How to make a cold smoked house. Homemade smokehouse - manufacturing, schemes, principles, types and secrets of smoking

Smoked meat and fish are famous delicacies. A wide variety of types of smoked meats can be bought in stores, but can factory-made products from a store be compared with home-made products? Therefore, some summer residents and owners of private houses who breed poultry and animals or are fond of hunting and fishing are thinking about purchasing a smokehouse. Its high cost can be a serious obstacle to this, but almost anyone can make a smokehouse on their own. To do this, you only need a properly selected drawing, suitable materials and a little time.

Features and Benefits

Making a smokehouse is a much less complicated and time-consuming process than it might seem at first glance. Of course, it all depends on the type that the owner decides to install on his site, but some options can be made on your own in just a few minutes. A homemade smokehouse in most cases will cost much less than a purchased one. It can be made from improvised materials, from old things that are no longer used on the farm, but have retained their properties.

A good and convenient smokehouse, corresponding to the size and volume of the summer resident's wishes, can be quickly made with your own hands right at their summer cottage.

Properly selected wood for smoking and temperature conditions allow you to create delicacies that are completely unique in taste and aroma on your site, which are very difficult to find on store shelves.

Types and purpose

There are two main types of smokehouses, one of which is suitable for hot smoking and the other for cold smoking. They differ from each other mainly in the manufacturing technology of the smokehouses themselves and the temperature maintained in the smoking chambers. Products depending on the method of smoking will also have a slightly different taste. With equal success, these smokehouses can be used for smoking meat, game, fish, lard, sausages.

First of all, it is worth considering cold smoked smokehouses. Their main feature is a long elongated chimney, which allows for complete combustion of flue gases.

Such smokehouses, in addition to the chimney, have two main blocks: a firebox and a smoking chamber. All harmful substances settle on the walls of the chimney, and the meat acquires a barely noticeable fragrant smoke. To manufacture a product in this way, it will take from three days to a week, and the shelf life of products produced using such smokehouses can average from three to twelve weeks.

In smokehouses designed for hot smoking, products are cooked much faster: the whole process takes from a quarter of an hour to several hours, it all depends on the size of the original product. In smokehouses of this type, it is customary to use not firewood, but special wood chips, which causes some structural features. So, the firebox in these smokehouses is located directly under the most hermetic chamber intended for smoking. The tightness of this chamber ensures uniform heating of the entire mass of the product.

In addition, there are universal smokehouses, which are a cross between cold and hot smokehouses.

In addition to a stationary smokehouse, there are also camping or portable mini-smokers: they look like a box with a lid. Such a simple design is very convenient: you can take it with you, for example, on a fishing trip or on a picnic.

What can be built from?

To make a smokehouse with your own hands, you can use a lot of improvised means - household items that have served their purpose are suitable, which are brought to the country in large quantities in the hope that someday they will find a use.

A wooden barrel is suitable for the smokehouse chamber, and the larger it is, the better, but for a small home production, a capacity of 50-100 liters is enough. However, it is important to remember that in no case should you choose resinous and tar-producing tree species. Spruce, pine, maple and birch are definitely not suitable. The best options would be trees such as cherry and apple, oak or alder.

In addition to the barrel, you can use any large metal box: an old refrigerator will do (this will even allow you to combine a smoke generator and a dryer in one block). It will turn out to make a camera, for example, from a gas stove. In the end, an ordinary metal bucket, an old pan, flasks, a medical bix or even an old fire extinguisher can serve as a container for a portable smokehouse: two grates are inserted inside, between which there will be meat or fish, and the bottom is covered with a thin layer of sawdust.

However, using metal elements in the manufacture of smokehouses, it is worth giving preference to items made of "stainless steel". Of course, this is a rather fragile and more brittle material that is more difficult to process, but it has a number of undoubted advantages: firstly, it is resistant to chemical components that smoke carries, and secondly, it does not oxidize at high temperatures and does not rusts, thirdly, it is easy to clean it from soot, soot and traces of fat.

If a smokehouse for the owner is a necessary attribute of a suburban area, then you can build a solid brick smokehouse. Its dimensions will correspond to the wishes of the owner, the main thing will be to ensure the correct flow of smoke into the smoking chamber. For the source of heating in such smokehouses, potbelly stoves connected to the chamber by a pipe are usually used.

How to prepare drawings?

If the smokehouse should become a functional element of the decor of a suburban area, then, of course, the drawings should be done by yourself. However, if there is no need for this, then it is better to use ready-made drawings. This is especially true for non-professionals, as this will help to avoid errors and inaccuracies. But even in this case, one should take into account the dimensions of the container, which it was decided to use for the main camera. Most likely, the scheme will still have to be slightly changed.

It is worth remembering that hot-smoked smokers are convenient due to their small size, and cold-smoked ones are rather bulky, but they allow you to produce products with a richer taste and longer shelf life. Mini-smoking sheds are distinguished by their simplicity of design.

Accessories

Despite the variety of items from which a smokehouse can be made, each design must have several indispensable components in order to make the smoking process convenient and technologically correct. In addition, during work, you should have some tools at hand - at least a welding machine and a grinder.

There must be at least one grate in the main chamber of the smokehouse. Products for smoking will be laid out on it. Such a lattice can be made from thin reinforcement.

The smoking chamber itself must be airtight. This will ensure that the products are evenly heated, and will also prevent the smoke from escaping ahead of time. In addition, if the dimensions of the smokehouse allow, the chamber should be provided with several smoking hooks.

Under the grate there should be a tray for smoldering chips and sawdust, and even lower - a box for ash. There may also be a heat source that provides smoldering sawdust. The third important element is the pallet, on which fats and juices will drain; it must be cleaned after each smoking session.

You can install a smokehouse on a fire, on gas, and even, if dimensions allow, on an electric stove.

An important design detail is the smoke generator. Of course, small smokehouses that work on the principle of hot smoking have it directly in the smoking chamber: the production of smoke is provided by sawdust, which is lined with the bottom of the chamber. For cold smoked smokehouses, artificial conditions for the formation of smoke will have to be created, because its total temperature should not exceed 35 degrees Celsius. Therefore, often for such smoke generators an electric heating element with a built-in thermostat and temperature sensors is used.

To improve the quality of smoking (in the case of a hot-type smokehouse), it is possible to install an additional fan or compressor in the design. They will provide additional more powerful pumping of smoke, so that smoked products will warm up and cook faster.

Sometimes a lid with a water seal is added to smokehouses: it is a small recess located along the perimeter of the smoking chamber, into which water is poured. This device creates a barrier that prevents air from entering the chamber and does not release smoke from the chamber.

Assembly Instructions

The variety of items from which it is possible to make a smokehouse raises legitimate questions about how to properly make a smokehouse at home. In fact, knowing the general technology and processes that products undergo during the smoking process, you can independently develop not only a diagram, but also step-by-step assembly instructions. However, for example, it is worth considering some of the most common and convenient options for making smokehouses.

The simplest design of polyethylene film

To make such a cold smoked smokehouse, you will need two meters of a very dense film, which is sewn together in the form of a bag. The dense film used by summer residents for greenhouses and greenhouses is best suited.

Next, you need to find a flat area on the site about one square meter in size. The platform is upholstered with high wooden stakes to fit the size of the film about two meters in height, and the stakes themselves are interconnected by thin transverse beams to give stability to the structure. Then the opposite stakes will need to be connected with diagonal bulkheads in approximately 2-3 rows. After that, the products prepared for smoking are hung on the rods so that they do not touch each other, and a prepared plastic bag is pulled over the structure - not to the very ground, a small space is left.

Burning coals are poured under the structure and covered with grass, after which the film is stretched to the ground and carefully clamped from all sides to give the entire structure tightness.

Products for cooking in such a smokehouse will take approximately three hours, after which the bag is removed and the products are aired. Particularly large pieces may need to be smoked again.

From a bucket

To make a similar smokehouse model, you will need an old bucket. One or two "stainless steel" gratings are placed inside it. If there are two grates, then the first, smaller one, is set about 10 cm from the bottom of the bucket, and the second is slightly higher. Then the bottom of the bucket is abundantly sprinkled with wood shavings or sawdust.

The smokehouse from the bucket is ready, it remains only to put the products for smoking on the nets, put the structure on the fire and cover with a lid.

From the barrel

The most traditional and simple option is to make a homemade smokehouse from a wooden or metal barrel. The principle of its manufacture is the same as in the case of a smokehouse from a bucket; the main difference lies in its much larger size, which allows you to equip the barrel not only with grates, but also with hooks for smoking.

A barrel can make a smokehouse for both types of smoking which can be very handy. In the first case, the heat source - the hearth, should be located directly under the barrel. For cold smoking, the barrel is installed in a pit, to which a chimney is drawn (approximately two meters long) from the hearth.

You can make a more complex version of the smokehouse, for which you will need not one, but two barrels.

The most convenient option would be to use two identical barrels with a volume of approximately 200 liters. They need to be welded together in the shape of the letter "T". The lower barrel will serve as a container for the future firebox, an opening is cut out on the side and a door is installed. The valve at the bottom of the furnace will allow you to adjust the intensity of combustion. The upper barrel will serve as a future smoking chamber: it is necessary to firmly and firmly fix a strong grate in it, on which smoked products will subsequently be laid out, and besides, it will be possible to cook barbecue on it. Plus, it can be used as an oven, placing baking dishes or simply foil-wrapped products on the grate.

For smoking, it will be necessary to arrange a brazier for sawdust in the lower firebox, while an open fire is bred under it. Sometimes sawdust is poured directly into wood coals, but this is a more laborious method that requires constant monitoring and attention. Otherwise, the products may burn and lose the necessary taste.

Then it remains only to hang the products over the grate, and put a tray on it, in which the flowing fat and juices will be collected. By the same principle, smokehouses are made from an old gas cylinder.

From an old refrigerator

Many summer residents prefer not to get rid of old non-working equipment, but to take it to the country. If you save a non-working refrigerator from the electric stuffing and other "insides", then the remaining box can be turned into a convenient and roomy smokehouse.

A small hole must be made in the roof for the future chimney. Inside the box, at different levels, six corners should be installed in pairs, on which grills for the tray and products and hooks for smoking, as well as a tray for fat flowing from the products, will subsequently be located. In addition to the fat pan, you will also need a sawdust or shavings pan; it is installed at the very bottom of the structure.

It is also important to ensure that the refrigerator door closes as tightly as possible and does not allow excess air to enter the chamber.

metal

This product already requires a more serious approach, but it is easy to weld it yourself. The simplest and most convenient shape for the master is a rectangle, while stainless steel is most often preferred as a material: it is easy to clean, withstands high temperatures well and has a long service life. But at the same time, "stainless steel" is quite difficult to process. Another material to look at is cold rolled steel: it is quite ductile, can withstand temperatures up to 650 degrees Celsius, but is prone to oxidation and rust.

By itself, this design resembles a box, to the walls of which corners are welded with gratings installed on them.

First you need two sheets of metal, one of which is divided into four parts, which will be the same if you plan to make a square oil lamp. You can divide the sheet with a grinder. Then, at an angle of 90 degrees (a carpenter's angle is used for this), the sheets are welded to each other, forming a box. To ensure tightness of the future smokehouse, it will also be necessary to boil the internal seams of the chamber. The bottom of the oil lamp is cut out of another metal sheet and welded to the box in the same way.

Finally, you can start making the camera cover. To do this, the grinder cuts four identical strips of a sheet of metal (preferably stainless steel) a little larger than the characteristics of the outer part of the box. Then the resulting cover is welded.

The last details will be the lower mounts for installing a tray in which fats and juices will be collected, and the upper ones for placing hooks on which lard, meat, fish or sausages are hung. It is also worth attaching a pair of handles around the edges of the smokehouse to make it easier to carry.

An ordinary electric stove can be used as a heat source for such a smokehouse. If you need to get higher temperatures, you can just as well place a smoker over a fire.

From a gas bottle or fire extinguisher

The process of making a smokehouse from a gas cylinder is somewhat complicated, but it is quite suitable for those who have this completely unnecessary thing on the farm and want to find at least some use for it.

To begin with, it is necessary, observing safety precautions, to release the remaining gas from the cylinder, and then carefully saw off the trigger valve. The remaining gasoline is also drained from the cylinder into any metal container and burned. Then the cylinder is well washed, a door is cut out in its wall through which products will be placed inside. Hinges are welded to the cutout site, on which the door will be held. Metal strips are cut from the bottom of the cylinder and half of the bottom is sawn off to provide the future smokehouse with a firebox. Finally, the firebox itself is made of metal sheets and welded to the cylinder, after which the entire structure must be calcined on fire.

Of brick and stone

Such a smokehouse is easy to manufacture, but rather complicated in its design. During construction, you will not need to use a grinder and a welding machine, however, the slightest mistake in the location of the chimney can render the finished smokehouse unusable. The advantage of this smokehouse is that it can be adapted for both cold and hot smoking methods: such a two-mode design turns out to be very convenient and multifunctional.

First you need to prepare the foundation for the future smokehouse. Due to the fact that brick and stone are heavy, it is impossible to mount such a structure directly on the ground: the earth may settle and the structure will be destroyed. It will not be superfluous to strengthen the foundation with the help of a lattice of reinforcement.

Then, when the foundation is ready, you can start laying the lower belt of the walls, and after that - the tunnel chimney. Its length is approximately two meters, and the pipe itself is well insulated to allow both cold and hot smoking. The insulating material can be any mineral insulation that can withstand high temperatures. Suitable, for example, glass wool.

By itself, the design of the future smokehouse should remain hollow. This can be taken into account and further use of empty niches for storing sawdust, firewood, etc. The highest temperatures will be observed directly in the furnace and in the furnace, so they will need to be made of refractory bricks. The remaining parts of the smokehouse can be laid out with any other types of bricks, even decorative ones.

Finally, you can start building the second brick belt. It will need to be separated from the first one with an even concrete screed or a concrete slab. Just as in the case of the foundation, it would be better to strengthen the layer with a steel reinforcement grid. Two chambers stand out, one of which will serve as a smoking chamber, and the second will become the basis for the Russian stove.

After that, the oven itself is built on. Since there will always be high temperatures here, as mentioned above, it must be built from refractory bricks. The advantage of this design is its versatility: it will serve not only as a source of heat for the smokehouse, but will allow you to bake food and even barbecue.

After the construction of the furnace, a smoking chamber is built next to the chimney: it can do without any additional finishing. The only thing is that it will be necessary to provide it with a tight hermetic door, preferably wooden, made of hardwood; cherry or apple trees are ideal.

Then, when the smoking chamber is built on, a pipe is attached to it at the top, providing smoke removal. Adjusting the draft in the pipe will allow the owner to produce both cold and hot smoking in one smokehouse - everything will depend on the intensity of sawdust burning in the furnace. With a low fire and a wide pipe diameter, the smoke will have time to cool enough to ensure cold smoking; if you limit the draft in the pipe and increase the intensity of combustion, then hot smoking will be carried out.

Chimney

The construction of a chimney for a stationary smokehouse is an important step that should be considered separately. You should not make it from brick and other porous materials, as the brick will actively absorb harmful substances from the smoke and moisture that comes through it. Accumulating these substances, over time, it will acquire an unpleasant odor, which will adversely affect the quality of the products prepared in the smokehouse.

Metal is best suited for the chimney, but even in this case, it will need to be cleaned regularly and the soot accumulated on the walls removed.

Many owners of home smokehouses prefer a chimney that is dug into the ground: thus, the soil qualitatively cools the smoke (which is especially preferable for cold smoking), and also absorbs the condensate that forms on the walls. Bacteria and microorganisms living in the soil process dangerous carcinogens contained in this condensate.

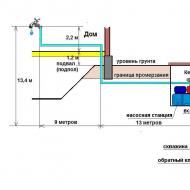

To make a smokehouse with such a chimney, a site with a small slope is located or artificially poured in the summer cottage, which will subsequently provide natural draft to the smoke. The smokehouse firebox is located under the slope, and a small groove is dug on the slope itself - the future chimney. It is covered with iron sheets, on top of which a layer of soil is poured, designed to create improved thermal insulation. Such a chimney is brought up to the smoking chamber.

In the next video you will see how to make a smokehouse from a barrel with your own hands.

Where is the best place to place?

It is very important to find the right place for a stationary smoker: this is not a small portable structure that can be stored at home or in the garage and taken out when needed.

When choosing a place, it is worth remembering that a large amount of smoke will come from the smokehouse, which should not enter the living quarters in the country. In addition, harmful substances can harm trees and other green spaces. Therefore, it will be quite difficult to choose the ideal place on the leeward side, moreover, it is purely individual for each house. The resulting products can be stored in the cellar, as long as the room is dry and cool.

The right smokehouse should take into account three main points, and the summer resident, engaged in the construction of such a structure, must also remember them. Firstly, uniform heating and fumigation should be carried out in the smoking chamber. Secondly, the smoke itself for smoking should be very light, not carrying harmful substances and heavy decay products that can give the meat an unpleasant taste. Thirdly, the design must be airtight to ensure uniform penetration of smoke into all layers of meat; additional smoke generators can serve the same purpose.

By the way, the smoke generator can be assembled on your own. A body is made of a metal can, a hole is drilled from the bottom to ignite the wood chips, and the upper part is tightly closed with a lid. A cooler from a computer can become a compressor. The whole structure is assembled with the help of welding air, and then it remains only to kindle sawdust or wood chips and turn on the cooler. The peculiarity of the smoke generator is that the built-in cooler does not push out the smoke, but draws it. Therefore, it must be connected directly to the smokehouse.

Traction is a prerequisite for smoking. It is not enough just to put the product in a chamber filled with smoke. Otherwise, meat / fish will simply evaporate, as a result of which it will acquire an unpleasant aftertaste. This is critical for cold smoking, in the case of hot smoking, everything is a little different, but it’s still worth following this rule.

To give the meat a rich taste, you should especially attend to the selection of the right tree species, the logs of which will be most fragrant when burned.

You should not, for example, use only birch logs in the smokehouse, as the meat can get an undesirable bitter aftertaste. Yes, and birch logs will first have to be cleaned of bark. It is also strictly forbidden to use coniferous trees for smoking. The reason for this is the abundant content of resins. It is best to add sprigs of juniper and cherry leaves to the logs: they will add pleasant notes to the aroma of meat. If there is a need to give the meat a certain color, then certain types of trees can also be used. Mahogany will give the meat a golden hue, alder and oak will give a deep yellow color, and hardwoods will give golden yellow tones.

In general, fruit trees like apples and pears and cherries have the most pleasant aroma. This is especially convenient for summer gardeners, who can use old tree branches for a smokehouse directly from their site.

Also, different tree species are used for different types of smoked meats: even if these types of trees do not grow in your summer cottage, it will not be difficult to purchase the appropriate wood chips in the store. So, alder chips remain the most versatile, on which almost any meat, lard, fish and even vegetables are smoked. Oak sawdust is used primarily for red meat and game. Willow and birch, which have a specific bitter taste, are used when smoking large game like elk or bear. And cheeses, nuts, vegetables and fruits are smoked on the softest cherries and apples.

Firewood and pieces of wood added to the hearth for aroma should not be larger than 5-10 cm in size. Larger pieces are more difficult to heat to the extent that they begin to char.

Before you put the log on the fire, it will not be superfluous to slightly moisten it: damp wood gives off abundant smoke, which is very important for smokehouses. However, do not overdo it with moisture: if too much steam is generated, the products will get soaked, which will significantly reduce their shelf life. In addition, to get a good plentiful smoke, after the formation of coals in the furnace, it is worth closing the pipe valve. At this point, active combustion stops, but sawdust that forms smoke begins to smolder.

To improve the quality of products, it is best to provide the fire with an active supply of oxygen. At the same time, it is impossible to fan the flame in the smokehouse: it is important that the firewood smolders, but does not burn.

It is very important to provide smoked products with a continuous supply of smoke from the beginning of cooking until its completion. This should be taken into account when placing pieces of meat or fish of different sizes in the smokehouse: small ones will be ready much earlier than large ones. For the latter, you will have to additionally pour sawdust and shavings into the pan, thus maintaining a constant temperature. However, do not forget about the danger of over-smoking products: the process must be carefully controlled and periodically check products for readiness.

Another method that significantly speeds up the smoking process is the preliminary boiling of meat or lard in water with salt and spices.

The optimum temperature inside the smoking chamber should range from 60-90 degrees Celsius. Even without temperature sensors, adjusting the temperature is quite simple: water in a small container, placed on the lid of the smoking chamber, should not boil. For cold smoking, slightly lower temperatures are chosen, for hot smoking, higher temperatures, sometimes reaching 120 degrees Celsius.

By the way, you can smoke not only meat, fish, lard or sausages. Smoked nuts, vegetables and fruits have interesting tastes. Special mention should be made of smoked cheeses. It all depends on the temperature inside the smokehouse and the sawdust and wood chips used inside.

Before the smoking procedure, it is better to place the products for some time in a separate drying cabinet, which allows you to get rid of excess moisture and thereby increase the shelf life of the product. It is easy to make it yourself: just take a volumetric box with a tight sealed lid, into the side of which a fan is inserted. Before placing the product in the cabinet, it is better to pre-salt. In the closet, he will have to spend from one to three days until completely dry.

Large stationary smokehouses can only be installed in the country or, in the case of living in the private sector, on the territory of your own home. Such structures require a lot of free space, in addition, they produce a lot of smoke, which can harm plants, enter the house and disturb neighbors.

» From the material presented by the author, you will learn how you can independently make a cold smoked smokehouse from wood and metal. Namely, the firebox and pipe will be iron, and the smoking chamber will be made of wooden beams and boards (linings of hardwood).

By building a smokehouse on your site, you can smoke products at any time convenient for you, as well as your smoked meats are much tastier and safer than store-bought ones, which are completely saturated with chemistry. You can also smoke for sale and start your own small business, smoked meat on the market leaves instantly).

The process of cold smoking takes place at a temperature of 15-25 C 0 The duration can vary from 1 day to a week, it all depends on the temperature and quantity, type of product put into the smoking chamber. Unlike hot smoking, here the meat is dried and moisture gradually comes out of it, saturated with fragrant smoke.

And so, let's look at what exactly the author needed to create a cold smoked smokehouse?

materials

1. metal pipe 150mm

2. pipe 80 mm

3. steel bar

4. bolt

5. wing nut

4. metal sheet 1mm and 3mm

5. wooden beam

6. lining

7. nails

8. self-tapping screws

9. roofing material

10. thermometer

11. rail

Tools

1. welding machine

2. grinder (UShM)

3. hacksaw

4. hammer

5. drill

6. ruler

7. tape measure

8. pencil

9. screwdriver

10. pliers

Step-by-step instructions for creating a cold-smoked smokehouse with your own hands.

First of all, the author creates a smoking cabinet from a bar and a board, it is advisable to use hardwood lining, because if you take a pine board, when directly heated during the smoking process, the board will begin to release resin and a characteristic pine smell.

A timber 5x5 cm long 1.8-2 m was taken and a frame was made, lining 15 pieces 3 m each, size 10x1.8 cm.

The bottom of the smoking chamber must be at least 50 cm from ground level.

The frame is sheathed with clapboard, this material is very good, because the board fits the board tightly and there are no gaps.

Spacers are installed inside to strengthen the structure.

The door is also made of timber and lining.

It is hung on hinges and screwed with self-tapping screws.

A hole is sawn in the bottom of the smoking chamber for the installation of a metal adapter for connecting the chimney pipe.

In front of the pallet, a lining with a handle from a tool cabinet is attached.

In the smoking chamber itself, metal troughs are made under the bevel, so that the fat flows down into the pan.

This stove has a steel bar grate inside, and an adapter for connecting a chimney pipe in the back.

At the bottom of the door, 10 holes are drilled, they are necessary for the formation of traction.

The stove is painted black with heat-resistant paint. A metal damper is screwed to adjust the thrust.

The chimney is prefabricated and has several elbows, that is, the length can be adjusted along the length.

A corner adapter is screwed to the bottom of the smokehouse.

All elements are assembled into a single design.

Firewood is laid in the firebox and a fire is made, after the firewood flares up, the door closes, and the holes at the bottom are blocked by a damper, that is, it is necessary to adjust so that the firewood smolders, and does not burn at full strength.

Smoked fish or meat are foods loved by many. Of course, this food is considered a gastronomic time bomb, as it is harmful in almost every sense. But from time to time to treat yourself to a smoked delicacy is not a sin.

Smoked beef, lard, and any kind of fish go well. To diversify your diet at a picnic, you can buy a ready-made dish at your own peril and risk, or you can cook this delicious treat yourself if you build a high-quality cold-smoked smokehouse with your own hands in your country house or backyard.

Types of smoking

What is smoking? This is a slow cooking process by exposing the raw product to the smoke that comes from smoldering wood. Thus, meat or fish does not overheat and is not exposed to open fire, and indeed high temperatures. Many cooks are sure that the right choice of smoldering wood species is extremely important for giving the dish one flavor or another.

In total, there are three options for cooking dishes in a smokehouse:

- Hot is the fastest way to cook a product. Meat or fish without excess fat is hung over a source of open fire, exposed to smoke heated to 80-140 degrees. The temperature depends on the type of product being cooked.

- Semi-hot. In this variant, the smoke is cooled with a short pipe. In this case, the temperature of the smoke drops to 50-60 degrees. Cooking in this case takes about a day.

- Cold is a variation of dried meat or fish. The raw product is cooked in smoke, which cools down to 15-40 degrees. In order to cool the stream of combustion waste to such a temperature, a special structure is constructed: a small trench is dug between the hung products and smoldering wood or a long pipe is laid. This method takes more time - at least several days, but the shelf life of the finished product increases significantly.

The smokehouse is designed not only for cooking meat or fish products, but also dairy products, as well as vegetables and fruits, which at the same time acquire new flavor notes. There are many ways to carry out the cooking process in a smokehouse.

The design of a typical smokehouse

Thus, the device of the smoking unit will also depend on the chosen method of preparing smoked meat or fish. If you want to do it, you can’t expect any difficulties - it’s quite possible to construct a decent smokehouse from any metal object at hand, even from an old rusty bucket. In the same case, if it is decided to cook the dish using the cold smoking method, building a smokehouse with your own hands will be somewhat more difficult. You will have to spend a little more time disassembling the device, planning and building the smokehouse itself. But this task is not impossible either.

Thus, the device of the smoking unit will also depend on the chosen method of preparing smoked meat or fish. If you want to do it, you can’t expect any difficulties - it’s quite possible to construct a decent smokehouse from any metal object at hand, even from an old rusty bucket. In the same case, if it is decided to cook the dish using the cold smoking method, building a smokehouse with your own hands will be somewhat more difficult. You will have to spend a little more time disassembling the device, planning and building the smokehouse itself. But this task is not impossible either.

Like any cooking appliance, cold type smokehouse can be made in two versions:

- Stationary, in which it is imperative to build an efficient chimney of sufficient length, which will cool the smoke to the desired temperature. But it is not enough to move the cooked product away from the flame - you need to properly direct the smoke coming from the firewood, which will require good traction. Accordingly, the chimney must have sufficient height. The type of chimney can be anything: it can be built of brick, galvanized or stainless steel pipes - it all depends for the most part on aesthetic preferences. Do not use only asbestos and polymer chimneys, as they can impregnate food with toxic emissions.

- Mobile option smoking unit does not require the construction of a chimney. In this case, a dug ditch of sufficient depth, width and slope will be involved in transporting the smoke.

Read also: Stainless steel smokehouse

Instead of a full-fledged heat source in the smokehouse, a simple smoke generator can be used, the use of which greatly simplifies the assembly of the smokehouse. You can fill this device with small wood fuel - chips or sawdust.

The simplest smoke generator is constructed from any steel container in the form of a cylinder - for example, a large thermos, from which the flask is removed and used as a simple oven.

To begin with, you should consider the general principles of building smokehouses with your own hands, after which - the design features of a wooden smoking chamber.

Technology for designing a fixed smokehouse

In order to get a high-quality and durable cold-smoked smokehouse, which will stand motionless in the summer cottage, You will need very few materials: several sheets of slate, a durable brick, a chamber for the cooked dish (bucket, barrel or cistern, depending on the planned cooking volumes - the smokehouse can have a steel or wood container), as well as a metal grill.

In order to get a high-quality and durable cold-smoked smokehouse, which will stand motionless in the summer cottage, You will need very few materials: several sheets of slate, a durable brick, a chamber for the cooked dish (bucket, barrel or cistern, depending on the planned cooking volumes - the smokehouse can have a steel or wood container), as well as a metal grill.

The process of building a smokehouse with your own hands takes place in several stages:

Read also: Finnish smokehouse Suomi

If the place chosen for the construction of the smokehouse has damp or loose soil, a foundation should be made under the chamber. To do this, you need to dig a rectangular pit that matches the size of the structure. The depth of the pit should be at least 30 cm.

The structure of the foundation should be like this:- the bottom of the pit is covered with large gravel;

- walls are formed from foam concrete blocks or monolithic concrete, for which formwork needs to be built;

- blocks are reinforced with a metal reinforcing mesh with large cells;

- the rest of the volume is filled with cement-sand mortar, prepared with a ratio of cement to sand of 1:3.

If the soil is sufficiently reliable, and its erosion by groundwater or other waters is unlikely, you can not build a full-fledged foundation and get by with just a brick pedestal.

Designing a mobile smokehouse

To build a camping version of the smokehouse, you will need a sufficient amount of dense polyethylene film, as well as a lot of any available material at hand: fresh tree branches, good boards, twigs. Of course, a mobile smokehouse can only be built with your own hands.

The design of the smokehouse takes place in four simple steps:

- A suitable site is selected at the halt site: a gentle slope or shore of a reservoir. The side to which the surface of the earth is facing must be windward so that the smoke does not fly away where it should not. As in the stationary version, a straight ditch of the same size is dug - 3 m long, 50 cm deep, the width does not matter. The ditch may slope to the horizon, but the angle should not exceed 60 degrees.

- The ditch is covered with found branches and boards and sprinkled with earth and turf. A fire is made at the lower end of the ditch, and a smoking chamber is set up at the upper end.

- In this case, the assembly of a solid container for cold smoking is not required; an ordinary frame made of boards is suitable, which should be covered with polyethylene. An exhaust slot is cut from above.

- In the resulting improvised chamber, cooked meat and fish are hung. In order for the cooking process to start, the fire must be burned out, only heated embers should remain. After all the flames have disappeared, the pit is covered with a dense cloth, leaving a gap to provide traction. The width of this gap is selected so that the coals smolder well, but do not flare up.

Assembling a smoking chamber made of wood

So, a cold smoked smokehouse consists of three main elements: a heat source, a chimney and a smoking chamber. And if the first two elements in any unit are similar, then when building the third one, you can let your imagination run wild. A good option would be to build a camera out of wood with your own hands, as it is quite simple, environmentally friendly and aesthetically pleasing. With high-quality assembly and decent wood processing, such a smokehouse will last a very long time.

So, a cold smoked smokehouse consists of three main elements: a heat source, a chimney and a smoking chamber. And if the first two elements in any unit are similar, then when building the third one, you can let your imagination run wild. A good option would be to build a camera out of wood with your own hands, as it is quite simple, environmentally friendly and aesthetically pleasing. With high-quality assembly and decent wood processing, such a smokehouse will last a very long time.

Smoked meat or fish is a delicious delicacy. In order to regularly pamper yourself with such a dish, it is not necessary to go shopping. You can cook smoked goodies right at home in a do-it-yourself smokehouse. It doesn't take long to turn your culinary dreams into reality. It is only necessary to study in detail the technology of self-manufacturing of structures for smoking or buy a ready-made one.

Peculiarities

Before you start building a smokehouse, it is necessary to familiarize yourself with some of its features.

- Smoking should be carried out at a temperature of 30-40 degrees.

- Properly cooked food can be stored even without a refrigerator for a year. At the same time, the taste will remain the same, and the quality will not deteriorate.

- The cold smoking process can take up to eight days. Moreover, it is divided into several stages - this is preparation, the smoking itself, which lasts up to five days, then for another three days the product is in the smokehouse itself.

- It has a fairly simple scheme that can be implemented without spending a lot of effort and materials on it.

- In addition, in order for the taste of dishes to be pleasant, it is necessary to make their fumigation process and temperature uniform. Otherwise, meat, fish or lard will be spoiled.

Types and purpose

Cooking smoked meats at home allows you to get delicious dishes, the quality of which you can be sure of. The same cannot be said about the quality of purchased dishes. The process consists of processing food with smoke in the way of cold and hot smoking. Products are very diverse - these are different types of meat, and fresh fat, and fish, and even delicious cheese. Smokehouses also come in two types: hot or cold smoked. They can be safely used for cooking in the country, at home, even when fishing. But for all this, it is necessary to select equipment for household smoking.

Mini smokehouse

One of the most common models is a mini-smoking shed. This design is universal, it has a small weight and is quite convenient and easy to use. Most often, such a device is used in hiking and in summer cottages. It has constant heating, therefore the quality of all materials used to create it is high. It uses stainless steel, the thickness of which reaches three millimeters. In addition, it is resistant to corrosion and high temperatures.

The mini-smoker is heated using an electric or gas stove. In some cases, heating can be done even on a fire. However, the shelf life of products made in this device is very short. At home, they can be stored for a couple of days, but in field conditions, where there is no refrigerator or cellar, the products should be consumed immediately.

There are also electric models that look like a conventional microwave oven. However, they can only be used at home, but not in nature. In addition, this design is small in volume, so there will not fit a lot of products.

For an apartment

The designs of such smokehouses allow you to cook delicious food even in the kitchen of a small apartment. There is no need to travel anywhere. However, there are several requirements for such smokehouses.

It needs to have a chimney. For this purpose, there is a special fitting in the lid where the hose is put on. Then it is brought out the window so that excess smoke goes out into the street, and does not fill the room. If this is not done, then it will get into the apartments of the neighbors through the ventilation pipes.

Another mandatory feature is a water seal, which is a recess between the lid and the wall of the container, which is filled with water. This prevents the smoke from getting in here.

If there is no water seal, then an airtight lid is needed. It also prevents smoke from seeping through.

Automatic

The source of such smokehouses is an electrician. They are used most often in restaurants and food industries. Their loading can be from 40 to 200 kilograms of products. The automation of such models is easy to use, so it does not require great skills from the person who cooks.

All that is needed is to put small chips or wood chips, put a pallet. This is done so that excess fat and moisture flow down there. Next, you can lay on the grate everything that should be smoked. Then the program is selected and the device is connected to the network. This process may well take from half an hour to one hour of cooking.

With tight seal

For cooking outdoors, a household unit with a water seal is the best way. Its design is practically no different from a standard smokehouse. The only difference is a water seal, the purpose of which is to keep smoke and unpleasant odors out.

With smoke generator

The use of this device allows the smoke to continuously enter the chamber where the product is smoked. It prolongs the process of so-called cold smoking for a couple of days. The smoke generator has a very simple device. This is a model that connects a chamber where smoke is produced using sawdust to a smoking chamber. The connection is made with pipes. Since the design is very easy to manufacture, you can design it yourself.

With thermostat

The thermometer helps to control the desired temperature level not only in the smoking chamber itself. There is also the possibility of measuring the temperature of food that is being smoked. The thermometer itself, installed inside the smokehouse, is a probe, in the middle of which there is a tube. Its length is fifteen centimeters. At the end is a display or indicator. The temperature for the preparation of a certain product is selected differently, when cooking, this must be taken into account.

electrostatic

This type of smokehouse is more suitable for use in summer cottages. They are also very often used for production workshops. They come in different sizes and are made from different materials. The set of functions that are in the smokehouse system also differs.

Principle of operation

The device of a high-quality home smokehouse is quite simple. The principle of its operation is that all ingredients are processed with fragrant smoke, not exceeding a temperature of thirty-two degrees. The hot air that passes through the entire pipe is cooled and condensed at the same time, that is, harmful components are precipitated. After this stage, already cleaned smoke goes into the chamber, and the condensate goes into the ground without harming the smoked products.

This ability to adjust is a big plus. It happens due to the fact that slate is located near the furnace. By spreading it, you can release unnecessary smoke through the existing hole. It must be adjusted before all products are loaded into the smoking chamber. After making sure that the smoke is fragrant and does not cause any harm to the environment, you can put the shutter back.

If you need to keep the smoke inside, then this can be done with the help of a damp burlap thrown over it, which is placed on iron bars. The burlap needs to be moistened every couple of hours.

The loading chamber can be arranged directly in the ground, slightly raising its top layer with the help of deadwood. From above it must be laid with fresh walnut branches. Since smoking is cold, it must be remembered that the products are not subjected to heat treatment, but are cooked thanks to light smoke.

Also, the correct process of preparing products, which is divided into several stages, plays a significant role here.

First you need to prepare a salt solution by pouring it into a container of water at a ratio of 40 grams per liter of pure water. After that, you need to mix everything thoroughly. Then you can lay in the brine products intended for smoking. If it is a small fish, then it must be kept in solution for three days, but if it is a very large fish or young pork, then the process will last four days. For tougher meats such as beef, the time is extended by one more day.

The next step is soaking the meat, which lasts from 6 to 24 hours. All this also depends on the product. Readiness is checked by pressing a finger on it. If the meat is pliable and soft, then it is ready.

After that, you can proceed to drying products. To do this, it is necessary that the water completely glass from it. If there is no time, you can blot the surface with a towel. Then you need to place the product in a box or cage, wrapping it with gauze so that flies do not flock, since the deposited larvae are not destroyed during such smoking. This process takes a couple of days. Then the blanks are placed in the smokehouse. After that, you can start smoking.

Dimensions

Such a cooking option as cold smoking implies affordable and uncomplicated cooking of products both in the country house and on fishing trips, and even in an apartment. However, in order for everything to turn out tasty and good, you need to choose the right equipment.

For fishing or hunting, you can take a mini-smoker. It is very popular because it is small and easy to carry. The dimensions of the smokehouse can be 300 by 300 or 200 millimeters, while the thickness of the steel from which it is made is approximately 1.5 millimeters.

You can also take homemade brick or wooden smokehouses. In this case, their sizes will be larger. Such structures can only be placed on your site. It is impossible to transfer them.

Rating of purchased models

The choice of purchased models is very diverse. There are many options for ready-made designs.

Finnish

Among the purchased models, one of the first places is occupied by the Finnish smokehouse. The device has good quality materials. Its base consists of stainless steel, which is most often used in the food industry.

It does not oxidize and does not rust. The smokehouse has a hydraulic lock, thanks to which it is completely sealed, so the smoke does not enter the kitchen. The thickness of its bottom is two millimeters, which allows it to withstand different temperatures. This model has a lot of positive feedback, because the finished product exceeds all expectations.

"Smoke Dymych"

Such a smokehouse is made of cold-rolled steel sheet. It includes a tank with a volume of thirty-two liters, a smoke generator, and a compressor.

Sawdust is placed in the smoke generator. The smoke that they emit enters the smoking container through a hose. It is regulated by an electric compressor. Smoking time - from 5 to 10 hours. Such a device has many advantages: the design is compact, so it can be stored anywhere, it is used both in the city and in the country. The smokehouse is on sale completely ready to use. Customer reviews design has only positive.

Advantages of homemade designs

Building a smokehouse with your own hands has many advantages. It must be installed away from the hearth, and the connection should be made using a long chimney pipe. The smoke coming out of the smokehouse is very useful in the fight against horticultural pests. They can't stand the high smoky air and die.

Homemade smokehouses can also be made from improvised materials, which will not require cash costs. To do this, you can even use a regular barrel. It is better if it is new or made from a simple piece of tin pipe. If the owner wants to make the smokehouse more solid, then material such as brick or wood is suitable for this. This design will allow smoking slowly and efficiently. Plus, it will serve the owner for more than one year.

Which is better?

If there was a desire to buy, and not build a smokehouse, the question immediately arises, which one is best. You should not rush into buying, it is better to understand all the options. When choosing a smokehouse, you must also not forget about its weight. For example, if the box has walls 6 millimeters thick and dimensions are 500 x 500 x millimeters, this option may not suit you.

Also, the choice depends on how the smokehouse will be used. If for recreation on fishing, then you need to take the option where the metal will be equal to 8 millimeters. Such a smokehouse is very light and convenient and will serve until its walls burn out.

For use at home, you can take a heavy stainless steel smokehouse, where the body will be up to two millimeters thick. It will last for many years, especially if you strengthen the body with additional ribs. To cook smoked meats at home, it is imperative to buy a smokehouse that will contain a hydraulic shutter to solve the problem of smoke removal. It can be easily transported from home to summer cottage, while closing the pipe with improvised means.

Material selection

Smokehouses are made from different materials. They can be made from wood, brick, and even from an old barrel. It is worth considering in more detail the design for their manufacture.

from brick

Outwardly, a brick smokehouse resembles a small house, which, among other things, can become an excellent decoration for a personal plot. But before purchasing materials, you need to make drawings and, based on them, buy materials. This will require:

- brick or blocks of foam concrete;

- combustion chamber or silicate brick;

- a cast-iron door for her firebox;

- double-glazed windows for natural light, while windows should be made on the north side;

- sand and cement for mortar;

- wooden beam for the truss system;

- corrugated board or metal tiles for the roof;

- chimney;

- door.

Wooden

There is another material used for the smoking chamber - this is natural wood, which is not only an environmentally friendly product, but also a material that does not emit harmful substances. To create a homemade smokehouse, wood species such as oak or cherry are suitable. The main thing is that they have a structure that will not be afraid of any negative effects of nature.

To make it, you need to purchase the following materials:

- bars;

- boards up to ten centimeters wide, the thickness of which will be one centimeter;

- boards for roof slopes;

- permeable roofing material;

- brick for the firebox;

- solution;

- waterproofing;

- chimney pipe;

- sheet of metal to put in front of the firebox.

Accessories

The design of portable smokehouses is very simple.

It requires the following accessories:

- smoke generator or stove;

- a compressor used to force smoke into the chamber;

- smoking chamber;

- a sealed and tight box, on the bottom of which sawdust or small chips are placed;

- a thermostat so that you can regulate the temperature, because it is different for each product;

- fan.

Manufacturing process

Before proceeding with the manufacture of a smokehouse at home, it is necessary to make drawings of the future structure. Only after that, using the developed scheme, you can build a smokehouse for cold smoking yourself. First you need to decide on the dimensions of the structure, and then choose a place for it.

Having chosen a brick smokehouse, it is necessary to make a project of this design. This will help you save time and choose the right place for installation. The site should have a length of four meters, and it is better if the place is sloping so that the chimney runs at the right angle. Having made the necessary calculations, you can dig a trench.

First you need to lay the foundation. Then, at the place where the smokehouse will be located, it is necessary to remove the soil. The pit should be up to 60 centimeters deep. Then formwork is installed in it, which should be 25 centimeters higher than the edges. Reinforcement is made, and an ordinary bucket is placed in the center of the pit, so that after pouring concrete, a recess is obtained.

Red bricks are used for the walls. The size of the smokehouse depends entirely on the wishes of the owner. In the middle, you can make a small window with access to the north side so that direct sunlight does not harm the products.

The roof of a brick smokehouse is light and easy to arrange. To do it, you need to build a truss system. Or OSB boards or moisture-resistant plywood are laid on them. And only then the tile is laid on a flat base.

For the construction of the furnace, you can use refractory bricks or a ready-made metal furnace. You will need a refractory pipe to remove smoke from the furnace to the smoking chamber. Its diameter must be very large so that the smoke moves slowly and, cooling down, leaves particles of soot on its walls. Above the hole where the smoke comes out, grates are placed and products that need to be smoked are hung.

To build a wooden smokehouse, you first need to dig a trench two bayonets deep. It should accommodate a pipe, a chamber for the furnace and the smokehouse itself. The smoke, falling into the pit, lingers there and is cleaned, and then rises into the smokehouse.

The door to the firebox must be made of cast iron and securely closed. Its base is made of brick, and the walls are led a little up above the ground. Then a wooden structure is placed on it. The trench where the chimney is located is covered with earth, and then well rammed. This is necessary in order for the pipe and smoke to cool.

The base for the camera is made from wooden bars. Then even boards are nailed to it, which should fit very tightly to each other. This is done so that smoke does not escape through the cracks. Then a hole is made in the roof into which the pipe is led.

Any smokehouse, even made in haste, should consist of a smoke generator, a smoke channel and a container used for smoked products. If, while on a hike or at a camp site, you want smoked meats, you can make a smokehouse using rods and plastic wrap.

This design is not at all complicated, but it must be done correctly. The frame is built from poles, a film is thrown on top, and products for smoking can be placed on skewers. Coals from a burnt out fire will serve as an excellent source of heat. For smoke, fresh branches with foliage are suitable. You can build a hearth by digging a hole in the ground or taking an ordinary bucket for this. The advantage of such a smokehouse is the speed of construction and the absence of purchased material. The disadvantage is that it is necessary to constantly monitor the focus.

This version of the smokehouse is perfect for those who go to the country for a while and do not want to build a full-fledged smokehouse in their area.

You can also pay attention to such a structure as a smokehouse from a barrel. Wood or other material is perfect for its base. You can't just use plastic. The bottom of the barrel is removed for the free passage of smoke. In its lower part, you need to make a compartment where firewood will be laid. Here you will need hinges on which the door will be put on. So the compartment can be closed.

Several holes are made in the bottom of such a barrel, which will serve as a blower, as well as a place to remove ash from the furnace. At a height of one third of the barrel, an iron sheet must be welded, which will serve as the bottom for the smoking chamber. To make it last longer, the thickness of the sheet should be about 4 millimeters.

On the opposite side of the firebox, a hole is made for the chimney. It is bent and welded to the combustion chamber. Its height must be small, otherwise the thrust will be large enough. Then the temperature will rise, which means that there will be an abundant release of juice and fat. To create an air gap, legs are welded to the barrel. It will also improve the burning of wood.

When there is a smokehouse available, you can start the cooking process. However, there are some tips to keep in mind. In order for smoked meats to have high taste, you need to make a lot of effort.

You can regulate the smoke not only with the help of wet burlap, but also with fresh branches of trees or bushes. For this, currants or cherries, which have an incredible aroma, are suitable. You can not use tree species such as pine or lilac, as well as birch. After all, they include essential oils, sweet juice and tar, which can soak products, thereby making them unusable.

The layer of branches laid on top of the smokehouse should be approximately 30 centimeters. This is enough for three days. By the state of the top leaves, you can determine the readiness of the product.

When starting to harvest firewood for smoking, you need to know that trees such as pear or cherry are best suited for this. However, before use, they must be cleaned of bark. If smoking takes place in the forest, then aspen or linden can be used as firewood. To give smoked meats a tart taste, you can take walnut or oak. In order to smoke fish that smell like silt, you must use willow or willow.

Do not use coniferous trees, otherwise they can ruin all products. Also, if the trees are infected with any fungi, they should not be taken either.

Also, do not forget about the preparation of products. Before you start smoking, you need to marinate the meat well. For this, any method known in cooking is suitable. Marinating must be done a day before the smoking process. You can also simply rub the meat with salt and spices. The finished product will keep better in the refrigerator.

It takes much less time to cook fish. It just needs to be well gutted and cleaned. Then hold in salted water to eliminate the unpleasant fishy smell. Then soak it in a saline solution, and in an hour it will be ready for smoking. Almost any fish is suitable for smoking, both small and large. As a rule, the choice depends on the size of the smokehouse itself and the availability of the necessary functions in it.

Chicken meat is slightly softer than pork, so four hours will be enough to marinate it. Salt and sugar are used for the marinade. Many add wine and spices. This adds flavor to the bird. But you can get by with a classic set of spices for chicken.

For pickling fat, a solution of salt, garlic and various spices is used. Marinating lasts two weeks. This is one of the longest processes. However, do not forget to periodically turn the pieces so that they are equally fragrant and appetizing from all sides. Before smoking, they must be washed well.

It is also worth knowing at what temperatures and how long a particular product is cooked. When using hot smoked products, they accumulate differently. For meat and fat, the temperature varies from 100 to 150 degrees, and the smoking time is two or three hours of cooking. The fish is cooked for approximately one hour at a temperature of 70 degrees, which then rises to 100 degrees. The chicken is smoked at 110 degrees for about two hours.

If cold smoking is used, the smoking temperature reaches 30 degrees Celsius. Because of this, the cooking process takes a lot of time. But the result will please anyone. After all, such products are not only very tasty, but also stored for a long time. For example, chicken hams are smoked for up to four days, and then kept for another three weeks, hanging in a dry room. But they keep for several months.

Grocery stores offer a wide range of smoked products, but buyers do not know what quality they are and with what additives. But everyone wants to eat only fresh and natural products. So how do you get out of the situation? It's easy, all you need is a do-it-yourself cold-smoked smoker. Video, photos and detailed instructions for the implementation of this project can be found in this article.

Read in the article

The essence of the operation of the apparatus for cold smoking

The basis of smoking dishes is the use of processing, which comes from smoldering wood. Whether you smoke meat, poultry, fish, vegetables or fruit, the cooking process is always the same. The box in which the smoking procedure takes place can be of almost any shape. Housing materials are also different: metal, wood, polyethylene and other non-toxic materials that do not allow air to pass through.

Cold smoking can be compared with conservation, because the smoke that settles on food during cooking has a temperature of 20-25 degrees, the time for complete readiness takes about 1-2 days (sometimes up to 6 days). During this time, all the water comes out of the smoked meats, which allows you to store such products for more than two weeks.

Note! The ideal time of year to use a cold smoked oil lamp is winter. At low air temperatures, the development of bacteria in the middle of the products practically does not occur, which negates the spoilage of the dish during the smoking process.

What is the smoke generation process for cold smoking?

Getting cold smoke practically does not differ from the type of coolant. The principle is always the same, but the designs for generating haze are different.

- If the smokehouse works on, then it is necessary to build an iron box for a fire or simply dig a hole and line it with stone. It joins on the side, which leads into the box of the oil lamp itself. The length of the pipe should be about two meters or more, so that the smoke from the fire has time to cool to 25 degrees before it enters the food.

- In the case of using gas or electricity, the iron box for the heat exchanger is made with two horizontal levels. At the bottom, heat is released, which heats the top sheet, on which chips or chips are poured from. The wood smolders and forms smoke that goes into the smokehouse. Smoke generation occurs regardless of how to make a cold smoked oil lamp.

Varieties of devices for cold smoking

Depending on the place of use, the volume of processed products, the type of heat source and other circumstances, they have different modifications.

Materials for the body of smokehouses

- Stainless steel. It is mainly used in factory models for home use. Less often, for improvised designs. In home-made versions, steel is used in the assembly of structures for hot smoking, as they are in direct contact with fire.

- Tree. A popular material due to its ease of processing during assembly, pleasant appearance, low cost. Some resinous breeds add additional flavor to products, which is a nice addition.

- Polyethylene film. Oddly enough, but domestic kulibins managed to adapt the film for under the body for the smokehouse. Quick assembly, low cost of construction and good taste of smoked meats prepared in such a know-how keep this type of material afloat.

- Stone and. Such building material is used for capital buildings of large volume. Although there are smaller specimens, they are rare. The main purpose of such smokehouses is commercial production at home.

- Any piece of iron, which has walls, a lid and a bottom, also has a chance to become a cold-smoked smokehouse with your own hands, the video + photo on this page is direct proof of this (case from, barrel, bucket, safe, gas cylinder, etc.).

Heat sources

- Bourgeoiska on . In this way they smoke in dachas, on the territory of a private house,. you can organize the work of a smokehouse, of any size.

- Gas-burner. More expensive option, but has its advantages. The possibility of adjusting the flame and autonomous operation that does not require intervention (throwing firewood).

- Electric heating. It is used in indoor smokehouses. Basically, smoke generation with the help of electricity is used in factory models, because building an electric smokehouse with your own hands without being friends with an electrician is quite dangerous.

Smokehouse locations

- On the street. This is the main place for such structures. Due to the fact that the process of burning firewood emits smoke and the smell absorbed into everything around, smokehouses are located away from, on and away from public streets. Often the body of the smokehouse is placed on a hill so that the smell disappears faster without spreading to the sides.

- In enclosed spaces. Either you have an apartment, but really want to cook smoked meats, or you own a private smokehouse at the factory level. If in the first option only electrical units can be used, then the second one allows the use of any type of fuel, because it is not difficult to organize smoke removal in an industrial building.

Important! Whatever variation of the smokehouse is present in your location, always follow the safety precautions during installation and operation. A sand box or fire extinguisher located next to the unit is never superfluous.

Cold smoking at home. Smokehouse design

Regardless of the shape and dimensions of the box, the design features and necessary fixtures do not differ.

Design features

Do-it-yourself smokehouse must have sealed walls that do not emit harmful substances when heated. There must be a chimney in the roof of the structure to remove excess smoke. Access inside must be organized so that you can easily work with products (the door must be on the entire front of the structure). The presence of a tray at the bottom of the smokehouse will facilitate the cleaning of the flowing liquid from the products, and the presence of all kinds of hooks, transverse rods and mesh trays will ensure the rational arrangement of future smoked meats.

Preparation of products before cold smoking

Before you start smoking, you need to make preparatory work. For vegetables and fruits, preparation consists in washing and extracting seeds and seeds. For foods such as meat, poultry, and fish, the preparation process is a little more complicated.

- Meat curds. The main preparation consists in salting the workpiece. But depending on the fat content in a particular piece of meat, the salt concentration should be different. If you are preparing salmon, it is better to use wet salting (130 grams of salt per liter of water. The concentrate is brought to a boil, noise is removed and allowed to cool). The reason why balyks are salted in this way is that meat without layers of fat dries out when dry salted, and the wet version does not allow soft tissues to split and the product will remain juicy when smoked. If you want to smoke balyk or balyk, then the dry salting option is suitable, because salt cannot completely penetrate the fat.

In both methods, the salted product must lie for two to 6 days, after which it is placed in clean water for soaking for 1-3 days. Further, the meat is hung out in a room with a temperature of 2-4 degrees, covered with gauze from insects and left to dry for a period of 1 to 3 weeks. Everything, the product is completely ready for smoking.

- Bird preparation. The carcass must be plucked, tarred, gutted and salted. Prepare the brine by adding 100 grams of salt, two tablespoons of vinegar and spices to 1 liter of water. Submerge the bird in the brine for three days. After the brine, you need to dry the carcass with a towel and hang it for drying in a cool place for 3-4 days. After these procedures, you can start smoking.

- Smoked fish. Fish must be handled with care; its gastronomic quality depends on the thoroughness of preparation. If you have fresh river fish, then you need to gut it, clean it from the husk and rub it with plenty of salt. The fish is kept in the salt crust for about three days (the time increases if the fish has been frozen). After salt, you need to hang the carcasses covered with gauze in a cool place and dry for one week (large specimens are bursting with skewers in the belly area). The fish is now ready for the cold smoking process.

Note! The components of the brine or salt rub are selected depending on the taste preferences of the cook and can consist of a huge variety of spices and herbs, because you yourself have the right to determine what to cook in the cold-smoked smokehouse you created with your own hands.

Choice of wood chips for cold smoking

The raw material for the formation of the necessary smoke is wood shavings or wood chips. The main thing is that the material should not be too fine structure and not have increased dryness. Otherwise, it will burn intensely and give the food a burnt taste. The optimal moisture level for wood chips is considered to be 65-70 percent, such a structure will create ideal conditions for creating smoke.

Types of wood suitable for smoking

Not all types of wood are suitable for smoked products, because some species give off a specific smell and negatively affect products. Ideal for: cherry, sweet cherry, apricot, pear, apple, aspen, beech, alder, oak and ash. Do not use conifers, they emit a large amount of resin.

Some manufacturers are engaged in the production of ready-made chips for smoking, but the main disadvantage is that the composition of the final raw material is unknown to the consumer. Unscrupulous manufacturers may add chemicals to improve smoke production. To avoid unpleasant moments, you need to make chips yourself.

Harvesting wood chips for cold smoking with your own hands

Wood should be harvested from pruning fruit or deciduous trees that have not been pre-treated with chemicals. After collecting the branches, you need to completely remove the bark, and then this. For processing into shavings or chips, a special tool is used, like an electric planer, but it can also be used (takes a lot of time). It should also be taken into account that the moisture content of the rock is always different, so it must be adjusted manually. If there is a lot of moisture, then it is necessary to dry the tree, and if it is not enough, then moisten it. Most importantly, remember that do-it-yourself cooked wood chips for smoking are environmentally friendly raw materials.

Do-it-yourself cold smoked smokehouse. Video, photo instruction

The idea of making your own smokehouse has a lot of advantages. The main advantage is not limited possibilities in the choice of dimensions, location and method of smoke generation. The device can be made for both outdoor and indoor use.

How to make a cold smoked smokehouse with your own hands

The process of constructing the structure will be described using the example of a stationary smokehouse in the courtyard of a private house.

Step-by-step instruction:

- It is necessary to plan a place on the site for a future smokehouse. You will need approximately 1 meter wide and 4 meters long.

- Using a shovel, it is necessary to dig a trench half a meter deep, 0.3 meters wide and for the entire length of the planned area. At the beginning and at the end of the trench, you need to organize two pits with dimensions of 0.5x0.5x0.5 meters. The side on which the hearth of the fire will be located should be lower in level than the opposite, at least 20 centimeters. This is due to the fact that at such an angle it will be easier for the smoke to reach the smokehouse itself.