Kosour do-it-yourself step-by-step instructions. Installation of stairs on stringers: diagrams and calculation

Residents of private houses and spacious apartments are increasingly paying attention to stairs on metal stringers. Its peculiarity lies in the ability to form an aesthetic and functional component of the structure. The more accurately the base is made, the easier it is to manufacture the steps. That is why it is recommended for beginners and professionals to first understand the features of such structures.

Depending on the architectural features of the premises and the financial capabilities of the owner, the design is carried out in two possible forms. In the first case, on the stringers, it provides for fixing the steps from the upper side.

The size of the side indent is from 10 to 13 cm, being largely dependent on the internal width of the flight of stairs.

The larger the ledge, the wider the step should be. It is extremely rare in such a case that installation occurs under the steps. The second option for installing a similar design is to fasten the steps between the stringers.

This includes the following design features:

- The maximum thickness of the kosour ranges from 10 to 14 cm, and the width is from 8 to 14 cm. Much depends on the number of steps.

- The use of incomplete and full risers, depending on the architectural features of the room. Both options are connected with dowels or glue.

- The presence of a side zigzag stringer.

At the design stage, it is necessary to take into account the features of the selected staircase modification. The more precisely this is done, the less time the installation process will take. Based on the information collected, a standard flow chart (TTK) is formed - a document that determines further work.

Varieties of metal stairs on stringers

Prior to the transition to the practical implementation of the approved project, it is necessary to carefully analyze everything. To a greater extent, this concerns the parameters of the stringers. At their core, they play the role of a kind of support for the steps.

The better it is made, the longer the steps will last. The most common view in all drawings is the straight form.

Its production is made of wood and metal. A combination of concrete and the materials mentioned above is used much less frequently. This is done in cases where it is necessary to make a large thickness of the steps.

Depending on the form of the structure, the following types are distinguished:

- Screw;

- Zigzag - it is also called broken;

- Straight.

In addition to the direct version, the architecture uses screw and broken. Their successful implementation requires certain experience and theoretical knowledge.

We build a metal kosour for stairs

Despite the external attractiveness of wood, metal continues to be the most sought-after material for forming the future foundation. This is due to the wear resistance of the material and not susceptibility to external influences.

To create it, you will need a pipe or a metal profile, the size of which matches the parameters of the future staircase.

First you need to fix all the dimensions. The collected information will help to determine the required amount of material with a greater degree of probability.

To make the measurement process more accurate, the following recommendations will help:

- Fix the height of the structure;

- Correctly determine the angle of inclination of the stairs;

- Mark the parameters of steps and risers on the drawing.

As experience shows, it is enough to fix the parameters of only a solid kosour. The situation is a little more complicated with DWG designs. In this case, the parameters listed above are fixed in the section.

Universal metal ladder on one stringer

Bold in all respects, an option made on one mount. It can be implemented only in the case when a significant load on the structure is not planned. In addition, it is necessary to take into account the geometry of the stairs. If one turn is followed by several more, then there is a need for two or more stringers.

Attention is also drawn to the physical parameters of the walls. If those do not allow us to conclude about their strength, then it is better to stop at the option with two iron clamps.

There are a few more tips from experienced builders:

- A prefabricated structure is a universal option that allows even with many external negative factors. Like building blocks, everything lines up in a free order.

- If there is no desire to abandon the original idea, then it is possible to qualitatively make a 1-string ladder as follows. Fastening to the wall is carried out at 4-5 points using metal pins.

- For homes with kids and 4-legged pets, running designs are suitable. Their essence is hidden in the name. You can literally run on them.

The only limitation is the requirement for a large free space.

Accuracy and precision are not only the courtesy of kings, but also a true friend of the builder. When fixing the necessary parameters, be sure to use a calculator that allows you to calculate everything with jewelry accuracy. The first thing to remember is that mathematical calculations for stairs on a wooden and metal base occur in different ways. Yes, there are some common features, but on this basis, you should not put an “=” sign between both technologies.

The direct calculation is as follows:

- The length of the supporting structure is determined based on the Pythagorean theorem. The desired parameter is obtained after calculating the square of the hypotenuse, followed by the extraction of the square root.

- The leg is the height of the flight of stairs from 1 to 2 floors. Here you need to add the distance from the top platform to the bottom step. In order to calculate the angle, it is necessary to measure the coefficient of inclination of the entire structure.

Rules for installing stairs on stringers

The rules for working with materials do not depend on which one is chosen for building stairs with your own hands to the second floor. It is more difficult to work with metal that requires the installation of fillies. In addition to it, be sure to use a base plate, which is made of a sheet of metal.

A step-shaped plate is cut out in such a way as to cover it without protrusions. After that, everything is welded to the carrier base with mandatory fixation with bolts.

A certain difficulty is presented by complex structures of a stepped type, equipped with a double stringer. In this case, you do not need to use the fillies mentioned above.

The further course of action is as follows:

- The use of bolts - with the help of dowels and a support leg, the stairs are fixed.

- The steel support is made in the form of a curved sheet fixed with 4 screws.

- The use of a wooden filly is advisable in cases where a beam acts as a beam. To fix the parts, studs or dowels are used.

Cut out tread - all supporting steps are fixed on the stringers with the help of self-tapping screws with the addition of glue.

Installation of stairs on metal stringers

Once everything is ready, you can safely proceed to the practical implementation of the project. In order for all the nodes to be in their places, it is recommended to put the drawing in front of your eyes. Beginners will make their lives easier by starting with the middle profile section of the stairs. In this case, it is easier to make the necessary adjustments. Even if there is a large or not very error, it will not be necessary to destroy everything to make adjustments.

Experienced designers have prepared several recommendations for beginners:

- All load-bearing elements must be hidden from view;

- Self-tapping screws and bolts with a large margin of safety are used;

- It is necessary to install the kosour on a previously prepared surface.

Do-it-yourself ladder on stringers (video)

A functional and outwardly attractive design, made on the basis of wooden or metal stringers, is suitable for a private house, cottage or office space with sufficient space. If there is none, then you can always choose a compact option. We are talking about a zigzag and a straight shape. Before installing each of them, careful measurements are taken.

In detail: stairs on stringers (photo examples)

Foreword

A wooden staircase on stringers is the most common type of this design. These beams with a comb are nothing more than a kind of stair bowstring, that is, the bearing parts of the march, which determine the strength of the entire structure.

Content

The device of the stairs on wooden stringers on the video.

A wooden staircase on stringers is the most common type of this design. These beams with a comb are nothing more than a kind of stair bowstring, that is, the bearing parts of the march, which determine the strength of the entire structure. Kosourov, depending on the configuration of the stairs, can be one or two, they are made either by assembly or by cutting.

Do-it-yourself stairs are most often mounted on stringers made of pine and oak, less often they are made of cedar, larch, mahogany, Oregon and Brazilian pine. Oak wood has a high density, so stairs made from this material will be durable and reliable. Coniferous wood is softer than oak, but it has its own advantage - it is more convenient to process it. It is not recommended to use coniferous woods, especially spruce, for the manufacture of steps, because due to the softness of the wood, the life of the stairs will be quite short. The humidity of the wood used for the construction of the stairs must correspond to the humidity of the air in the premises in which the structure will be mounted.

You will learn how to make stringers for stairs with your own hands, and how to mount the structure, in this material.

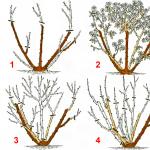

Do-it-yourself installation of stairs on two stringers made of wood

The manufacturing technology of kosour is carried out in two ways: by the assembly method and by cutting (or cutting). In the first case, a beam is made in accordance with the design dimensions. Separately, triangles are made, the dimensions of which are determined by the lifting step and the width of the tread. After that, the triangles are connected to the beam and the result is a kosour. Assembly technology saves material. In the second case, a kosour is cut out from a workpiece of the required size. This method allows you to make two symmetrical load-bearing parts of the ladder structure from one workpiece at once.

For the manufacture of a stringer of a wooden staircase, boards with a thickness of 50-70 mm and a width of at least 250-300 mm are used. Since it is quite difficult to find a flat and knotless board of this width, moreover, made from a single array of wood, for the manufacture of stringers it is recommended to use glued boards that do not have knots, are not subject to twisting and cracking, and their width is sufficient to make cuts.

Treads from solid single or two narrow tongue-and-groove boards must be laid on stepped cutouts in the stringers of the stairs in the house, the thickness of the tread will depend on the width of the march.

For steps with a length of 800, 1000, 1200 mm, you should choose boards with a thickness of 40, 50 and 60 mm, respectively. The ratio of the thickness of the tread to the width of the march is approximately 1:20.

To make the stringers for the stairs as strong as possible, keep in mind that a deviation from this proportion is allowed only towards the thickening of the tread (or you can increase the number of stringers under the steps to 3-4 pieces).

It is allowed to protrude the front edge of the tread up to 50 mm relative to the plane of the riser. In this case, it is desirable that the protrusion be rounded. The ends of the treads must be hemmed with a planed bar, puttied and painted or veneered.

There are no special requirements for the wood of the risers; they must be made of planed boards with a thickness of 18-25 mm. The ends of the boards will turn out to be open, and to give them a more beautiful look, it is recommended to file them at an angle of 45 °. It is best to make treads and risers from wood of the same species.

The main thing in the device of kosour stairs is their reliability. From one workpiece, you can cut stringers of different geometry. Those of them that do not have cuts in the places of support on the platform beams are more reliable, since they have fewer weakened sections and, therefore, there will be no chipping of wood at the place of support.

But for the installation of such stringers of the stairs, a higher landing beam is required so that there is no reduction in the height of the passage under the stairs. The presence of the upper frieze step in the staircase facilitates the design task. This step can completely repeat the size of an ordinary step, be narrower or it may not be at all.

Thus, the upper frieze step, together with stringers for wooden stairs, can, as it were, be pushed into the platform beam. Therefore, without changing the slope of the flight of stairs, it becomes possible to vary the horizontal dimensions of the stairs. But at the same time, the height of the platform beam increases, the implementation of attachment points becomes more complicated and the height of the passage under the stairs is reduced. Therefore, if there are upper frieze steps in the design, stringers are most often used, the upper end of which has washed down. Thus, the increase in the height of the platform beam is partially compensated.

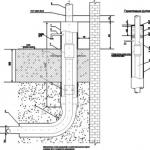

The lower part of the stringers rests on the floor beams of the lower floor. In the case of a two-flight staircase, the support is carried out on the beams of the interfloor platform. This part of the stairs can be located on beams that are in relation to the stairs both in the longitudinal and in the transverse direction.

If the support of the kosour falls on the transverse beams, then the issue with the knot is solved similarly to the upper part, that is, you can cut down either the kosour or the beam.

In the manufacture of stringers for stairs, in case they fall on the longitudinal beams, they can be mounted at close range to the balusters previously sawn into the beam and firmly fixed.

It is also possible to interconnect two longitudinal beams with the help of an additional transverse bar, against which the lower part of this supporting stringer should abut.

It should be borne in mind that any cuts (cuts) of wooden elements can actually lead to a weakening of the original sections.

Poorly executed assembly often becomes the cause of the destruction of the structure. If there is a choice from various design solutions for nodes, then it is better to refuse tie-ins, and use nodes with steel fasteners (angles, clamps, bolts, etc.).

The stringers of a wooden staircase erected by one's own hands can abut both the upper and lower parts against the building structures of the ceilings. In this case, you can not use fasteners at all. But this option is possible only if the stops in the upper and lower parts of the stringers are absolutely rigid and do not involve any movement, which in most cases is difficult to implement.

As a rule, stairs are erected according to the non-expansion version, similar to the schemes of layered truss systems.

Here you can watch a video of mounting stairs on two stringers:

Making and fixing wooden stringers for stairs with your own hands

To make a ladder stringer with your own hands, you will need a flat board with a thickness of at least 40 mm and a width of at least 300 mm.

When creating straight flights of stairs that have the same stringers, it is recommended to use a stencil to mark the cutouts for the steps. It can be made independently from a small sheet of plywood and two wooden slats. From the corner of the plywood sheet, you need to measure the distances corresponding to the width of the tread and the height of the riser.

The points obtained should be connected with a straight line, along which rails will be installed and fastened with nails on both sides of the sheet. Further, using this stencil in the stringer, it is necessary to mark and cut out the corresponding grooves.

In the manufacture of stairs with winder wooden steps, the stringers on both sides of the structure will have a different shape. In this case, the cutouts must be marked according to the dimensions of each step. It should be remembered that the height of the risers remains the same, but there are changes in the width of the tread, therefore, the angle of inclination of the stairs also changes. From its inner side there are steps with a narrow part of the tread, and from the outer side - with its wide section.

From the inside of the structure, the rise will be steeper than from the outside, but at the same time, the stringers of the stairs will still be parallel to each other, the changes will only affect the length of the cut, on which the dimensions of the step tread depend. The markup template must have movable guides. In addition, it must be reconfigured every time when marking the next winder step.

If the cuts in the stringers are too deep, which will weaken the structure of the stairs, it is recommended to install three or four stringers under the steps. The number of stringers must also be increased if thin boards are used as treads. This is necessary in order to prevent their deflection under the influence of operational load.

For the manufacture of stepped stringers, it is problematic to choose boards that are wide enough, straight and without knots, so you can use another option.

Filly can be triangular in shape and installed directly on the upper longitudinal edge of the kosour. The fastening of the filly on the kosour is made on the dowels, which must be installed in pre-selected adjacent elements of the grooves and fixed with glue.

For the strength of attaching the fillies to the stringers of the wooden stairs, it is recommended to use a more complex scheme, according to which you need to cut a small cutout in the stringer and choose fillies of complex shape. In addition, dowels and glue can be used to attach fillies to the stringer.

Treads and risers are recommended to be connected using screws and glue, as the nail connection becomes weaker over time. The tread and riser are fastened with screws, an additional triangular rail or in a groove. Also, to connect the wooden parts of the stairs, it is recommended to use various overhead strips and metal corners. The reliability and strength of the connection is ensured by a nail-free connection - using wooden dowels.

When connecting hardwood parts, softwood dowels are used, and hardwood dowels, respectively, are necessary for joining softwood parts. Otherwise, the pin, instead of connecting the parts, on the contrary, will split them.

Staircase with wooden steps on one central stringer

The ladder can also be made on one reliable powerful stringer. Boards used to make treads must be planed and sanded with sandpaper. A staircase with a central stringer does not reduce the space of the room, it becomes an interior decoration.

The central kosour is the only support of the structure. Usually it is made from a bar with a section of 340 x 200 mm. Do-it-yourself kosour for wooden stairs can be done as follows: first you need to glue a few boards and place them under the press. Then the glued boards need to be strengthened with transverse wooden dowels or bolts. Oak, larch, pine wood is suitable as a material for this design and finish. There is a variant of the steep location of the stringer, when the staircase in a private house is used as an auxiliary one (for example, to the attic).

In this case, the lower end of the stringer is fastened to the floor, and the upper end (using bolts and dowels) is fastened to the beam that supports the platform structure.

For such a ladder, it is not required to make cuts, the method of its installation is similar to the one with which the ladder is installed. Thus, the main task is to strengthen the bottom of the structure (to prevent it from slipping) and the top (so that the stairs do not fall to the side).

Here are photos of stairs on one stringer:

The triangular fragments of the kosour must be sawn according to the template in such a way that the parallelism of the platforms on which the steps are subsequently installed is observed. Cuts and corners must be leveled with a rasp or grinder, then install the stringer in place, attaching it to the floor and the beam of the site with self-wedging dowels and bolts with washers recessed into the tree in a secret way.

Duck step treads can be used for an auxiliary ladder. They are made from planed boards. After marking, it is necessary to drill holes with chamfers for fasteners. Each step is mounted in a secret way on four bolts with washers to the stringer or to an additional transverse beam. The cross beam should be attached to the stringer half a tree. To intercept the pulling moment when a load occurs on the console of the transverse beam, these beams must be provided with additional reinforcement to the stringer. To do this, you need four wooden dowels. Chamfers with recessed bolt heads must be sealed with synthetic mastic or wood putty in the same color as the main structure. Then the entire staircase must be covered with a layer of colorless varnish.

If there is not enough space allocated for the stairs, there is a need for winder turning steps. But such a structure is a complex structure - a hybrid of two straight single-flight stairs and a spiral staircase element.

Watch the video "Do-it-yourself ladder on stringers" to better understand how such a design is made:

If you decide to design a rise to the floor yourself, you definitely need to know how to make stringers for stairs. If you make everything with your own hands, it is important to know the features of all elements, their types and manufacturing rules.

Features and types of construction

Before deciding to make a kosour for the stairs with your own hands, you need to understand in more detail the features of this part. In fact, this is the supporting element of the stairs, which serves as support for the steps.

Straight stringers are used most often

The type of product largely affects the calculation of materials for stairs on stringers. Stringers can be made of wood, metal, concrete, or a combination of both. The following elements are distinguished by form:

- straight;

- broken lines;

- screw.

The simplest option for most stairs is straight. That is what is worth considering in more detail.

Features of the calculations

If you decide to do all the work with your own hands from start to finish, first of all you need to think about developing a staircase project. To do this, you need to calculate all the necessary parameters. The calculation of stairs on wooden or metal stringers is made according to almost the same principle.

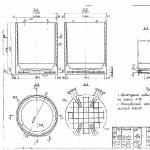

Estimated data for marking the stringer

To determine the length of the supporting part, use the Pythagorean theorem. In this case, you need to look for the square of the hypotenuse, which, after extracting the root from it, will mean the length of the bar. The legs in this situation are the height of the span from the floor of the first floor to the second, as well as the distance from the first step to the platform from above. The angle is determined by the level of inclination of the structure.

The calculation of the shape of the stringer of the stairs is based on the chosen method of fastening the steps. If fillies are used, the bar is taken smaller, otherwise you need to add the height of the tread to it. With a staircase width of more than 150 cm, in addition to the side stringers, an additional central one is installed.

Wooden kosour

The most common version of stairs is on wooden stringers. To make them with your own hands will require a minimum of effort.

To make the structure durable and last you as long as possible, it is better to choose solid hardwoods, although working with them is a little more difficult and longer.

In the manufacture of stairs made of wood, as a rule, two stringers are used.

First you need to calculate the thickness of the board. The larger the ladder in height and width, the stronger the support should be, which means that the board needs to be picked up thicker. If the design involves mounting without a filly, the following steps are performed:

- Mark the cutouts. To do this, you need to use a triangle. One of its sides corresponds to the depth of the tread, and the other to the height of the riser. The hypotenuse of such a right triangle runs along the edge of the beam.

- Using a jigsaw or a circular saw, cut out the extra fragments according to the markup.

- Determine the dimensions of the steps. This largely depends on how they are attached. They can be fixed both close to the edge of the kosour, and go beyond its limits by 2-3 cm.

But if you decide to use fillies, then you don’t need to cut the sidewalls, for this you simply use a straight bar made of solid or glued laminated timber. Depending on the height of the riser and the depth of the tread, the filly may look like a triangle or a trapezoid. For the triangular version, it may be necessary to saw out a small section of the beam so that the step goes under the next one a little.

A more complex, but reliable option is a ladder constructed on a metal stringer with your own hands. To make this option, you will need a metal profile or pipe, it is from these materials that the basis for the stairs is usually made.

Metal is a very durable material, so one central stringer is often enough.

To determine the required amount of materials, you need to make a calculation based on the data on the height and slope of the stairs, as well as the dimensions of the steps and risers. In most cases, one central stringer is sufficient. The metal is able to withstand a huge load, but a lot also depends on the quality of the connection of the parts of the stairs.

The simplest way is to make a stringer from a straight element. For example, take a pipe whose dimensions correspond to the given parameters. Mark the position of future steps on it and fix the fillies. They are small pieces of pipe or profile with a base plate on top. The ideal connection method is welding. The seams should be strong, but at the same time invisible. Holes are made in the plate, which are necessary for fixing the steps.

Ways of fastening steps

Depending on what material you decide to make stringers from, the method of fastening the steps of the stairs also depends. If you chose metal, you need to use fillies. For the steps prepare the base plate. The best option is a sheet of metal cut into the shape of a step. It is welded to the supporting element, and the steps are fixed with bolts.

An exception may be complex stepped structures with a double stringer. Then fillies are optional.

Various mounting options for steps

If the preliminary calculation showed that it is possible to fit a staircase on wooden stringers in the opening, then it is worth considering several options at once:

- Die-cut treads- the steps are attached directly to the stringers using self-tapping screws or dowels and an adhesive mixture.

- wooden filly- additional fragments of stairs are fixed on the beam with dowels, dowels, studs or self-tapping screws.

- steel support- steps are fixed on a flat curved support, which, in turn, is attached to the screws.

- Bolza- the back part of the stairs is fixed on the stringers with the help of a metal support leg and a dowel.

If you decide to build a staircase with your own hands, think over several options in advance and choose the most suitable one, based on the available materials and existing skills.

A wooden staircase on stringers is considered the simplest design for self-production. However, its manufacture also has many nuances, non-observance of which can lead to structural fragility. Therefore, before starting the construction of stairs with such fasteners, it is important to study the types of products, as well as the technology for their creation.

Stringers are wooden beams located along the edges of the stairs. The lower part of these beams has an even shape, and the upper part is cut in the form of a zigzag. A feature of wooden stairs with stringers is that steps are installed on these side beams. At the same time, the treads often overlap, protruding beyond the stringers.

Kosours can be constructed from the following materials:

- Concrete. Building a structure is very labor intensive. It involves laying out the formwork, which is a draft version of a wooden staircase. Subsequently, concrete mortar is poured into the formwork;

- Metal. The manufacture of stringers from this material involves the use of special tools for cutting and welding metal;

- Wood. For the manufacture of supporting elements, a minimum set of conventional carpentry tools is used.

The material for creating stringers is selected under the steps and handrails of the stairs. In this case, most often the supporting elements are made of wood.

Technical requirements

When manufacturing stairs on stringers, the following technical requirements should be taken into account:

- Installation of stairs can be carried out at an angle of 20-75 0 . In this case, the optimal angle of elevation is 40-45 0 ;

- Single-march structures should include no more than 18 steps;

- All steps must be the same height and width;

- The width of the stairs with stringers should not be less than 0.8 m;

- The length of the tread cannot be less than 20 cm. The optimal value is 25-30 cm;

- The height of the steps should be 15-20 cm;

- Stair structures with stringers that have more than 3 steps must be equipped with railings with a height of at least 0.9 m.

Also, the requirements for the design of the stairs on the stringers involve the use of exclusively high-quality lumber, as well as the production of accurate calculations and the correct installation of the product.

Types of stairs on stringers

Products have several classifications. So, according to the number of stringers used during installation, stairs are:

- Single. All steps are placed on one kosour, located in the middle of the structure. Since the load on the support element is high in this case, the stringer is made of metal;

- Double. This type of ladder is the most common. Support elements are located at the edges of the structure;

- Triple. In the product, in addition to the side stringers, an additional supporting element is installed in the middle of the treads. This design helps to prevent excessive deflection of the steps and their damage when placing a large weight on them.

For stairs with a large width of steps, the number of stringers may be more than three.

According to their form, kosours can be:

- Comb or zigzag. A kosour of this type on the side looks like steps. Usually the part is made from a single sheet of wood;

- Filly. Most often, this type of construction is used in the construction of a single stringer staircase. On each crest of the kosour, special wide plates or boards, called fillies, are installed. They are an additional support for the tread. Usually fillies are made for wooden stairs on metal stringers.

Wooden structures with a standard width of steps are most often equipped with double or triple comb stringers. At the same time, the stairs themselves, in their form, can be marching or spiral.

Materials for the manufacture of wooden stairs

When choosing a material for building stairs on stringers with your own hands, you should pay attention to the strength and durability of wood. To create products, lumber from such trees can be used:

- Pine;

- Ash;

- Alder;

- Cedar;

- Birch;

- Maple;

- Larch;

Pine and birch are used with a small and strictly limited budget. The material has low strength indicators. In addition, birch is in dire need of protective impregnation, since the wood is prone to decay with high humidity in the room. Oak boards can be used in the construction of stairs in capital houses. The reason for this is the significant weight of the wood.

The main tools and material that are used to build a wooden staircase on the stringers with your own hands are:

- Wood for creating supporting elements. Its thickness must be at least 6 mm;

- Finished steps or boards for their manufacture;

- Pencil and square ruler for marking wood;

- Roulette;

- Anchor bolts;

- Bands;

- Level;

- Wooden rounded bars or lamellas. Railings will be constructed from them;

- Electric jigsaw;

- self-tapping screws;

- Screwdriver or screwdriver.

Also, a saw, a hacksaw, and even a grinder can be used to trim wood. For reliable fixation of the steps, wood glue can be used additionally. And when constructing steps of a closed type, fixing the tread with the riser is done using self-tapping screws and metal corners.

Mounting process technology

The process of creating a staircase on stringers includes several successive stages:

- Carrying out preliminary measurements and calculations.

- Building a drawing of the future design.

- Manufacturing of stringers.

- Creation of steps.

- Assembly of the stairs and its installation in the selected location.

- Fixing fences.

The obligatory final stage of work is the finishing of wood with protective impregnations and decorative materials.

Measurements and calculations

Calculations of the dimensions of the future stairs should be carried out based on the type of construction. Be sure to take into account all the technical requirements for the product. The main dimensions on which to rely when making calculations are:

- The height of the future stairs. The value is the distance from the floor of the first to the second floors;

- The angle of inclination of the structure;

- Step width.

Having this data, it is easy to calculate the required dimensions and shape of all future structural elements. In this case, it should be borne in mind that the angle between the steps, and therefore between the teeth of the comb, should be 90 0. The number of steps is determined by dividing the total height of the structure by the height of one step. Meters are used as units of measurement.

For the convenience of calculating the dimensions, individual elements of a wooden staircase on stringers, you can use special online construction calculators. This will not only save time, but also protect against possible errors in the calculations.

Building a drawing

To understand the geometry of the future structure and the principles of its subsequent assembly, a staircase drawing is made before starting work. For the convenience of its use, the drawing of the stairs is performed in several projections. All the calculated dimensions of the parts are applied to the resulting scheme.

The scheme is as convenient as possible while maintaining a single scale for all parts within the same drawing.

Manufacturing of stringers

For the manufacture of stringers, marking lines of cuts for future comb teeth are applied to two identical wooden beams. In order to correctly mark the lines, the height and length points of the steps are marked on the square ruler. Applying a ruler with dots to the edge of the beam from which the kosour will be created, the outline of the cut is outlined with a pencil. By the same principle, markings are applied to the second beam.

Wood cuts are made along the marking lines. The work is carried out using a jigsaw or other suitable tool.

Making steps

When creating steps for stairs, it takes into account the type of future structure. For an open-type product, only the manufacture of a tread is required. But at the closed staircase on the stringers there should also be risers.

To create steps, ready-made boards of a suitable size are used. If there are none, wooden bars are cut from a solid board. In this case, the dimensions of the tread correspond to the length and width of the step. The dimensions of the riser correspond to the height and width of the step.

The dimensions of the riser must clearly correspond to these values, while for the tread, deviations in dimensions are allowed in the larger direction. In this case, the horizontal part of the steps will slightly protrude from the sides of the stairs, and hang over the bottom step. However, the excess of the nominal dimensions should be no more than 1-1.5 cm for each side of the tread.

Ladder assembly and installation

The assembly and installation of the stairs is carried out in the following sequence:

- Finished stringers are laid out on a flat floor, at a suitable distance from each other. In this case, temporary fixation of the stringers along the edges with the help of strands is possible. After that, the zigzags of the supporting elements are lightly smeared with building glue, when it is applied.

- Risers are applied to the vertical lines of the comb. These elements are fixed on the supports with self-tapping screws.

- After installing all the vertical elements, treads are laid on the horizontal lines of the comb. Their fixation to the ends of the supports is carried out on self-tapping screws.

When all steps are securely fixed, the stairs are mounted to the floor of the first and second floors, at an appropriate angle of inclination, using anchor bolts or other suitable fasteners.

Railing installation

In stairs with stringers, the installation of the railing is carried out in the tread. For the construction of these safety elements, at the beginning and at the end of the structure, support balusters are installed on both sides of the steps. In each of the treads, a small depression of 1-1.5 cm is drilled, the diameter of which corresponds to the section of the railing. The resulting holes are lightly smeared with building glue, after which a railing is inserted into them, strictly vertically. To deepen them securely, the lamellae are lightly tapped from above with a rubber or wooden mallet or mallet.

The mounted railing is covered with a beam with holes drilled in it at the appropriate points. This beam will act as a handrail. At the edges, it is fixed with grooves and glue into balusters.

Finishing work

Finishing a wooden staircase consists in impregnating the material with protective solutions that will protect the product from the influence of changes in humidity and ambient temperature. Usually, a stain or a special primer is used for these purposes. When using wood stain, it can slightly tint the wood.

Decorative finishing is done with paint or varnish. Any finish should be applied thinly and in several coats. Between the application of a new decorative layer, the surface must be sanded with fine-grained sandpaper. The application of each subsequent decorative layer, or its grinding, is possible only after the previous coating has completely dried.

The flight of stairs on stringers is a simple design and easy to manufacture. Kosour (bowstring) - the main bearing support of the stairs in the form of an inclined beam, on which steps and railings are installed from above, the protruding end of the step is visible from the side (clearly shown in the photo).

It is made of metal, concrete or wood. It is a popular element of the span due to its uncomplicated and reliable design, it supports the steps and carries the main human load. Depending on the shape of the structure, the stringers are distinguished: broken, straight and screw. This ladder element can be located on the sides or in the center of the building.

Calculation of the parameters of the stairs on the stringers

In order for the staircase to be solid, aesthetic and safe, you need to know certain dimensions:

- Height (H1);

- Horizontal length (L1);

- Passage height (H2);

- Depth of a horizontal ladder element (treads) (l);

- Height of the vertical stair element (risers) (h);

- Number of steps (n);

- The length of the flight of stairs (L).

Let's start counting (watch the video):

Pay special attention to whether there is enough space above the person's head when lifting. The height between the ceiling and the stairs corresponds to at least 2 m.

Do-it-yourself construction of a wooden staircase on stringers

Consider the simplest design - a straight staircase on stringers, you see the image in the photo. This is an easy option for giving, under the span you can equip a pantry or mezzanine. For this element, it is recommended to use a wooden beam measuring 150 x 60 mm. When erecting steps, a board with a thickness of 40-50 mm is suitable, for erecting risers a board of 20 mm. For a long service life, it is better to use strong woods - oak, maple and beech. Great attention must be paid to the quality of the material. The boards are carefully sharpened and sanded.

There are 2 types of placement of steps on the stringer. In the first case, special cutouts are made in the shape of a triangle and the subsequent fastening of steps to them. In the second option, steps are installed on top of the filly (shallow gash for steps) with the help of wooden dowels (wooden rod) or on screws. The dowels are tightly fixed in certain grooves with wood glue.

To simplify the process of cutouts and maintain identical dimensions, it is better to use a stencil. It can be made from simple plywood and a wooden block that will determine the exact direction. The die should be nailed so that a triangle is formed, in which the leg should be equal to the depth of the tread, and the next leg to the height of the riser. The angle between certain legs is necessarily equal to 90 degrees.

Securely attach wooden blocks to the floor of the 1st floor and the platform of the 2nd floor, they will be excellent supports for stringers. First you need to combine wooden blocks with stringers with special self-tapping screws or metal corners and put the resulting structure in accordance with the project. Constantly monitor the horizontality of the flight of stairs building level. When the stringers are installed, you can mount the risers, and then the treads. So that the treads do not cause a creak, it should be firmly fixed with metal threaded rods and nuts.

Attaching railings to stairs

The main elements of the railing are a baluster (a leg supporting the railing) and a handrail (a wooden bar for connecting railing posts). It is better to use factory blanks of stair samples. The height of the railing is 95-100 cm.

Balusters are located exactly in the middle of each step. For fixing, dowels are used (diameter 25-30 mm), before installation, it is necessary to drill the railing legs with a carpentry drill (pen). To make the fastening stronger, coat the dowels with casein or epoxy glue. File the balusters to the measured batten angle, fasten the batten, then screw on the handrails securely.

We hope that this article will help you build a ladder on the stringers with your own hands. It will not be a difficult construction task for you, you will save a lot of your money.