Connection for copper and aluminum cables. Aluminum and copper wires - how to connect? Terminal blocks for connecting wires

There are still a considerable number of premises where electrical wiring is made of aluminum. Moreover, modern systems are based on the use of copper as a conductor. That is why the problem of joining wires made of these dissimilar materials is relevant. How to connect copper and aluminum wires will be discussed below.

Electrochemical corrosion

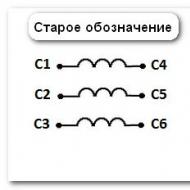

You can often come across statements that it is undesirable to combine copper and aluminum into one whole. From the point of view of material compatibility, these are fair statements. What about combining copper and galvanized or steel and silver? There are many options for metal pairs, and it is difficult to remember which ones are compatible with each other and which ones are not. To simplify the task, there are special tables, one of which is presented below.

Table of electrochemical potentials (mV) arising between connected conductors.

To understand the issue, you need to know what processes occur when different conductors of electricity touch each other. If there is no humidity, the contacts will be reliable in any case. However, in practice, such a situation is impossible, since there is always moisture in the atmosphere, which disrupts the connections.

Every conductor of electricity has some electrochemical potential. This circumstance is used by humans for practical purposes, for example, accumulators and batteries operate on the basis of different potentials.

When moisture gets on contacting metal surfaces, a short-circuited galvanic environment occurs and one of the electrodes is deformed. One of the two metals is destroyed in the same way. Thus, to determine the compatibility of metals, it is necessary to have information about the electrochemical potential of all materials involved in the reaction.

What happens if copper is combined directly with aluminum?

What happens if copper is combined directly with aluminum? According to technical regulations, mechanical joining of metals is permitted if the electrochemical voltage between the two materials is not higher than 0.6 mV. For example, from the table above, it can be established that in the case of joining aluminum and copper, the electrochemical potential is 0.65 mV, which is significantly higher than when joining the same copper with duralumin (0.20 mV).

And, nevertheless, if you really need it, you can also combine materials that are not entirely compatible, such as copper and aluminum. How to connect copper and aluminum wires will be discussed below.

Overview of connection methods

Several methods are used to connect aluminum and copper wires. Moreover, in each of the described cases, special devices will be needed. Let's consider each type of docking separately.

This type of connection is the most common because it is simple and cheap. If done correctly, a wired connection using nuts and bolts will ensure reliable contact for the entire life of the wiring and electrical devices. In addition, you can always disassemble the connection, connect additional conductors, etc. Thanks to the threaded connection, the relevance of electrochemical incompatibility of metals is lost, and it becomes possible to join aluminum and copper, thick and thin wires, stranded and single-core. It is important to avoid direct contact between dissimilar materials by making gaskets from spring washers.

To do the job you will need a bolt and nut, as well as a washer (it must be made of anodized steel).

The connection is made as follows:

- We remove the insulating layer from the wires to a short length (about four bolt diameters). We also strip the conductor, especially if its cores have been oxidized. We form rings from the veins.

- First, an aluminum conductor is screwed to the bolt in one girth.

- We put on the puck.

- Now it’s the turn of the copper conductor. We also screw it in one turn.

- Next, screw the nut in such a way as to achieve a reliable connection.

Note! If the docking is carried out for operation in a room where, according to technical conditions, there is vibration, an additional nut will be required for a high-quality result.

Terminals

There are several options for terminal connections. One option is the so-called “nuts”. Such an unusual name for terminal blocks is due to their external resemblance to nuts. Several types of “nut” terminals are available.

The most primitive model in its design has three demarcation plates inside. The conductors are located between the plates. In this way, direct contact between dissimilar materials is avoided. At the same time, the “nuts” allow you to maintain the supply circuit of the electrical circuit.

To achieve the integrity of the circuit, it is necessary to strip the supply conductor from the insulating layer, unscrew a couple of bolts, install the bare wire between the plates and tighten the bolts again. The insulator must be removed from the outlet ends, and then the wires must be directed into holes located perpendicular to the inlet channel. Next, the conductors are fixed between other delimiting plates.

There is also a more complex model on the market, the design of which is designed in such a way that there is no need for cutting conductors. The fact is that the plates of the device contain teeth, which, when squeezed by bolts, simply tear the insulating layer. The described docking option is considered very reliable.

There is another option for terminal blocks - ordinary blocks. The device is a strip with terminals. To connect two dissimilar materials, you need to strip their ends and route the wires into the terminals. The ends are secured with bolts that are located on top of the terminal holes.

Wago terminal blocks

Connecting copper and aluminum wires can be done using Wago terminal blocks. This device belongs to the above-mentioned terminals, however, we should talk about the Wago pads in a little more detail due to their popularity among buyers.

Wago comes in two versions: disposable with a non-removable wire and reusable - with a lever that allows repeated installation and removal of the conductor.

Wago is used for all types of single-core wires whose cross-section is between 1.5 and 2.5 square millimeters. The block can be used in distribution boxes with a current strength of up to 24 amperes. However, in practice it is believed that 10 amperes is more than enough and higher values will lead to overheating.

To connect the conductors, you need to force one of them into the block hole, as a result of which it will be securely fixed there. To remove the conductor from the hole, you will also need to apply force. It should be borne in mind that as a result of removing the wire from the disposable terminal block, the contact may be deformed, so the next time reliable contact is not guaranteed.

It is much more convenient to use a reusable Wago device. A characteristic feature of this terminal block is the presence of an orange lever. Using such a device, you can connect or disconnect all types of wires with a cross-section from 0.08 to 4 square millimeters. The permissible current level is 34 amperes.

To create a connection, you need to remove 8-12 millimeters of insulation from the wire, lift the lever upward, and direct the wire into the hole in the terminal block. Next, return the lever to the reverse position, thereby fixing the wire in the terminal.

The only significant drawback of Wago is its higher cost compared to traditional terminals.

Rivets

This method of joining dissimilar conductors resembles a bolted one. However, instead of a nut and bolt, a rivet is used to form a permanent connection. In other words, once fixed, it is no longer possible to remove the rivet without damaging it.

To make the connection, we strip both conductors of insulating material, and also bend the wires into rings. Next, we string one of the rings onto the rivet, after that we put on a steel washer, then we string the ring again, but with the second conductor.

The rivet has a head on one side. Now you need to flatten the second side, thereby forming a second cap, which will act as a fastener. The deformation of the rivet is carried out either with a hammer or with a special tool similar to pliers. The method of joining with rivets allows you to obtain a very high-quality connection.

Soldering iron

If desired, you can solder two dissimilar metals. However, this will require compliance with some technological nuances.

As for copper, there will be no problems with soldering, but with aluminum the situation is more complicated. The fact is that as a result of soldering and under the influence of oxygen, an amalgam appears on the metal surface. This alloy film is incredibly chemically resistant, which is why it does not form adhesion to solder. To remove the film you will need a solution of copper sulfate, a Krona battery and a piece of copper wire.

On the aluminum wire, we clean the area for soldering, and after that we apply a little vitriol there. We fix the aluminum wire on the negative pole of the battery, and fix the copper wire with one end on the positive pole, and put the other end in copper sulfate. After some time, the aluminum will be covered with a copper layer, onto which a copper conductor can be soldered.

Connection quality

In most of the previously discussed cases, rigid fastening of conductors stripped of the insulating layer is used. However, when joining copper and aluminum, one important technological nuance must be taken into account: aluminum under the influence of load acquires plasticity, as experts say, it begins to “flow”. As a result of this process, the connection weakens, and therefore the bolts need to be tightened regularly. If you do not tighten the bolts in time, the terminal may simply catch fire due to severe overheating.

There are a number of rules that you can follow to achieve a quality connection:

- Conductors with multiple cores should not be clamped too tightly. The wires in such wires are too thin, they easily break under pressure. The consequence of ruptures is an overload on the remaining wires, which can lead to a fire.

- It is important to choose the right terminal taking into account the cross-section of the conductor. If the channel is too narrow, the conductor will not fit, and if it is wide, it will fall out.

- Brass sleeves and terminals are very fragile, so do not clamp them too hard.

- You should pay close attention to the markings, which indicate the maximum possible current strength. Moreover, it is better not to achieve this indicator, limiting yourself to no more than 50% load.

Note! It is not recommended to buy unnamed products made in China. Connectors are too important a part to skimp on. It is best to give preference to products from well-known companies (for example, the Swiss company ABB).

Stranded wires

As mentioned earlier, conductors with many cores should not be overly pinched. To connect stranded wires, sleeves or ordinary twists are most often used. We'll talk about these methods in a little more detail below.

Sleeves

The sleeve is a protective cap made of plastic, under which there is a hollow metal tip. First of all, it is necessary to remove the insulating layer from the conductor. Next, the strands are twisted into one whole, and the resulting “pigtail” is directed into the sleeve. Next, the sleeve is crimped (pliers are suitable for this operation). The tip of the sleeve is inserted into the terminal. To increase the reliability of the connection, the sleeve can be treated with solder.

Twist

Among professional electricians, twisting is not respected. However, there are situations when twisting is the most convenient way out of the situation (for example, to create a temporary connection or in the absence of the necessary materials).

So, twisting of copper and aluminum is permitted only after thorough cleaning of the aluminum surface. If the copper conductor has many cores, all existing wires must be collected into one “pigtail”. The copper also needs to be coated with solder - this will improve contact.

When twisting, it is important to prevent the wires from breaking. It is best to cover the ends with insulating protective caps, which can be purchased at any hardware store.

Note! Twisting is not allowed in rooms with humid air.

So, there is nothing complicated in connecting copper and aluminum conductors. You just need to remember the cost of a mistake: incorrectly connected wires can cause not only the failure of electrical appliances, but also a fire.

Connecting wires made of dissimilar metals (a particular and most common case is copper and aluminum) is most often necessary in cases where the home wiring is made of copper conductor, and the entry into the house is made of aluminum.

It happens the other way around. The main thing here is the contact of dissimilar metals. Copper and aluminum cannot be combined directly.

The reasons lie in the electrochemical properties of metals. Most metals, when combined with each other in the presence of an electrolyte (water is a universal electrolyte), form something like a regular battery. For different metals, the potential difference upon contact is different.

For copper and aluminum this difference is 0.65 mV. It is established by the standard that the maximum permissible difference should be no more than 0.6 mV.

If there is a higher potential, the conductor material begins to deteriorate and become covered with oxide films. The contact will soon lose reliability.

For example, the electrochemical potential difference of some other pairs of metals is:

- copper - lead-tin solder 25 mV;

- aluminum - lead-tin solder 40 mV;

- copper – steel 40 mV;

- aluminum – steel 20 mV;

- copper – zinc 85 mV;

Twisting wires

The simplest, but least reliable way to connect conductors. As mentioned above, you cannot directly twist copper and aluminum wires. The only possible contact option for such materials is tinning one of the conductors with lead-tin solder.

It is very difficult to tin the aluminum at home, but there will be no problems with copper. A powerful piece of solder and a little rosin or other flux for soldering copper and copper alloys is enough. Tinned copper and pure aluminum conductors are tightly twisted together using pliers or pliers so that the wires wrap tightly and evenly around each other.

It is unacceptable for one conductor to be straight and the other to wrap around it. The number of turns must be at least 3-5. The thicker the conductors, the fewer the number of turns you can make. For reliability, the twisted area can be wrapped with a bandage made of thinner tinned copper wire and additionally soldered. The twisting area must be carefully insulated.

Threaded connection

The most reliable connection of wires is threaded (bolted). The conductors are pressed against each other using a bolt and nut. To make such a connection, it is necessary to make rings at the ends of the connected wires with an internal diameter equal to the diameter of the bolt.

Just like for twisting, the copper core must be tinned. Multicore wire must be serviced (even if wires of the same metal are connected).

The resulting compound looks like a sandwich:

- bolt head;

- washer (with an outer diameter no less than the diameter of the ring on the wire);

- one of the connected wires;

- second wire;

- washer similar to the first one;

- screw;

The copper core does not need to be tinned, but in this case a steel washer must be placed between the conductors.

A significant disadvantage of this method is its large dimensions and, as a consequence, difficulties with insulation.

Terminal blocks

The most technologically advanced way to connect wires is to use special terminal blocks.

The most technologically advanced way to connect wires is to use special terminal blocks.

And finally, a few tips that you should take into account in order to protect yourself in the future and not redo the work:

- For stripping conductors You should not use side cutters, pliers or other tools with a similar operating principle. In order to cut the insulation without affecting the body of the wire, considerable experience is required and still in most cases the integrity of the wire will be compromised. Aluminum is a soft metal, but it does not tolerate bending very well, especially if the integrity of the surface is damaged. It is possible that the wire may break during installation. And it’s much worse if this happens a little later. It is necessary to remove the insulation with a sharp knife, moving it along the conductor, like stripping a pencil. Even if the tip of a knife removes some layer of metal, a scratch along the wire is not terrible.

- For tinning copper conductors Under no circumstances should you use acid-containing fluxes (zinc chloride, etched hydrochloric acid, etc.). Even thorough cleaning of the connection will not save it from destruction for some time.

- Stranded conductors Before installation, it is necessary to irradiate it to obtain a monolithic conductor. The only exceptions are spring clamps and terminal blocks with clamping plates.

- Washers, nuts and bolts for detachable or permanent connections should not be made of galvanized metal. The potential difference between copper and zinc is 0.85 mV, which is significantly greater than the difference when copper and aluminum are directly connected.

- For the same reason, you should not purchase overly cheap terminal blocks. unknown manufacturer. Practice shows that the metal elements in such pads are often zinc coated.

- You can't use advice protect the direct connection of copper and aluminum conductors with various water-repellent coatings (grease, paraffin). Machine oil is difficult to remove from leather alone. The sun, air, and negative temperatures will destroy the protective coating much faster than we would like. In addition, some lubricants (especially grease oil) initially contain up to 3% water.

How to connect two aluminum wires to each other? It would seem like a rather banal question, but even here the first answer that comes to mind is not always correct. After all, twisting of wires is prohibited according to the PUE standards, and any wires can be connected only by crimping, soldering, welding and using screw clamps. And we’ll talk about how to do it correctly in our article.

But we propose to start our conversation with a quick analysis of the properties of aluminum wire. This will allow you to identify problem areas and understand possible problems during its installation.

- Let's start with the advantages of aluminum wire. The main one is the price, which is an order of magnitude lower than that of its main competitor - copper.

- Another advantage of this material is its lightness. This has led to its widespread use in power lines, where weight is very important.

- Well, the last advantage is its resistance to corrosion. Aluminum is almost instantly coated with a persistent oxide film, which prevents further oxidation. At the same time, this film also has negative aspects - it is a very poor conductor of electric current.

- Then there were only continuous shortcomings. And the first of them is the low electrical conductivity of aluminum. For this material it is 38×106 S/m. For comparison, for copper this parameter is 59.5 × 106 S/m. This results in the fact that, for example, a copper wire with a cross-section of 1 mm2 is capable of passing a current almost 2 times greater than a similar aluminum wire.

- The next significant disadvantage is that aluminum wires have very low flexibility. In this regard, they cannot be used in places where the wiring is subject to repeated bending or other mechanical stress during operation.

- Well, and finally, the instructions say that aluminum has such a bad property as fluidity. As a result of thermal and mechanical influences, it can lose its shape, which has an extremely negative effect on contact connections.

Note! According to the PUE standards, since 2001 it has been prohibited to use aluminum wire for installing electrical wiring in residential premises. This ban significantly reduced the use of aluminum electrical wiring in everyday life.

Methods for connecting aluminum wires

As we said above, aluminum wires can be connected in four main ways - screw or bolt clamps, pressing, welding and soldering. Let's look at the features of each of these types of connections.

Connecting aluminum wires using the compression method

Let's start with the most common connection method - compression. It can be of several types - bolted, screw or using a pressure spring, which is used in Wago terminals.

|

|

Connecting aluminum wires to each other using this type of connection has one drawback. If you use conventional screw terminals, then using a screw you can completely or partially press down the soft aluminum core. This will either reduce or completely destroy contact. |

|

|

To exclude this option, the connection should be made through special contact nozzles made of brass. Brass has less elasticity and is more difficult to bend. Therefore, such attachments provide reliable contact and eliminate the possibility of damage to the wire. |

|

|

For bolted connections of aluminum wire, special lugs should also be used. They are attached to a wire or cable using the crimping method and then these lugs are connected using a bolted method. |

|

|

As for Wago terminals, everything is much simpler here. This type of connection cannot damage the wire, so such terminal blocks can be used without additional attachments. This somewhat compensates for their higher price. |

Connecting aluminum wires using the pressing method

Recently, connecting aluminum wires with a sleeve has become increasingly popular. This is partly due to the widespread use of crimpers or, as they are also called, crimping pliers. This tool allows you to crimp wires of different sections, ensuring fairly reliable contact.

- The connection of wires by crimping is carried out using special sleeves. These sleeves are available in different diameters and materials. To connect aluminum wires, either aluminum or brass sleeves should be used. Copper should not be used under any circumstances, since the connection of these two materials can lead to the formation of galvanic isolation and ultimately the complete destruction of the aluminum conductor.

Any cable consists of aluminum or copper current-carrying conductors. According to the electrical installation rules, the usual twisting of such wires is strictly prohibited. But there are situations during installation when there are no options other than connecting aluminum and copper wire. There are many such opportunities. All that remains is to choose an accessible and safe one.

Electrochemical destruction of metals

The opinion that it is impossible to combine aluminum and copper is often mentioned. This is true from the analysis of the chemical compatibility of metals. In the world of modern technology, you can find dozens of matings of metal pairs.

There is a concept of electrochemical potential difference, the indicators of which are summarized in a special reference table. Take from it as necessary indicators and are determined with compatibility:

- Copper - lead-tin solder 25 mV.

- Aluminum - lead-tin solder 40 mV.

- Copper - steel 40 mV.

- Aluminum - steel 20 mV.

- Copper - zinc 85 mV.

To imagine what is happening, it is necessary to understand the reactions that electrodes made of different metals undergo upon contact.

To imagine what is happening, it is necessary to understand the reactions that electrodes made of different metals undergo upon contact.

In the absence of moisture, the reliability of contact is undeniable. But there is no ideal situation. Atmospheric humidity always negatively affects the quality of connections. Any conductor has a certain electrochemical potential. This property is used in practice in the operation of rechargeable batteries.

Getting onto the contacting surfaces from various compounds, water creates a short-circuited galvanized environment. One electrical conductor begins to deform. The material from which it is made is also subject to destruction.

Methods for connecting wires made of different metals

Technological rules allow direct connection of different metal conductors with an electrochemical potential coefficient of over 0.6 millivolts. According to the tabular data, for a combination of aluminum and copper it is equal to 0.65 mV, which makes such a combination unacceptable. However, there are ways to correctly interconnect different wires.

Cable connection by twisting method

Most famous, but an unreliable technique is called twisting. This method does not require special skills and is easy to make. For these reasons, it is used quite often. Before connecting the aluminum wire with copper, you need to imagine what is happening in a similar combination with temperature changes and precipitation:

- There is a gap in the connection.

- Increased resistance at the ligament point.

- Heat.

- Oxidation of cables, destruction of contact.

This method is not suitable for ensuring secure communication. Although, if you perform certain operations, in some cases you can use twisting to connect aluminum and copper wires:

Threaded connection of wires

A similar method is performed by clamping the ends of the cable into a bolted fastening. This is the most reliable connection between aluminum and copper wires together. It guarantees tight contact for the entire period of use of the twist. Replacing bolts of different lengths makes it possible to combine an unlimited number of cables:

- Different sections.

- Stranded and monolithic.

- With washers to prevent direct contact with copper and aluminum conductors.

Procedure:

- Cut the insulating coating to the length required for fastening.

- Sand and degrease the cleaned areas. Tin the multi-wire cable. Connect the cores using threads through steel washers.

- Tighten the nut tightly.

- Shock absorbers are placed in front of the outer washers to prevent pinching and breaking of the wire. When crimped, it will straighten and the connection will be fixed.

Connecting different cables with a terminal block

Splicing cables through terminal connections has become widespread in recent times. Although the quality of contact it is inferior to the bolted one, there are also undeniable advantages:

- The wires are connected in random order.

- There is no need to make connecting rings and put on ferrules.

- The design features of the terminal blocks do not allow short circuits of the wires.

- Isolation of the contact point is not required.

- The work on connecting the terminal contacts is simple.

The ends of the wires are exposed by approximately five millimeters, inserted into the clamp and pulled through. This method is indispensable when connecting aluminum cables, the cores of which break due to repeated bends.

The ends of the wires are exposed by approximately five millimeters, inserted into the clamp and pulled through. This method is indispensable when connecting aluminum cables, the cores of which break due to repeated bends.

Repairing damaged cables using terminal blocks also turns out to be the only acceptable option due to the short length of the wires. After splicing, a junction box is installed.

From the numerous connecting devices, not least occupied by the German Vago spring terminal blocks of the same company. They are either disposable or with a clamp for repeated splicing of the wire. Such terminal blocks are used when working with single-wire wires with a cross-section from one and a half to two and a half squares made of any metal in insulating boxes. According to the passport, they are designed for twenty-four amperes in load. The contacts are treated with a special compound to prevent oxidation.

These are the simplest devices to use. The wire is stripped and forcefully inserted into the block. The fixation is reliable. It is possible to get the wire out with good effort. The spring block is destroyed and reuse is impossible, which is the biggest drawback of this product.

Wago reusable terminal blocks with an orange lever are designed for the use of wires of any type with a cross-sectional area of up to four square millimeters and currents of up to thirty-four amperes. Apply repeatedly until completely worn out.

The method of application is available to anyone. The insulation is stripped to a distance of approximately ten millimeters, the lever is raised, the wire is placed in the channel and the lever slams shut. The connection is fixed.

Vago terminal blocks are effective devices for installation of electrical networks. They do not require the use of special tools, but are quite expensive.

Monolithic connection method

The technique for making such a connection is similar to a threaded one. A rivet and a special device - a riveter - are used as a fastening element. The rivet is a hollow aluminum rod, thickened on one side. A wire pin with a cap is placed in it. When passing through the cavity, it creates a thickening on one side. Then the pin breaks off, forming a rivet.

The technique for making such a connection is similar to a threaded one. A rivet and a special device - a riveter - are used as a fastening element. The rivet is a hollow aluminum rod, thickened on one side. A wire pin with a cap is placed in it. When passing through the cavity, it creates a thickening on one side. Then the pin breaks off, forming a rivet.

If you do not take into account the price of the riveter, this method of contact becomes the most affordable besides twisting. The disadvantage of such contact is its disposability and the impossibility of disconnection if the work is performed incorrectly.

The use of special copper sleeves will be another way to permanently connect conductors. They are produced in various sizes, each with its own cable section. The bare ends of the wires are threaded through them and crimped with special pliers. This method is the most compact along with twisting.

Connecting wires by soldering

If desired, dissimilar wires can be soldered. This method must take into account certain technological features. Before connecting the wires correctly, aluminum and copper must be prepared for soldering. Copper doesn’t require any special tricks. Aluminum wire is another matter. On its surface, under the influence of ambient air, an oxide film - amalgam - is formed. It resists chemical attack and solder does not stick to it.

If desired, dissimilar wires can be soldered. This method must take into account certain technological features. Before connecting the wires correctly, aluminum and copper must be prepared for soldering. Copper doesn’t require any special tricks. Aluminum wire is another matter. On its surface, under the influence of ambient air, an oxide film - amalgam - is formed. It resists chemical attack and solder does not stick to it.

To neutralize it, you will have to make a simple device. The tip of the aluminum wire is stripped and treated with a solution of copper sulfate. Take a battery and attach this conductor to its minus. The copper wire is fixed to the positive with one end, and the other is dipped in the same solution. After a certain period of time, the aluminum will be covered with a copper coating and will become available for soldering.

Specifics of connections for outdoor installation

Electrical connections in outdoor installations are exposed to various weather conditions. Insulation requirements are more stringent. To prevent short circuits, a Walnut clamping kit is used.

Electrical connections in outdoor installations are exposed to various weather conditions. Insulation requirements are more stringent. To prevent short circuits, a Walnut clamping kit is used.

Its plastic shell contains metal clamps in which the wires are connected by tightening the screws. The housing halves are tightly compressed with screws or spring rings. Such a cocoon guarantees protection from external weather fluctuations. This is a rather large connection, but in outdoor conditions it is not critical.

When repairing electrical wiring in old houses, you may encounter a situation where you have to change large sections of wiring. However, in most cases, the old wiring is made of aluminum, and you only have copper wire at your disposal to replace it. In general, connecting conductors from such different materials is strictly prohibited, but it happens that there is simply no other way out. Let's look at how to connect aluminum and copper wires so that there is no short circuit or fire.

Why you can't combine copper and aluminum

To do this, you should strain your memory and remember the school course in chemistry and physics.

To begin with, let's remember what it is galvanic cell. Simply put, a galvanic cell is a simple battery that generates electric current. The principle of its appearance is based on the interaction of two metals in the electrolyte. So, the twist between the copper and aluminum wire will be the same battery.

Galvanic currents quickly destroy the material. True, in dry air their appearance is excluded. And if you twist it to the socket, it will not fall apart in a few hours. However, later troubles with such wiring are guaranteed.

Over time, the materials from which the wires are made are destroyed, and at the same time constantly resistance increases. If a powerful current consumer is connected to the outlet, the twist will begin to heat up. Regular use of such an outlet increases the risk of fire.

Therefore, connecting an aluminum conductor to a copper conductor is strictly prohibited. However, emergency situations arise when making such a connection is simply necessary.

Let's look at several ways to connect aluminum and copper wire. These methods will help you successfully cope with a difficult task.

Twist

Is in the simplest way install the wires. It does not require special knowledge or qualifications. However, it is not the most reliable connection method. Due to temperature fluctuations, the metal expands. As a result, a gap is formed between the conductors, increasing the resistance. After some time, the contact oxidizes and breaks down.

Of course, this will not happen within a year, but if the connection must function for a long time, then it is worth thinking about other methods of fastening.

The very principle of fastening using the twisting method is that both conductors wrapped around each other. For a better connection, the copper cable is tinned with solder. Stranded copper wire will have to be tinned.

Threaded connection

To connect copper and aluminum in this way you will need a pair of simple washers, one spring washer, screw and nut. This method is very reliable - contact between conductors will be ensured for many years. For this fastening, neither the cross-section of the wire nor its type - stranded or single-core - matters.

The insulation is removed from the end of the wire. The spring washer is put on the screw, then a regular washer is put on, then a ring of aluminum wire. It is supported by a simple washer. After that, a copper conductor is put on, and then a nut is screwed onto the screw. She squeezes the entire joint tightly.

A multi-core cable must be tinned with solder before connecting.

Connection using terminal block

This is a modern method of wiring. Although it is slightly inferior in reliability to the threaded connection method , the method has its advantages:

- connection can be made very quickly;

- When connecting, you can get by with a small supply of wire.

Let us explain the last thing, it happens that a small piece of cable sticks out from the wall or ceiling. It is impossible to twist - there is very little wire. And the twist made on the ceiling will not last long; after some time the wires will simply break off. And the terminal block will hold both conductors with screws for a long time. Then the block completely eliminates contact between the two stripped conductors.

Installation is carried out as follows: the end of the wire stripped of insulation (about 5 mm) is inserted into the terminal hole of the block, after which the locking screw is tightened.

The terminal block must not be hidden in plaster or in a wall without a junction box.

Flat spring clamp and terminal block

This method appeared not so long ago. There are two types of such connection: disposable and reusable. There is a special lever for the last connection in the terminal block. Thanks to it, the wire can be inserted and removed several times. Terminal blocks of this type can successfully connect copper and aluminum stranded wires of various types.

This method appeared not so long ago. There are two types of such connection: disposable and reusable. There is a special lever for the last connection in the terminal block. Thanks to it, the wire can be inserted and removed several times. Terminal blocks of this type can successfully connect copper and aluminum stranded wires of various types.

Widely used for installing chandeliers and connecting wires in junction boxes. It takes some force to insert the wire into the hole in the terminal block. To pull out the conductor you will need to put in even more effort. For practical use, it is better to use reusable models. In the event of an error, the connection can be quickly redone.

This installation is very simple. First with cable insulation is removed(approximately 10 mm.). Then on the reusable terminal block you need to lift the lever, insert the wire, and then return the lever to its original position. It's simple!

Rivet

The reliability is not inferior to a threaded connection and has its own Advantages and disadvantages:

- such a connection is established very quickly;

- it is very durable, reliable and affordable;

- however, unlike threaded fasteners, this connection is disposable.

Installation is carried out using a special tool - a riveter. An aluminum wire is placed on the rivet, then a spring nut, followed by a copper wire and a flat washer. Then the riveter is used and the connection is ready.

It is worth mentioning that the connection area must be insulated.

Soldering

Is it possible to solder conductors made of different materials? It is quite possible if comply with certain conditions.

Is it possible to solder conductors made of different materials? It is quite possible if comply with certain conditions.

There will be no problems with soldering copper, unlike aluminum. An amalgam is formed on the surface of this metal, which exhibits amazing resistance in chemical terms. That is, the solder cannot stick to it. This phenomenon often surprises novice electricians.

To solder two different conductors, you should stock up on a solution of copper sulfate, a Krona battery and a piece of copper wire. The future soldering area is carefully cleaned on the aluminum wire. Then they drip on this place copper sulfate solution.

The copper wire is connected to the positive pole of the Krona battery and dipped in copper sulfate. An aluminum conductor is connected to the negative terminal of the battery. After a while, a layer of copper will settle on the aluminum, onto which you can solder the desired wire without any problems.

Conclusion

Once again, it is worth noting that any wire connection must be insulated.

Connections can be placed in special distribution boxes.

If you plan to make the connection yourself, then you should not resort to the soldering method. It requires certain experience and qualifications. It is better to use another of the above methods for connecting aluminum and copper conductors.

The most accessible and common methods were discussed in the article. However, if you have no experience in carrying out such work, it is better to turn to professionals.