Necessary equipment for the well. Step-by-step arrangement of a well for water: instructions for organizing autonomous water supply with your own hands

The organization of an uninterrupted water supply system is an important and responsible process.

The fastest and most reliable option is drilling and arranging a well for water.

If drilling work can be entrusted to specialized companies, then you can equip a water well with water-pressure equipment yourself.

Working equipment for wells

Improvement of the well provides for the development of a water mine and the installation of special installations. For these purposes, modern equipment for a well under water is used:

- caisson;

- pumping unit;

- hydraulic accumulator;

- cap.

The use of the caisson

At the request of the owner of the hydraulic structure, the caisson can be equipped with additional devices:

- filters for water purification;

- membrane-based reservoir;

- pressure gauge;

- operating pressure switch for the pump;

- automated controls.

The caisson is equipped with a strong neck with a reliable fixing lid.

Such installations are made from various materials that are inert to damage, corrosion and destruction: plastic, metal, aluminum alloy.

To equip a well in the country with your own hands, it is recommended to use cylindrical containers with a diameter of 100 cm, a height of 200 cm. If desired, the installation can be made independently.

Submersible pumping equipment

In order for the finished well in the country to function reliably, it is necessary to choose the right pumping equipment. The choice of a submersible pump is determined by two parameters - productivity and pressure of the water jet. In addition, it is important to take into account the size of the hydraulic structure, the length of the drains, and the fluid flow at peak load.

For uninterrupted water supply, the pressure in the system should be from 1.4 to 3 atmospheres with a water intake column height of 33 meters.

Hydraulic accumulator

To competently and beautifully equip a water intake point, you will need to install a hydraulic accumulator. It maintains and gradually changes the working water pressure in the equipped hydraulic structure. Also, the tank is designed to store a minimum water supply and protect against water hammer.

Modern hydraulic accumulators are represented by a single design, the differences are in the volume of liquid for which they are designed. For a summer residence and a country house, a hydraulic tank with a capacity of 15 to 55 liters is enough, for cottages, private hotels and boarding houses - from 100 to 950 liters.

headroom

It is a protective device with openings for pulling water pipes and power cables, installing pumping equipment, and protecting the hydraulic structure from biological and other pollution, as well as precipitation.

Well drilling is carried out with various devices: a hand drill, a rope-impact installation, equipment equipped with an electric motor and a tripod.

The determination of a suitable diameter and depth of the well is carried out taking into account the type of soil in the area, the characteristics of the aquifer and the pumping equipment used to operate the facility.

Laying water pipes

Fine crushed stone and sand are poured into the bottom of the structure, the thickness of each layer should be at least 12 cm.

To prevent the possible , finished .

It is recommended to make small holes around the entire perimeter of the pipe at a level of 20 cm from the bottom of the structure to increase the water pressure. A mesh filter is installed in the end part of the pipe.

To equip the mine, a water pipe with a length of 2 to 2.5 meters and one connecting elbow is used. The first pipe is installed at the required depth of the well so that the emphasis is on the bottom of the pit. Next, the installation of the next pipe is carried out with fixation to the first element by screwing onto the thread.

Step by step installation of the caisson

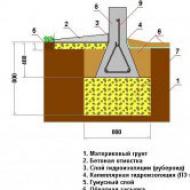

The standard well construction scheme provides for the installation of a caisson. All work is performed in the following order:

- We equip a pit for the tank around the finished hydraulic structure. The overall dimensions of the pit are determined by the dimensions of the caisson: the depth is 200 cm, the width is at least 160 cm. A casing string must pass through the center of the pit. At the surface level of groundwater, it is recommended to deepen the pit by 50 cm to ensure timely pumping of water.

- We make a hole in the tank, the size of which is equal to the diameter of the casing string. We lower the installation into the pit in the central part of the column.

- We cut off the column and fix it to the bottom of the caisson tank by welding. We carry out the connection of the supply wire of the submersible pump and the water pipe to the finished structure. We fill the container with soil to such a level that the lid is visible on the surface.

Installation of pumping equipment

How to properly equip a well using a reliable submersible pump? The installation process is carried out in compliance with the following rules:

- The bottom and walls of the hydraulic structure are thoroughly cleaned of debris, the water is pumped until complete removal of foreign impurities.

- Installation of equipment is carried out so that the distance between the body and the bottom of the structure is at least 100 cm, while the pump is completely in the water.

- At the same time, a water pipe and a supply pump cable are mounted.

- At the end, a check-type valve and a starting protection device are installed.

- The finished system is checked for tightness and performance.

- To fix the pump on the head structure, a metal alloy cable in a protective braid resistant to corrosion is used.

Protective head mounting

Structurally, the head consists of the following parts:

- carabiner and flange connector;

- dense rubber rings;

- fasteners;

- covers.

You can ennoble the well with a head in the following order:

- During installation, the column is cut, cleaned and treated with a protective composition against corrosion and decay.

- The supply cable of the pump and the water pipe are passed through the inlet cover of the structure.

- Pumping equipment is joined to the pipe. The hanging end of the cable is fixed to the carabiner with an eye bolt located inside the cover. A flange and a sealing ring are fixed to the column.

- The pump is immersed to the bottom of the well, a cover is fixed on top of the fixing bolts.

Final installation of the hydraulic tank

Installation of a hydraulic tank in wells and wells ensures uninterrupted operation of the water supply system for a private house or bath. How to equip a water well equipped with a hydraulic accumulator?

The hydraulic tank is connected to the pumping equipment and provides a constant supply of water. When the tap is opened, the liquid flows from the hydraulic structure to the tank, and then to the consumer.

When installing the storage tank, a non-return valve for water is installed in parallel. Before and after the construction of the tank, a drain valve is mounted. For reliable fixation of the hydraulic tank, it is recommended to use a rubber seal.

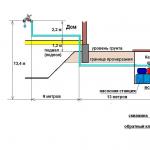

Organization of a well without a caisson

Arrangement of a well without a caisson is possible in the case when the structure is not used all year round, but seasonally - in summer, spring or autumn. Also, the absence of a caisson is justified if there are separate buildings on the site, in which the equipment necessary for the functioning of the hydraulic structure can be installed.

Do-it-yourself well construction without a caisson with a pit is the most practical and affordable option. In this case, the pit provides reliable protection of the well casing from the negative impact of the environment.

WHAT IS NECESSARY FOR WELL CONSTRUCTION

A water well is the best solution for a private house or summer cottage, which allows you not to use water from a centralized pipeline, but to provide yourself with a reliable source of clean artesian water.

One of the main structural devices is the caisson. To equip a water well, it is necessary to select the right specialized equipment, which includes a pump, a well head and a hydraulic accumulator (its main function is to change and maintain the required level of fluid pressure in the main well system).

The main guarantee of the efficiency of a water well will be its tightness. At the same time, the caisson is mounted with a neck, which fits the lid as tightly as possible. The submersible pump will perform the main function. A stable working pressure for this type of well is 1.8-3 atmospheres.

The caisson is an integral part of the entire structure. Its appearance resembles a standard sealed side of various capacities, which performs a protective function in the water intake system. The caisson aims to neutralize the risk of water freezing or mixing with contaminated groundwater. It is also possible to install filtration equipment, a pressure switch, a membrane tank and other structural elements there. At the top of the device, a cap is mounted on the neck. During the drilling process, all physical parameters that relate to the diameter, depth of the well, as well as soil parameters (its density, composition, layers and groundwater level) are taken into account.

The installation of the caisson takes place in a dug hole. A casing pipe is mounted in this pit - it is welded to the caisson by electric welding. Next, the electric cable is connected, which is carried out from the pump, as well as a pipe for water outlet. The caisson, after installation and connection of all structural elements, is covered with soil (only its cover remains in the open air). Its use in the well allows it to be operated all year round.

Additionally, the well includes the following elements:

- Caisson;

- Pump;

- Hydraulic accumulator (is an equally important element of the entire well design, providing comprehensive protection of all systems from water hammer and a sharp pressure drop);

- Connection cable;

- A pipe system for connecting a well to a house or watering units;

- Pressure switch;

- Distributor.

During the installation process, a complex of works is carried out, which eliminates the risk of mechanical damage or disruption of the work cycle. At the same time, the organization of the well operation allows not to take up much useful space in the territory of a private yard or garden (most of the systems are installed in the well itself).

Under the caisson, a concrete cushion is formed, which excludes its rollback or violation of the position as a result of the impact of the movement of soil or groundwater.

The main stages of well construction

A well can be drilled in any desired location. However, the optimal distance will be as close as possible to your home. This will eliminate the need for a long pipeline. Consider the fact that the main device - the caisson, will take a total of at least four square meters of space.

This is financially beneficial by reducing the amount of consumables and reducing the list of required earthworks. Reducing the length of the pipeline will require less pump power. Drilling is carried out automatically, which eliminates the violation of the level of the well or its backfilling after this work. Anti-corrosion pipes will eliminate the risk of corrosion even after five or ten years of operation.

Caisson installation

The main requirements for the installation of a caisson is the preparation of a pit, the average depth of which reaches two meters. The exact parameters of the dimensions are determined by the size of the container, however, the width must be at least one meter.

Descent and installation of the pump

The key requirement for the installation of the pump is a comprehensive cleaning of the well before it is lowered. After that, the head is fixed, which is aimed at sealing the wellhead.

Installing a hydraulic accumulator

The hydraulic accumulator provides uninterrupted water supply. A filled container with a pump will guarantee access to clean water without delay.

Systems installation

This is the final stage, after which the water well is ready for operation. The systems include all additional elements that are used for the final connection, including a summer tap and a relay.

A well is one of the most popular ways of extracting water, the use of which allows owners of suburban areas to have a double benefit: obtaining high-quality water and saving financial costs. Having drilled a well, it is possible to provide water supply at any time of the year. But a narrow hole in the ground cannot yet act as a full-fledged source of water supply, only the arrangement of a well for water makes it possible to make life-giving moisture suitable for use and consumption.

Selection of the necessary equipment

Having drilled a water well, you can begin to equip it. To ensure uninterrupted water supply, it is necessary to install special equipment, which includes: a caisson, a pump, a hydraulic accumulator and a head for the well.

The scheme for arranging water wells in the country is generally the same, the differences can only be in the selection and installation of individual elements

Before you start arranging the well, you should correctly select the structural elements in order to protect yourself in the future from unnecessary hassle and the cost of repairing expensive equipment.

Purpose of the caisson

The caisson is one of the main structural elements for the arrangement. Outwardly similar to a barrel, a waterproof container is designed to protect water in the intake system from freezing and mixing with groundwater.

In a sealed design, you can place automatic equipment, cleaning filters, a membrane tank, pressure switches, pressure gauges and other components, thereby freeing the living quarters from unnecessary units and devices. The caisson, as a rule, is equipped with a neck with a tight-fitting lid.

Caissons are made of corrosion-resistant metals - stainless steel and aluminum, or plastic, which is not subject to decay and other destruction processes.

Submersible pump

In order for your well to serve properly in the next few decades, you need to competently.

The choice of product depends on its performance and maximum pressure. To date, the most popular pumps are European manufacturers, for example: Grundfos, Water Technics Inc.

When calculating, as a result of which the parameters of the product are determined, the diameter and depth of the well, the length of the water pipes, the peak water flow from all connection points are taken into account.

For stable operation of the water supply system, it is necessary to maintain a working pressure in the range from 1.5 to 3 atm., Which is equal to 30 m of water column.

Hydraulic accumulator

The main function of the accumulator is to maintain and smoothly change the fluid pressure in the water intake system. In addition, the tank provides a minimum supply of water and protects against water hammer. The devices differ only in the amount of water they can hold, ranging from 10 to 1000 liters.

For a small country house with 3-5 taps, it is enough to install a hydraulic tank with a capacity of 50 liters

Well cap

Allows you to protect the well from contamination with debris and runoff of melt water. The design sealing the well is also designed to simplify the operation of the technical well, and in particular the suspension of the pump.

The head can be made of both plastic and cast iron. Plastic products are able to withstand a suspended load, the mass of which does not exceed 200 kg, and cast iron - 500 kg

The main stages of well construction

Household owners who do not have enough time, knowledge and skills to understand communication schemes can always entrust this responsible work to specialists.

Particularly artisans will do everything themselves. But even if someone will carry out all the work for you, you will need to check everything. So, the organization of autonomous water supply takes place in several stages.

Caisson installation

To install the caisson, it is necessary to prepare a hole, which should be dug around the well to a depth of 1.8-2 meters. The dimensions of the pit are determined by the dimensions of the container, on average its width is 1.5 meters. As a result, a pit should form, in the middle of which a casing pipe sticks out.

If the pit is filled with groundwater, it is necessary to create an additional recess in order to pump it out in a timely manner.

In the bottom of the caisson itself, it is necessary to cut a hole equal to the diameter of the insulating casing pipe. The prepared caisson can be lowered into the pit, placing it in the center of the wellbore. After that, the casing pipe can be cut and welded to the bottom of the caisson by electric welding.

It is necessary to attach a pipe for water outlet and an electric cable of the pump to the assembled structure. The caisson is covered with a layer of soil: only a cover should remain above the surface, acting as an entrance to the structure.

The caissons are mounted below the level of soil freezing and are additionally equipped with: a lifting ladder, a hydraulic storage tank, pumps, compressors and other operational water-lifting devices

Submersible pump installation

Despite the fact that the process of installing the pump itself is quite simple, some nuances must be taken into account when installing it:

- before installing the pump, thoroughly clean the well by pumping water until the water stops sedimenting in the form of sand and other particles;

- the pump in the well is placed so that it does not reach 1 meter to the bottom of the source, and at the same time it is completely immersed in water;

- in parallel with the installation of the pump, a plastic pipe is installed (water is supplied upward through it), and a cable (to control the operation of the pump motor);

- the start-up protection device and the check valve are mounted after the preliminary installation of the pump;

- after installing the system, it is necessary to regulate the pressure in the tank in such a way that it should be 0.9 of the pressure when turned on;

- the cable with which the pump is attached to the head cover must be made of stainless steel or have a waterproof braid.

After installing the pump, you can install a cap that seals and protects the wellhead.

Installing a hydraulic accumulator

It is impossible to ensure uninterrupted water supply without installing a hydraulic accumulator.

The accumulator can be installed both in the caisson itself and in the basement of the building

The principle of operation of the system is quite simple - after turning on the pump, an empty tank is filled with water. When you open a faucet in the house, water enters it from the accumulator, and not directly from the well. As the water is used up, the pump automatically turns on again and pumps water into the tank.

Installation of the container in the engineering system must be done, leaving free access for repair or replacement in the future. A non-return valve must be provided at the installation site of the tank, in the direction of water flow. Before and after placing the tank, it is necessary to install a drain cock to drain the water. Fixing the accumulator with a rubber seal will reduce the level of vibration.

For a comfortable stay in a private house, it is necessary to establish a good water supply. The most common source of water is a well or.

Of course, you will have to put a lot of effort into building a well with your own hands, but the result will certainly please you.

Why you should opt for a well:

- First of all, well water is cleaner because it is extracted from a great depth;

- The well can be operated for quite a long time;

- The well fills up with water very quickly;

- And finally, it is important that drilling a well can be done by hand, without the involvement of expensive equipment.

Wells are of several types.

Artesian wells are called wells, the depth of which can reach 70 meters.. It is impossible to make such a well without the use of technology, and therefore it is not suitable for us.

A well "on the sand" is more suitable for us, primarily because, unlike an artesian well, it is not necessary to make permits for drilling.

Do-it-yourself well drilling methods

The filter is completed by winding a stainless steel wire, and a fine mesh is placed on it from the same stainless steel.

The process of drilling a well occurs by raising the projectile and lowering it into free fall. With each blow, the well deepens a little. Every 50 cm, the projectile is released from, and the whole process is repeated anew. Having cut a well, you can start arranging.

Well construction

When arranging a well for uninterrupted water supply, it is necessary to install special equipment:

caisson- the main element for arranging a well, it is designed to protect water from freezing and mixing with groundwater. The caisson is equipped with a neck with a tight-fitting lid. The caisson is usually made of a cylindrical product with a diameter of 1 m and a height of 2 m.

caisson- the main element for arranging a well, it is designed to protect water from freezing and mixing with groundwater. The caisson is equipped with a neck with a tight-fitting lid. The caisson is usually made of a cylindrical product with a diameter of 1 m and a height of 2 m.- a submersible pump is selected based on its performance and pressure. The calculation is done by determining the parameters: well depth and diameter, pipe length, water flow. In order for the water supply system to work well, the operating pressure must be maintained within 1.5-3 atm.

- - maintains water pressure in the water intake system, protects against water hammer, providing a minimum supply of water. The volume of such devices ranges from 10 to 1000 liters.

- headroom- protects the well from melt water runoff and debris.

- Stages of arranging a well for water:

1. We install the caisson by digging a hole around the well about two meters deep and 1.5 meters wide. We lower the caisson into the pit, placing it in the center. Then we cut the bypass pipe and weld it to the bottom of the caisson using electric welding. We attach the electric cable of the pump and a pipe to this design to remove water. We fill the caisson with soil so that only a cover remains on the surface.

2. We install a submersible pump observing some features:

-pump water until there are no impurities in it;

- installation to be carried out at a height of 1 m from the bottom;

- at the same time we install a plastic pipe for water supply and a cable for controlling the work to adjust the pressure. After installing the pump, install the head.

3. Installation of the hydraulic accumulator is carried out taking into account free access for repair or replacement in the future.

It is necessary to provide a check valve in the direction of water flow, and to drain the water- drain valve. The use of a rubber seal when fixing the accumulator will help reduce the level of vibrations. You can place the accumulator either in the basement of the house or in the caisson. On this, the work on the arrangement of the well can be considered completed.

It is necessary to provide a check valve in the direction of water flow, and to drain the water- drain valve. The use of a rubber seal when fixing the accumulator will help reduce the level of vibrations. You can place the accumulator either in the basement of the house or in the caisson. On this, the work on the arrangement of the well can be considered completed.

Thus, now you know that drilling a well for water in the country and doing it yourself is troublesome, but doable.

The drilling of a water well should be followed by the process of its arrangement. Special equipment for wells, such as a caisson, a cap, a hydraulic accumulator and other devices, helps to organize an uninterrupted transfer of water. They will be discussed in this article.

To equip a well in the country you need a large number of elements. Among them, a special place was occupied by:

- Hydraulic accumulator for transferring water under pressure in the required direction.

- Adapters. One - brings the pipes through the casing, the second - provides sealing when the caisson is abandoned.

- Pump and parts for its installation. Needed to get water.

- Pressure switch. Controls the pump and controls its operation.

- Check valve. It lets water in one direction (to the dacha or other building for which the borehole water supply was installed).

- Plumbing polyethylene pipes, from which the water supply system is formed. In the future, they are used only for household purposes.

- Pressure gauge. Must be installed to control the level of water pressure in the pipe system.

- Borehole head. Designed for sealing the casing string.

- Caisson, a waterproof chamber that is needed to protect well equipment from water ingress.

- Cable. It must be made exclusively of stainless material and equipped with the same stainless clamps.

- Tees. Needed to create branches from the main water pipe.

- Faucets and hoses to direct water to specific points in the home.

- Nipples, preferably brass. They have threaded edges. Needed to connect pipes.

- Various types of fasteners and connecting elements designed for a specific project.

- Consumables (electrodes, sealant, etc.).

Characteristics of the main equipment

Caisson

One of the main elements of the well equipment. It looks like a waterproof barrel. Its installation is due to the need to protect the water in the system from pollution and freezing.

Purification filters, pressure gauges, pressure switches, a membrane tank and other components can be installed in a sealed structure. This will free the living space from the heap of extraneous units and devices. Most often, the caisson has a neck, to which the lid fits snugly. Traditional materials for manufacturing are stainless steel, aluminum, or plastic. The main requirement is resistance to corrosion, and ideally resistance to other destructive processes.

Important! The most demanded caisson with parameters: height - 2 meters; diameter - 1 meter.

Instead of a caisson, you can use an adapter. Its main advantages:

- Fast installation;

- Relative cheapness;

- No need to dig a hole for installation

Hydraulic accumulator

Well equipment includes the installation of a hydraulic accumulator. The main task of this mechanism is the smooth adjustment and maintenance of water pressure in the water intake system. Moreover, the accumulator is able to provide a minimum supply of fluid and protect against water hammer. These types of devices have the same set of functions. They differ only in volumes (capable of holding 10-1000 liters).

Important! In appearance, hydraulic accumulators look like oval-shaped tanks. They are of vertical and horizontal type.

headroom

This well equipment performs protective functions. It is necessary to protect the source from the ingress of debris and melt water into it. The mechanism seals the well and simplifies its further operation, facilitates the installation of the pump.

Important! Most often, the head is made of plastic and cast iron. Plastic structures withstand a suspended load weighing up to 200 kg, cast iron - up to 500 kg.

Proper organization of a water well will make it a permanent working source, regardless of the season, which will create comfortable living conditions in the country.

Pump

To establish and guarantee the operation of the well for several decades, you need to choose the right pump. To determine the parameters of the product, it is necessary to measure the depth and diameter of the well, determine the length of water supply lines and calculate the peak flow. Pumps differ in pressure and performance. To ensure stable operation of the water supply system, pressure should be maintained in the range from 1.5 to 3 atmospheres.

Equipment for a well of this type has three types:

- Surface pump. Recommended for installation in a well, where the dynamic water level does not fall below 7 m from the ground level.

- Submersible vibration pump. A budget option. Its installation in the water supply system is an extreme measure. The pump has a small capacity and adversely affects the integrity of the walls of the well.

- Centrifugal pump downhole. Optimal equipment for the well.

Pressure gauges

The installation of a pressure gauge is necessary to be able to measure the pressure. Standard requirements for devices:

- Reliability. The longer the equipment lasts, the better. The most durable is a pressure gauge that has a steel case and a durable mechanism (for example, copper-brass). The glass in its composition must certainly be technical.

- visibility. A manometer is needed for visual monitoring of pressure indicators. Therefore, it must have a well-marked scale.

- High class of accuracy.

membrane tank

This well equipment looks like a metal tank with a rubber membrane. It can have a different capacity, as well as a replaceable or non-replaceable rubber partition. The membrane tank is able to accumulate water and supply it at a certain time under a certain pressure, reducing the load and reducing possible risks.

Important! Membrane tanks with a capacity of 8-30 liters need wall mounting. Larger tanks are usually installed on special legs.

Installation of a membrane tank is best done before the branching of the water supply. Additional loads on the tank are not allowed. Before installing the tank, you need to find in the room the possibility of feeding the system and draining the water.

Pressure switch

The device maintains optimal pressure in the water supply and helps to automate the filling of the hydraulic tank. Without a relay, autonomous operation of this system is impossible.

Important! A simple two-contact pressure switch does not function separately from the accumulator.

Automation system

The choice of automation is just as important as the selection of the pump. It consists of a power electrical component, command relays and protective elements. What is the purpose of the system? Automation is needed to protect the electric motor and pump from breakdowns. The control panel helps to avoid overheating of the pump, and the relay regulates and stabilizes the pressure in the accumulator and water supply system.

Cleaning filters

To solve the problem of water pollution, you need to install filters. Their main functions:

- Iron removal. The filter relieves water of characteristic taste and smell, protects pipes from rapid loss of functionality.

- Rigidity softening. Water undergoes ionic treatment. As a result, sodium ions replace potassium and magnesium ions.

- mechanical cleaning. Fine impurities that destroy equipment are reduced or removed from the water.

- Bacteria cleansing. Usually, activated carbon or ultraviolet light is used in the filter to eliminate the negative effect of chemical and biological fertilizers that enter the source from the soil and affect the composition of the water.

Important! The filter is not installed for artesian wells. Fine-grained impurities are not typical for them, and coarse-grained impurities cannot get into the water.

Main types of filters:

- Mesh:

- Non-flushing. Cleaned by hand only.

- Self-cleaning. Cleaning is done automatically without stopping the water supply.

- Sorption. Improve the taste, smell, color of the liquid, remove chlorine and organic compounds from it. Before using the sorption filter, disinfect the water.

- Cartridge.

Filtered through a replaceable cartridge made of plastic or steel. Used to purify a small volume of liquid. They can perform various functions.