The distance between the reinforcement in the strip foundation. Ways to properly reinforce the strip foundation in detailed instructions with diagrams and drawings

Reasons why you need to reinforce a reinforced concrete foundation

In a reinforced concrete structure, each component - concrete or reinforcement - performs a different function. Concrete in tension is able to elongate only a fraction of a millimeter. At high tensile loads and transverse shear forces in an unreinforced concrete structure, deformations can occur, leading to cracking and the appearance of other defects, up to destruction.

The steel frame members of reinforced concrete can take tensile loads ten times greater than those that concrete can take. Plastic rolled steel, having the ability to elongate without breaking by 5-25 mm, works in tension, preventing the development of deformations in the structure beyond the allowable limits.

A monolithic foundation tape is a system of beams connected to each other at corners and intersections, lying on a solid elastic soil base. Soils are constantly affected by climatic factors - they freeze in winter and thaw in spring, are moistened by surface or groundwater, while increasing or decreasing in volume.

The forces arising in this case from below are transferred to the foundation, and with a constant load from the building from above, compressive and tensile forces arise in the structure. In this case, compression and tension can be experienced by different sections of the section of monolithic beams that make up the strip foundation.

Therefore, the main scheme for reinforcing a strip foundation is a three-dimensional frame with the location of rolled steel products at the top and bottom of the cross section. If the width of the sole of the tape exceeds the width of the wall by more than 600 mm, then the sole is additionally reinforced with flat meshes.

When designing, it is determined which reinforcement is needed for the strip foundation.

What reinforcement is used to reinforce strip foundations

Reinforcement of the strip foundation is carried out by means of spatial frames and flat meshes, in which rolled steel products are divided into workers, which perceive the main tensile forces, and constructive, which serve to fix the working rods.

Consider which steel rods can be used for a strip foundation. As a working one, corrugated steel of class A3 is used, according to another classification A400, produced according to GOST 5781-82* or A500C according to GOST R 52544-2006. Corrugated rolled products contribute to better adhesion of working rods to concrete. Reinforcement of the strip foundation with A500C rolled products allows welding frames and meshes. As a constructive, rods with a smooth surface of class A1 or, according to another designation, A240 are used.

We wrote about the use of working reinforcement of classes A3 and A500C, the differences between them, the benefits of using A500C, the features of installing frames and meshes in the article "".

All reinforcement work must be carried out following the instructions of the technical documents. SP 52-101-2003 "Concrete and reinforced concrete structures without prestressing reinforcement", SNiP 52-01-2003 "Concrete and reinforced concrete structures", using which you can reinforce the strip foundation with your own hands.

Calculation of the reinforcement diameter and the number of working bars for the tape

The diameter of round bars for a strip foundation is determined on the basis of a calculation that takes into account the loads carried by the foundation. The load is collected from all load-bearing walls in the application for 1 linear meter along the length of the foundation. The total load includes:

- own weight of wall structures made of different masonry materials, lightweight concrete blocks, wood, monolithic reinforced concrete, etc.;

- own weight of floors - reinforced concrete or wood, collected from 1 m 2 and half of the span between the bearing walls;

- the weight of people, furniture, partitions, equipment, etc., acting on floors, collected from 1 m 2 and half of the floor span. Accepted by SNiP 2.01.07-85* "Loads and impacts";

- the weight of the coating and roof structures, collected from 1 m 2 and half of the span;

- weight of snow cover in winter, taken according to SNiP 2.01.07-85*.

After collecting the loads, the width of the belt structure is calculated taking into account the bearing capacity of the base. We gave examples of how to properly collect loads, calculate the width of the tape and the thickness of the anti-heap cushion in the article "".

There are also tables for collecting loads for different types of walls and floors, the values of the calculated resistances of various types of soils, which can be used when calculating any strip foundations intended for low-rise buildings. For a quick calculation, a calculator is provided on the article page.

The calculation of reinforcement is carried out taking into account the accepted dimensions of the foundation structure - the width of the sole and the height of the section according to the method SNiP 2.03.01-84* "Concrete and reinforced concrete structures". In order to correctly calculate the reinforcement of the strip foundation according to SNiP, you should contact professional designers.

And we will give a simplified calculation method.

Simplified calculation of strip foundation reinforcement

A simplified calculation of rolled steel for a strip foundation consists in selecting the number of working rods, as well as their diameter, according to the main indicator - the minimum percentage of reinforcement.

According to requirements p.5.11 Table 5.2 Benefits to SP 52-101-2003 the total area of working rods that can absorb tensile forces should not be less than 0.1% of the cross-sectional area of the calculated reinforced concrete structure.

Since a monolithic tape has the form of a beam, which is affected by multidirectional forces, the stretched zones can be both at the top and at the bottom of its cross section.

Thus, the main condition for the calculation is the presence in both sections of the section of the structure of longitudinal working rods with a total area of at least 0.1% of the total section area.

Formula for calculating the percentage of reinforcement by clause 5.11 of the Manual to SP 52-101-2003:

$$\quicklatex(size=25)\boxed(\mu_s = \frac(A_s)(b \times h_0) \times Pr )$$

Where:

Pr - unit equal to 100%;

A s ; - the desired total area of the working rods, mm 2;

b – tape width, mm;

h 0 ; - working height of the cross section, in mm.

From this formula, you can find the required minimum area of the rods:

$$\quicklatex(size=25)\boxed(As = b \times h_0 \times 0.001)$$

When calculating, it is necessary to take into account the rules for reinforcing the strip foundation set forth in Allowances for SP 52-101-2003 in the "Guidelines for the design of concrete and reinforced concrete structures from heavy concrete (without prestressing)".

According to clause 5.17 of the Manual to SP 52-101-2003 the minimum diameter of each of the working rods is limited to 12 mm.

Initial data: monolithic strip foundation for external walls with a section of 600 mm (b - width) by 500 mm (H - full height);

First, we determine h0, which will be equal to the height of the section without a protective concrete layer.

The protective layer that must be maintained for the lower rods on the bottom of the tape, laid on sand or gravel preparation - 70 mm. But for the upper reinforcement, the protective layer is 30 mm, so we take the average value - 50 mm:

h0 = H - 50 = 500 - 50 = 450 mm

We determine the cross-sectional area of \u200b\u200bthe tape that will be used in the calculations:

b x h0 \u003d 600 x 450 \u003d 270,000 mm 2

The required minimum area of the working rods As in each sectional zone will be equal to:

As \u003d b x h0 x 0.001 \u003d 270,000 x 0.001 \u003d 270 mm 2

To select the diameters of the working rods and their number according to the minimum required area, we present Table 1.

According to the table, we find the nearest values for a minimum diameter of 12 mm, provided that 3 rods are installed. The value will be between columns with 2 (226 mm 2) and 3 rods (339 mm 2), we accept more - 339 mm 2 for 3 rods.

As a result, we finally accept 3 working rods with a diameter of 12 mm in both cross-sectional zones.

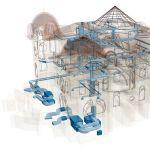

Strip foundation reinforcement schemes

Here are two main schemes for reinforcing a monolithic reinforced concrete foundation, which can be used in low-rise construction.

Scheme 1 - if the width of the tape is equal to the width of the wall

Scheme 2 - if the width of the tape exceeds the width of the wall

In both cases, the tape is reinforced along the length with a spatial frame, the working rods of which, located in both zones of the cross section of the structure, perceive and compensate for tensile forces.

If the tape protrudes beyond the edge of the base by more than 0.5 m, tensile forces will occur in the sole area perpendicular to its axis. In order to compensate for these forces, the reinforcement of the bottom of the tape is additionally used in the transverse direction to the axis of the wall.

The optimal solution in this case is knitting a mesh consisting of working and structural rods and laying it before installing a spatial frame.

When constructing spatial frames, in addition to longitudinal working rods, transverse reinforcement is used, which serves not only to connect longitudinal rolled products into one structure, but also to perceive transverse, cutting loads on the tape. Transverse reinforcement also counteracts the formation of cracks in the structure and prevents lateral buckling of the working rods.

As part of the spatial frames, the transverse rolled products are used in the form of clamps that cover the longitudinal working rods along the perimeter of the frame. For clamps, fittings with a smooth surface of class A1 are used, having a diameter of 6-8 mm.

In a white paper SP 52-101-2003 "Concrete and reinforced concrete structures without prestressing reinforcement" the reinforcement diameters are determined under different reinforcement conditions, which are given in Table 2.

In addition to the requirements for the use of reinforcing bars of a certain diameter and class for various elements of spatial frames and flat meshes, the standards provide for a number of rules for the reinforcement of monolithic structures.

Rules for reinforcing a monolithic strip foundation

In the production of tape reinforcement, the following regulatory rules must be observed:

- working rods installed in the longitudinal direction of frames and grids must have the same diameter. In the case of using reinforcement with different diameters, rods with b O the larger diameter must be located in the lower zone of the tape;

- with a belt width exceeding 150 mm, the number of longitudinal working elements placed in one level should not be less than 2;

- the distance in the frame between the longitudinal elements installed at the same level is not allowed less than 25 mm in the lower row of the frame and less than 30 mm in the upper row. When constructing spatial frames, it is also necessary to provide places for the passage of deep vibrators. In these places, the clearance should not be less than 60 mm;

- the step of the rolled products in the strip foundation, provided for the installation of clamps or transverse elements, must be within ¾ of the height of the structure and not more than 500 mm;

- the protective layer of concrete provided for the working reinforcement of frames or meshes located at the sole of the tape should be 35 mm for concrete preparation, 65 mm for preparation from sand or crushed stone;

- protective concrete layer on the lateral and upper sides of the structure - 40 mm, for clamps or transverse rods - 10 mm.

Fabrication of frames and meshes

In the case of using ordinary rolled products of classes A1, according to another classification A240, and A3 (A400), reinforcement is knitted under a strip foundation, for which special knitting wire is used. Welding of reinforcing elements is possible only when using rolled products of class A400C or A500C.

Knitting wire is made of low-carbon steel, has a diameter of 0.8-1.4 mm and is designed specifically for the manufacture of elements of the supporting frame of reinforced concrete structures. When knitting frames and nets, lengths of 30 cm are used, which are pre-cut.

Consider how to knit reinforcement for a strip foundation. To perform this type of work, a special tool is used: hand hooks or nozzles for a screwdriver, knitting guns, pliers, tongs and wire cutters.

A loop is made from the pieces of knitting wire, which is passed around the junction of the reinforcing bars, then the ends are twisted manually using a knitting hook or mechanically using a screwdriver nozzle or a gun.

Since rebar frames and meshes have a limited length, the question may arise: how to tie reinforcement for a strip foundation. Along the length, frames and meshes are joined using: overlap without welding or welding in the case of using rolled products of class A400C or A500C.

When welding with an overlap, the length of the rods of the reinforcement to be connected should not be less than 10 diameters.

In the case of overlapping, the length of the bypass of reinforcing bars must be at least 20 diameters of the elements to be joined and at least 250 mm.

To calculate the total volume of material, you can use the reinforcement calculator for the strip foundation, located on this page.

Reinforcement of corners and joints

At the junctions and corner joints of the tape, the greatest concentration of stresses occurs, so these nodes must be further strengthened.

For reinforcement, the installation of additional rods is used according to the following schemes:

When reinforcing the angle of the tape, additional L-shaped and trapezoidal rods are installed, which are attached to the working rods in the upper and lower levels of the connected frames.

When strengthening the T-shaped intersection, additional trapezoidal rods are installed in the upper and lower levels of the connected frames.

When strengthening the mutual intersection, trapezoidal rods are installed.

Reinforcement of the corners of the strip foundation can also be carried out according to the following schemes:

Calculation of the amount of reinforcement

Initial data: a low-rise building measuring 10 x 12 m with an average load-bearing wall located on the long side. Tape section 400 x 400 mm. Reinforcement - a spatial frame of 6 bars of working reinforcement with a diameter of 12A3. Clamps made of smooth rolled products with a diameter of 6A1 are located with a step of 400 mm.

Determine the total length of the tape:

10 x 2 + 12 x 3 = 56 m.p.

The length of the working rods will be equal to:

56 x 6 = 336 m.p.

Length of one clamp:

0.4 x 4 / 1.15 \u003d 1.39 m (1.15 is the coefficient for converting the perimeter of the tape section into the length of the clamp)

Number of clamps:

56 / 0.4 = 140 pcs.

Clamp rod length:

140 x 1.39 = 194.6 m.p.

We increase the calculation results by 5% - this is a margin that takes into account the cutting of reinforcement and waste.

Working fittings: 336 x 1.05 = 353 m.p. or 352 x 0.888 = 313 kg

Clamps: 194.6 x 1.05 = 204 m.p. or 204 x 0.222 = 46 kg

For a quick calculation of the amount of materials, you can use the reinforcement and formwork strip foundation calculator located here.

Methods and techniques for reinforcing a strip foundation from an expert of the site portal

The above two main schemes, according to which it is possible to reinforce a strip foundation, as well as schemes for reinforcing corners and intersections for low-rise buildings, have been repeatedly used and tested in real construction in difficult soil conditions - with foundations made of subsidence and heaving soils. Therefore, I recommend using these diagrams and the information provided on the selection of steel rods and the design of frames for houses 1-2 floors high under any soil conditions.

When building more complex and critical structures for the design of the foundation, you should contact professional designers.

Technical concrete can withstand strong mechanical stress, but requires additional reinforcement. To ensure high-quality bearing capacity, reinforcement of the strip foundation is made, due to which the efficiency and durability of the work performed is enhanced. It is also carried out in tiled structures, piles and pillars, although there is no such need.

Work rules

First you need to prepare a reinforced frame that will strengthen the base in case of deformation or uneven masonry. Such actions create bending loads, which are unrealistic to get rid of without reinforcement. In progress you need to follow some rules:

Metal armored frames are bound, welding of corner elements is not allowed, as it may not withstand the load. Builders do not advise using welding, as it can damage the section. For work, use the layout of class A400 rods.

In the step-by-step instructions for creating a foundation with your own hands, the choice of materials is key. In the process of reinforcing a strip foundation 50 cm wide rods of different categories are used:

Proper foundation reinforcement can increase your building's strength by 245%, increase its mechanical strength by more than 150%, eliminate possible settlement and reduce edge fragility. Do you still think rebar stitching is a waste of money?

Important rules for knitting reinforcement and basic SNiP

Before you start embroidering your future foundation with reinforcement or wire, you need to roughly calculate the load on it in order to determine which section of the bar you need. You don’t need to know for sure, as they always take with a margin. For example, when building a temporary metal structure with a wall weight of up to 400 kg / 1 m 2, reinforcement with a diameter of 8 millimeters can be used. When building a cinder block garage with walls up to 3 meters high, a rod with a cross section of 12 millimeters is used. If you are building a two-story cottage, then you will have to embroider with more serious metal - a diameter of 14-18 millimeters.

Of course, you can give this project for calculations to experienced specialists who will save money and select the minimum allowable value, but if a few thousand rubles do not play a big role, take it with a margin. Often there is a desire to complete a floor with an attic or make a multi-level heavy roof - the base must be ready for such a "turn of events". There are several SNiPs that regulate the manufacture of this design. Let's consider them in more detail.

- SNiP 7.3.4 states that the minimum distance between two vertical rods must be at least than the cross section of the gain itself, and preferably 2-3 times more. The maximum value is not indicated, since it is already chosen personally for each project, it depends on the masonry method, the presence of a sealant, the brand of cement, the quality of the aggregate and other factors.

- SNiP 7.3.6. The distance between two parallel longitudinal rods should be no more than 40 centimeters. The greater the load on the base, the smaller this distance will be. The minimum distance for the strip foundation is 10 centimeters with a reinforcement diameter of 14 mm.

- SNiP 7.3.7 regulates the step of transverse reinforcement. A value of no more than half the working height of the section should be taken, but, in no case, it should not exceed 30 centimeters.

Adhering to these SNiP, you will get reinforcement according to "book standards". But there are several rules that have been developed specifically by builders to facilitate the process of establishing a foundation. These recommendations are time-tested and will significantly improve the physical and mechanical properties of your structure, as well as save a little on the purchase of materials.

- Reinforcement cannot be welded together. Heating the metal significantly degrades its properties., but strong connections are generally useless there - they are held by concrete, not metal, which you will weld for hours.

- Reinforcement is subject to corrosion, so you need to deepen it from all sides into concrete so that it serves for decades. On the sides, the metal should “go” into the concrete by 8 centimeters at least, from below by 10, from above by 10.

- It is impossible to make cross connections at the corners, the rods should not intersect perpendicularly, it is better to take and bend the metal of the required shape so that the next joint is no closer than 100 centimeters from the corner. The largest load always falls on them, and the connection in a short section of the section will not give the desired strength.

- Corners should be additionally reinforced with crossbars and verticals. Very often, people simply do cross-stitching, believing that the mass will rely, for some reason, on the rod itself. But such knitting of reinforcement for the base is simply unacceptable, because you will get 2 separate blocks that will not have any connection with each other. The sense of this action is exactly 0.0%. We need U-shaped and L-shaped reinforcements at the corners and at the first crossbars from them.

We have analyzed the basic rules on how to make high-quality foundation reinforcement, the diagram for which is below. Now you can proceed to the phased construction of this structure and analyze all the nuances in more detail.

Step-by-step instructions on how to make a reinforcing cage for the foundation with your own hands

Preparation of the pit and jointing is a responsible process. Reinforcement plays one of the most important roles here. In order to do everything right, the design was as strong and connected as possible, everything must be done according to the following instructions.

>Step 1: We expose the formwork.

Before knitting reinforcement for the foundation, you need to prepare a place for it. First, we dig a hole of the required size, mainly 40 centimeters wide (for a house) and a depth of 90 centimeters, depending on the weight of the future structure and the characteristics of the soil. Next, we install wooden beams 50x50 mm in the corners, to which we nail the longitudinal boards. We raise the foundation and translate it smoothly into the base.

Important: even if you have an almost flat pit below ground level, you still need to set up the formwork from the boards, and from even planks. This is done so that the reinforcing elements are at the same distance from the outside of the concrete - this is an important point to consider. The formwork is fixed on the outside with earth or sand and water, and on the inside with wooden spacers (the length must be the same).

>Step 2: We install vertical supports for metal frames.

First of all, you need to set the verticals to which the horizontal reinforcing belts will be tied, and then the crossbars. Suppose that the foundation will have 4 corners - the simplest design. Then in each corner you need to step back 6 centimeters from the inner and outer walls, then mark the place and hammer in the rod, align it with a plumb line.

>Step 3: Attach the horizontal frame.

As a rule, these are 2 parallel straight lines, which are wound with ordinary knitting wire. Important: they cannot be welded to verticals and crossbars, as high temperature will significantly worsen their physical and mechanical properties.

>Step 4: Screw on the crossbars.

This can be done manually or with the help of special knitting guns, which will greatly simplify the work. The step of the crossbars should be at least 40 centimeters, best of all - 60-65 cm. Remember that a very dense mesh is not a guarantee of high strength. We only need to give the concrete flexibility and eliminate the risk of settling.

>Step 5: We strengthen.

First of all, we strengthen the corners with L-shaped and U-shaped elements, we make oblique struts between the lower trim and the upper parallel elements. The sides can be supplemented with oblique ones between parallels, longitudinal branches can be installed from the upper corner of one edge to the bottom from the other edge.

Pouring concrete on the frame

We have just figured out how to reinforce the foundation, now we will consider how to pour concrete correctly so as not to violate the integrity and increase the strength of the structure. The first step is to make a good foundation. To do this, we pour 5 centimeters of broken brick or cinder block under the first strapping belt. Next, we fill it with a liquid solution so that it penetrates well into all the cracks and ensures maximum strength of the sole.

Foundation reinforcement is a very important part of building the foundation of a house. Reinforcement creates strength for foundations of various designs, made from a variety of materials.

This primarily applies to strip foundations, in which a large mass of concrete presses on the soil. Reinforced foundation design is a classic example of how simply and effectively the properties of a building structure can be improved using theoretical knowledge and practical experience.

Why reinforce concrete?

Reinforcement began to be used quite a long time ago - since the 18th century. First, concrete structures were reinforced by placing metal on top of concrete, and then a method was invented to strengthen the reinforcement by internal laying. Why is concrete reinforced? Concrete is a material that is very strong in compression, but very brittle when stretched. The tensile strength index is 10-30 less than in compression. Reinforcing steel, and now various composite reinforcing materials, make it possible to build foundation and wall structures that compensate for the shortcomings of one or another material.

Thus, a reinforced strip foundation can withstand:

- from below - tensile pressure;

- the upper part of the foundation resists the great pressure of the walls and the roof from above;

- from the sides and bottom, the foundation is affected by the force of frost heaving of the soil, the pushing force of which can exceed the weight of the house.

How is reinforcement installed?

Reinforcing mesh in concrete formwork is laid longitudinally and transversely. Longitudinal reinforcement takes on the heaviest loads, and therefore it is laid from below and above the poured base. If the foundation is not lower than 15 centimeters in height, then the crossbars of the transverse reinforcement are also arranged. Usually. in the case of choosing a metal reinforcing product, use steel bars with a diameter of 5 to 8 mm.

During the construction of the reinforcing mesh, it is fastened together, creating a single reinforcing frame structure. Tying reinforcement into one frame eliminates the possibility of incorrect redistribution of loads. Thus, the reinforcing frame creates powerful resistance to the weight of the house, as well as to forces that lift the foundation or try to test it in tension. The distance between the longitudinal reinforcement bars is fixed at 400-500 mm. The pitch of the reinforcement, which is installed transversely, should not exceed 300 mm.

The step width and reinforcement density must be calculated taking into account:

- used element of reinforced concrete structure;

- the size of the element in width and height;

- calculated value, which ensures the effective involvement of concrete and reinforcement in compliance with the rigidity of the structure;

- in longitudinal reinforcement, the distance between the rods should not exceed twice the height of the section of the concrete element.

Strip foundation: the subtleties of reinforcement

A monolithic strip foundation is reinforced not only along the walls of the structure. A reinforcing mesh is laid at the base of the foundation on a sand cushion, and then formwork, stones, gravel, broken bricks, and then all this mixture is poured with concrete.

The reinforced monolithic foundation is very resistant to heaving of the soil. If such a reinforced foundation is laid below the freezing point, then we can expect the construction of a strong and durable foundation. If the foundation walls are higher than 50 centimeters, then they will experience a powerful one-sided lateral load of the soil, and therefore such foundations are necessarily arranged with reinforcement.

When the strip foundation contains a complete reinforcement frame, the reinforcement cannot be directly attached to the open ground and formwork elements. This can provoke the appearance of rust, which is unsafe for steel reinforcement structures, which can rot and crumble as a result. The safe layer to protect the frame should be at least 45-75 centimeters.

Foundation reinforcement angles are the special attention of builders. It is the corner structures that experience increased stress. To create corner bends, it is necessary to bend wire corners at the place where the frame is created. If the reinforcement is carried out by simply seizing straight reinforcing steel bars with wire, then the strength of the structure will be orders of magnitude lower, and it will not be able to become a monolithic frame. In fact, in this case, it is possible to obtain, considering the situation from an engineering point of view, several separate beams, and not a common monolithic reinforced mass. This sharply reduces the possibility of resistance of the foundation structure not only to compression, but also to the most dangerous stress for concrete structures - tension, lateral forces.

If the reinforcement is carried out for an obtuse corner of the foundation, then the structure of the reinforcement cage is enhanced by additional adhesion to the external reinforcing structure, as well as the installation of clamps in transverse manufacturing.

Reinforcement calculation

Before starting reinforcement, it is important to calculate the amount of materials needed for its implementation. To do this, you need to determine the required cross-section of the rods used for reinforcement.

If you are building a farm building for storing inventory or accommodating a small workshop, then reinforcement with a cross section of up to 10-12 millimeters is quite suitable. If a strip concrete foundation is reinforced, then a larger reinforcement section is required - from 15-20 millimeters. In addition, the reinforcement should preferably have periodic surface profiling. This creates additional strength of the reinforcing frame. Rods for additional reinforcement, including for vertical installation, can be thinner - from 10 millimeters in cross section. If the lower longitudinal row is laid, then the distance to the upper row is usually at least 30 centimeters.

For ease of calculation, it is suggested to build on this indicator: if the length of one part of the reinforced concrete element is 3 meters or a little more, then the smallest diameter of the reinforcing bar should be 12 mm. If we take into account all the loads and evenly distribute them over the element, then it is required to make two reinforcement belts with a bar with a cross section of 12 mm or more. What will be the diameters of the transverse reinforcement? If the reinforcement frame is not more than 80 centimeters, then the minimum cross section of the reinforcement is 8 mm.

All these calculated data are indicative. As we have already said, they can be used to estimate the required work, and not for a specific house, since there are a lot of features of the house design that must be taken into account. First of all, the features of the walls, the weight of the roof, the internal sections, the type of floors.

Reinforcement technology

When reinforcing, it is important to remember one important building rule - concrete, a mortar for pouring the body of a monolithic strip foundation, covers the reinforcing cage on all sides by at least 50 millimeters. That is, if the cross section of the foundation is 400 by 400 millimeters, then the cross section of the frame will be 300 by 300 millimeters.

The assembly of the frame is carried out after the preparation of the necessary rod with the desired section and surface:

- the step in the reinforcement strip foundation usually does not exceed 30-50 centimeters;

- steel stiffeners are put on reinforcing bars;

- reinforcement is fixed at the corners of each of the ribs;

- fastening is carried out with twists or special fixing one-piece elements, including the installation of the frame by welding;

- the section of the frame must be quadrangular;

- after mounting the frame, it is placed in place for laying the foundation;

- when laying, an indent of 50 mm from the bottom and walls of the trench is maintained;

- broken brick, stone or concrete fragments are poured under every fourth rib to prevent bending.

Strengthening frame joints

In order to connect the elements of the frame, several methods are used.

- overlap connection provides for the connection of reinforcement by outlets, not less than 50 centimeters long;

- by means of lining, the reinforcement is connected using trimmings of reinforcement, bent and U-shaped clamps with a length of junction to the reinforcing bars of 50 cm on each side.

Reinforcing belt can be fastened

- directly;

- angular way;

- T-shaped.

In order to connect the reinforcement, a strong knitting wire is used, which has a cross-sectional diameter of at least one millimeter. The metal ribs of the reinforcement cage are fixed on top of the wire twists, put on the cage before connecting the reinforcement. If the reinforcement is overlapped, the dimensions of the ribs are slightly increased.

If welding is used in the connection, then the joints may experience strength problems due to strong heating and giving them the properties of a brittle hardened iron surface. This, in turn, can lead to the destruction of the reinforcement. Thus, welding fastening is not recommended for significant loads on the foundation structure.

Metal and concrete in one team

Reinforcing the foundation, creating a frame made of metal or composite rod, allows you to create a strong and durable connection between concrete and metal or composite. Such connections withstand enormous loads, last more than 100 years and can create a solid foundation for any type of home.

In the construction of a reinforced foundation, it is important to know the properties of materials and make the correct calculation, apply a consistent technology for laying the frame. Without the use of all this professional knowledge, foundation reinforcement will be ineffective and will not be able to ensure the strength of the entire building structure. For several centuries now, foundation reinforcement has made it possible to use all the best properties of the two most common building materials - concrete and metal - during construction.

A shallow strip foundation, which can be easily erected in the shortest possible time with your own hands, is most often used for the construction of low-level buildings or fences in a summer cottage. To increase its stability and strength, reinforcement is performed.

Before starting any work, it is necessary to clear the area: remove vegetation and remove debris. According to the pre-made markings, it is necessary to dig trenches. This can be done manually or with the help of special equipment. For that, so that the walls are even, it is recommended to install formwork. The frame is usually installed together with the formwork. Then the solution is poured in layers, waterproofing is carried out using sheets of roofing material. If the technological sequence is followed correctly the service life of the strip foundation is from 20 years. But it is recommended to carry out repairs every 10 years.

Why reinforce strip foundation

The question is often asked how to properly reinforce the strip foundation with your own hands. Concrete is strong enough but not flexible enough. He can cope well with compressive load, but fail under tensile loads.

Concrete works extremely poorly in tension, and in order to “help” it, steel reinforcement is introduced for tensile layers of concrete, which takes on the tensile forces

To increase the strength of the base and extend its service life, reinforcement of the strip foundation is used, which can be done by hand, without involving specialists. It is enough to follow the technological sequence and select the material of good quality.

After all, if the work is performed in compliance with all requirements, then the strength of the foundation improves markedly:

- rebars laid horizontally significantly increase tensile and bending strength;

- rods arranged vertically serve as reinforcing elements and provide shear strength.

To reinforce the strip foundation, rods of different diameters are used, depending on the purpose.

How to calculate the amount of reinforcement and its diameter

Thanks to this calculation, you can find out how many reinforcement bars and what sizes are needed in order to give sufficient strength to the strip foundation. In this case, reinforcement of different types and thicknesses is used.

For the construction of a strip foundation for a residential building, ribbed rods with a diameter of 10-20 mm are used, and smooth round rods with a diameter of 6-12 mm are used for transverse and vertical reinforcement.

The reinforcement scheme depends on the minimum content of longitudinal bars and their minimum diameter. So, according to the norms of SNiP, the longitudinal rods must be at least 0.1% of the cross-sectional area of \u200b\u200bthe tape. For example, if the height of the strip foundation is 1200 mm and the width is 400 mm, then, based on the calculations, the minimum total cross-sectional area of the rods is 480 mm2.

The reinforcement scheme depends on the minimum content of longitudinal bars and their minimum diameter. So, according to the norms of SNiP, the longitudinal rods must be at least 0.1% of the cross-sectional area of \u200b\u200bthe tape. For example, if the height of the strip foundation is 1200 mm and the width is 400 mm, then, based on the calculations, the minimum total cross-sectional area of the rods is 480 mm2.

The figure obtained in the previous calculation must be divided by the section of the selected reinforcement. This will be the approximate number of longitudinal rods for the frame.

But you can choose the number of rods of a certain diameter according to the table:

| Number of rods | |||||||||

| Diameter, mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 6 | 28,3 | 57 | 85 | 113 | 141 | 170 | 198 | 226 | 254 |

| 8 | 50,3 | 101 | 151 | 201 | 251 | 302 | 352 | 402 | 453 |

| 10 | 76,5 | 157 | 236 | 314 | 393 | 471 | 550 | 628 | 707 |

| 12 | 113 | 226 | 339 | 452 | 565 | 679 | 792 | 905 | 1018 |

| 14 | 154 | 308 | 462 | 616 | 769 | 923 | 1077 | 1231 | 1385 |

| 16 | 201 | 402 | 603 | 804 | 1005 | 1206 | 1407 | 1608 | 1810 |

| 18 | 254,5 | 509 | 763 | 1018 | 1272 | 1527 | 1781 | 2036 | 2290 |

| 20 | 314,2 | 628 | 942 | 1256 | 1571 | 1885 | 2199 | 2513 | 2828 |

Reinforcement, depending on the steel grade, has different tensile strength

In addition, the minimum allowable diameter of the reinforcement bars should be taken into account.

Depending on its use, it will differ:

In order to perform the calculation of materials for reinforcing the tape base, it is necessary to measure or calculate the length of its tape and multiply by the number of longitudinal rods at all levels.

In order to calculate the required number of transverse rods, the number of clamps to be installed is calculated (the length of the tape is divided by the distance between the clamps) and multiplied by the length of the reinforcement required to make one clamp. In the same way, a calculation is made if not clamps are used, but pieces of reinforcement.

In order to calculate the required number of transverse rods, the number of clamps to be installed is calculated (the length of the tape is divided by the distance between the clamps) and multiplied by the length of the reinforcement required to make one clamp. In the same way, a calculation is made if not clamps are used, but pieces of reinforcement.

How to properly reinforce the strip foundation with your own hands

When the calculation is completed, the required number and cross-sectional diameter of the longitudinal rods for reinforcing the strip foundation are selected, it is necessary to select a knitting pattern for the frame.

There are several options. It is better to choose a simple and reliable one. Sometimes a scheme is chosen according to which only the lower or only the upper part of the tape base is reinforced. But this should not be done. After all, the foundation is influenced by the weight of the house itself, on the one hand, and on the other hand, the force of frost heaving of the soil can cause stress in the upper parts of the foundation. Hence, it is necessary to reinforce both the upper and lower parts of the base.

The middle part can just be ignored. But if the number of reinforcing bars is such that it cannot fit in two rows (top and bottom), then, of course, you should think about arranging an additional tier in the middle.

It is better to think over and apply a simple reinforcement scheme from a square or rectangle. Then, if at the same time the axes of the frame are made correct, then the base itself will be strong and stable.

Frame installation

It is necessary to take into account in advance the compatibility of the length of the foundation with the length of the supplied reinforcement. This will help reduce the number of joints and save material resources.

Specialists it is recommended to make a footing before installing the frame. Such a sand and gravel cushion is performed as follows: the base of the foundation is poured with a concrete solution with a layer of 5-8 mm and it is expected to solidify.

If it is decided to do without footing, then stands are installed under the lower rows (tiers) of reinforcing bars. At the same time, it is ensured that a gap of at least 15 mm is obtained between such a pillow and the reinforcement so that the concrete solution can penetrate from below and thereby strengthen the reinforcement.

For mounting horizontal rows most often use round ribbed reinforcement, the diameter of which is 10 -16 mm. Longitudinal rods can be connected with horizontal transverse reinforcement. Longitudinal reinforcement rods are fastened with overlapping reinforcement not less than 50 cm long.

If at the same time the height of the strip foundation is more than 0.15 m, the upper and lower levels must also be fastened with vertical reinforcement bars. For this, smooth reinforcement with a diameter of 6-8 mm is often used. It is recommended to use rod clamps as transverse and vertical reinforcements, which are bent like a frame and mounted according to the size of the frame.

But, no matter what scheme of reinforcing the strip base is chosen, one must not forget that the distance between the reinforcement and the formwork, as well as the top layer of concrete pouring, should not be less than 15 mm.

The rods are connected to each other with a soft steel knitting wire.. To facilitate the work, you can use special devices. For example, a knitting hook. It can be purchased at the store, or you can do it yourself. All you need is a piece of rebar and a wooden or plastic handle.

The hole inside the handle should be such that the core, together with the hook, can rotate freely when tying the wire. So, it is folded in half and brought under the joint of the reinforcement. With the sharp part of the hook, hook the loop of wire and make 2-3 turns, tying it to the other end. In this case, do not tighten it tightly so as not to break it. Some use welding. But experts do not recommend using it, because. joints are often corroded.

When performing work, it is necessary to ensure that the diameter of the longitudinal rods for the strip base is the same and is placed evenly across the width of the entire foundation. If for some reason the diameter of the rods is different, then the reinforcement of a larger diameter is placed in the lower part of the tape. It should be strictly ensured that the reinforcement bars of the upper level of the frame are placed above the gaps between the bars of the lower level.

Craftsmen adapt a homemade crochet hook to a screwdriver and, thereby, dramatically speed up the process of knitting a frame

Reinforcement of the strip foundation can be done by hand without purchasing expensive tools. It is enough to follow the technological sequence and use materials of the recommended sizes. In this case, the life of the base will be long.

For more information on how to properly reinforce the foundation with your own hands, you can watch the video: