on your site.

A brick smoking chamber is equipped in the same way as a barrel. The bottom of the brick chamber can be made from the lid of a barrel or from scrap materials. Sand-clay mortar is used for laying bricks.

We make a chamber for cold smoking from sheet iron

To make a chamber, a sheet of iron is cut, bent into the shape of a cube without one side (the top), and the seams are welded.

The smoking chamber can be built from a variety of materials and items: a bucket (this is a small barrel), an old pressure cooker or a refrigerator.

Craftsmen even make it to speed up cold smoking. In such a smokehouse, the thermal effect of the electric heater on the wood chips produces smoke. The heating element is periodically switched off, thereby achieving the desired temperature of the smoke upon entering the smoking chamber. The smoke rises through the holes, passes through the mesh of the explosive block and becomes positively charged. When smoke enters the chamber, it interacts with the products that are suspended on hooks. The hooks are connected to the negative pole of the BB block. Products attract positively charged smoke particles and these particles settle on them.

DIY hot smoked smokehouse

Hot smoking takes significantly less time because the process takes place at smoke temperatures ranging from 50°C for meat to 120°C for fish. Reduce the temperature - increase the smoking time.

Schematically, such a smokehouse looks like this: a container with sawdust or shavings is placed over an open fire or on a high temperature source (heated oven). The temperature at which the sawdust will slowly smolder is important, not the fire source itself. Smoke from sawdust penetrates into the smoking chamber where the products are placed. A tray is installed under the products to collect the fat released during smoking. Excess smoke is discharged through the chimney or holes in the chamber lid.

We make a smokehouse for hot smoking from a barrel

The difference from a cold smoking chamber will be the need to equip a firebox. The firebox can be placed directly in the barrel:

- Several holes are cut in the bottom of the barrel through which ash will be removed and which will serve as an ash pit for the firebox.

- A piece of the wall is cut out from the bottom of the barrel, from which the firebox door is made. A piece measuring 200x300 mm will be enough. Hinges and a latch handle are welded to the door.

- About a third of the barrel's volume is allocated for the firebox, the rest will be the smoking chamber. The firebox and chamber are separated by a sheet of metal 4 mm thick. This sheet will serve as the bottom of the chamber. It is welded to the walls.

- A hole is cut in the bottom of the chamber for the chimney. The diameter of this pipe must match the diameter of the chimney at the top of the chamber. Do not get carried away by the length of the chimney; excessive draft in the firebox is not needed. The chimney is welded to the wall of the barrel.

To make more efficient use of the volume of the barrel, the firebox can be placed directly under it. In this case, it is better to make the firebox out of refractory bricks, with holes for inserting sawdust and removing excess smoke. The barrel is installed on the firebox, and the freed volume is used to place additional grates.

Advice . To control, attach a mechanical thermometer with a remote sensor to the wall of the barrel. Such a thermometer can save you from many mistakes while you gain experience. You can use the old-fashioned method and splash a few drops of water on the surface. If it doesn't hiss, there's nothing to worry about.

A mini-smokehouse can be easily equipped in an ordinary metal bucket. Sawdust and shavings are poured into the bottom of the bucket, and a grate is installed on top. At the very top of the bucket, holes are made in the walls for the rods. Hooks are hung on the rods. We get two options for placing products in a small volume. In the lid of such a “smoking chamber” it is necessary to provide holes for the smoke to escape. The bucket is placed on the fire. A big fire is not needed, the sawdust should only smolder. As soon as the smoldering process begins, you can lay out and hang the products for smoking and close the lid. Smoking will take from 30 minutes to an hour.

Another option for a mini-smokehouse is a metal box with a perforated lid, which can be installed on the grate over burnt coals in the grill. We fried kebabs, sat down at the table and put the smokehouse on the grill. A good option for hiking or fishing.

Having understood the principle of operation of a hot smoker and after a series of experiments with a barrel, you can think about a more presentable design. You can weld a beautiful smokehouse from stainless steel or lay it out of brick.

An excellent option for a summer residence would be to combine a smokehouse and a barbecue on one site and in one volume.

DIY smokehouse and barbecue made of brick

The work will require time and effort, but it is worth it - the result will delight you for many years.

First, choose a suitable location on the site, remembering fire safety. For convenience, you can bring water and sewerage to this place. Develop a sketch of your structure and be sure to draw up a drawing for laying each row of bricks. You will see, such a drawing will make your work much easier.

You can do without a concrete mixer and mix the solution manually, but a little mechanization will speed up the work several times. Prepare all necessary materials and tools.

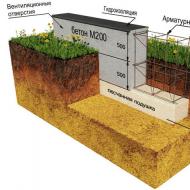

The work begins with clearing and planning the selected site and making a foundation. A brick smokehouse with a barbecue is already considered a permanent structure and a strip foundation is indispensable. A wooden formwork is installed in the dug pit, which must be covered with roofing felt. A layer of rubble stone is laid, filled with crushed stone and filled with mortar.

Important ! A day later, after the first layer has dried, the next one is done and so on. The number of layers depends on the size and weight of the structure.

The last layer is checked by level, leveled, waterproofed and left for several days until completely dry.

Instead of a rubble foundation, you can build a concrete one. Such a foundation needs to be reinforced.

For masonry, use red stove brick. Start by laying out the first row of bricks without using mortar. This will help you make markings and determine where to install the grilles.

Start laying by mixing sand-cement mortar with the addition of lime. The usual ratio is 3:1:1. Water is added in volume so that the solution looks like thick sour cream. The second and subsequent rows are laid staggered, laying bricks starting from the corners. Constantly check the horizontality of the laid out rows. The corners must be reinforced with wire.

To install the brazier, corners and fittings are installed between the walls of the oven. The firebox must be made of heat-resistant metal or cast iron.

It is easier to install the lattice if several bricks are laid protruding into the structure.

Space for firewood and various household appliances can be provided in the overall volume of the structure.

The smokehouse is made of two volumes located one above the other. This will give you a hot smoker. It can be easily converted into a smokehouse for cold smoking by placing a portable stove or hearth at the required distance and connecting it to the chamber with a chimney. So you can make a smokehouse with your own hands for hot and cold smoking.

You choose the design style of the building and its decoration according to your taste.

These are not all the ways to make a smokehouse with your own hands for hot and cold smoking. Among them there are very cheap (option with a bucket) and quite expensive (grill-smokehouse made of bricks). It's up to you to decide, but in any case, there will now always be a place for delicious smoked products on your table.

Smoked meat and fish are famous delicacies. A wide variety of types of smoked meats can be bought in stores, but can factory-made products from a store compare with home-made products? Therefore, some summer residents and owners of private houses who raise poultry and animals or are interested in hunting and fishing are thinking about purchasing a smokehouse. A serious obstacle to this may be its high cost, but almost anyone can make a smokehouse on their own. To do this, you only need a correctly selected drawing, suitable materials and a little time.

Features and Benefits

Making a smokehouse is a much less complicated and time-consuming process than it might seem at first glance. Of course, it all depends on the type that the owner decides to install on his site, but some options can be made independently in just a few minutes. In most cases, a homemade smokehouse will cost much less than a purchased one. It can be made from scrap materials, from old things that are no longer used in the household, but have retained their properties.

A good and convenient smokehouse, corresponding in size and volume to the wishes of the summer resident, can be quickly made with your own hands right at your summer cottage.

Properly selected wood for smoking and temperature conditions allow you to create on your site delicacies that are completely unique in taste and aroma, the likes of which are very difficult to find on store shelves.

Types and purpose

There are two main types of smokers, one of which is suitable for hot smoking, and the other for cold smoking. They differ from each other mainly in the manufacturing technology of the smokehouses themselves and the temperature that is maintained in the smoking chambers. Depending on the smoking method, products will also have a slightly different taste. With equal success, these smokehouses can be used for smoking meat, game, fish, lard, and sausages.

First of all, you should consider cold smoked smokehouses. Their main feature is a long, elongated chimney, which allows for complete combustion of flue gases.

Such smokehouses, in addition to the chimney, have two main blocks: a firebox and a smoking chamber. All harmful substances settle on the walls of the chimney, and the meat acquires a barely noticeable aromatic smoke. To produce a product using this method, it will take from three days to a week, and the shelf life of products produced using such smokehouses can average from three to twelve weeks.

In smokehouses designed for hot smoking, products are cooked much faster: the whole process takes from a quarter of an hour to several hours, it all depends on the size of the original product. In smokehouses of this type, it is customary to use not firewood, but special wood chips, which determines some structural features. Thus, the firebox in these smokehouses is located directly under the most sealed chamber intended for smoking. The tightness of this chamber ensures uniform heating of the entire mass of the product.

In addition, there are universal smokehouses, which are a cross between cold and hot smokehouses.

In addition to the stationary smokehouse, there are also camping or portable mini-smokehouses: in appearance they resemble a box with a lid. This simple design is very convenient: you can take it with you, for example, fishing or on a picnic.

What can you build from?

To make a smokehouse with your own hands, you can use a lot of available materials - used household items that are taken to the dacha in large quantities in the hope that someday they will find a use will do.

A wooden barrel is suitable for the smokehouse chamber, and the larger it is, the better, but for small home production a container with a volume of 50-100 liters is enough. However, it is important to remember that under no circumstances should you choose tree species that are resinous or tar-producing. Spruce, pine, maple and birch are definitely not suitable. The best options would be trees such as cherry and apple trees, oak or alder.

In addition to the barrel, you can use any large metal box: an old refrigerator will also do (this will even allow you to combine a smoke generator and a dryer in one block). You can make a chamber, for example, from a gas stove. In the end, a container for a portable smokehouse can be an ordinary metal bucket, an old saucepan, flasks, a medical jar or even an old fire extinguisher: two grates are inserted inside, between which there will be meat or fish, and the bottom is covered with a thin layer of sawdust.

However, when using metal elements in the manufacture of a smokehouse, you should give preference to items made of “stainless steel”. Of course, this is a rather fragile and more brittle material that is more difficult to process, but it has a number of undoubted advantages: firstly, it is resistant to the chemical components carried by smoke, secondly, it does not oxidize at high temperatures and does not rusts, thirdly, it is easy to clean it from soot, soot and traces of grease.

If a smokehouse is a necessary attribute for the owner of a suburban area, then you can build a solid brick smokehouse. Its dimensions will correspond to the wishes of the owner, the main thing will be to ensure the correct flow of smoke inside the smoking chamber. For the heating source in such smokehouses, potbelly stoves are usually used, connected to the chamber by a pipe.

How to prepare drawings?

If the smokehouse should become a functional element of the decor of a suburban area, then, undoubtedly, it is worth making the drawings yourself. However, if there is no need for this, then it is better to use ready-made drawings. This is especially true for non-professionals, as this will help avoid mistakes and inaccuracies. But even in this case, one should take into account the size of the container that it was decided to use for the main camera. Most likely, the scheme will still have to be slightly changed.

It is worth remembering that hot smokers are convenient due to their small size, while cold smokers are quite bulky, but they allow you to produce products with a richer taste and a longer shelf life. Mini-smokehouses are distinguished by their simplicity of design.

Accessories

Despite the variety of items from which a smokehouse can be made, each design must have several essential components to make the smoking process convenient and technologically correct. In addition, during work you should have some tools on hand - at least a welding machine and an angle grinder.

There must be at least one grate in the main chamber of the smokehouse. Products for smoking will be laid out on it. Such a grid can be made from thin reinforcement.

The smoking chamber itself must be sealed. This will ensure even heating of the products and will also prevent the smoke from evaporating ahead of time. In addition, if the size of the smokehouse allows, you should provide the chamber with several hooks for smoking.

Under the grate there should be a tray for smoldering shavings and sawdust, and even lower - a box for ash. There may also be a heat source that provides smoldering for the sawdust. The third important element is the tray onto which fats and juices will drain; it must be cleaned after each smoking session.

You can install the smokehouse on a fire, on gas, and even, if size allows, on an electric stove.

An important design detail is the smoke generator. Of course, small smokehouses operating on the principle of hot smoking have it directly in the smoking chamber: smoke production is provided by sawdust, which covers the bottom of the chamber. For cold smoked smokehouses, it will be necessary to create artificial conditions for the formation of smoke, because its total temperature should not exceed 35 degrees Celsius. Therefore, such smoke generators often use an electric heating element with a built-in thermostat and temperature sensors.

To improve the quality of smoking (in the case of a hot smokehouse), it is possible to install an additional fan or compressor into the design. They will provide additional, more powerful pumping of smoke, due to which smoked products will warm up and cook faster.

Sometimes a lid with a water seal is added to smokehouses: it is a small recess located around the perimeter of the smoking chamber into which water is poured. This device creates a barrier that prevents air from entering the chamber and does not allow smoke to escape from the chamber.

Assembly Instructions

The variety of items from which it is possible to make a smokehouse raises natural questions about how to properly make a smokehouse at home. In fact, knowing the general technology and processes that products undergo during the smoking process, you can independently develop not only a diagram, but also step-by-step assembly instructions. However, as an example, it is worth considering several of the most common and convenient options for making smokehouses.

The simplest design made of polyethylene film

To make such a cold smoked smokehouse, you will need two meters of very dense film, which is sewn together in the form of a bag. The best choice is a thick film used by summer residents for greenhouses and greenhouses.

Next, you will need to find a flat area approximately one square meter in size on the site. The platform is covered with tall wooden stakes to the size of the film, about two meters in height, and the stakes themselves are connected to each other by thin transverse beams to give the structure stability. Then the opposite stakes will need to be connected with diagonal bulkheads in approximately 2-3 rows. After this, the products prepared for smoking are hung on the rods so that they do not touch each other, and a prepared plastic bag is pulled over the structure - not all the way to the ground, a small space is left.

Burning coals are poured under the structure and covered with grass, after which the film is stretched to the ground and carefully clamped on all sides to make the entire structure airtight.

It will take approximately three hours for the products to be cooked in such a smokehouse, after which the bag is removed and the products are ventilated. Particularly large pieces may require re-smoking.

From the bucket

To make a similar model of smokehouse, you will need an old bucket. One or two stainless steel grates are placed inside it. If there are two grates, then the first, smaller one is installed about 10 cm from the bottom of the bucket, and the second is slightly higher. Then the bottom of the bucket is generously sprinkled with wood shavings or sawdust.

The bucket smokehouse is ready, all that remains is to place the products to be smoked on the grids, put the structure on the fire and cover with a lid.

From a barrel

The most traditional and simplest option is to make a home smokehouse from a wooden or metal barrel. The principle of its manufacture is the same as in the case of a bucket smokehouse; the main difference is its significantly larger size, which makes it possible to equip the barrel not only with grates, but also with hooks for smoking.

A barrel can make a smokehouse for both types of smoking, which can be very convenient. In the first case, the heat source - the hearth - should be located directly under the barrel. For cold smoking, the barrel is installed in a pit, to which a chimney (approximately two meters long) is drawn from the hearth.

You can make a more complex version of the smokehouse, which will require not one, but two barrels.

The most convenient option would be to use two identical barrels with a volume of approximately 200 liters. They need to be welded together in a "T" shape. The lower barrel will serve as a container for the future firebox; an opening is cut out on the side and a door is installed. The valve at the bottom of the stove will allow you to regulate the intensity of combustion. The upper barrel will serve as the future smoking chamber: a strong grate must be tightly and rigidly fixed in it, on which the smoking products will subsequently be laid out, and it will also be possible to cook a barbecue on it. Plus, it can be used as an oven, placing baking dishes or simply food wrapped in foil on the grill.

For smoking, it will be necessary to arrange a sawdust brazier in the lower firebox, and an open fire will be lit under it. Sometimes sawdust is poured directly into wood coals, but this is a more labor-intensive method that requires constant monitoring and attention. Otherwise, the products may burn and lose the necessary taste.

Then all that remains is to hang the food over the grill, and place a tray on it, into which the draining fat and juices will be collected. Using the same principle, smokehouses are made from an old gas cylinder.

From an old refrigerator

Many summer residents prefer not to get rid of old non-working equipment, but to take it to their country house. If you rid a non-working refrigerator of the electrical filling and other “innards”, then the remaining box can be turned into a convenient and spacious smokehouse.

It is necessary to make a small hole in the roof for the future chimney. Inside the box, at different levels, six corners should be installed in pairs, on which grates for the tray and products and hooks for smoking will subsequently be located, as well as a tray for fat draining from the products. In addition to a tray for fat, you will also need a tray for sawdust or shavings; it is installed at the very bottom of the structure.

It is also important to ensure that the refrigerator door closes as tightly as possible and does not allow excess air to enter the chamber.

Made of metal

This product already requires a more serious approach, but it is not difficult to weld it yourself. The simplest and most convenient shape for a craftsman is a rectangle, but stainless steel is most often preferred as a material: it is easy to clean, withstands high temperatures well and has a long service life. But at the same time, “stainless steel” is quite difficult to process. Another material to consider is cold rolled steel: it is quite ductile, withstanding temperatures up to 650 degrees Celsius, but is susceptible to oxidation and rust.

This design itself resembles a box, to the walls of which corners with grilles installed on them are welded.

To begin with, you will need two sheets of metal, one of which is divided into four parts, which will be identical if you plan to make a square smokehouse. You can divide the sheet using a grinder. Then, at an angle of 90 degrees (a carpenter's angle is used for this), the sheets are welded to each other, forming a box. To ensure the future smokehouse is sealed, it will also be necessary to weld the internal seams of the chamber. The bottom of the smokehouse is cut out of another metal sheet and welded to the box in the same way.

Finally, you can start making the camera cover. To do this, use a grinder to cut four identical strips of metal sheet (preferably stainless steel) with a size slightly larger than the characteristics of the outer part of the box. Then the resulting cover is welded.

The last parts will be the lower fastenings for installing a tray in which fats and juices will be collected, and the upper ones for placing hooks on which lard, meat, fish or sausages are hung. It is also worth attaching a couple of handles to the edges of the smokehouse to make it easier to carry.

A conventional electric stove can be used as a heat source for such a smokehouse. If higher temperatures are needed, the smoker can just as easily be placed over a fire.

From a gas cylinder or fire extinguisher

The process of making a smokehouse from a gas cylinder is somewhat complicated, but it is quite suitable for those who have this completely unnecessary thing in their household and want to find at least some use for it.

To begin with, it is worthwhile, observing safety precautions, to release the remaining gas from the cylinder, and then carefully saw off the release valve. The remaining gasoline is also drained from the cylinder into any metal container and burned. Then the cylinder is washed thoroughly, a door is cut into its wall through which the products will be placed inside. The hinges on which the door will be held are welded to the cutout. Metal strips are cut off from the bottom of the cylinder and half of the bottom is sawed off to provide the future smokehouse with a firebox. Finally, the firebox itself is made from metal sheets and welded to the cylinder, after which the entire structure must be calcined over a fire.

Made of brick and stone

This smokehouse is easy to manufacture, but quite complex in its design. During construction, you will not need to use a grinder and a welding machine, however, the slightest mistake in the location of the chimney can render the finished smokehouse unusable. The advantage of this smokehouse is that it can be adapted for both cold and hot smoking: this dual-mode design turns out to be very convenient and multifunctional.

First you need to prepare the foundation for the future smokehouse. Due to the fact that brick and stone are heavy, such a structure cannot be mounted directly on the ground: the ground may settle and the structure will be destroyed. It would not be superfluous to strengthen the foundation using a grid of reinforcement.

Then, when the foundation is ready, you can begin laying the lower chord of the walls, and after this, building a tunnel chimney. Its length is approximately two meters, and the pipe itself is well insulated to ensure the possibility of both cold and hot smoking. The insulating material can be any mineral insulation that can withstand high temperatures. For example, glass wool will do.

The structure of the future smokehouse itself should remain hollow. You can take this into account and use empty niches in the future to store supplies of sawdust, firewood, etc. The highest temperatures will be observed directly in the firebox and in the oven, so they will need to be made of refractory bricks. The remaining parts of the smokehouse can be laid out with any other types of bricks, even decorative ones.

Finally, you can start building the second brick belt. It will need to be separated from the first by a flat concrete screed or a concrete slab. Just as in the case of the foundation, it would be better to strengthen the layer with a steel reinforcement grid. There are two chambers, one of which will serve as a smoking chamber, and the second will become the basis for the Russian stove.

After this, the stove itself is built on. Since there will always be high temperatures here, as mentioned above, it must be built from fire-resistant bricks. The advantage of this design is its versatility: it will not only serve as a heat source for the smokehouse, but will allow you to bake food and even barbecue.

After constructing the stove, a smoking chamber is built next to the chimney: it can do without any additional finishing. The only thing is that it will be necessary to provide it with a tight, airtight door, preferably a wooden one, made of deciduous trees; Cherry or apple trees are ideal.

Then, when the smoking chamber is built on, a pipe is attached to it at the top to ensure smoke removal. Adjusting the draft in the pipe will allow the owner to carry out both cold and hot smoking in one smokehouse - everything will depend on the intensity of sawdust combustion in the firebox. With low heat and a wide pipe diameter, the smoke will have time to cool enough to provide cold smoking; If you limit the draft in the pipe and increase the intensity of combustion, then hot smoking will occur.

Chimney

Construction of a chimney for a stationary smokehouse is an important step that should be considered separately. You should not make it from brick or other porous materials, since the brick will actively absorb harmful substances from the smoke and moisture coming through it. By accumulating these substances, over time it will acquire an unpleasant odor, which will negatively affect the quality of the products prepared in the smokehouse.

Metal is best suited for a chimney, but even in this case it will need to be cleaned regularly to remove the soot accumulated on the walls.

Many owners of home smokehouses prefer a chimney that is dug in the ground: In this way, the soil effectively cools the smoke (which is especially preferable for cold smoking), and also absorbs condensation that forms on the walls. Bacteria and microorganisms living in the soil process the dangerous carcinogens contained in this condensate.

To make a smokehouse with such a chimney, a platform with a slight slope is located or artificially poured at the dacha, which will subsequently provide natural draft for the smoke. The smokehouse firebox is placed under a slope, and a small ditch is dug on the slope itself - the future chimney. It is covered with iron sheets, on top of which a layer of soil is poured, designed to create improved thermal insulation. This chimney extends all the way to the smoking chamber.

In the next video you will see how to make a smokehouse from a barrel with your own hands.

Where is the best location?

It is very important to find the right place for a stationary smoker: this is not a small, portable structure that can be stored at home or in the garage and taken out when needed.

When choosing a location, it is worth remembering that a large amount of smoke will come from the smokehouse, which should not enter the living quarters in the country house. In addition, harmful substances can harm trees and other green spaces. Therefore, choosing the ideal place on the leeward side will be quite difficult, and for each house it is purely individual. The resulting products can be stored in the cellar, as long as the room is dry and cool.

A proper smokehouse must take into account three main points, and the summer resident, when constructing such a structure, must also remember them. Firstly, uniform heating and fumigation must be carried out in the smoking chamber. Secondly, the smoke itself for smoking should be very light, not carrying harmful substances and heavy decay products that can give the meat an unpleasant taste. Thirdly, the design must be airtight to ensure uniform penetration of smoke into all layers of meat; Additional smoke generators can serve the same purpose.

By the way, you can assemble a smoke generator yourself. A body is made from a metal can, a hole is drilled at the bottom for igniting wood chips, and the upper part is tightly closed with a lid. The compressor can be a computer cooler. The entire structure is assembled using welding air, and then all that remains is to ignite the sawdust or wood chips and turn on the cooler. The peculiarity of the smoke generator is that the built-in cooler does not push smoke out, but pulls it in. Therefore, it must be connected to the smokehouse directly.

Traction is a prerequisite for smoking. It is not enough to simply put the product into a chamber filled with smoke. Otherwise, the meat/fish will simply evaporate, as a result of which it will acquire an unpleasant aftertaste. This is critical for cold smoking; in the case of hot smoking, everything is a little different, but it’s still worth following this rule.

To give the meat a rich taste, you should take special care in selecting the right tree species, the logs of which will be the most aromatic when burned.

For example, you should not use only birch logs in the smokehouse, as the meat may get an undesirable bitter taste. Yes, and birch logs will first have to be cleared of bark. It is also strictly forbidden to use coniferous trees for smoking. The culprit is the abundant resin content. It is best to add juniper branches and cherry leaves to the logs: they will add pleasant notes to the aroma of the meat. If there is a need to give the meat a certain color, then you can also use certain types of trees. Mahogany will give the meat a golden hue, alder and oak will give a dark yellow color, and hardwoods will give golden yellow tones.

In general, fruit trees like apple and pear trees and cherries have the most pleasant aroma. This is especially convenient for gardeners who can use old tree branches directly from their site for a smokehouse.

Also, different tree species are used for different types of smoked meats: Even if these types of trees do not grow on your summer cottage, it will not be difficult to purchase the appropriate wood chips in the store. Thus, alder chips remain the most universal, on which almost any meat, lard, fish and even vegetables are smoked. Oak sawdust is used primarily for red meat and game. Willow and birch, which have a specific bitter taste, are used when smoking large game such as elk or bear. And cheeses, nuts, vegetables and fruits are smoked on the softest cherries and apples.

Firewood and pieces of wood added to the fireplace for aroma should not be larger than 5-10 cm in size. Larger pieces are more difficult to heat to the point that they begin to char.

Before putting the log on the fire, it’s a good idea to slightly moisten it: raw wood produces abundant smoke, which is very important for smokehouses. However, you should not overdo it with humidification: if too much steam is generated, the products will become soggy, which will significantly reduce their shelf life. In addition, in order to get good, abundant smoke, after the formation of coals in the stove, it is worth closing the pipe valve. At this moment, active combustion stops, but the sawdust that produces smoke begins to smolder.

To improve product quality, it is best to provide the fire with an active supply of oxygen. At the same time, you cannot fan the flame in the smokehouse: it is important that the wood smolder, but not burn.

It is very important to provide smoked products with a continuous supply of smoke from the beginning of cooking until its completion. This should be taken into account when placing pieces of meat or fish of different sizes in the smokehouse: small ones will be ready much earlier than large ones. For the latter, you will have to additionally pour sawdust and shavings into the tray, thus maintaining a constant temperature. However, do not forget about the danger of over-smoking products: the process must be carefully controlled and the products must be periodically checked for readiness.

Another method that significantly speeds up the smoking process is to pre-boil meat or lard in water with salt and spices.

The optimal temperature inside the smoking chamber should range from 60-90 degrees Celsius. Even without temperature sensors, adjusting the temperature is quite simple: water in a small container placed on the lid of the smoking chamber should not boil. For cold smoking, slightly lower temperatures are chosen, for hot smoking – higher temperatures, sometimes reaching 120 degrees Celsius.

By the way, you can smoke not only meat, fish, lard or sausages. Smoked nuts, vegetables and fruits have interesting tastes. Smoked cheeses are also worth mentioning. It all depends on the temperature inside the smokehouse and the sawdust and wood chips used inside.

Before the smoking procedure, it is better to place the products for some time in a separate drying cabinet, which allows you to get rid of excess moisture and thereby increase the shelf life of the product. It’s easy to make it yourself: just take a large box with a tight sealed lid, into the side of which a fan is inserted. Before placing the product in the cabinet, it is better to pre-salt it. It will have to spend from one to three days in the closet until completely dry.

Large stationary smokehouses can only be installed in a country house or, if living in the private sector, on the territory of one’s own home. Such structures require a lot of free space, and they also produce a lot of smoke, which can harm plants, enter the house and disturb neighbors.