What is the difference between inverter welding and simple welding? Welding inverters vs welding transformers

In the construction industry, both traditional welding machines and more technologically advanced inverter ones are used. What is the specificity of both? What is the difference between a welding inverter and a welding machine classified as a conventional unit?

What is a welding inverter?

This type of welding machine is characterized by the ability to convert direct electric current into alternating current. This unit contains the following main components:

- rectifiers - network and frequency;

- filter;

- frequency converter - the actual inverter;

- transformer;

- Control block.

The welding inverter works like this.

Alternating current from the electrical network, which has a frequency of 50 Hz, is fed to the mains rectifier. After that, the current is respectively rectified and then smoothed by means of a filter. Then it is fed to the inverter, in which it is converted into an alternating frequency with a high frequency - about a few tens of kHz. After that, the voltage is reduced by means of a transformer to a level of about 50-60 V, while its strength increases to about 100-200 A. Then the current is rectified by means of a frequency rectifier - already in the process of arc welding.

The frequency converter - the inverter - can be regulated by the welder, due to which the optimal operating parameters of the unit are ensured. For this, another functional element of the inverter welding machine is involved - the control unit.

The main advantages of inverters:

- low weight and dimensions;

- high energy efficiency of welding;

- high precision welding.

Disadvantages of inverters:

- units in many cases require special storage conditions - in terms of temperature, air humidity;

- sensitivity to low temperatures;

- high price, high cost of maintenance and repair.

What is a traditional welding machine?

The "classic" welding machine is characterized primarily by its simple design. Its main functional element is a transformer.

The traditional welding machine works like this.

Alternating current from the electrical network is sent to the primary winding, as a result of which the magnetization of the transformer core is formed. Then the current passes through the secondary winding - in it the magnetic flux forms an alternating current, characterized by a lower voltage in comparison with what is supplied to the primary winding. Its voltage depends on the number of turns on the secondary winding.

The traditional welding machine functions, therefore, due to electromagnetic induction, at which a large current is generated - sufficient for welding, at its low voltage.

The main advantages of traditional welding units:

- no requirements for special storage conditions;

- lack of sensitivity to low temperatures;

- low price, low maintenance.

Disadvantages of the respective devices:

- large weight, dimensions;

- not the most outstanding energy efficiency and accuracy.

Comparison

The main difference between a welding inverter and a traditional type welding machine is the presence of a current converter in the first device. In addition, the units under consideration differ in the aspect:

- weight, dimensions;

- energy efficiency, welding accuracy;

- requirements for storage conditions;

- sensitivity to low temperatures;

- prices, services.

It can be noted that, as a rule, the use of traditional devices requires a higher qualification of the welder.

Having determined what is the difference between a welding inverter and a traditional type welding machine, we will reflect in a small table its main criteria in relation to the aspects discussed above.

Table

| Welding inverter | Conventional Type Welding Machine |

| Includes converter | Does not have a converter |

| Has small dimensions, weight | Has large dimensions, weight |

| May require special storage conditions | As a rule, does not require special storage conditions |

| Features high energy efficiency | Relatively low energy efficiency |

| Features high welding precision | It is characterized, as a rule, by lower welding accuracy |

| Sensitive to low temperatures | Not too sensitive to low temperatures |

| Costs more, involves more expensive maintenance | Costs less, implies cheaper service |

*information posted for informational purposes, to thank us, share the link to the page with your friends. You can send interesting material to our readers. We will be happy to answer all your questions and suggestions, as well as hear criticism and wishes at [email protected]

Today, inverters are increasingly used for welding. Their production and sales are growing, their use is becoming commonplace. Inverter welders today can be found in a small workshop, at a large industrial enterprise, a construction site, or simply in the household of a private house. What is their difference from ordinary (transformer) welding machines? Consider six parameters that are important for any device, and the differences between the inverter and traditional devices in these parameters. We especially note that Resanta welding machines are sold at the link http://www.avtogen.ru/svarochnye_invertory/brand-is-resanta/, see prices.

The quality of the resulting seam

It should be mentioned right away that the quality of the seam is most influenced by the professionalism of the welder, and not by the type of device used. However, with equal skills of the worker, such a feature of the inverter comes into play as the stability of the constant welding current, which does not depend on the supply voltage fluctuations. Accordingly, this current gives a more stable arc and a minimum of metal spatter. The seam will naturally be better.

Of considerable importance is the smooth regulation of the welding current, carried out in a fairly wide range. This allows you to choose the current in such a way that it is optimal for the specific parts to be welded and the electrode used. It is clear that a correctly set current will also affect the quality of the seam, all other things being equal.

Mobility, dimensions and weight

The inverter converts the alternating current of the network into direct current, which, using transistor circuits, is changed into high-frequency alternating current (about 50,000 Hz). This current is converted by a high-frequency transformer into a welding current that forms an electric arc. The principle used in inverters makes it possible not only to obtain excellent current-voltage characteristics, which make it possible to achieve high quality welding, but also to exclude a bulky power transformer from the design of the device.

Due to the use of high frequencies, the dimensions and weight of the transformer are reduced several times, and this leads to the fact that the weight and dimensions of the entire apparatus are reduced. For comparison - conventional welding machines (transformer type) weigh from 20-25 kg or more, and inverters - within 4-10 kg. It is clear that the mobility of the units with such a difference in weight does not make sense to compare, the inverter definitely wins in this parameter.

Power consumption

Compared to other types of welding machines, the inverter consumes relatively little energy and takes less time to work. When working with electrodes with a diameter of 3 mm, the consumption of a conventional welding machine is about 7 kW, and even the cheapest and simplest inverter is unlikely to exceed 4 kW. At idle, consumption drops by an order of magnitude.

The main advantage is that energy is consumed only in the amount that is necessary for welding. Work with a 4 mm electrode can be carried out at a current value of 160A, however, with a supply voltage of about 180 volts, the quality will not be the best with such an electrode. In this case, you need a device of greater power or the use of electrodes of smaller thickness.

Efficiency

The efficiency of the inverter-type welding machine is above 90%, respectively, almost all the energy consumed goes into action, that is, it is used on the arc. The absence of a power transformer not only reduces the mass of the device, but also eliminates losses for the magnetization of iron cores, heating of the windings due to the mutual influence of magnetic fields. There is no power loss on the regulating shunt.

From this we can conclude that the efficiency of the inverter is clearly higher than the efficiency of conventional welders, losses tend to minimum values.

Price

Comparing the prices of welding machines, you can see that the cost of inverters has seriously approached the price of traditional devices. If earlier inverters were more expensive by 2 times or more, today the difference rarely exceeds 20%. Manufacturers from China played an important role here - the prices for their products have always been highly competitive.

Reliability and unpretentiousness

The electronic control of the inverters provides a reliable feedback of the parameters of the arc current with the output properties of the device - when ignited, the device creates an additional impulse that facilitates the formation of an arc. A short circuit almost instantly turns off the welding current - this eliminates the effect of "sticking" of the electrode. Ease of operation, reliability of the device benefit from this.

Their sensitivity to dust and humidity negatively affects the operation of inverters. It is necessary, if possible, to protect the inside of the device from dust entering through the ventilation openings, it is a good idea to periodically clean the device. Store the inverter in a warm, dry place to prevent moisture from forming on the board elements.

The inverter device does not tolerate drops and shocks very well, due to the presence of electronic filling. In terms of unpretentiousness, this type of welder loses to conventional welding transformers.

This is a tool that literally everyone will need on the farm. When working with metal, it is almost impossible to avoid such a process as welding, which means that you cannot do without a welding machine either. In some cases, if you need professional welding, it is better to hire a specialist. However, most tasks (when working in a garage or in the country) can be done independently, while saving money.

The most popular models of welding machines are transformer and inverter welding machines. Consider their main characteristics and compare - which device is still better to choose for your own domestic needs.

Inverter welding machines, in turn, are easier to use. These models are more modern and improved, which is why they can boast of compactness and light weight. The technologies used to create inverters have reduced the weight of the main transformer, and at the same time made it more efficient.

Despite the fact that transformer welding machines have been on the market for much longer, inverters can compete with them in terms of the quality of the work performed. Transformer models are reliable and easy to use, you can adjust the current in them thanks to a special knob that turns the core. On the one hand, this is good - everything is reliable, no electronics that can easily let you down, only mechanics. Simplicity of a design prevents difficult repair work. On the other hand, it takes a long time to turn the adjustment knob, and the scale with the indicators on the transformer gives not entirely accurate information - it is unlikely that it will be possible to adjust the current value without deviations.

The inverter, in turn, is equipped with electronic filling, which in many ways makes it easier to work with the welding machine. The front panel is equipped with a current regulator. In order to switch the value, the knob just needs to be turned to the desired number. In addition, most models of inverter welding machines can be connected to a standard household network.

In addition, learning to weld on a welding transformer is much longer and more painstaking than on an inverter welding machine, which is more loyal to welders with minimal experience. Welding with alternating current is a complicated matter, and with a DC inverter, a quality seam will work out fine even for a beginner. In addition, many inverters are capable of operating in argon-arc welding mode. But it is worth noting that devices of this type are more expensive and are not very resistant to pollution and humidity, and also do not tolerate power surges. This is due to their electronic filling, which must be handled very carefully. But you should not refuse this welding machine because of this - with proper care, such a model will last a long time.

For the use of a welding machine in everyday life, a current of 160-200 A is sufficient, in many cases they work even with a lower value. When choosing a welding machine, you must first take into account the technical characteristics of the model. For example, it is necessary to have information about the duration of continuous operation (NVD), which is measured as a percentage. For example, if the NVD is 30%, then the duration of cooking at the specified current strength will be three minutes. Most inverter devices work without problems from household models of generators, the power of which is 5 kV and above.

The cooking process itself is also different for the models. When welding with a transformer apparatus, several disadvantages appear. These include insufficient arc stability and low mode stability, which depends on drops in the electrical network. Inverter devices show themselves much better from this side - inverters provide a stable direct current, independent of voltage drops. As a result, a more stable arc is formed during welding, and the metal is subject to less spatter. In the inverter, the welding current is regulated more smoothly, in addition, many devices are equipped with additional useful features.

The issue of energy consumption is also very acute when choosing a welding machine. Inverters are more economical, some of them consume electricity at the level of household appliances. Less energy consumption guarantees lower costs, which means inverter devices are more profitable in this matter.

As for the cost, transformers win here. Inverter models are usually two or more times more expensive than transformer models. Repair work is also cheaper for transformers. However, do not rush to conclusions. If you calculate the cost of a welding machine, taking into account several categories of expenses, then everything becomes not so unambiguous. The following categories are usually considered:

- salary;

- the cost of additional working materials;

- the cost of electrical energy;

- the cost of equipment and additional accessories.

If we present all these aspects as a percentage, then the cost of the device itself will take less than five percent of the total costs. This means that more modern devices will be more profitable - even with an overpayment at the time of purchase, a welding inverter pays for itself much faster than a transformer, at least by saving electricity.

Summarizing, I want to say that when buying an inverter, first of all, you should correctly assess your knowledge in the field of welding machines. In the absence of sufficient experience, there is a chance that you simply choose the wrong model that you really need. In such a situation, you should rely on the opinion of specialists and turn to them for help.

In general, the inverter welding machine is a more modern equipment that is distinguished by its practicality and economy. As a result, they can be considered a better purchase for domestic needs. Welding transformers are more often used in production, where stationary installations are more convenient. Not everyone can handle this type of equipment. Many professional welders hone their skills for years to achieve truly first-class results when welding with a transformer type machine.

Attention! The product images shown on the website, including color, size, may differ from the actual appearance of the product. Changes in designs, technical characteristics, appearance, configuration of the goods are possible, without deteriorating its consumer qualities, without prior notice to the consumer. In case of any doubt, before buying, check the technical specifications and equipment on the official website of the manufacturer, as well as with the sales managers. Appearance, the presence of the necessary characteristics and configuration, check at the time of receipt of the goods.

The final price may differ from the prices indicated on the site.

AC(English alternating current) - alternating current.

DC(English direct current) - direct current.

MMA(Eng. Manual Metal Arc) - manual arc welding with stick electrodes. We know it under the name RDS.

TIG(eng. Tungsten Inert Gas) - manual welding with tungsten non-consumable electrodes in a shielding gas (argon) environment.

MIG/MAG(Eng. Metal Inert / Active Gas) - semi-automatic arc welding with a consumable electrode wire in an inert (MIG) or active (MAG) gas environment with automatic wire feed.

PV(PR, PN, PVR) - on duration - the time that the device is able to operate at a certain current (the current is indicated together with PV) before automatic shutdown due to overheating. The PV value is indicated as a percentage relative to the standard cycle, which is taken equal to 10 or 5 minutes. If the duty cycle is 50%, this means that with a cycle of 10 minutes, after 5 minutes of continuous operation, 5 minutes of inactivity is required for the machine to cool down. This parameter can be equal to 10%, so you need to pay attention to it. The concepts: duration of operation (PV), duration of work (PR), duration of load (PN) have different meanings, but the essence is the same - the continuity of welding.

An easy-to-understand diagram of a welding transformer is as follows:

A simple diagram of a welding transformer: 1 - transformer; 2 - reactor with variable inductance; 3 - electrode; 4 - welded part.

To limit the short-circuit current and stable arcing, the transformer must have a steeply falling external current-voltage characteristic ( . To do this, they either use transformers with increased scattering, as a result of which the short-circuit resistance is several times greater than that of conventional power transformers. Or, a reactive coil with a large inductive resistance is included in the circuit with a transformer with normal scattering - a choke (the choke can be included not in the secondary winding circuit, but in the primary circuit, where the current is less). If the inductance can be changed at the inductor, adjusting it, they change the shape of the external current-voltage characteristic of the transformer and the arc current I 21 or I 22 corresponding to the arc voltage Ud.

Welding current control. The current strength in welding transformers can be regulated by changing the inductive resistance of the circuit (amplitude regulation with normal or increased magnetic scattering) or by means of thyristors (phase regulation).

In amplitude control transformers, the required welding current parameters are provided by moving moving coils, magnetic shunts or using a separate reactive coil as in the figure above. In this case, the sinusoidal form of the alternating current does not change.

Scheme of a welding transformer with movable windings: 1 - primary winding, 2 - secondary, 3 - rod magnetic circuit, 4 - screw drive.

Scheme of a welding transformer with a movable magnetic shunt: 1 - primary winding, 2 - secondary, 3 - rod magnetic circuit, 4 - movable magnetic shunt, 5 - screw drive.

There may be a simple change in the number of turns used in the transformer winding, to reduce the open circuit voltage and hence the welding current.

Transformers with thyristor (phase) regulation consist of a power transformer and a thyristor phase regulator with two anti-parallel thyristors and a control system. The principle of phase regulation consists in converting a sinusoidal current form into alternating pulses, the amplitude and duration of which are determined by the angle (phase) of the thyristors.

Scheme of a welding transformer with thyristor control. BZ - task block, BFU - phase control block.

The use of a thyristor phase regulator makes it possible to obtain a welding machine, the characteristics of which compare favorably with the characteristics of a transformer with amplitude regulation. In more complex control circuits than in the figure above, a square-wave alternating current is generated. And in this case, for example, an increased rate of transition of the pulse through the zero value is achieved, as a result of which the time of current-free pauses is reduced and the stability of the arc burning and the quality of the weld are increased. What can not be said about the oscillogram shown above, on it the current-free gaps are larger than those of transformers with amplitude regulation and the quality of welding is worse.

Another advantage of thyristor devices is the simplicity and reliability of the power transformer. The absence of steel shunts, moving parts and associated increased vibrations makes the transformer easy to manufacture and durable in operation.

According to the type of supply network, welding transformers are single-phase and three-phase. The latter, as a rule, can also be connected to a single-phase network. The figure below shows a single-phase and three-phase transformers with current regulation by a magnetic shunt.

Advantages and disadvantages of welding transformers. The advantages of welding transformers include a relatively high efficiency (70-90%), ease of operation and repair, reliability and low cost.

The list of disadvantages is longer. First of all, this is the low stability of the arc, due to the properties of the alternating current itself (the presence of current-free pauses when the electric signal passes through zero). For high-quality welding, it is necessary to use special electrodes designed to work with alternating current. Negatively affect the stability of the arc and fluctuations in the input voltage.

The welding transformer cannot weld stainless steel, which requires direct current, and non-ferrous metals.

If the power of the AC welding machine is large enough, its weight may cause certain difficulties when moving the transformer from place to place.

And yet, an inexpensive, reliable and unpretentious welding transformer is not such a bad choice for a home. Especially if you rarely have to cook, and there is not enough money to buy a more functional model.

Welding rectifiers

Welding rectifiers are devices that convert the alternating mains voltage into a direct welding voltage. There are many schemes for constructing welding rectifiers with various mechanisms for generating the output parameters of current and voltage. Various methods of current regulation and formation of the external current-voltage characteristic of rectifiers are used ( read about the current-voltage characteristic at the end of the article): changing the parameters of the transformer itself (moving coils and sectioned windings, magnetic shunts), using a choke, phase regulation using thyristors and transistors. In the simplest devices, the current is regulated by a transformer, and diodes are used to rectify it. The power part of such devices consists of a transformer, a rectifier unit on uncontrolled valves and a smoothing choke.Block diagram of the welding rectifier: T - transformer, VD - rectifier unit on uncontrolled valves, L - smoothing choke.

The transformer in such a circuit is used to lower the voltage, form the necessary external characteristic and control the mode. More modern and advanced devices include thyristor rectifiers, in which mode control is provided by a thyristor rectifier unit, which performs phase control of the thyristor turn-on moment. The formation of the necessary external characteristics is carried out by introducing feedback on the welding current and output voltage.

Block diagram of the welding rectifier: T - transformer, VS - thyristor rectifier unit, L - smoothing choke.

Sometimes a thyristor regulator is installed in the primary winding circuit of the transformer, then the rectifier unit can be assembled from uncontrolled valves - diodes.

Block diagram of the welding rectifier: VS - thyristor rectifier unit, T - transformer, VD - rectifier unit on uncontrolled valves, L - smoothing choke.

Semiconductor elements of rectifiers need forced cooling. To do this, they put radiators blown by a fan.

The figure below shows a diagram of a welding rectifier in which a change in the resistance of the transformer and current regulation is provided using a magnetic shunt - by closing or opening it using the knob on the front panel of the device.

Schematic diagram of a welding rectifier with a magnetic shunt: A - circuit breaker, T - transformer, Dr - magnetic shunt, L - light-signal fittings, M - electric fan, VD - diode rectifier unit, RS - shunt, PA - ammeter.

Single-phase AC rectification circuits are used in circuits with low power consumption. Compared to single-phase circuits, three-phase circuits provide significantly less rectified voltage ripple. The operation of a three-phase Larionov bridge rectification circuit using diodes, used in many welding rectifiers, is shown in the figure below.

Advantages and disadvantages of welding rectifiers. The main advantage of rectifiers, in comparison with transformers, is the use of direct current for welding, which ensures ignition reliability and stability of the welding arc and, as a result, a better weld. It is possible to cook not only carbon and low-alloy, but also stainless steel and non-ferrous metals. It is also important that welding with a rectifier produces less spatter. In essence, these advantages are quite enough for an unambiguous answer to the question of which welding machine to choose - a transformer or a rectifier. If, of course, do not take into account prices.

The disadvantages include the relatively large weight of the devices, the loss of part of the power, a strong "drawdown" of the voltage in the network during welding. The latter also applies to welding transformers.

Welding inverters

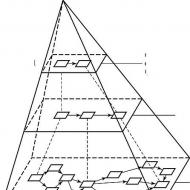

The word "inverter" in its original meaning means a device for converting direct current into alternating current. The figure below shows a simplified diagram of an inverter-type welding machine.

Block diagram of the welding inverter: 1 - mains rectifier, 2 - mains filter, 3 - frequency converter (inverter), 4 - transformer, 5 - high-frequency rectifier, 6 - control unit.

The operation of the welding inverter is as follows. Alternating current with a frequency of 50 Hz is supplied to the mains rectifier 1. The rectified current is smoothed by filter 2 and converted (inverted) by module 3 into alternating current with a frequency of several tens of kHz. Frequencies of 100 kHz are currently being achieved. It is this stage that is the most important in the operation of the welding inverter, which allows to achieve huge advantages over other types of welding machines. Further, with the help of transformer 4, the high-frequency alternating voltage is reduced to idle values (50-60V), and the currents are increased to the values necessary for welding (100-200A). The high-frequency rectifier 5 rectifies the alternating current, which does its useful work in the welding arc. Influencing the parameters of the frequency converter, they regulate the mode and form the external characteristics of the source.

The processes of current transition from one state to another are controlled by the control unit 6. In modern devices, this work is performed by IGBT transistor modules, which are the most expensive elements of the welding inverter.

The feedback control system generates ideal output characteristics for any method of electric welding ( read about the current-voltage characteristic at the end of the article). Due to the high frequency, the weight and dimensions of the transformer are reduced significantly.

According to their functionality, inverters of the following types are produced:

- for manual arc welding (MMA);

- for argon-arc welding with non-consumable electrode (TIG);

- for semi-automatic welding in shielding gases (MIG/MAG);

- universal devices for operation in MMA and TIG modes;

- semiautomatic devices for work in MMA and MIG/MAG modes;

- devices for air-plasma cutting.

As you can see, a significant part of the volume is occupied by radiators of the cooling system.

Advantages of inverters. The advantages of welding inverters are great and numerous. First of all, their low weight (4-10 kg) and small dimensions make it easy to move the machine from one welding site to another. This advantage is due to the smaller size of the transformer due to the high frequency of the voltage it converts.

The exclusion of the power transformer from the circuit also made it possible to get rid of losses for heating the windings and remagnetization of the iron core and achieve high efficiency (85-95%) and an ideal power factor (0.99). When welding with an electrode with a diameter of 3 mm, the power consumed from the network for an inverter-type welding machine does not exceed 4 kW, and for a welding transformer or rectifier, this figure is 6-7 kW.

The inverter is capable of reproducing almost all kinds of external current-voltage characteristics. This means that it can be used to perform all major types of welding - MMA, TIG, MIG/MAG. The device provides welding of the alloyed and stainless steels and non-ferrous metals (in the MIG/MAG mode).

The device does not require frequent and prolonged cooling during intensive work, as required by other household types of welding machines. Its PV reaches 80%.

The inverter has a smooth adjustment of welding modes in a wide range of currents and voltages. It has a much wider range of welding current adjustment than conventional devices - from several amperes to hundreds and even thousands. For domestic use, low currents are especially important, which allow welding with thin (1.6-2 mm) electrodes. Inverters provide high-quality formation of the seam in any spatial position and minimal spatter during welding.

Microprocessor control of the device provides stable current and voltage feedback. This allows you to provide the most useful and convenient functions of Arc Force, Anti Stick and Hot Start. The essence of all of them is a qualitatively new control of the welding current, which makes welding as comfortable as possible for the welder.

- The Hot Start function provides an automatic increase in current at the start of welding, making it easier to strike the arc.

- The Anti Stick function (anti-sticking) is a kind of antipode of the Hot Start function. When the electrode comes into contact with the metal and there is a threat of its sticking, the welding current is automatically reduced to those values that do not cause the electrode to melt and weld to the metal.

- The Arc Force function (arc forcing) is realized when a large drop of metal separates from the electrode, reducing the length of the arc and threatening to stick. An automatic increase in the welding current for a very short time prevents this.

These convenient features allow low-skilled welders to successfully cope with the welding of the most complex metal structures. For those who have ever worked with a welding inverter, the question - which welding machine is better - does not exist. After a transformer or rectifier, working with an inverter turns into a pleasure. It is no longer necessary to "hollow" the electrode in order to ignite an arc that does not want to ignite, or frantically tear it off if it is tightly welded. You can simply put the electrode on the metal and, tearing it off, calmly ignite the arc - without worrying that the electrode can be welded.

Inverter welding machines can be used with large drops in mains voltage. Most of them provide welding in the mains voltage range of 160-250V.

Disadvantages of welding inverters. It is difficult to talk about the shortcomings of such a perfect device as a welding inverter, and, nevertheless, they exist. First of all, this is the relatively high price of the device and the high cost of its repair. If the IGBT module fails, you will have to pay an amount equal to 1/3 - 1/2 of the cost of a new device.

The inverter imposes increased requirements, in comparison with other welding machines, to the conditions of storage and operation, due to its electronic filling. The device does not respond well to dust, since it worsens the cooling conditions for transistors, which get very hot during operation. They are cooled with aluminum radiators, the deposition of dust on which impairs heat transfer.

Dislikes electronics and low temperatures. Any minus temperature is undesirable due to the appearance of condensate on the boards, and minus 15°C can become critical. Storage and operation of the inverter in unheated garages and workshops during winter is undesirable.

Welding semi-automatic

Speaking of welding equipment, one cannot ignore semi-automatic devices - devices for welding in a shielding gas environment with a mechanized feed of the welding wire.

Welding semiautomatic device consists of:

- current source;

- control unit;

- welding wire feed mechanism;

- a pistol (torch) with a sleeve-electric wire, through which the supply of protective gas, wire and electric signal is carried out;

- gas supply system, consisting of a gas cylinder, an electromagnetic gas valve, a gas reducer and a hose.

Welding rectifiers or inverters are used as a current source. The use of the latter improves the quality of welding and increases the amount of welded materials.

According to the design, semi-automatic welding machines are double-case and single-case. In the latter, the power source, control unit and wire feeder are housed in one housing. For double-case models, the wire feed mechanism is placed in a separate unit. Usually these are professional models that support long-term operation at high current. Sometimes they are equipped with a pistol water cooling system.

Semi-automatic welding in MMA mode is no different from working with a conventional welding machine. When using the MIG/MAG mode, an electric arc burns between a continuously supplied consumable welding wire and the material. Carbon dioxide (or its mixture with argon) supplied through the gun protects the welding zone from the harmful effects of oxygen and nitrogen contained in the air. Using semi-automatic welding machines, high-alloy and stainless steels, aluminum, copper, brass, and titanium are welded.

Semi-automatic welding is one of the most modern arc welding technologies, ideal not only for production, but also for the home. Semiautomatic devices are widely used in industry and everyday life. There is information that at present in Russia up to 70% of all welding work is carried out by semi-automatic welding. This is facilitated by the wide functionality of the equipment, high quality welding and ease of operation. The semi-automatic welding machine is very convenient for welding thin metal, in particular, car bodies. Not a single car service enterprise can do without this most convenient equipment.

Choosing a welding machine

The choice of welding machine should be made according to specific needs. Before you go to the store, you need to know the answers to the following questions.- What metal - by brand and thickness - is to be welded?

- Under what conditions will the work be carried out?

- To what extent?

- What are the requirements for the quality of work and qualifications of the welder?

- And, finally, how much can be spent on the purchase of a welding machine?

Depending on the answers to these questions, the requirements for the purchased equipment should be formed.

If you have to weld not only carbon and low alloy steel, but also high alloy and stainless steel, then the choice must be made between a welding rectifier and an inverter. If you have to weld metals that require protection from oxygen or nitrogen in the air, such as aluminum, then you will need welding in a shielding gas environment, which can be provided by a semiautomatic device with MIG / MAG mode.

In general, if we talk about the versatility of equipment, then the best choice, perhaps, would be a semi-automatic device with MMA and MIG / MAG modes. Its presence will allow you to perform almost any work on welding metals, which you only have to deal with in everyday life.

If you have to deal with thin (thinner than 1.5 mm) metal, preference should again be given to a semiautomatic device.

Operation at sub-zero temperatures, especially at values below 10-15 °C, is undesirable for inverters. Strong dustiness also affects them badly. The conclusion is this. If you have to work at very low temperatures in conditions of high dust content, there may be no other option but to choose a welding machine without state-of-the-art electronics - a welding transformer, a diode rectifier or a semi-automatic device based on the latter.

High requirements for the quality of welding and low qualification of the welder definitely incline to the choice of a welding inverter with its ease of use and Arc Force, Anti Stick, Hot Start functions.

A large amount of work requires a high duty cycle (duty cycle) from the welding machine, otherwise too much time will be spent on downtime during its cooling. PV is one of the characteristics that distinguish household welding machines from professional ones. For the latter, it is quite large or even reaches 100%, which means that the device can work without interruption for as long as you like. If we talk about household models, then the PV of inverters is significantly superior to the PV of welding transformers and rectifiers. It is better to take 30% as the minimum value of PV.

When choosing a welding machine, you need to think about the neighbors. If you have to cook a lot, and the mains voltage is low and unstable, you should choose a welding machine for your home, taking into account the power it consumes. The constant flashing of light bulbs, which occurs during the operation of powerful welding transformers and rectifiers, excites universal hatred for welder neighbors. The inverter with its energy saving and anti-stick function will not harm good neighborly relations. When the electrode comes into contact with the metal to be welded, the welding transformer drains the mains, while the inverter simply reduces the welding current (terminal voltage), plus the inverter is more efficient at low mains voltage.

Basic requirements for power sources for welding

To meet their intended purpose, current sources must meet certain requirements, the main of which include the following:- the open circuit voltage must ensure the ignition of the arc, but not be higher than values that are safe for the welder;

- power sources must have devices that regulate the welding current within the required limits;

- welding machines must have a specified external current-voltage characteristic consistent with the static current-voltage characteristic of the welding arc.

An arc can occur either in the event of a gas (air) breakdown, or as a result of the contact of the electrodes with their subsequent withdrawal to a distance of several millimeters. The first method (air breakdown) is possible only at high voltages, for example, at a voltage of 1000 V and a gap between the electrodes of 1 mm. This method of starting an arc is usually not used due to the danger of high voltage. When the arc is powered by high voltage current (more than 3000V) and high frequency (150-250 kHz), air breakdown can be obtained with a gap between the electrode and the workpiece up to 10 mm. This method of ignition of the arc is less dangerous for the welder and is often used.

The second method of ignition of the arc requires a potential difference between the electrode and the product of 40-60V, therefore it is used most often. When the electrode comes into contact with the workpiece, a closed welding circuit is created. At the moment when the electrode is removed from the product, the electrons that are on the cathode spot heated from a short circuit break away from the atoms and move towards the anode by electrostatic attraction, forming an electric arc. The arc quickly stabilizes (within a microsecond). The electrons that come out of the cathode spot ionize the gas gap and a current appears in it.

The arc ignition speed depends on the characteristics of the power source, on the current strength at the moment the electrode contacts the workpiece, on the time of their contact, and on the composition of the gas gap. The arc excitation speed is affected, first of all, by the magnitude of the welding current. The greater the current value (with the same electrode diameter), the greater the cross section of the cathode spot becomes and the greater the current will be at the beginning of the arc ignition. A large electron current will cause rapid ionization and transition to a stable arc discharge.

With a decrease in the diameter of the electrode (ie, with an increase in current density), the transition time to a stable arc discharge is further reduced.

The arc ignition speed is also affected by the polarity and type of current. With direct current and reverse polarity (i.e., the plus of the current source is connected to the electrode), the arc excitation speed is higher than with alternating current. For alternating current, the ignition voltage must be at least 50-55V, for direct current - at least 30-35V. For transformers that are designed for a welding current of 2000A, the open circuit voltage should not exceed 80V.

Re-ignition of the welding arc after its extinction due to short circuits by drops of electrode metal will occur spontaneously if the temperature of the electrode end is high enough.

The external current-voltage characteristic of the source is the dependence of the voltage at the terminals and the current.

In the diagram, the source has a constant electromotive force (Ei) and internal resistance (Zi), consisting of active (Ri) and inductive (Xi) components. At the external terminals of the source we have voltage (Ui). In the "source-arc" circuit, there is a welding current (Id), which is the same for the arc and the source. The source load is an arc with active resistance (Rd), the voltage drop across it is Ud=I Rd.

The equation for the voltage at the external terminals of the source is the following: Ui = Ei - Id Zi.

The source can operate in one of three modes: idle, load, short circuit. When idling, the arc does not burn, there is no current (Id = 0). In this case, the source voltage, called the open circuit voltage, has a maximum value: Ui = Ei.

With a load, a current (Id) flows through the arc and the source, and the voltage (Ui) is lower than at idle by the amount of voltage drop inside the source (Id Zi).

In case of a short circuit, Ud=0, therefore, the voltage at the source terminals Ui=0. Short circuit current Ik=Ei/Zi.

Experimentally, the external characteristic of the source is measured by measuring voltage (Ui) and current (Id) with a smooth change in load resistance (Rd), while the arc is simulated by a linear active resistance - a ballast rheostat.

The graphical representation of the obtained dependence is the external static current-voltage characteristic of the source. When the load resistance decreases, the current increases and the source voltage decreases. Thus, in the general case, the external static characteristic of the source is falling.

There are welding machines with steeply falling, gently dipping, rigid and even increasing current-voltage characteristics. There are also universal welding machines, the characteristics of which can be steeply falling and hard.

External current-voltage characteristics of welding machines: 1 - steeply falling, 2 - gently falling, 3 - rigid, 4 - increasing.

For example, a conventional (normally dissipated) transformer has a rigid characteristic, and a rising characteristic is achieved by feedback, when the electronics increase the source voltage as the current increases.

In manual arc welding, welding machines with a steeply falling characteristic are used.

The welding arc also has a current-voltage characteristic.

First, with an increase in current, the voltage drops sharply, as the cross-sectional area of the arc column and its electrical conductivity increase. Then, with increasing current, the voltage almost does not change, since the cross-sectional area of the arc column increases in proportion to the current. Then, with an increase in current, the voltage increases, since the area of the cathode spot does not increase due to the limited cross section of the electrode.

As the arc length increases, the volt-ampere characteristic shifts upward. A change in the electrode diameter is reflected in the position of the boundary between the rigid and increasing sections of the characteristic. The larger the diameter, the higher the current will fill the end of the electrode with a cathode spot, while the growing area will shift to the right (shown in the figure below by a dotted line).

Stable arcing is possible provided that the arc voltage is equal to the voltage at the external terminals of the power source. Graphically, this is expressed in the fact that the characteristic of the welding arc intersects with the characteristic of the power source. The figure below shows three characteristics of the arc of different lengths - L 1 , L 2 , L 3 (L 2 >L 1 >L 3) and the steeply falling characteristic of the power supply.

The intersection of the current-voltage characteristics of the source and the arc (L 2>L 1>L 3).

Points (A), (B), (C) express the zones of stable burning of the arc at different arc lengths. It can be seen that the greater the slope of the source characteristic, the smaller the change in the welding current with fluctuations in the arc length. But the length of the arc is maintained during the combustion process manually, therefore it cannot be stable. That is why only with a steeply falling characteristic of the transformer, fluctuations in the tip of the electrode in the hands of the welder will not greatly affect the stability of the arc and the quality of welding.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

The assembly of metal structures using welding equipment is in many cases preferable to the method of fixing with fasteners. The interpenetration of molten metal gives a strong connection.

Installation using rivets, bolts, special mechanisms is appropriate, if necessary, to ensure the replacement of a part, during repairs, maintenance work. Information about what welding machines are, what are the features of their operation, will help you make the right choice when buying.

transformers

The principle of operation is based on lowering the input voltage to the level necessary to create a stable arc. The transformer, the main piece of equipment, has two windings: primary and secondary. What types of welding machines are there?

The voltage is regulated in two ways. The first is the amplitude method, when the windings are physically displaced relative to each other. This is done using a special mechanism.

The simplest solution is to divide the winding into several parts, connecting / disconnecting which achieve the desired voltage. The second is phase regulation, which is provided by thyristors. A more productive method that makes it possible to regulate the current according to many characteristics.

Rectifiers

This category is an evolutionary development of transformer equipment. In the circuit of the device there is a diode block that converts alternating current to direct current. More favorable conditions are created for maintaining the arc. It is more stable and even.

There is a noticeable reduction in metal spatter. Any type of electrodes can be used in the work. The rectifier is more versatile than its transformer counterpart. It is possible to work not only with ferrous, but also with non-ferrous metals. By changing the polarity, other characteristics of the apparatus are obtained, for example, for welding aluminum.

Good quality of seams, reasonable price, reliability of the equipment make it popular among professionals and home craftsmen. The disadvantages include the considerable weight of the device, the need to have the skills to work with it and a strong influence on the supply network in which power surges are noted.

semi-automatic

A category that is steadily increasing in terms of the number of devices sold. The principle of operation is based on the behavior of metal in a protective gas environment. There is no traditional electrode.

Its role is played by wire, which can be ordinary or flux-cored, with the addition of substances that improve the quality of welding. The medium used is argon and carbon dioxide. It is customary to divide the equipment into the following groups:

- device with forced gas supply;

- equipment with the ability to turn off the gas supply;

- a device without gas, which works only with flux electrodes, which create a protective layer over the welding site during operation.

Semi-automatic machines are widely used in households, large enterprises, car service stations. Fine adjustment allows you to weld metal less than 1 mm thick with good quality.

The operation of the device requires knowledge, but there is no need to have stable arc control skills, as in working with a transformer. It is necessary to strictly follow the recommendations of the instructions and the advice of specialists.

inverters

The welding machine itself is small, relatively light, and today it can be bought at prices comparable to analogues that work on a different principle, although there is a difference in price, but not as significant as it was in the first images of equipment of this class. The inverter configuration is as follows:

- transformer;

- electronic circuit;

- throttle.

The device of inverter type is mobile. High efficiency and minimal energy consumption make it possible to connect it to the household network. The popularity of the equipment became possible after the manufacturers technologically eliminated the shortcomings characteristic of the first models of equipment.

Today, inverters are considered the most convenient device for domestic use, they have a high reliability class. Therefore, today both private craftsmen and small industrial and agricultural enterprises have it.

Most often, when consulting at a point of sale with a manager, the question is - What are the welding machines for home use? - you can hear the following answer - Inverters.

Argon arc welding machine

The equipment belongs to a special class. It was developed for high-quality welding of non-ferrous metals, although it is also used for iron-based alloys.

The narrow specialization of technology limits its use in the private sector, but there are many household-class devices on sale. By configuration, they do not differ from professional analogues and consist of the following elements:

- source of constant (preferably) or direct current;

- gas reducer;

- special burner;

- an oscillator that converts the current into high frequency pulses to create a non-contact arc.

A characteristic feature of the argon-arc apparatus is a non-consumable electrode. In most cases, they are made of tungsten, which has a significant resource and can be replaced with a new one during long-term use.

A stable arc in an argon environment, less often helium, makes it possible to work with alloys, the welding of which is impossible under other conditions, since the oxygen contained in the air creates an oxidizing film, an amalgam.

Spot welding machine

For individual operations during the assembly of structures, this type of equipment becomes very popular. The device has a characteristic shape: two electrodes are located in the same plane and during operation they heat pre-fixed parts and deform them at the point of contact, which was the reason for the name of this class of equipment.

This happens in a fraction of a second. An electric high-frequency current pulse melts the metal in a small area, without the formation of scale, burning, or overheating of the part. For this reason, the assembly is often made even from parts coated with paints and varnishes.

Apparatus for gas cutting and welding

A class of equipment that does not use electricity as a melting metal, but gas. The usual modification of the acetylene apparatus using calcium carbide is now giving way to more advanced equipment with liquefied gas in cylinders, although it continues to be successfully operated in private households and housing and communal services organizations.

Regardless of the method of supplying the energy carrier, the equipment is divided into three categories:

- Welding. A special burner is used. The reducer limits the gas supply, which is optimal for welding. Cutting with such a device is not reasonable, it takes too long.

- Universal. The ability to adjust the gas supply, the shape of the burner allows you to successfully cook and cut metal.

- Cutters. Designed for cutting large structures into separate parts. A burner of a special shape, up to a meter long or more. A powerful supply of oxygen and gas blows out the molten metal.

Video: How to choose the right welding machine

Gas equipment has its pros and cons. The advantages include: low cost, slow heating and cooling of the metal, sometimes this feature is needed, the ability to fully control the processing time using the power of the flame.

The seam is of high quality with the appropriate qualifications of the master. In addition, a gas burner can not only cook metal, but also harden and release it. The disadvantages include the duration of the process, a sufficiently large heating area, and explosiveness.

Plasma welding

A modern way of connecting, cutting metal. Little is used in everyday life, but in the production of products from high-strength, stainless steels, this method has become very popular. The temperature in the plasma nozzle reaches 30,000 °C.

This allows you to quickly produce high-precision welding in a limited area. Plasma welding technology is indispensable when working with metals of considerable thickness. The use of the method has greatly reduced the operation time in relation to other types of equipment.

The equipment is quite expensive and there is not much of it in private hands. What are the types of welding machines of this type? Structurally, it is possible to cook both with an arc and with a plasma jet.

In both cases, an inert gas is needed to create the medium and a non-consumable electrode. Power devices are of three types: microplasma (0.1-25 A) medium (25-150 A) and equipment for high currents (over 150 A).

Information about the characteristics of the main types of welding equipment will help determine which machine will be the best in a particular situation. For home use, it is not necessary to buy expensive professional equipment.

In terms of basic indicators, budget models are not much inferior to special counterparts. The main difference is the time of continuous operation. Professional equipment can work for hours, unlike simple analogues. Understanding what welding machines are, what characteristics they have, making the right choice is much easier.