Sauerkraut - classic recipes for the winter. Pickled cabbage

Souring is a method of preservation based on the fermentation of sugars in plant raw materials by lactic acid bacteria. The preservative in this case is accumulating lactic acid.

Depending on the type of preserved raw material, its composition, microflora features, the technology used, the fermentation process proceeds differently.

In cabbage, the epiphytic microflora of which is represented by various types of lactic acid bacteria, preservation occurs due to lactic acid accumulating during fermentation. Salt is needed only at the beginning of fermentation - to extract cell sap from raw materials. When processing other types of vegetable raw materials (cucumbers, tomatoes, roots, etc.) there is less accumulation of lactic acid, therefore, a higher salt concentration is used, in addition, a wider range of spices is used. This method of processing is called salting.

A similar method of processing fruits and berries is called urinating This raw material contains more sugar than vegetables. For canning use special fillings containing not only salt, but also sugar. Preservation occurs due to joint lactic acid and alcoholic fermentation.

Regardless of the terms used, there is no fundamental difference between souring, salting and urinating. They are based on similar physical processes and biochemical change of fresh raw materials, allowing to significantly extend the shelf life of fruits and vegetables.

Osmosis and diffusion phenomena are observed from physical processes during fermentation. The salt added to the raw material causes these processes. It increases the osmotic pressure in the environment surrounding the plant cells. As a result of osmosis, cell sap rushes in the direction of greater concentration of substances and flows out of tissues. This phenomenon is called plasmolysis. As a rule, the phenomenon of plasmolysis occurs at the beginning of the fermentation process and causes a decrease in the mass and volume of the raw material. The diffusion process is manifested somewhat later when the concentrations of substances outside and inside the cells begin to equalize. The cell wall of plants is actually a semi-permeable membrane through which, due to diffusion, the interchange of solutes occurs. As a result of diffusion, the volume and mass of vegetables is partially restored. This is facilitated by the constant desire of cells to maintain the necessary turgor, that is, a certain pressure of the cytoplasm on the cell wall and vice versa.

Physical processes in the souring of vegetables perform a kind of auxiliary function. The basis of fermentation is biochemical processes. The complex of these processes is called fermentation. The predominant microbiological process is lactic fermentation. All the technology of fermentation is aimed at facilitating this process in every way.

Lactic acid bacteria are on the surface of vegetables and make up their natural microflora. The lactic acid bacteria, mainly of the genus Lactobacillus, are especially well-seeded with internal leaves of cabbage. The main causative agents of lactic acid fermentation in sauerkraut are L. brevis and L. pentoaceticus (according to the old classification - Bacillus brassicae fermentatae). Along with lactic acid bacteria, a number of other bacteria and yeast take part in the fermentation of cabbage.

Lactic fermentation in cucumbers causes L. plantarum (= Bacillus cucumeris fermentati).

At present, the fermentation process in sauerkraut has been studied quite well. According to the predominant development of a group of microorganisms and the reactions taking place, the whole fermentation process is divided into four stages.

At the first stage, the whole microflora of the cabbage develops simultaneously. These are mainly rod-shaped microorganisms of the Pseudomonas family, Enterobacter cloacae, Flavo-bacterium rhenanum (= Erwinia herbicola), cocci, and other gas and acid-forming bacteria. Most of them actively consume oxygen and thus create favorable conditions for the subsequent development of anaerobic lactic acid bacteria. In this stage a small amount of lactic acid is accumulated, but formic, acetic and succinic acids are already formed, a large amount of carbon dioxide and hydrogen is released, causing strong foaming.

In the second stage of fermentation, aerobic microflora gradually gives way to anaerobes. Heterofermentative lactic acid bacteria Leuconostoc mesenteroides begin to develop, the concentration of lactic acid reaches 1%. Acetic acid, ethyl alcohol, mannitol, various esters also accumulate. All these substances are involved in the formation of taste and smell of the product.

The duration of the first two stages is from 3 to 6 days.

The third stage is considered the main preservative. During this period, there is a maximum accumulation of lactic acid with the participation of L. plantarum homofermentative lactic acid bacteria. In this case, only one lactic acid is formed, there are no foreign metabolic products and gases. The concentration of lactic acid reaches 1.5%. The duration of the third stage at low temperatures is about 3 weeks.

At the fourth stage, the activators of heterofermentative lactic acid fermentation are reactivated, mainly L. brevis. These microorganisms are capable of fermenting not only sugars, but also peptoses, and are also good aromatics that ultimately form the taste and aroma of sauerkraut.

The whole process of fermentation lasts from 3 to 5 weeks. Attempts to activate the introduction of pure cultures of lactic acid bacteria L. plantarum and Leuconostoc menenteroides did not give positive results compared with the fermentation on a spontaneous microflora.

The processes occurring during the fermentation of cucumbers, tomatoes and other vegetables, in general, are similar to the processes of sauerkraut. The only difference is that fermentation of vegetables occurs after pouring them with saline (the salt concentration is from 3 to 7%, depending on the type of vegetables). As with sauerkraut, due to plasmolysis, part of the cell sap of vegetables, including carbohydrates, necessary for the development of lactic acid bacteria, goes into saline solution. However, in the epiphytic microflora of vegetables, less lactic acid bacteria are present, the resulting brine contains few carbohydrates, which results in less accumulation of lactic acid than in sauerkraut.

As a whole, the specific feature of vegetables affects the result of fermentation. So, in the initial stage of cucumber fermentation, the soil bacteria remaining after washing was actively developed. Then the process continues weak acid formers Leuconostoc mesenteroides, Streptococcus faecalis, Pediococcus cerevisiae. In the same period, favorable conditions are created for the development of yeast and mold fungi, which should not be allowed.

As with cabbage fermentation, the main acid-forming agent is the homofermentative lactic bacterium L. plantarum, and L. brevis promotes the accumulation of acetic acid, alcohol, mannitol, and dextran in cucumbers.

The total amount of lactic acid formed is 1-1.5%. When stored in the cold, this amount ensures the safety of cucumbers.

A variety of fermentation is urinating. Fruits (berries) are poured with a solution consisting of a mixture of salt (1-1.5%), sugar (2-3%) and rye malt (0.5-0.75%). Thanks to the malt in the pot, the amount of sugars increases, which contributes to the better development of microorganisms.

The preservative effect during urinating is achieved by lactic fermentation with the participation of L. brevis and alcoholic fermentation caused by the yeast Saccharomyces ellipsoideus. As a result, 0.6-1.5% of lactic acid, 0.8-1.8% of alcohol accumulates.

Thus, the main preserving agent in all of the above methods of processing vegetables and fruits are the waste products of microorganisms, which is taken into account in the corresponding production technologies.

For souring using white cabbage late or medium varieties.

Early ripening varieties of cabbage for this purpose are undesirable because they have a reduced sugar content and loose tissue, and therefore they produce a poor quality product.

For souring the following varieties of white cabbage are recommended: mid-ripening - Belarusian, Saburovka, Slava Altai, Slava Gribovskaya, Mozharskaya; Late ripening - Amager, Moscow late, Slavyanka, Zavadovskaya, Kubyshka.

The technical stage of cabbage maturity is characterized by fully formed dense heads of cabbage, the weight of each of which must be at least 0.7 kg.

By chemical composition, cabbage should contain about 10% of dry substances, including 4-5% of sugars. The amount of nitrogenous substances in the raw material is from 1 to 2%, which ensures the normal development of lactic acid microorganisms. Cabbage is rich in vitamin C (26-60 mg%), which is well preserved in the fermentation process.

It is desirable to recycle heads of large size. The more cabbages, the less waste in the processing of cabbage.

Cabbage before souring free from the cover green leaves. Defective leaves are also removed at the same time. The stump is cut flush with the head. The stump is rich in valuable chemicals - sugars, ascorbic acid. However, it has a coarse fabric that may undesirably affect the taste of the product. In order for the presence of the stalk in sauerkraut to be slightly imperceptible, it is cut with a knife into 4-6 parts or reamed.

The cabbage prepared in this way is ground - chopped, receiving chips 2-3 mm thick and up to 5 mm wide, or chopped into pieces of 8-12 mm in size.

To improve the quality of products, carrots cut into circles or chips are added to the cabbage; sometimes use apples of small or medium size, as well as berries - lingonberries or cranberries. In addition, spices are used - cumin or bay leaf.

For sauerkraut in industrial conditions, use cemented or wooden voshniki (vats) with a capacity of up to 20 tons each. For small scale production, barrels with a capacity of up to 200 liters can be used for pickling cabbage.

New wooden packaging contains tannins and resinous substances in wood that can cause darkening and degrade the taste of the product. In order to avoid this, new wooden preschoolers are poured with water for 15-20 days, changing the water during this time 3-4 times. After soaking, the whalers are washed with a hot solution of caustic (0.2%) or soda ash (0.5%) and then with cold water. When using old wooden preschoolers, they are limited to washing with hot water and soda.

In order to avoid brine leakage, the walls of the preschoolers are covered with a thin layer of white food molten paraffin, sometimes adding rosin to it.

Before loading the cabbage, the dogmen fumigate for 8–10 hours with sulfurous anhydride obtained by burning cherenous sulfur. At the same time, the followers close the sheet with a tarpaulin, and also strictly adhere to safety regulations.

The barrels are prepared in the same way as the preschoolers, but instead of washing with soda solution, fill them with this solution into 1/3 of the container and heat the solution to a boil with steam supplied by a hose through a tongue-and-groove hole. Then the hole is closed (wooden stopper and rolled barrel for 10-15 minutes. The concentration of caustic soda solution is 0.08%, and soda ash - 0.2%. It is desirable to fumigate the drums by burning sulfur wicks.

Cemented tanks are plastered from the inside with high-quality cement with zinc surface and covered with an insulating layer of paraffin with the addition of 50% rosin.

Chopped cabbage together with auxiliary materials are loaded into a preschooler, smoothed, densely tamped and sprinkled in layers of table salt, which is added in the amount of 2-2.5. These conditions stimulate the development of lactic acid microorganisms, and in addition, contribute to the preservation of vitamin C contained in cabbage.

In the first period of fermentation, abundant gas formation is observed, as a result of which the cabbage volume increases by 2-3%. Although in the future the volume of cabbage is significantly reduced and becomes less than the initial one, preschoolers should not be overloaded during filling in order to avoid loss of juice. Sometimes they practice laying the upper layers of cabbage with a cone that protrudes beyond the limits of the preshnik to a height of 0.5–0.8 m. In this case, temporary plywood boards are extended in the forebears.

The cabbage loaded into the preschool is covered on top with washed cabbage leaves, and then with canvas. Cabbage leaves can also be laid on the bottom of a prednik.

A wooden under pressure circle is placed on the cabbage over the fabric, which is pressed with a screw press so that a brine layer with a height of 3-5 cm is formed above the surface of the circle.

In the absence of a screw press, a load (oppression) weighing 70-100 kg per 1 ton of cabbage is placed on the compression circle. The created pressure accelerates the release of juice by the cabbage and promotes the formation of brine.

High quality sauerkraut can be obtained by applying pure cultures of microorganisms that cause lactic acid fermentation. These cultures are administered as a starter. Sourdough with the help of a watering can to water each layer of cabbage, laid in the foremen.

Pure cultures of non-gas-forming lactic acid bacteria B. brassicae fermentati and Sacch yeast are used to make sourdoughs. brassicae fermentati, which the plants receive in liquid media, pre-packaged in bottles.

Lactobac also provides good quality sauerkraut. plantarum, which multiplies rapidly, fermenting cabbage juice to a content of 0.6-0.8% of lactic acid in the first days of fermentation.

The preparation of the leaven is the reproduction of pure cultures of microorganisms. This process is done for bacteria and yeast separately. As a medium for fermenting, use cabbage juice and cabbage broth.

Juice is taken from the preschoolers on the third or fourth day after the start of the fermentation of cabbage. In the later period of fermentation, juice is unsuitable for the manufacture of ferment, since it contains few nutrients (sugars) due to the fact that they were used by lactic acid microorganisms in the fermentation process. If the amount of the selected juice is not enough, then it can be diluted with boiled water in a ratio of 1: 1, then add sugar at the rate of 1% to the amount of diluted juice. The juice is filtered through a cloth and boiled for sterilization for one hour.

Cabbage decoction is produced by cooking fresh chopped cabbage in water. When the cabbage is softened, the broth is filtered and added to the juice.

In order to eliminate the influence of extraneous microflora, the nutrient medium obtained from cabbage juice and broth is sterilized with steam for 30-40 minutes at 105-110 ° C.

After sterilization, the nutrient medium is poured into barrels, cooled to 30 ° C, and then 1% pure liquid culture is added through the tongue-and-groove hole, stirred and left to stand for 3 days. For effective reproduction of lactic acid microorganisms, the temperature of the medium in the process of aging should be 25-30 ° C.

In order that extraneous microflora does not develop, the barrels are treated with steam, the tongue-and-groove openings are sterilized with alcohol before the introduction of pure cultures; thermometer, which check the ambient temperature, wipe with alcohol, etc.

Prepared yeast, obtained from lactic acid bacteria, is cloudy, has a pleasant sour taste and smell. Under a microscope, single sticks or short chains consisting of 2-3 bacteria are distinguishable in it.

Pure culture of yeast after its reproduction in the described way has a pleasant smell characteristic of the fermented products; copious foam is released on the surface. Under the microscope, small, slightly oval-shaped budding cells are visible.

The appearance of the film in the surface layer of the leaven is unacceptable, as it indicates the development of extraneous microflora.

After the breeding of pure cultures of bacteria and yeast, they are mixed and the resulting leaven is added to the amount of 1.25% of the cabbage that is put into the predator (including 1% of the leaven of bacteria and 0.25% of yeast). The acidity of the finished ferment is 0.7-0.8%.

The fermentation process that occurs when sauerkraut can be divided into three stages.

AT first stage salt removes moisture contained in raw materials and causes plasmolysis of cabbage cells. The extractive substances found in cabbage cells are transferred to brine. At the beginning of the fermentation process, the brine concentration is high and microorganisms in it cannot develop. As further moisture is released from the raw material, the brine concentration drops and conditions for microbiological processes are created.

Strong gas formation begins, caused by the activity of yeast, coli bacteria, Leuconostoc mesenteroides and other microorganisms. The resulting foam is removed, as it is a good medium for the development of foreign microorganisms. At the same time, lactic acid bacteria, which gradually occupy the dominant position, begin to act.

The beginning of the reproduction of lactic acid bacteria ends the first stage of the process. This stage should be carried out quickly so that the lactic acid that is formed suppresses the development of foreign microorganisms as soon as possible.

Second stage - major fermentation - characterized by the accumulation of lactic acid as a result of the decomposition of sugars caused by the action of B. brassisae fermentati, B. brassicae acidi, L. cucumeris, L. plantarum, etc. In the last stages of the process, bacteria like L. pentoaceticus, which show activity even at lactic acid concentrations close to 2.5%. At the end of fermentation, non-gas-forming lactic acid bacteria predominate.

The nature of the products of fermentation and, consequently, the taste of sauerkraut, as well as the rate of fermentation depend on the temperature at which this process takes place.

The most favorable for both the first and second stage of the process is a temperature of about 20 ° C, at which fermentation lasts 10 days. At this fermentation temperature, the relatively rapid development of lactic acid bacteria is ensured, and therefore side processes are inhibited. At the same time, sauerkraut turns out to be of good quality, with a lower content of alcohol and volatile acids, with a higher degree of preservation of ascorbic acid than in cases where the fermentation process takes place at a lower temperature.

As the temperature drops to 10-12 ° C, the duration of the fermentation process is doubled compared with the duration at 20 ° C. At a temperature below 15 ° C, fermentation stops when the concentration of lactic acid in the product reaches 1%. At lower temperatures, fermentation is delayed for 2-3 months, and at close to 0 ° C, it may not occur at all. Temperatures above 25 ° C are also undesirable, since they contribute to the active development of extraneous microflora.

Lactic fermentation is suspended when the product forms 1.5-2.0% lactic acid. The most pleasant to taste is cabbage acidity of 0.8-1.2%. The acid content in the product is controlled by changing the temperature at which the fermentation is carried out, as well as the concentration of salt. The content of table salt in sauerkraut is 1.2-2.0%.

Third stage The fermentation process is characterized by the fact that the accumulated lactic acid begins to inhibit the activity of lactic acid bacteria. At the same time, under conditions of high acidity, molds and membranous yeasts thrive, which destroy lactic acid. In order to prevent the development of these microorganisms, sauerkraut should be stored at 0h 2 ° C.

The product is stored in the same preschoolers in which it was fermented, or overloaded in barrels.

Where climatic conditions allow, it is advisable to keep cabbage in the preschoolers under ice shelter. The unloading of sauerkraut from preschoolers can be mechanized. The VD Anisimov machine, designed for this purpose, consists of a trolley having a turntable on which an arrow is mounted. At the end of the boom there is a gripping mechanism consisting of teeth that can be moved apart and compressed. For unloading the bottom of the preschool containing a lot of brine, removable brushes that form the buckets are put on the teeth.

Cabbage, loaded into the barrels, tightly tamped in order to eliminate its contact with air. After capping, the barrels are filled with brine through the tongue-and-groove opening and sent to storage. When storing cabbage is stored, it is ensured that it is always covered with brine in order to avoid loss of vitamin C and unwanted microbiological changes.

Cabbage kvasyat not only in a shredded or chopped form, but also whole heads of cabbage. For this purpose, they use dense heads of cabbage, which are preliminarily freed from the covering leaves. Heads (whole or halves) can be kvass shifting layers of chopped or chopped cabbage, adding, as usual, table salt.

In addition, whole heads of kvass and without chopped cabbage. In this case, the cob of the heads is incised, and then they are laid in the foremen and poured with a solution of sodium chloride at a concentration of 4%.

To lengthen the shelf life of sauerkraut at the end of fermentation can be preserved, sterilizing it after packaging in hermetic containers. To this end, the sauerkraut unloaded from the boatmen or barrels is separated from the brine, allowing it to drain freely. Then the cabbage is subjected to inspection and packaged in a glass container. Since sauerkraut easily darkens in the air, the processing process must be carried out quickly, so that the cabbage remains without brine for no more than 5-7 minutes.

Separated from cabbage juice is heated in double-sided boilers until boiling. If necessary, the juice can be diluted with a 1-2% solution of table salt in a ratio of not more than 1: 1.

Cabbage juice is highly corrosive. Therefore, boilers and equipment must be made of non-corrosive material - stainless steel - or coated with enamel.

When packaging in tare, first pour the brine, then put the cabbage, slightly pressing it. The amount of cabbage when laying is 85-90%. The cabbage must be covered with brine, otherwise it will not warm up evenly, which may lead to further damage to canned food. The filled container is rolled on a vacuum sealing machine, sterilized at 100 ° C and cooled. Since the sauerkraut darkens and softens during sterilization, this product has not received distribution.

Abroad, the practice of packaging sauerkraut in plastic bags with a capacity of 500 g. To avoid discoloration of cabbage under the influence of ultraviolet rays, polyethylene is painted in pale green or pale yellow.

Defects of sauerkraut. The main defects that are sometimes observed in sauerkraut during storage in non-hermetic containers are: discoloration of the product, unwanted softening of the tissue, the appearance of mucus. Under certain conditions, rotting and spoilage of sauerkraut can occur.

The darkening of the cabbage is caused by its oxidation with oxygen in the air when brine flows out and the cabbage surface is exposed. The cause of darkening is sometimes the development of extraneous microflora. This is observed when the fermentation temperature is too high (about 30 ° C) or in the case of uneven distribution of sodium chloride in the hammer. Increasing the salt concentration in certain areas of the prednik delays the development of lactic acid bacteria, creating conditions for the activity of foreign microorganisms. Darkening is sometimes caused by chemical reactions between tannins extracted from wooden containers and iron compounds, table salt added to the product. Finally, the darkening of the cabbage may be the result of the onset of decay of its upper layers.

The activity of extraneous microflora can cause not only darkening, but also other changes in the color of the product. In particular, under the influence of Torula yeast mushrooms, sauerkraut becomes pink. These mushrooms are aerobes, and therefore pinking is observed in the upper layers of cabbage. The development of yeast, causing pink staining, contribute to elevated fermentation temperature, as well as factors that hinder the development of lactic acid microorganisms (significant acidity of cabbage juice, low content of nitrogenous substances).

In addition to pinking, yeast can cause the formation of a white film on the surface of the product.

The softened, flabby consistency of sauerkraut is due to the reduced amount of salt that is added during fermentation. At the same time, a sufficiently rapid release of juice is not ensured and the beginning of fermentation is delayed. This factor, as well as the increased temperature of the process and aerobic conditions, disrupt the normal development of lactic acid bacteria and the usual sequence of microbiological and biochemical processes for fermentation. As a result, extraneous microflora leads to softening of the sauerkraut tissue.

Occasionally, the appearance of mucus, which degrades the taste of the product, is caused by the rapid reproduction of some races of lactic acid bacteria. This phenomenon takes place at elevated fermentation temperatures, which are therefore undesirable from all points of view.

Product rot caused by bacteria. Sometimes they are preceded by the abundant growth of mold fungi that consume lactic acid. Reducing the amount of lactic acid can lead to the further development of putrefactive microflora in sauerkraut. Rotting can occur if the fermentation process is carried out incorrectly and especially if the required storage conditions for the finished product are not satisfied.

If you find an error, please highlight a piece of text and click Ctrl + Enter.

Sauerkraut is the favorite preparation for the winter for millions of people. And not only here in Russia, but also in other countries of Europe and Asia. As soon as the first frosts occur on the street, then it is time to harvest for this vegetable.

Before starting the recipe, let me tell you what happens during the starter process itself. This is important for understanding the whole process. When you do something consciously, knowing why it is needed, it is much more difficult to make a mistake. And the result in this case is more predictable.

It is believed that if we salt a certain product, the salt is preservative and helps to protect the product from spoilage. In part, this is the case. But not in this case.

When we make sauerkraut, the preservative is lactic acid, which accumulates in vegetables. And this acid is formed due to lactic acid bacteria that are on the surface of fresh cabbage leaves. Nutrition for them is sugar, which is also found in the leaves of the vegetable culture.

Therefore, for pickling you need to choose large cabbages of a light color. They are juicy, tasty, at the same time elastic. When you cut them, their leaves literally sprinkle fresh juice. The taste of these leaves are slightly sweet, they want to eat even fresh, without stopping.

And only autumn varieties are suitable for pickling, best picked up by the first frost. The heads of cabbages all summer gained weight, juice, various vitamins and useful substances, and stored sugar. Which is simply necessary for a successful leaven.

Therefore, when you buy cabbage, then choose large, always white forks. No wonder the name of this cabbage - white. It is from this and get the most delicious snack for the winter.

And so, it is now clear that sugar contributes to a good fermentation process. But this will not be enough, without the necessary air temperature. In order for the fermentation processes to start and our cabbage to become fermented at its best, a temperature of 15 to 22 degrees is needed. If the temperature is below this value, the fermentation processes will be sluggish and long. Cabbage peretozhit, and we do not get the desired taste. If the air temperature is higher than the desired value, then the cabbage will quickly soften, lose its appearance and become useless to no one.

Delicious fermented cabbage can be determined without even trying, namely, only by appearance and smell. It is light and elastic, has such a fragrance that it will be difficult to pass by.

This is the cabbage I propose today to cook in the simplest classical way.

Sauerkraut for the winter on the classic recipe - a step by step recipe

Calculation of products I offer for 1 kg of cabbage. I do it for convenience. Thus it will be easier to make a proportion for any weight. After all, all of her kvasyat in different volumes, someone will ferment and a whole keg, and someone only a three-liter jar.

We will need:

- white cabbage - 1 kg

- salt - 10 - 15 gr (1 - 1.5 tsp)

- carrots - 1 pc (small)

- bay leaf - 1 - 2 pieces

- black allspice - 3 - 4 peas

Cooking:

At the beginning of the article, I already told you that in order to ferment you need to choose large white forks. They should be tight and elastic to the touch. Now in the season there is just a huge offer of different varieties. So, should be divided varieties, some of them are better suited for storage, while others are better to pickle and sour.

Among the first there are varieties that are not particularly designed for pickling. Some of them gain strength only a month or two after they have been collected. These are so-called hybrid varieties. Only by this time the amount of sugars necessary for fermentation accumulates in their leaves. And it is clear that if you pickle such a vegetable right after harvesting, then it will be difficult to get the desired taste, and even probably not possible.

Some varieties have thick, rough veins, and there is very little juice in the leaves. They are also well stored, but it is not possible to salt salted tasty cabbage. From it, even a delicious salad can not be prepared.

Such varieties as Slava, Podarok, Gribovskaya, Belarus, Sibiryachka ... and others are considered traditional for salting. But, in principle, it is possible to determine the suitable cabbage for salting or not and not knowing the variety, but simply to determine it by its appearance and taste.

When they start selling this vegetable in large quantities, bringing it to the markets directly on the machines, I look first of all at its appearance. If it suits me, I buy a head out and carry it home. I try there, and if the cabbage is juicy, sweet and tasty, it means you can go and buy as much as you need. Try to choose with the largest and white copies.

Why I explain it in such detail, because the correct cabbage is almost the main key to success in pickling. Therefore, give your choice a worthy attention.

Now let's get to the recipe itself.

1. Remove the top, so-called cover leaves from the cabbage. Rinse the head with cold water, holding the cob with the hand. So the water will only wash the top layer and the plug will not get inside. Put the cabbages on the table to make the glass water, then wipe with a dry towel.

2. Cut the cabbage into two parts and chop each of them in long, thin strips. To do this qualitatively you need to stock up on a good sharp knife. And if you have a special shredder in which there are two or three sharply sharpened knives at once, then in general everything can be shredded very quickly and without any particular difficulties. There are a great many varieties of such shredders at the moment.

And before the cabbage just chopped in wooden troughs with a special chop. And now such devices are still used. I also have this somewhere. But I prefer cabbage, so I do not use these devices.

The stump is not shred, just throw. Earlier, when mother salted cabbage, then we, being children, stood in line for them. Now we don’t give them to children. It is believed that they accumulate a large amount of nitrates, and this product is harmful to health. Maybe so, but no, no, no, for myself I clean the stalk and eat it with pleasure.

3. Salt the chopped vegetable and slightly crush it with your hands. But only lightly, so that the cabbage is only slightly moistened. And some, especially juicy varieties, do not even require it. This heading is immediately visible, just starting to cut it, the juice from under the knife and sprinkles.

Cabbage of these varieties simply salt and mix, then tightly tamped in a bowl for salting. After quite a bit of time, a sufficient amount of juice will appear.

Sometimes cabbage turns salted. This is due to the fact that some people believe that the more salt they put, the better the cabbage will be stored.

So, I know that you can ferment cabbage without salt at all. It is stored, of course, less than salty, and not so tasty. But still sour and stored! We remember that the fermentation process does not cause salt, but sugar. Therefore, add salt is not much, but just as much as required by prescription. Or rely on your taste. You can try the sliced product, it should taste the way a cabbage salad usually turns out.

4. Carrot rubbed on a coarse grater. Add it to the total mass.

Do not press cabbage with carrots. Without this procedure, it will remain white and beautiful for the entire shelf life.

5. Add allspice and bay leaf. Stir again.

6. Harvest sauerkraut can be in cans, in large enameled pans, in tubs and barrels. Later I will tell you how to prepare tubs and kegs for pickling.

Banks and pots just need to be thoroughly washed and dried. Pay attention to that in a pan there were no chips and rust spots appeared in these places.

Remove the top leaves of the vegetable and cover them with the bottom. You can skip this procedure. But I used to do it, and share my experience with you. In general, I consider this procedure necessary and obligatory for pickling in barrels and tubs.

7. Put the cabbage into the pickling bowl, pressing it down lightly with your hands.

When you salt a lot of cabbage, for example in large twenty-liter pans or coils, it is best to do it in small batches. Sliced one in the head of cabbage, salted, slightly crushed, mixed with carrots, laid out in a saucepan and tamped tightly. Then proceed to the next batch, and so on until the end.

Large volume will be harder to tamp. It is important for us that the vegetable starts up juice, which will be enough for a good fermentation process. And for the best education of the juice is better to handle the cabbage is not very large portions.

8. When all the cabbage is in the container, it should be carefully pressed down by hand, put the cabbage leaves and cover with a double - triple layer of gauze or linen cloth. Tuck the edges so that the sliced vegetable does not protrude.

Put on a gauze flat plate of a suitable volume, the larger it is, the better. This will be a guarantee that the whole cabbage will be covered with juice. My grandmother had a wooden circle specially cut out for the pot. He was both oppression and "cover". Thanks to him, one could not be afraid that mold would appear on the surface.

9. Put oppression on top. It can be a carefully washed and scalded cobblestone, or a can of water. The cobblestone is good because you can subsequently close the pan with a lid. The bank can only be used for a few days while the fermentation process is going on. At this time, the pan can not close. Then you will need to find something more suitable.

The oppression is needed so that the whole cabbage was covered with juice. It is important. If this is not done, then mold will appear on top, it will not take long to wait. And it is completely useless to us, it spoils the taste and appearance. From the mold, the cabbage turns gray, that is, it loses its appearance. Naturally, this affects its taste.

Therefore, do not ignore oppression. He needed necessarily. And preferably for the entire storage process.

10. Leave the stockpot at the room temperature for 1 - 2 days. Time depends on the temperature in the room. If it is very hot, one day is enough; if it is cooler, then it will take two days.

At this time, we can not forget about our stocking. She will need to pay attention several times a day. Namely, armed with a long wooden stick, pierce it in several places to the very bottom three to four times a day. Especially like to do little kids. They take full responsibility for this instruction. It is very interesting for them to observe how after another penetration, bubbles rising from the fermentation processes rise to the outside.

In addition to escaping gas bubbles, foam is also formed on the surface. Don't let that scare you, cabbage is fine. Regard it as an excellent signal, the fermentation processes go as it should.

Pierce chopped cabbage with a stick should be required. If gas bubbles do not come to the surface, they will make the finished product taste bitter.

Do not store at this temperature longer than this time. Just one extra day and cabbage perekiset enough. And it will not be saved. It will become soft, it will have an unpleasant taste. You can’t even make a stew out of such a product, it will all be felt.

11. After these 1 - 2 days of standing at room temperature, the pot with the billet will need to be placed in a cooler room, where the temperature should be 16 - 18 degrees. This is the ideal temperature for further fermentation. It ends in 2 - 3 weeks. During this time, you can poke cabbage with a stick at least 1 - 2 times a day.

Each time removing the oppression and gauze. And then again returning everything in place.

If, however, such a nuisance happened, and mold appeared on the surface, then it must be carefully removed. And wash the napkin, oppression and plate in hot, salted water.

12. When the fermentation process is over, and this will be seen by the fact that bubbles stop rising and foam is formed, the contents need to be moved to a cold place, and stored at 0 - 2 degrees all the time.

Usually they store it on loggias and balconies, and if there are no such conditions, then they shift it into three-liter jars and store it in a refrigerator. Store should also cover the contents of gauze, and to figure out how to organize the oppression.

In the refrigerator, the approximate temperature is 4 degrees. For storage it is somewhat larger than necessary. But if the bank has a sufficient amount of brine and good pressure, then it will be stored.

By the way, this tricky way of using oppression is used for cans. Simply put the capron lid in the jar and press it contents.

The cabbage prepared in this way is tasty without any additives. You can eat it just without everything. Well, if you chop onions into it, and season it with vegetable oil, then you simply cannot find a salad.

It is also indispensable for the preparation of vinaigrettes, many first and second courses. Should it be reminded that it is a source of various vitamins and nutrients? Probably not, everyone knows this and so, from early childhood. And no one even has to persuade her to eat. As soon as she appears on the table, she becomes his queen. And so the whole winter ... She does not get bored either in the fall, or in the winter, or in the spring.

Now, of course, very tasty cabbage can be bought both in the market and in the store. Experts who procure it, know a lot about it. But not all! If you have already found a path to a good supplier, then you can buy and buy. But not always this track is available. It may be half the winter, while we protopchem it.

And having prepared it yourself, you can not even waste time searching. Just when I wanted, I got the cabbages from the loggia or from the refrigerator, and enjoy its taste as much as our organism requires.

The proposed method is not the only classic option. This is the so-called brine-free process. But you can cook it with brine.

Sauerkraut - recipe with brine for 3 liter jar

This method is often used for sauerkraut in the apartment. It is very convenient for salting the product in banks. The most convenient way to harvest it in a three-liter jar. It is convenient to store such cabbage in the refrigerator, and to prepare not really big parties.

Basically, this method of preparation differs little from the first recipe. The main difference is that the pickle is also prepared, and the cabbage is pre-sliced and placed in a jar. Since the brine contains both salt and sugar, it is this that contributes to the onset of fermentation. It also provides an opportunity to quickly ferment the entire workpiece.

And I must say that this method is quite fast. On the third day, the product is completely ready for use. No need to wait two - three weeks, so it's time to enjoy its taste.

That is, in the first embodiment, there is a natural fermentation, and here we help him in this.

This recipe is very fond of housewives, and men are not averse to using it for cooking. We now live in a fast time, and it is very much appreciated. Therefore, if the same product can be cooked faster, then often choose it.

Recipe time tested. The result is always predictable and always happy. Therefore, choose it and harvest the cabbage on it. He will definitely not disappoint you!

What can sauer cabbage

In different regions of Russia methods of fermentation may vary. The recipe is almost the same, but the methods have a difference. In the European part of Russia, quite a few carrots are added, and the final product has a pronounced white color. Often bright cranberries are used as an additive for taste and color.

In the Far East and Siberia, more carrots are added. Cabbage is more sweet to the taste and has a light carrot shade in color. By the way, in Central Asia more carrots are also added (this is how we salted it when we lived there).

However, these are not all ingredients used in salting. Kvass it with such additional ingredients

- apples, Antonovka variety is best. Put them in one piece, in halves and quarters. In general, who likes more.

- carrots

- hot peppers

- beetroot

- parsnip. It can be used together with carrots, and instead. It turns out very tasty!

Of course, the berries in this process are not the last, this

- already mentioned cranberries

- cowberry

- juniper berries

As spices added

- allspice peas

- bay leaf

Very - very - very tasty fermented kochanchiki. Never cooked like that? Then take note rather. Cook once, and then you will always cook the cabbage only with them. Telling how to do it.

Everything is done exactly as described in the recipe. The only thing that a kilogram of cabbage in this case is indispensable. Salting cabbages in the pan should be at least 5 liters of volume, and of course a larger volume is also welcome.

The first layer must be laid out cabbage. It is better that the layer was at least 10 cm thick.

Then cut cabbage into large chunks, at least 15 cm in size. And if the heads are small in size initially, you can only cut them in two halves, or even cross them crosswise. Each of them should be rubbed with a small amount of salt, rubbing it literally inside. Then tightly lay the next layer. Thoroughly press.

And the next layer is ordinary again, made of cabbage, cut into strips and mixed with carrots.

So you can alternate layers, while allowing capacity for salting. All tightly tamped. To achieve the formation of juice. Similarly, cover the top layer with cabbage leaves, gauze or a napkin. Put a flat plate on top and put the oppression.

Also poke a stick, carefully avoiding forks.

How to prepare a container for pickling cabbage

In the villages before they salted cabbage in tubs and small kegs. There were no refrigerators, and the cold cellar was the only storage place. Moreover, the barrel was buried in the ground by 30–40 centimeters to maintain the required temperature.

But since they did it from year to year, and the barrel served its service for many years, the container had to be processed before salting the cabbage.

Although we do not live in the village now, but I have two oak barrels. In one of them, I salt in another cabbage. And every year I process the container in the way I found in one of my books. And now I will share with you the ways I know. Suddenly, someone will come in handy.

First I want to note the fact that in barrels and wooden tubs it turns out just incredibly tasty sauerkraut. In addition to taste, it also receives an incomparable aroma.

But new barrels, and old ones often crack, and brine can flow through the gaps. Oak barrels are better in this respect, the wood is stronger and less cracked. But they also require treatment to prevent mold.

Therefore, the container must be processed on the subject, so that it does not crack, and to be thoroughly disinfected.

So that the whole brine does not flow out of the barrel, they must be soaked in order for the wood to swell. To do this, put the keg in the basin and pour water into it. Leave for a while. If water flows through the gaps, then add it again. So stand until the tree absorbs water and the flow does not stop. At the final stage you can bring a few sprigs of heather from the forest. Put them in a barrel and pour boiling water. It is useful for aroma and disinfection.

To disinfect the barrel, you can still fumigate with sulfur. Also, as the pits before laying there vegetables for storage, fumigate with sulfur checkers. And in the case of a barrel, special wicks are used, which are ignited and left in the tank until complete combustion.

Also, the barrel can be disinfected by laying cobblestones heated on a fire inside, or one large stone. This should be done extremely carefully, so as not to burn yourself. And in order to keep the cobblestone cool a little longer, it is still poured with boiling water, and the tub is tightly closed with a lid.

In the future, this stone can be used as a yoke.

So tubs and barrels are a good thing, but they require careful attitude and attention.

At the end of the article I want to tell you that in addition to the described methods of sauerkraut cabbage, there are also other ways of its preparation. For example, they can be attributed. There are many such methods, and 7 of them I can offer you in an article that you can find by clicking on the link.

These are also pretty quick cooking methods that are also tasty. One cabbage "Pylyustka" with beets is worth something!

I hope that the recipes written today, and most importantly the advice, will stand in good stead, and you can always harvest very tasty and flavorful cabbage for the winter.

I wish you excellent preparations and enjoy your meal!

What is vegan and syroedu in winter and spring? Fruits and many vegetables from their region are no longer available, and overseas arrive in such a way that you think again ten times, can these fruits be used or harmed?

Recipes and traditions of our ancestors come to the rescue. Not having the opportunity to eat kiwi and pineapples all year round, residents of the central belt, the Urals and Siberia, from time immemorial, were engaged in harvesting and storing vegetables for the winter. The simplest methods turned out to be the most correct from the point of view of health! Sour and pickling.

Today's my story about sauerkraut.

Possessing a tonic effect, sauerkraut activates the body's defenses, and thanks to its antioxidants and rich vitamin composition, it is an excellent prophylactic against viral and seasonal diseases (flu, colds, etc.). It also fights against pathogenic bacteria, reducing the harm they have on our body.

Regular consumption of sauerkraut not only improves the gastrointestinal tract, but also prevents the development of diseases such as peptic ulcer and duodenal ulcer. A fiber-rich vegetable normalizes digestion, and vitamin U regulates stomach acidity. Due to the presence of pyridoxine (vitamin B6), which is responsible for the active breakdown of proteins, and the lactic acid enzymes, the formation of which occurs during the fermentation of the product, very successfully fight against E. coli and other bacteria.

Vitamin C is particularly abundant in it, which helps strengthen the immune system and slow down the premature aging of cells and tissues. 200 grams of the product contains half of its daily allowance, while it is presented in cabbage in two forms - free (ascorbic acid) and bound (ascorbigen), which is not destroyed even during long-term storage, and under the influence of moderate heat treatment turns into ascorbic acid .

Despite the fact that it is a fermented product, we end up with a product that is in weak brine of lactic acid, it inhibits the action of yeast and bacteria and makes our product safe to use.

The fermentation process that occurs when sauerkraut can be divided into three stages.

In the first stage, table salt extracts moisture contained in raw materials and causes plasmolysis of cabbage cells. The extractive substances found in cabbage cells are transferred to brine. At the beginning of the fermentation process, the brine concentration is high and microorganisms in it cannot develop. As further moisture is released from the raw material, the brine concentration drops and conditions for microbiological processes are created.

Strong gas formation begins, caused by the activity of yeast, coli bacteria, Leuconostoc mesenteroides and other microorganisms. The resulting foam is removed, as it is a good medium for the development of foreign microorganisms. At the same time, lactic acid bacteria, which gradually occupy the dominant position, begin to act.

The beginning of the reproduction of lactic acid bacteria ends the first stage of the process. This stage should be carried out quickly so that the lactic acid that is formed suppresses the development of outsiders as soon as possible.

As the temperature drops to 10-12 ° C, the duration of the fermentation process is doubled compared with the duration at 20 ° C. At a temperature below 15 ° C, fermentation stops when the concentration of lactic acid in the product reaches 1%. At lower temperatures, fermentation is delayed for 2-3 months, and at close to 0 ° C, it may not occur at all. Temperatures above 25 ° C are also undesirable, since they contribute to the active development of extraneous microflora.

Lactic fermentation is suspended when the product forms 1.5-2.0% lactic acid. The most pleasant to taste is cabbage acidity of 0.8-1.2%. The acid content in the product is controlled by changing the temperature at which the fermentation is carried out, as well as the concentration of salt. The content of table salt in sauerkraut is 1.2-2.0%.

The third stage of the fermentation process is characterized by the fact that the accumulated lactic acid begins to suppress the activity of lactic acid bacteria. At the same time, under conditions of high acidity, molds and membranous yeasts thrive, which destroy lactic acid. In order to prevent the development of these microorganisms, sauerkraut should be stored at a temperature of 0-2 ° C.

What should be considered when saucing cabbage in order to get the very useful product?

We are engaged in souring or salting vegetables for their preservation, increasing the nutritional value and improving the digestibility of vegetables. Safety is achieved only with the observance of technology, which involves the creation of a brine containing lactic acid. An environment in which bacteria and yeast do not live. In case of violation of technology, both of them will literally turn your vegetables into a loose, slippery product of the most fancy color and smell in just a few hours! But the right product, at a storage temperature of 0-2C, you get out of the brine in February or March and try to do something with it, rot or ferment. I've tried. Until now lies in the compost almost untouched!

The nature of the products of fermentation and, consequently, the taste of sauerkraut, as well as the rate of fermentation depend on the temperature at which this process takes place. The most favorable for both the first and second stage of the process is a temperature of about 20 ° C, at which fermentation lasts 10 days. At this fermentation temperature, the relatively rapid development of lactic acid bacteria is ensured, and therefore side processes are inhibited. At the same time, sauerkraut is good in quality, with a lower content of alcohol and volatile acids, with a higher degree of preservation of ascorbic acid.

Cabbage before souring free from the cover green leaves. Defective leaves are also removed at the same time. The stump is cut flush with the head. The cabbage prepared in this way is ground - chopped, receiving chips 2-3 mm thick and up to 5 mm wide, or chopped into pieces of 8-12 mm in size. To improve the quality of products, carrots cut into circles or chips are added to the cabbage; sometimes use apples of small or medium size, as well as berries - lingonberries or cranberries. In addition, spices are used - cumin or bay leaf.

Put the cabbage in an enameled bowl (remember the acid?) As follows: put large cabbage leaves on the bottom, then put a layer of cabbage with carrots rubbed with salt in a saucepan, put some spices (caraway, sweet pepper or pepper), tamp it down. Repeat the procedure until the end of the cabbage. The ideal value for salt is 2-2.5% by weight (of all!). From above, we also cover sauerkraut with large sheets of cabbage. Then we put a plate on the cabbage sheets and some load on the plate (on the basis of 100g of cargo per 1kg of cabbage). Under the pan, be sure to put a basin - the cabbage will secrete juice that will go beyond the edges of the pan.

Approximately once every two days you will need to pierce the cabbage so that accumulated gas will come out of it.

I want to draw your attention to the fact that very little salt is needed and it serves as a catalyst for extracting juice from cabbage, then lactic acid microorganisms make everything! And yet, cabbage is one of the unique products, the fermentation of which, at least does not impair its nutritional value and usefulness!

Such a seemingly ordinary process, like sour cabbage, can also be considered from a scientific point of view: an interspecific fight of bacteria takes place in an enamelled bucket with cabbage. As a result, lactic acid is formed from sweet sugars, which makes cabbage fermented.

One of the popular ways of souring cabbage involves the use of an enamelled bucket, a wooden circle, a cobblestone and a pelvis to drain the brine. And everything begins with the fact that the cabbage is chopped with a combine, then salt is poured, preferably not iodized, otherwise the cabbage will turn out to be completely non-crisp. Finally, grated carrots and other ingredients — cranberries, apples, etc. — are also added there. Such cabbage will be stored until spring and will not deteriorate. This means that microorganisms will not be created in it, which will turn valuable substances into all sorts of muck.

The best way to get rid of bad bacteria is to have good ones.

so many species of bacteria of the genus Lactobacillus are known to modern science.

In the domestic food literature one can read that special strains of lactic acid bacteria Lactobacillus and yeast are responsible for this process.

During industrial harvesting, pure cultures of these strains are specially kneaded into cabbage. On the Internet, there are recipes for making sourdough for cabbage, but they raise many questions. A particularly large amount of yeast: yet their proprietary reaction — the conversion of sugar into alcohol and carbon dioxide — is not exactly what is required in this case.

In fact, if the cabbage did not grow in the space greenhouse, but in the open field, then it always has its own bacteria and yeast on it. As the centuries-old experience has shown, they are quite suitable for fermentation.

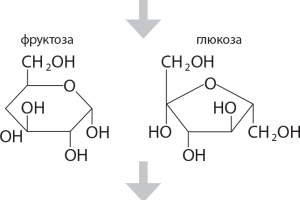

How it works

1. Sucrose Fresh Cabbage

2. Cleavage of sucrose

3. Bacteria convert sugars into acids, alcohols and esters

4. Sauerkraut

The composition of this microbial collective varies greatly, and for sure our sauerkraut is produced by completely different strains than the German one.

Yes, and with the kinds of complete clarity no. In the mid-twentieth century, it was believed that four types of bacteria were leading in a good acid-free ecosystem. Then came the science of metagenomics, examining the genetic material of all the microscopic inhabitants of a particular sample at once, and spoiled the coherent picture, finding many previously undetected species in cabbage.

If you go back to the biological component of the process, you can remember that salted cabbage under oppression generously emits juice, which is a breeding ground for bacteria. During this rich in sugars, the juice flares up a stormy interspecific struggle with the suppression of rivals and the survival of the strongest.

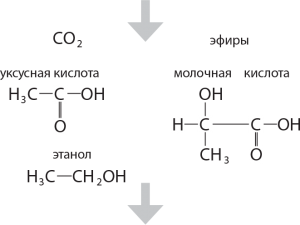

First, hasty species breed, turning sugar into a variety of products: lactic and acetic acid, ethanol, CO2.

Esters are also formed, giving a spicy smell to cabbage. Carbon dioxide, of course, churns the juice - it can even go over the edge, and at this stage it is better to put the bucket “bioreactor” in the pelvis.

From time to time it is possible to poke cabbage with a wooden stick, giving a gas outlet. But do not mix: the right bacteria need anaerobic (oxygen-free) conditions.

Gradually, their environment is acidified so that not everyone can survive in it. The most persistent, primarily representatives of the genus lactobacilli, remain, and among the reactions, the conversion of glucose into lactic acid, that is, sweet fresh cabbage into sour, is dominant. This continues until the sugar reserves are exhausted, and the acid does not suppress the vital activity of all microorganisms, including harmful ones.

The warmer, the faster the process. The ideal is 20 ° C, at lower temperatures, fermentation is delayed, at higher temperatures, harmful bacteria can get over useful ones. Therefore, it is better to put the cabbage near the balcony.

And when the process is completed, it is possible to carry it out on the balcony, unless, of course, the board is not minus thirty.

Lactic acid, like all acids in general, is corrosive to metals, therefore, cabbage must be prepared and stored in wooden, enamelled or glassware. For the same reason, cabbage and pickle should not be poured on by those who suffer from gastritis or a stomach ulcer. The main beneficial property of sauerkraut inherited from fresh cabbage is high content of vitamin C, as well as other vitamins and antioxidants. Just right for the winter.

on "Kota Schrödinger"