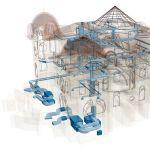

Check valve for water heater installation diagram. Check valve for a water heater (boiler): what is it for and how to use it

The main function of the non-return safety valve in the water heater system is to compensate for the increase in the volume of water in the tank during heating and prevent it from returning to the water supply, and additionally to protect against pressure drops in the supply line or the operation of heating elements in the absence of water supply. On the piping diagram, it is located between the shut-off valve and the inlet pipe of the boiler; it is prohibited to place tees or other valves in this area. Its presence is mandatory, this device serves as direct protection against emergencies. The choice of a specific type of valve for a water heater depends on the volume of the storage tank, for the called manufacturers it is included in the standard kit, but if necessary, it is enough just to buy a replacement and install it on your own.

The design includes two parts, outwardly they resemble perpendicularly connected cylinders with different diameters. The larger one acts as a check valve and consists of three simple elements: plates, seats and springs. When cold water is supplied inside the water heater, it opens, after filling and exceeding the pressure above the water supply, it closes automatically. When HW is consumed, the process is reversed and the tank is filled again. It is impossible to use only this type of protection, as well as to install stopcocks to turn off the check valve (leads to overheating of heating elements in an empty water heater). Does a cylinder with a smaller diameter have a tighter spring when the internal pressure exceeds the standard? the drain opens and excess water is discharged, a suitable hose is connected to prevent hot water from escaping into the open space.

Thus, the use of valves implies protection functions:

- From a drop in pressure in the supply line, water hammer and air ingress into the water heater.

- From overheating of the boiler and boiling inside the tank.

- From the ingress of hot water into the supply pipe.

The higher the volume of the water heater, the more excess liquid is discharged. For example, for a boiler of 100 liters, this value reaches up to 3-4 liters per day. During operation, it is worth paying attention to possible signs of breakdown, in particular: poor transmission or its complete absence, leakage in cold mode.

Varieties

The main criterion for selecting a valve for a water heater is the operating pressure of the water (both in the water supply and inside the tank). Depending on the volume of the boiler, the following capacities are used: up to 50 liters, from 50 to 200 and above 200. Accordingly, the protection class is selected from these indicators, experts recommend purchasing the most reliable devices for water heaters with a large volume, regardless of their cost. According to the principle of operation, all check valves are divided into direct and folding. The first variety is a butterfly valve with vertical movement (they work only under the pressure of the working medium), the second - with placement under the saddle.

According to the degree of complexity, all reverse and safety components for a water heater differ in:

1. Non-separable - the simplest budget option, water shutoff is carried out due to the opposition of a spring or disk. This is a classic check valve and nothing more, such protection is only allowed for water heaters with a minimum volume, its main function is to keep the heating elements from overheating when the tank is empty. When installing such devices, the working condition is necessarily monitored; at the slightest suspicion of a marriage or breakdown, they change. This variety is not suitable for collecting excess pressure; for these purposes, you need to buy a separate safety valve.

2. A complicated complex for a water heater that combines both functions. It includes a ball valve, safety and shut-off (check) valves, outlet for draining. The process of controlling discharges of excess heated liquid is visual, not automated, and the protection efficiency is high. The disadvantage of this group is the flow of water onto the floor; to eliminate such a problem, additional equipment is required with a flexible hose connecting the outlet valve directly to the sewer.

3. Group of hydraulic safety, the main difference is the inclusion of a pressure reducer in the piping circuit of the water heater. Also included in the kit: safety and non-return safety valve, siphon. This option is selected for industrial systems, the group is placed on a pipe with cold water. The presence of a siphon allows you to easily drain the excess directly into the sewer.

Replacement Guide

The need for this procedure arises in case of physical wear, weakening of the spring, clogging with salt deposits, or defective parts. Another reason for the constant leakage of the check valve is associated with excessive pressure in the supply pipe, in this case it is recommended to install a reducer. Leaving a breakdown for a long time is fraught with the same consequences as in the absence of a fuse. The replacement process is carried out according to the following scheme:

1. Power off the water heater.

2. Blocking the supply to the device: at the entrance in front of the boiler or common around the apartment.

3. Complete emptying of the storage tank.

4. Dismantling (unscrewing) the old safety valve.

5. Installing a new one, sealing using seals, linen tow or fum tape. The thread is turned with a key 3-4 times.

6. Water supply, checking the tightness of connections.

The correct direction of water is easy to determine: a red arrow is drawn on most devices, and this information is also duplicated in the attached instructions. Before starting installation, it is recommended to check the operation of the unit; in the process of tightening the connection of the relief and check valves, do not put pressure on the thread or exert excessive force. It is easy to check the reliability of a new fuse - a full tank of the water heater is filled and the maximum temperature is set (at 30-40 ° C the device may not work, especially with small volumes of the boiler), after a while the discharge begins to drip.

But for complex hydraulic groups, other installation and control schemes apply, in this case it is important to follow the manufacturer's instructions. For obvious reasons, the installation of only a check valve in the water heater system is unacceptable (as well as the installation of heating fittings), the presence of an output to relieve excess internal pressure is mandatory.

When arranging an alternative hot water supply system, a safety valve for the water heater is installed, the principle of operation of which is very well known to specialists.

If you need to install hot water equipment yourself, you need to know not only the design features, but also the basic rules for installing such fittings.

Storage boilers are popular household appliances designed to heat water.

Storage-type water-heating equipment may differ in design features, but the prevailing majority of such devices are represented by metal water tanks with installed heating elements in the form of heating elements.

Water heating equipment is designed in such a way that the same amount of water is constantly inside the tank, the volume of which is replenished as needed.

In the process of heating, a natural expansion of water occurs and an increase in the initial volume of liquid by about 2.5-3.0%. Thus, the amount of water in a tank designed for 100 liters, as a result of heating to 80 ° C, will increase by about three liters.

Safety check valve for boiler on 1/2″ thread without flag

The absence of a pronounced compression of the liquid can provoke a rupture of the walls of the tank and the formation of a leak of varying severity.

Among other things, the reason for the failure of the water heater may be too high pressure in the water main. If the water supply network is characterized by a pressure level above 6 atm., then it becomes necessary to install a special gearbox.

In the absence of hot water consumption and while maintaining the level of heating, problems can occur represented by overpressure, which often causes the failure of hot water equipment.

What is the function of the valve?

What is a water heater safety valve and how does it work? Many consumers independently upgrade water heating equipment by removing the check valve.

Of course, under conditions of a sufficiently high and stable pressure inside the plumbing system, this option will function correctly for some time, but the very first failure causes the device to go out of working condition.

Valve on the water heater

For example, with insufficient pressure inside the pipeline, a process of natural displacement of cold liquid by hot water occurs with its movement back into the plumbing system. The result is the exposure of the heating elements and their inevitable, fairly rapid overheating.

Burnt-out heating elements are not capable of completely compromising the safety of operation of a water heater, but highly heated heating elements cause a sharp rise in pressure in the plumbing system.

In this case, the ingress of water onto a hot heater causes its evaporation, a lightning-fast increase in pressure and a guaranteed strong rupture of the water heater reservoir, with the release of boiling water and steam to the outside. To prevent such problems, a safety valve device is used.

Boiler safety valve device

It should be remembered that the safety device prevents the supply of water from the heater to the water supply system, smooths out possible pressure fluctuations and prevents the formation of powerful hydraulic shocks, facilitates the discharge of excess water through the fitting and ensures the safe operation of water heating equipment.

Valve design

The safety valve device for a water heater or the so-called "safety group", depending on the design, may have some features.

The following devices are available:

The following devices are available:

- intended for water-heating equipment with a volume of not more than 100 l;

- service boilers with a volume of 100-200 l;

- built-in water heaters with a tank capacity of 200 liters or more.

The features of valve devices of the first category are affordable cost and a non-separable type of housing. They have a short service life, but they can be replaced quite often. It is these devices that are most often equipped with budget models of water heaters.

The second type of "safety group" is complemented by a ball valve and a special pipe for connecting to the sewer system. Most often, such devices are made in a collapsible case, which makes it possible to replace individual faulty elements.

The most expensive and most modern valve devices are "safety groups", which are used in hot water equipment with an increased tank capacity. Such devices are characterized by the addition of standard equipment, in the form of a pressure gauge, pressure reducer, strainer and a special sump.

During the installation of a water heater, it is unacceptable to replace the safety valve device with a blast or emergency valve intended for installation in heating systems.

Why do you need a forced reset handle?

Often, the safety valve device is equipped with a special lever, through which water is drained from the reservoir of water-heating equipment in manual mode.

The valve with a drain handle allows for easy and convenient emptying of the storage tank of the water heater during any repair work and for the purpose of preventive inspection of the inside of the tank or cleaning it from accumulated scale.

Water supply to the water heater

The principle of operation of the safety valve

The safety valve device used in hot water equipment would be more correctly designated as an effective valve system. A pair of such elements is located inside a brass or nickel-plated perpendicular-shaped body.

The lower part of such a housing is represented by a check valve, which helps prevent the outflow of water from the water heater reservoir under conditions of reduced pressure in the plumbing system. Inside the perpendicular branch of the volumetric body, another valve device is installed, the task of which is to release a certain amount of water at elevated pressure.

Valve with emergency lever

The principle of operation of the safety valve device is quite simple:

- in conditions of filling the tank with water and with the hot water tap open, the pressure inside the water-heating equipment is below the water level, which causes the disc plate to be pressed inside the check valve device;

- when equalizing the pressure indicators inside the water-heating equipment and the plumbing system, the plate is pressed against the body walls with the help of a spring, which helps to block the flow of water into the water-heating unit;

- in the conditions of the switched on mode for heating, a relatively smooth increase in the temperature indicators of water is carried out, and, accordingly, an increase in pressure inside the system to the limit values;

- the achievement of threshold pressure indicators stimulates the compression of the built-in spring on the safety valve, which is accompanied by the opening of the outlet to the fitting. In this case, the water is partially drained until the indicators are normal, after which the spring device closes the outlet and the water does not flow out.

- the principle of operation of the safety valve device is determined by the dripping of water from the fitting, which accompanies heating and lowering the pressure level inside the plumbing system. Draining water needs to be drained, so a special transparent pipe is used, which is fixed at the outlet with a well-tightened clamp.

The tube installed on the fitting must be reinforced, but transparent, which will allow it to easily withstand overpressure and control the constant performance of the valve device.

The safety valve device refers to pipeline fittings, which are intended to protect water heaters from destruction, under conditions of excessive pressure.

Such an element allows automatic discharge of excess fluid into the sewer system.

The performance of the valve device may be impaired by dirt entering the internal part or as a result of damage to the disk part of the equipment.

It is for this reason that it is necessary to provide the valve with regular preventive inspections, and, if necessary, timely replacement of worn parts with similar new elements.

Related video

The operation of water heating equipment is directly related to a change in the pressure level in the system. Its adjustment is necessary for the safe operation of the electric storage boiler. Modern water heaters are equipped with automatic protection against high pressure in the tank. However, the safety valve for the water heater is essential to ensure safe operation.

Purpose

The device of the storage boiler is based on maintaining a certain volume of hot water, which is automatically replenished when it is used. In the absence of outflow from the tank, the electric heating element continues to work. Hot water expands, its impact force inside the tank increases.

Water is a substance that is practically incompressible. When the temperature rises to 80⁰ C, it increases in volume by 2-3%. Excessive pressure inside the tank can damage it, create an emergency situation.

To relieve excess water pressure, a safety safety device is used - a safety valve. Mounted on the branch pipe for entering cold water into the boiler. Through it, excess volume is removed to the outside. When the pressure inside the tank is normalized, the protective mechanism closes, the outflow of excess volume stops.

Design features

Safety valve device for water heater:

- Frame

- Relief fitting

- release lever

- Two poppet valves with opposite actuation direction

- Relief valve spring

- check valve spring

Structurally, the safety valve looks like two cylinders placed perpendicular to each other. The large cylinder has a threaded part at the ends for mounting to a water heater and a water pipe. Inside the cylinder there is a check valve pressed by a spring.

Perpendicular to the large cylinder is smaller in diameter. On one side, it enters the cavity of the large cylinder. On the other side there is a plug or forced pressure release handle. In the cavity of the small cylinder there is a drain pipe with a poppet valve in the opposite direction of operation.

Structurally, it looks like two cylinders placed perpendicular to each other. The large cylinder has a threaded part at the ends for mounting to a boiler and a water pipe. Inside the cylinder there is a check valve pressed by a spring.

Perpendicular to the large cylinder is smaller in diameter. On one side it enters inside the large one, on the other side there is a plug or a handle for forced discharge of water pressure. Inside the cavity of the small cylinder there is a drain pipe with a poppet design in the opposite direction of actuation.

Principle of operation

The safety safety valve is a direct acting device. When the tank of the water heater fills up, the force of the liquid will depress the poppet valve, making it possible to fill the tank.

After filling the tank, the water pressure inside will increase, under its influence the check valve of the large cylinder will close, preventing the outflow back through the plumbing system. As the liquid inside the tank decreases, its force of action gradually decreases. The non-return valve is pressed out, resuming the filling of the tank.

Increasing the temperature increases the pressure level. Under its influence, above the permissible value, the plate-shaped design of a small cylinder is triggered, a drainage hole opens, and the excess volume is brought out. The pressure inside the system equalizes, the reverse returns to its original position.

Functions

- Prevents backflow of fluid from the storage tank.

- Removes excess volume from the water heating tank to stabilize the internal pressure.

- Levels pressure drops inside the central water supply system.

- The forced reset lever can be used to drain when performing maintenance.

- Extends the life of the electric heating element, water heating equipment.

- Saves energy by preventing the heating element from running idle.

- Protects against an emergency situation of overheating, explosion of the storage boiler.

Kinds

They differ in the following points:

- Release lever. It is needed to check the correct operation of the mechanism, it is advisable to check it once a month. By lifting the lever flag, you can empty the storage tank. It is important to pay attention to the device flag. Some models are made with a small screw attached to the lever - to prevent accidental opening, emptying the tank.

- Arrow on the body, designation of the nominal working pressure of the safety mechanism. It is recommended to purchase devices with these designations on the case in order to choose the best option.

- Drain plug. Produced in different shapes. An oblong, stepped shape is preferable, so that it is more convenient to put on the outlet hose, crimp it with a clamp if necessary.

- No release lever. When purchasing this modification, you should pay attention to the presence of a threaded cover. It will allow further maintenance (remove blockages, scale, pollution). This is the preferred option.

- For large-capacity boilers (from 60 liters), other models are produced with additional mechanisms: a ball valve, a pressure gauge, a regular fitting thread. These models are more diverse in species composition. You can choose the option you like best. The cost of them increases significantly compared to standard counterparts, it can even reach the level of the price of cheap heating equipment.

Safety or reverse?

Installing the opposite instead of the safety one can lead to unpleasant, life-threatening consequences.

The reverse will prevent the outflow of hot water from the boiler tank through the plumbing system. The liquid warms up to the maximum temperature, its impact force inside the tank increases. If the thermostat fails, the temperature will continue to rise along with the pressure, which will increase the boiling point.

When excess volume is discharged through the water tap, the boiling point will return to 100⁰ C, but the temperature in the tank will still be much higher. Instantaneous boiling of the remaining liquid, the release of a large amount of steam will lead to a strong explosion that will damage the water heating equipment, the walls of the room.

If the safety valve is not installed

Without a safety mechanism installed, the water heater will not work properly.

With a constant volume inside the storage tank, an increase in temperature will cause an increase in the impact force. Having reached a value that exceeds the pressure level of the central water supply network, it will begin to push hot liquid through the water supply. If you do not open the hot water tap, the normal pressure inside the tank will be regulated by ejecting it into the cold water pipe. Water heating equipment will waste electricity.

If the pressure in the water supply system decreases (load reduction at water pressure stations at night, accident, repair work), the supply pipe will be empty. Hot water from the storage tank of the water heater will pour out through the empty pipe. For models without automatic control of the operation of the electric heater (or with malfunctioning automation), the heating element will heat idly, which will lead to its burnout.

- You should choose a spring mechanism. It is reliable and has good resistance.

- It is recommended to take into account the features of the water supply system, if necessary, install a reducer to adjust the pressure of the water supplied from the central water supply network.

- It is necessary to take into account the throughput of the protective mechanism.

- It is necessary to correlate the maximum allowable pressure level in the water heating system with the operating pressure of the safety mechanism. If the pressure of the latter is low, water will constantly flow from it. If high, it will not work when the water pressure rises above the allowable level.

Installation

- The water heater must be disconnected from the electrical network, empty the storage tank.

- Install the valve mechanism on the pipe with cold water. Connect one end to the pipe, mount the other into the boiler. It is necessary to follow the direction of water movement (indicated by an arrow on the body).

- If necessary, install a water reducer up to the valve structure to stabilize the water pressure from the central water supply system.

- Connect the drainage outlet of the mechanism with a flexible hose to the sewer system. To monitor proper operation, it is recommended to supply a transparent hose.

- When hidden installation behind water heating equipment is prohibited:

- install locking devices between the boiler and the safety valve mechanism;

- make the distance from it to the boiler more than two meters.

How to check the correctness?

You can check the serviceability by turning on the water heater (do not open the hot water tap) and wait until the water is completely heated to the maximum possible temperature. After a while, excess water should drip from the protective protective mechanism.

The valve will not operate if:

- the hot water faucet is faulty (pressure will be released through it);

- the thermostat is set to 30-40⁰ C (the water will not warm up to the extent that the pressure inside the reservoir tank reaches an acceptable level);

- the operating pressure of the safety valve device is high, does not correspond to the capacity of the water heating equipment (the maximum allowable pressure in the storage tank will not be sufficient to trigger the safety valve mechanism. May have dangerous consequences).

Water from the valve device must be periodically discharged. If this does not happen and all the listed cases are excluded, the fuse itself is faulty. It must be replaced with a new one, after checking its performance.

A safety mechanism must be installed on water heating equipment to ensure long, uninterrupted, safe operation of the device. You should choose the most suitable option for all design and functional parameters, otherwise its activity will be inefficient, and even dangerous. In this case, it is necessary to periodically check its serviceability, about once a month. If a malfunction is detected, the inoperative valve must be replaced with a new one.

It is very dangerous to independently improve it, replace it with a check valve mechanism. This will lead to unpleasant consequences, due to which, it is likely that you will have to replace the purchased water heater with a new one.

Friends! More interesting stuff:

How to make a solar water heater for your home with your own hands?

How to make a solar water heater for your home with your own hands?

The quality of the piping of the water heater allows not only to increase its service life, but also increases the level of safety during operation. The installation of the boiler is carried out according to the manufacturer's instructions and taking into account connection standards. The safety valve for the boiler is an important element of the device, belonging to the safety group.

Why do we need a safety element, how to properly install a water heater and what principle of operation of the device we will consider further. Remember that non-compliance with the installation rules can happen not just a small nuisance, but a real tragedy.

Safety valves (also known as safety valves) are confused with "check valves". There are some similarities between the two species, but, in fact, they are completely different elements.

check valve is responsible for the supply of a liquid medium through the pipeline in only one direction. At the same time, the task of the safety valve is to protect the sewer pipe and connected devices from failure and destruction, which can occur as a result of excessive pressure in the system.

- spring devices;

- lever devices;

- magnetic spring;

- lever-cargo.

The confusion in concepts arises from the fact that the functions of these elements include the formation of a barrier that does not allow the liquid medium to move in the opposite direction.

There are several types of valves that are used in complex household appliances to protect against pressure surges. Allocate:

- spring devices;

- lever devices;

- magnetic spring;

- lever-cargo.

The use of one or another type of stop valves depends on the type and characteristics of the medium, as well as the purpose of the water supply (for example, sewerage). Most often, gas, oil, combustible materials, chemical and other aggressive mixtures, steam move through pipes.

Even on the body you can find an image of an arrow that indicates the direction of movement of water in the system through the heating tank in the boiler. Please note that plumbers it is not recommended to frequently use the drain lever for forced draining of water to prolong valve life. If you need to service the water heater, you can disconnect the water pipes and drain it.

Why is it important to have a check and safety valve

When selling water heaters, the safety valve is already installed because it is a required component. However, moving the water heater to another wall may result in the loss of a part.

Avoid craftsmen who, when transferring the water heater, instead of fuses, can insert a check valve.

Incorrect piping of the boiler can become a threat not only to health, but also to people's lives. This is due to the fact that when water is heated, the thermodynamic action often gets out of control, making the boiler an explosive device. Pressure and a large amount of steam accumulate inside the tank, which leads to an explosion.

The safety valve in the same situation works in a completely different way: when the critical temperature and pressure are reached, the spring in the cylinder is compressed and the liquid with vapor escapes. This quickly leads to normalization of the pressure in the system. Installation of a safety element on a water heater is a mandatory requirement!

In no case do not install and connect the boiler with your own hands, call a plumber who will quickly and reliably perform all the necessary actions.

We have already mentioned that water heaters are sold with a safety valve installed. However, you will need to take the trouble to find and set this element in case:

- loss;

- wear or breakage of the element.

How to choose the right element? You can do this with water heater suppliers by model number. Pay attention to advice! Buying a valve with a small or, conversely, a large value of the limit value should not be! For example, in the first case, there will be a constant leak on the boiler or from the tank, and in the second case, it is likely that the valve will not function correctly when an emergency pressure occurs.

The thread on the element must clearly match the mounting fittings. Please note that to form a tight connection, you will additionally need linen thread and a rubber gasket.

Tying instructions

The boiler piping includes the obligatory installation of a safety valve. For cold water supply, you will need a PVC pipe and the element itself. However, the connection option using an American, a drain tap and a tee is considered the best.

brass tee

You should not save on such a cheap element that provides security. The safety valve extends the life of the water heater, performing a protective function, and its operation without this device is strictly prohibited by regulatory documents.

Storage water heaters are installed not only in private houses that are not connected to central communications, but also in apartments for a comfortable waiting for the completion of repairs planned by public utilities.

For the safe operation of water heating equipment, it is necessary to purchase and install a safety valve for the boiler that protects the household appliance from pressure surges in the cold water supply system. In addition, this valve is also called a check valve, since it prevents water from flowing back from the storage tank in the event of an emergency shutdown.

Therefore, in the absence of water in the cold water supply system, you can not worry about the safety of the electric heating element. The heating element will not remain “dry” and will not burn out. The presence of a safety valve will allow you to easily drain the water from the boiler if you need to clean the tank from accumulated deposits in the process of heating water or replace a heating element that has served its time.

A serviceable safety valve is able to ensure long and stable operation of storage boilers.

In the process of heating water in the storage tank of the water heater, its volume increases. In a closed system, according to the laws of thermodynamics, as the temperature of a substance increases, so does the pressure level.

To control the water temperature in boilers, manufacturers install temperature controllers and thermostats on manufactured products. If these devices fail, then the water in the tank will boil, which will lead to a noticeable increase in pressure and an even greater heating of the liquid.

The avalanche flow of the described process, in the end, will lead to the formation of a crack in the walls of the storage tank, through which some of the hot water will pour out. The vacated space will immediately be filled with cold water coming from the plumbing system.

This will lead to an instantaneous boiling of all the liquid in the tank, accompanied by the release of a huge amount of steam and, as a result, the explosion of the container, bursting under its influence.

The safety valve will not allow the pressure to exceed the allowable values by dumping part of the liquid into the sewer system.

In addition to ensuring the integrity of the equipment in the event of critical situations, safety valves perform several other important functions, which include:

- preventing the return of heated water from the boiler back to the water supply;

- smoothing pressure surges of cold water at the inlet to the water heater tank, which prevents the possibility of water hammer;

- dumping excess fluid from the tank at the time of a critical increase in temperature and pressure;

- providing the possibility of draining water from the storage tank of the water heater for scheduled preventive maintenance and necessary repairs.

Valves that manufacturers currently produce can have a variety of designs. The kit, along with the main product, may include pressure gauges, various shut-off valves, etc.

When choosing a safety valve for a boiler, one should take into account the fact that the purchased device must comply with the parameters of the operating hot water supply system in the house.

The diagram clearly shows the device of a safety valve for a water heater (boiler), all elements of which are provided with pointers with inscriptions

How does such a valve work?

The safety valve of the boiler also performs the functions of a check valve, which is reflected in its design. Schematically, the product can be represented as two thin-walled cylinders located at right angles to each other, having different sizes, endowed with a common working cavity.

If you look inside a larger cylinder, you can see a check valve installed there, the design of which includes a plate, a spring and a seat machined in the body of the product. The thread applied on both sides of this part of the protective device allows it to be connected to the inlet pipe of the electric boiler.

The smaller cylinder also contains a shut-off device similar in design to the check valve described above, but differs from it only in the presence of a stiffer spring.

Most relief valves have a function to adjust the opening pressure by changing the compression ratio of the spring. The drain hole is located directly behind the locking mechanism. It is recommended to connect a transparent tube to this hole, which allows you to observe the water discharged from the tank.

The safety valve operates according to the following algorithm.

- With the valve in the open position, mounted on the inlet line, water passes freely into the container through the hole resulting from pulling the check valve disc from the seat. At the same time, the incoming liquid does not have access to the drainage hole, because the safety spring has a stiffness designed for a higher pressure compared to the plumbing value of this value.

- At the moment of full filling of the boiler, the pressure level in the tank and in the line equalizes, due to which the check valve closes. An increase in the temperature of the heated water in the storage tank causes an increase in the pressure force on the check valve disc, which is even more tightly pressed against the seat. Therefore, the heated water cannot return to the cold water supply pipes.

- When users begin to consume hot water for domestic needs, the pressure inside the water heater begins to drop and reaches a value less than the water pressure value. At this moment, the plate is wrung out from the saddle and the process of filling the tank with water begins.

- If the thermostat breaks down, then an uncontrolled increase in temperature will begin, which will cause an increase in pressure to a critical level. Here, as a result of the compression of the safety valve spring, it will be possible to drain excess fluid through the drainage hole into the sewerage system through a transparent hose.

A small lever is needed to force the opening of the drainage hole, through which water is discharged and pressure is reduced.

Waste of electricity without check valve

A hot water supply system with a water heater can function without a shut-off valve, but then, in the event of an increase in pressure, hot water will be squeezed into the supply line. This will lead to an overrun of electricity, because the device will have to heat more water.

The extra wound kilowatts will need to be paid for, which will not add joy to the owner of an apartment or house. In addition to the financial side of the matter, there are also practical inconveniences. After all, instead of cold water, warm water can run from the taps.

These problems must be added to the disadvantages that were described above. Therefore, do not agree to the installation of a water heater without installing a safety valve.

The cost of this brass product is incomparable with the costs incurred to purchase a boiler.

The information on the safety valve body helps to choose the right part for the initial installation or replacement during the repair of the water heater

How to connect a water heater

After installing the water heater, proceed to connect it. To do this, they take a tee, try it on, winding it on the cold water inlet, marked in blue. If there is not enough thread, then a few turns are added with a special device so that the tee is set correctly.

Then they wrap the thread with tow, coat it with a paste that provides a tight connection, and wind the tee, tightening it with an adjustable wrench. Next, a tap is screwed onto the side outlet of the tee to ensure that water is quickly drained from the boiler in case of replacing a burned-out heating element or cleaning the tank from scale.

Also, the connection is sealed with tow or tape for threaded connections. From below, a safety valve is connected to the tee, focusing on the arrow showing the direction of cold water entering the water heater. The arrow is located on the valve body.

Next, one part of the American is wound onto the safety valve. The second part of the American is screwed onto the tap and a connection is made with the first part. Then, an adapter is screwed into the faucet for connection to the water supply with propylene pipes.

Next, make a connection to hot water. To do this, they wind the first part of the American on the outlet pipe of the boiler, marked in red. The second part of the American is wound onto the shut-off crane. Perform the connection.

Then, an adapter sleeve is also screwed onto the tap for soldering the propylene pipe. It remains to connect the boiler to the cold and hot water supply system. Propylene pipes can be replaced with flexible pipes.

The connection diagram of the water heater (boiler) to the hot and cold water supply systems shows the sequence in which the device is installed

Alternative way to mount a non-return valve

This method was invented by a craftsman who had a problem with the safety valve being contaminated by sediment from a pressurized hot water tank. If a piece of rust gets under the piston plate on the seat, then the valve can no longer work correctly. It remains open all the time.

To prevent such a development of the situation, it is necessary to mount the valve at the level of the middle of the tank. That is, in the same way as described above, a tee is connected to the inlet pipe of the boiler, and then the connection is made a little differently.

The drain tap is screwed on from below, and the pipe is taken to the side, corners are placed, again the pipe, and somewhere at the level of the middle of the tank a safety valve is installed. After it comes a shut-off valve and a fitting, through which the device is already directly connected to the water supply.

With this method, the valve always remains clean and the poppet piston does not “hang” above the seat. In addition, in the absence of water in the system, such a curved connection serves as a kind of water seal.

You can learn more about this installation method from the video.

During operation of the boiler, make sure that the drain hole on the safety valve is not clogged or blocked. The drain can become clogged with rust, small solids and other impurities found in tap water.

To check its working condition, a small amount of water is periodically discharged by pressing a special lever or turning the handle. The instructions supplied with the water heater safety valve describe how the valve's forced opening mechanism works.

Installing a filter to purify tap water partially solves the problem. It is undesirable to change the factory settings of the spring stiffness in valve models endowed with such an adjustment.

Such interference can lead to the destruction of the water heater tank due to the excess of the permissible pressure values inside the household appliance.

Forced discharge of water from the boiler in order to reduce the pressure in the tank is carried out by pressing the lever

Constantly dripping water - what to do and how to fix it?

Some boiler owners are faced with the problem of constant seepage of water through the drain hole. Water can drip from the drain for two reasons:

- incorrect valve setting;

- too high pressure in the cold water supply system.

The first problem is fixed by replacing or adjusting the device, which must be done with a hex wrench. At the same time, the clamping nut located at the inlet inside the valve is slightly tightened.

You can get to this nut by partially disassembling the device, in which the lever, nut and sealing washer are removed. In general, you can solve the problem faster by buying a new valve.

The second problem associated with high pressure in the system disappears when the pressure reducing valve is installed.

The connection of a tube with transparent walls to the drainage hole was made without bringing it into the sewerage system

Connection of a branch in the form of a transparent tube from the drain hole of the safety valve to the sewerage system through a branch pipe with an oblique inlet

Problems and ways to solve them

The cause of the incorrect operation of the water heater should be searched for immediately, as soon as the first signs appear. It is advisable to test all elements of the household appliance, starting with the thermostat, safety valve and heating element. Most often, it is these parts of the boiler that break.

In the event of a valve breakdown, the masters advise not to save money by repairing the part, but to immediately purchase a new analogue. The model is selected according to the pressure level for which the valve is designed, indicated on the body of the product. This information is also indicated in the safety valve instruction manual.

There are situations when the valve does not function due to a hidden marriage, which is not possible to identify. It is not worth spending time searching for a defect in the design of the part, since the boiler must be operated for its intended purpose.

Therefore, the defective valve is replaced with a new device. If the resource of the installed safety valve is exhausted, then it is also dismantled and a new device is installed. By changing the valve, you can not worry about how the water heater works.

The supplied part will ensure reliable and safe operation of water heating equipment.

The disassembled safety valve allows you to see the screw, which adjusts the degree of spring stiffness with a screwdriver

Install the water heater and properly tie it under the power of any novice master. After reading the article and watching the videos, you can do everything yourself, saving on paying for installation work done by third parties.

If you think that everyone should do their job at a professional level, then invite specialists. Experienced craftsmen will help you choose the right safety valve model, buy the missing fittings, and connect the boiler to cold and hot water in accordance with construction standards.

Do not listen only to those unfortunate masters who consider safety valves to be unnecessary links in the piping chain of a water heater connected to the water supply. Never skimp on your safety!