How to knead concrete for.

The composition of the foundation is not only the presence of all the required elements, but also the selection of the appropriate concrete for pouring. Its proportions, the calculation of the volume for the foundation will vary greatly for each base under the house.

For the foundation, cement with a brand of at least M200 should be taken.

Today, various types of foundations are used, among them it is necessary to single out the structures of slab, pile, strip foundations. Sometimes combined options are used.

What should be the composition of the strip foundation?

The most commonly used construction of a strip foundation, which is simple and economical. This design consists of a shallow concrete strip, which is arranged around the perimeter and under the load-bearing walls of the house.

In some cases, ready-made concrete blocks, bricks can be used for it. In this case, the duration of the work does not depend on the curing time, only the time for the masonry mortar to dry is taken into account. But it is also required for its preparation.

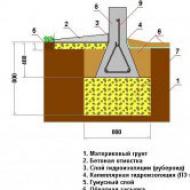

Cake for the tape base of the house includes:

- sand and gravel pad at the bottom of the trench;

- removable formwork from a conventional edged board (removed after the concrete has hardened);

- concrete tape running along the perimeter and under the bearing walls;

- waterproofing the upper part of the strip foundation.

In manufacturing, such a base is considered one of the simplest; it can be erected on almost any type of soil.

To calculate the material, you only need to know such tape parameters as height, width and overall length. In some cases, the foundation is reinforced before pouring with metal reinforcing bars, which enhances its strength and bearing capacity.

Back to index

What does a pile foundation include?

The pile foundation for the house is a foundation in the form of special support pillars. This option is used when building on difficult soils, on slopes, on swampy or sandy soils. The house in this case exerts uniform loads on the ground due to the features of this design.

To prepare such a base, not so much is needed, the design pie consists of the following elements:

- sand and gravel pad at the bottom of the well;

- support pillars, which are poured with concrete after installation;

- for grillages, a special belt is used, which is used as a base for the house.

There is a type of pile foundation, which is a combination of tape and support (piers are erected between the pillars to a small height). It doesn't take much time to prepare.

Back to index

Slab foundation and its composition

A slab type of base for a house is a base, which is a monolithic, reinforced slab made of concrete. The recipe for such a base is simple, but very reliable. The slab base pie includes:

- base of sand and gravel;

- plate (can be of several types: ordinary solid, lattice);

- waterproofing on the top.

The slab itself is reinforced with special metal fittings. may include reinforcing polymer additives that enhance strength, resistance to various loads. But there are also disadvantages here. To lay the foundation, a large consumption of materials is required. In addition, during the construction of a slab base, it is impossible to arrange an underground garage, a spacious basement.

Back to index

Foundation concrete: application features

For the construction of the base, concrete of various grades is used in a variety of proportions. Everything here depends on the type of foundation itself, the requirements for it. One of the most important issues with are the proportions of the ingredients. When choosing what will be the composition of concrete for the construction of a slab monolithic, pile (columnar), strip foundation, the following features must be taken into account:

- for must exactly correspond to the expected loads and construction conditions. In this case, the design will be strong and very reliable.

- The base for the house can be of various designs (slab, pile or tape). To arrange it, blocks, support posts or a liquid mixture for pouring can be used. But in any case, it is recommended to use only factory concrete mixes, which are of high quality. It is not recommended to make slabs or poles from a dry mix at home.

- The composition of concrete includes: cement of the selected brand, fillers (gravel or crushed stone, sand, granite sand), water. Plasticizers, special reinforcing additives are often used. The proportions of such a mixture depend on what kind of cement will be used, what brand of concrete should be obtained in the end.

- For the foundation, it is necessary to take cement, the brand of which is not less than M200.

- The strength of the concrete mix for the foundation largely depends not only on the right proportion, but also on the quality of the fillers. It is recommended to use different-grained materials that will evenly fill all voids.

- After preparation, concrete can only be used for two hours, after which it begins to dry and lose its qualities.

- Water plays a big role in the preparation of concrete. You can not make the mixture too liquid or too thick, in its consistency it should resemble thick sour cream.

Back to index

The composition of concrete mixtures for the foundation

The composition of concrete, as already mentioned, includes components such as gravel, sand and water. The base takes on the load from the structure, so it is very important to take into account all factors when calculating the mixture. The proportions will differ depending on which brand of concrete will be used. For example, to build a house, you need to use concrete grades from M200, but for ordinary garden paths, M100 is also perfect.

Consider the proportions and volumetric composition of concrete for various grades:

- M200, mass composition - cement 1 kg, sand 2.8 kg, crushed stone 4.8 kg, volumetric composition for every 10 liters of concrete (sand / crushed stone) - 25:42, the amount of concrete for every 10 liters of cement - 54 liters.

- M250, mass composition - cement 1 kg, sand 2.1 kg, crushed stone 3.9 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 19:34, the amount of concrete for every 10 liters of cement - 43 liters.

- M400, mass composition - cement 1 kg, sand 1.1 kg, crushed stone 2.5 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 11:24, the amount of concrete for every 10 liters of cement - 31 liters.

- M450, mass composition - cement 1 kg, sand 2.8 kg, crushed stone 4.8 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 10:22, the amount of concrete for every 10 liters of cement - 29 liters.

The higher the brand of concrete for the mixture, the greater the amount of cement will be contained in the composition. Therefore, it is important to correctly determine which brand is needed in order to. The M300 and M400 are optimal, which are quite enough to build a foundation even for a massive country house.

In this article, we will consider with you: what concrete is, what it consists of, what brand of concrete is, in what proportions it contains components and how to make concrete for different types of foundation.

We think most of you already know what concrete is. Recall that this is a mortar for erecting strong stone structures in construction. It is used to create foundations, ceilings, supports and pillars, dams and dams, roads and blind areas around buildings. In short, the scope of concrete is very extensive. We will consider with you a special case, namely concrete for the foundation.

For the construction of the foundation of buildings, outbuildings, fences, etc. use concrete consisting of:

- Cement is the main component of concrete for the foundation. It is the main binding filler in concrete.

- Sand - in concrete for the foundation, there must be clean, medium-sized quarry or river sand. No impurities such as clay are allowed in it.

- Crushed stone - granite or gravel crushed stone of a fraction of 5-20 mm is required for the foundation.

- Water must be clean.

- Plasticizer - Recently, various plasticizers for concrete have been widely used. If you want to make high-quality concrete for the foundation, be sure to use a plasticizer suitable for your needs. It will greatly facilitate your mixing and application of concrete, cleaning tools, increase the time of working with concrete, add strength and plasticity to it. There are also special additives for working in the cold, adding waterproofing properties to concrete for the foundation and others.

The composition and proportions of concrete for the foundation determine its brand. What it is? Read more about it.

Grade of concrete for the foundation

We will immediately decide with you that the grade of concrete M100 - M350 is suitable for building the foundation. Now let's see what it depends on and what it is.

Everything is quite simple: the letter M denotes the grade of concrete and shows the tensile strength in numbers. Those. how many kilograms per square centimeter the concrete of this brand will withstand the load. The M200 grade, the most common for the construction of foundations for private houses, means that the concrete will withstand a load of 200 kg per cm2.

In addition to the brand of concrete, often use such a thing as a class of concrete. It is marked with the letter "B". For the foundation, concrete of class B7.5 - B25 is suitable. See below the table of conformity of the class and brand of concrete.

So, what brand or class of concrete is suitable for a certain type of foundation?

What kind of concrete is needed for the foundation

Depending on which building you want to build a foundation for, you need to choose the right brand of concrete. The more responsible and heavier the structure is, the stronger the concrete for the foundation should be and the higher the brand or class of concrete should be.

To build the foundation of light outbuildings, such as a gazebo, a greenhouse, a chicken coop, concrete M100-M150 is suitable.

For baths, garages, etc. you can use concrete M150-M200.

For the foundation of a private house, use concrete grade M200 and higher.

All these figures are highly arbitrary. And if you do not have a project of the structure being erected, and you doubt the sufficient strength of the future foundation, take concrete of a higher class. Also keep in mind that self-prepared concrete for the foundation may differ in brand from the factory one. And usually down.

So, you have decided on the brand of concrete for your foundation. It's time to find out what proportions of concrete for the foundation must be observed for this.

It's no secret that most "home builders" use standard formulas with the proportions of components to prepare concrete for the foundation.

Basically, two types are used:

- For "ordinary" concrete - 1 part cement, 3 parts sand, 5 parts crushed stone. Water is added to a minimum, but to a plastic consistency.

- For "strong" concrete - 1 part cement, 2 parts sand, 4 crushed stone.

In principle, such formulas have the right to life, because they are suitable for most foundations in private buildings. If you want to build your foundation correctly, use the table that will tell you the proportions of concrete for the foundation.

The table shows not only the proportions of concrete for the foundation in kilograms, but also the proportions in parts. Since many builders use to measure the desired proportions, for example, in buckets or shovels. If it is more convenient for you to use this method of dosing the components, then in the table you will find the proportions of concrete for the foundation in buckets. Because "parts" can be replaced by any measure of volume. Be it buckets, shovels, scoops and even hands.

Do not forget that the proportions of concrete for the foundation in kilograms and buckets are not the same thing. Because cement, sand, gravel and water have different specific gravity. A bucket of 10 liters will weigh 10 kg of water, about 12 kg of cement, 14 kg of sand and 15 kg of gravel. But these figures are conditional, because. cement can be both loose and caked. The sand is wet, and the gravel is large or small.

Advice! To facilitate the calculation of the composition of concrete, use one of our free online.

And finally, watch the video, which clearly explains how to make and all the proportions of concrete for the foundation. Good luck building!

Correct concrete according to standards. Video.

Concrete comes in various grades, which are classified according to its strength, such as M100, M150, M200, M300, etc. Both the composition and the proportions of its components largely depend on the brand of concrete.

To be honest, if you use purchased concrete, then you don’t have to worry about its composition and proportions. You only need to name the brand of concrete, the fraction of crushed stone used in it and the address where to deliver it, and the manufacturer, in turn, is obliged to take into account your wishes and prepare the concrete mix strictly following the technology.

What determines the composition of concrete for the foundation

It is not always possible to order ready-made concrete due to various difficulties. In this case, you will have to prepare concrete for the foundation yourself, and in order to prepare a high-quality mixture, you must strictly observe the proportions of all components.

So what should be the composition of concrete for the foundation in order to give it maximum strength and reliability throughout the entire life of the building?

It will not be possible to answer this question unambiguously, because a lot depends on the components used, the type of foundation, its area of application, soil moisture, and many other factors.

We have already talked about how to pour the foundation and save on this, and we will not repeat ourselves, today we will consider the components that make up concrete, as well as their exact proportions.

The main components that make up concrete

As a rule, the following components should be present in good quality concrete:

1. Cement

2. Sand (river or washed)

3. Crushed stone (gravel)

4. Water

5. Various additives

The main link in concrete is cement. He, with the help of water, connects the individual grains of sand into a single creamy mass - a solution. Cement can be of various types and brands, the most popular are M400 and M500, which will be discussed further. Also on sale are the M200 and M300 brands, but they are rarely used in private construction.

The main link in concrete is cement. He, with the help of water, connects the individual grains of sand into a single creamy mass - a solution. Cement can be of various types and brands, the most popular are M400 and M500, which will be discussed further. Also on sale are the M200 and M300 brands, but they are rarely used in private construction.

The next component is sand. It, as already mentioned, is necessary to dilute the cement and obtain a solution. The sand used should not contain various impurities, vegetation and foreign objects. Therefore, it is desirable to use "washed" sand or river sand. The most common admixture in sand is clay or lime. If there are lumps or stones in the sand, it must be sieved.

The next component is sand. It, as already mentioned, is necessary to dilute the cement and obtain a solution. The sand used should not contain various impurities, vegetation and foreign objects. Therefore, it is desirable to use "washed" sand or river sand. The most common admixture in sand is clay or lime. If there are lumps or stones in the sand, it must be sieved.

Such an admixture in the sand as clay, for example, will not allow the laid concrete to shrink completely until it has initially hardened. Thus, already relatively hard concrete will continue to shrink, leading to cracks in it.

rubble, or as it is called, gravel is the main component that is part of the concrete for the foundation and is its basis. In other words, crushed stone is for concrete, it is like a brick for a brick wall. It can be of various fractions (the size of one stone) from 5 mm, depending on the purpose of the future concrete structure. The average size of the fraction used in concrete for the foundation is (5 - 10) mm or (10 - 20) mm.

rubble, or as it is called, gravel is the main component that is part of the concrete for the foundation and is its basis. In other words, crushed stone is for concrete, it is like a brick for a brick wall. It can be of various fractions (the size of one stone) from 5 mm, depending on the purpose of the future concrete structure. The average size of the fraction used in concrete for the foundation is (5 - 10) mm or (10 - 20) mm.

Often crushed stone in concrete is replaced by other components, such as expanded clay, slag, etc., but such concrete is not used for foundations, so we will not consider them.

Water- an indispensable component, not a single construction site takes place without it. Water is the element by which all other dry ingredients are mixed. Also, water is involved in the process of concrete hardening, so it must also be added, observing the proportions. Water must be stocked up in advance, because during pouring, there will simply not be enough time to carry it from outside the construction site.

Water- an indispensable component, not a single construction site takes place without it. Water is the element by which all other dry ingredients are mixed. Also, water is involved in the process of concrete hardening, so it must also be added, observing the proportions. Water must be stocked up in advance, because during pouring, there will simply not be enough time to carry it from outside the construction site.

Various additives are used in concrete to improve its performance, both during curing and eventually. In other words - if, for example, you need a strip deep foundation, then frost-resistant additives are added to the concrete, if it is necessary to obtain a plastic concrete mass, then various plasticizers are added. Also, additives can be used to accelerate hardening, to increase the final strength, and many others.

Various additives are used in concrete to improve its performance, both during curing and eventually. In other words - if, for example, you need a strip deep foundation, then frost-resistant additives are added to the concrete, if it is necessary to obtain a plastic concrete mass, then various plasticizers are added. Also, additives can be used to accelerate hardening, to increase the final strength, and many others.

The proportions of the components in the composition of concrete

We have already figured out what is included in the composition of concrete, now let's talk about what proportions of the components to use, how to properly and how to mix it all.

Almost always, speaking of the proportions of concrete, we mean the ratio of one volume of cement to a certain amount of the same volumes of sand, crushed stone and water.

First of all, as I said, the proportions of the components directly depend on the brand of concrete required. The brand of cement itself also plays an important role.

To begin with, consider the proportions of the components for Portland cement grade M400, since it is the most popular:

In the process of preparing concrete for the foundation, there is no need to use high-precision scales and measuring cups, it is enough to measure volumes with ordinary metal buckets, for example, 10 liters.

| Concrete brand | M100 | M150 | M200 | M250 | M300 | M400 |

| Water volume, l | 11 | 10 | 9 | 7,5 | 6,5 | 5 |

The amount of water added depends not only on the proportions of the remaining components and the brand of concrete, but also on how wet the sand and gravel are in your area. The table shows the approximate volume of water per 1 volume of cement. And it is possible to determine exactly how much water per volume of cement only experimentally.

As a rule, in practice, pouring concrete for a foundation in normal soil, such exact calculations are not used, but average proportions are taken - 1 bucket of cement, 3 buckets of sand, 4 - 4.5 buckets of crushed stone and about 1 bucket of water.

- Since the foundation must be monolithic, it must be remembered that 2 people manually, using a concrete mixer, will be able to prepare and pour a maximum of 2-3 m 3 of concrete per day. It is advisable to foresee this, and find the required number of assistants in advance.

- It is better to mix concrete with mechanical or electric mixers. Mix the concrete mixture well with a shovel in the bath - it will not work.

- When using a concrete mixer, it is not always convenient to mix the dry mix first and then add water. This approach threatens to "stick" sand to the back wall of the mixer. It is best to first pour most of the necessary water, then cement, and then sand and gravel.

- Naturally, M400 concrete will be much stronger than M100, but it will also be much more expensive for a foundation made of such concrete. Therefore, there is no need to immediately chase after the most durable; in most cases, the M200 with a good reinforcing cage can also come up.

- If you are pouring concrete at sub-zero temperatures, then I advise you to read my article on this topic. Properly arrange the heating of concrete and its insulation.

- Concrete that is too liquid for a foundation levels well and is more comfortable to work with in some cases, but too much water in the concrete composition will adversely affect its structure and ultimate strength. Too little water - there will be great difficulty in leveling and moving the concrete. Therefore, always stick to average viscosity values.

- For the installation of a conventional strip buried foundation on good soil, concrete of a grade of about M200 can be used, but for a strip non-buried foundation, concrete of increased strength is used.

Concrete is the most common material used in construction. Most often it is used to create a foundation for a building. The performance characteristics of the foundation, such as frost resistance, thermal conductivity, moisture resistance and strength, directly depend on what qualities and what proportions concrete has. In this article, we will consider the most optimal proportions of concrete, its components, their choice, methods of preparing and pouring concrete.

The composition of concrete for the foundation

The main composition of concrete consists of 4 main components:

- Cement.

- Sand.

- Gravel.

- Water.

Cement always acts as a link, sand and gravel act as fillers, and water is a universal solvent, with the help of which a concrete solution is formed.

In addition to the main components, special additives can be added to the concrete solution, which can perform various functions. For example, additives that accelerate the hardening process of the solution, or increase the moisture resistance and frost resistance of the final product.

Required concrete strength

Perhaps the most important characteristic of concrete is strength, because this concept hides the ability of concrete to withstand all loads. To determine such loads, it is necessary to calculate the weight of the future home, all communications and the load from weather conditions, whether it be snow or rain. After that, all the values \u200b\u200bare summed up and divided by the base area. The values obtained show the possible load per square centimeter of the foundation. So the strength of the finished foundation should be greater than the result obtained.

The strength of concrete depends on its brand, that is, if the concrete has the M400 brand, this indicates that it is able to withstand a load of 400 kg per square centimeter.

More details about strength and grade can be found in the table below.

You can independently make a concrete solution using various containers to determine the weight and volume of the components, whether it be a bucket, a barrel or a dump truck.

The table below shows the ratio of cement, sand and gravel for the foundation, depending on the brand of cement.

To date, there is a fairly large selection of varieties of cement, among which the most popular are:

- Ordinary Portland cement. This type is used exclusively for filling objects that are used in normal conditions. Concrete made from this type has average values of moisture resistance and frost resistance.

- Slag portland cement. This type of cement is used exclusively for pouring monolithic structures, which are most often installed in a mild climate, where there are not too often severe frosts and high humidity. Concrete made from such cement has good moisture resistance characteristics, but it hardens somewhat longer than other types.

- Pozzolanic type of Portland cement. This type of cement is used exclusively for pouring lightly loaded foundations, which are located in conditions of high humidity. Since concrete made from such cement is very resistant to moisture, it cannot provide adequate strength.

- Fast hardening cement. This type of cement is used in all weather conditions, since the concrete made from it hardens in a matter of days. However, this type of concrete sets too quickly and must be poured only at one time from a concrete mixer.

Sand for the manufacture of concrete mortar must be clean, without various debris, clay and silt impurities. Usually, river sand of medium fractions is used for these purposes. In addition, sand should not contain organic impurities (that is, flora and fauna), so it is recommended to sift it before use.

The main function of sand is to replace expensive cement, and therefore if the concrete is very cheap, this indicates the minimum amount of cement and the maximum amount of sand in it. However, if there is too much sand in the concrete, the final concrete product will have low strength.

As for gravel or crushed stone, they should have fractions of no more than 7 mm in diameter, since the main function of gravel is to reinforce the solution. It should be noted that the more gravel or crushed stone in the finished solution, the stronger the final result will be, but too much of it still cannot be used.

How much water is needed to create concrete?

Water for concrete mortar must be taken clean, without any kind of impurities. In addition, water should not contain salt, as this can lead to corrosion of the metal parts of the foundation. Water is added to prepare the solution at the very last moment, when all the dry ingredients have been mixed together. As a rule, the volume of water is from 250 ml to 1 liter per kilogram of concrete. However, it is not recommended to use too much water, as the viscosity of the solution will depend on this.

To correctly determine the composition of concrete for the foundation and its proportions, to obtain a particular brand, you can use the table below.

For example, if you take 20 kg of cement, then you need to add about 60 kg of sand and 100 kg of crushed stone to it, that is, you should get a ratio of 1: 3: 5.

So concrete, which has the M150 grade (proportions 1: 3.5: 5.7, respectively) can be used to create a light house, however, for the construction of heavier and larger houses, it is necessary to use the M200 grade and higher.

As for the amount of water, it should not exceed 0.65-0.7 parts of the amount of cement.

Only an experienced specialist can determine which brand of concrete should be used in a given situation and weather conditions, because using a brand of concrete that significantly exceeds the required one is not advisable and will be quite costly.

Preparation of concrete solution

Having decided on the proportions for a particular brand, you can begin to knead it. To do this, first of all, prepare all the materials in the amount that is necessary, after which you need to perform the following steps:

- It is necessary to mix all the dry ingredients of the concrete. To do this, sand, cement and crushed stone are mixed in the right proportions and mixed until a homogeneous mass is obtained. This is best done in a manual concrete mixer.

- Further, when the whole mass has become homogeneous, water is gradually added to the container in a small stream until the required viscosity is obtained.

- The consistency of the solution should be homogeneous and resemble thick sour cream.

- The prepared solution should be used within 2 hours.

The pouring of concrete, as a rule, is carried out in a pit or trench prepared for this, in which a pillow has been previously laid and the foundation has been reinforced, waterproofing and formwork has been installed.

Filling is carried out at a time, pouring in several layers is allowed, while filling in subsequent layers is necessary even before the previous one has set. In order for the previous layer to grab well with the next one, it is necessary to moisten it with water.

When the foundation is poured, its surface is leveled with a rule and left until completely solidified. To avoid the occurrence of air voids, it is also necessary to compact the concrete using a special vibrator.

Finally, the foundation is covered with polyethylene or roofing material to avoid exposure to direct sunlight and cracking of the surface. The foundation will gain its strength within a month after pouring the concrete.

Finally, it must be said that the performance characteristics of the final product directly depend on the proportions and composition of the concrete mix for the foundation, so it is very important to observe them correctly.

Composition: water, cement, sand and gravel/rubble. Proportions: if you count 10 kilograms, then cement - 10 kg, sand - 30 kg, gravel or crushed stone - 40-50 kg. To make concrete grade M300 or M400, you need half the water than the weight of the remaining components. Example: in this case, 80-90 kg of a dry mixture is obtained (cement (M500 / M600) + sand + gravel / crushed stone), which means 40-45 liters of water are needed. If the solution is too thick, dilute with water. It's best to stick to a consistency that allows the concrete to be stirred with a shovel, but still apply force (and so that the mortar doesn't run off the shovel too quickly and easily).

Wet sand also contains moisture. Either dry it or take away a few liters of water. Also check the sand for cleanliness. The purer it is, the better the setting in the solution.

Crushed stone or gravel, use a fine fraction (1-2 cm, no more).

Do not buy cement long before construction. It quickly absorbs moisture and deteriorates. Better 1-2 weeks before the preparation of the concrete mixture.

It is desirable to fill any foundation in the warm season. In cold weather, you have to heat the water and the solution so that it does not begin to set earlier. Otherwise, it will lose a lot of strength, because it will not be firmly connected to the reinforcement and will not be compacted.

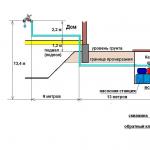

How to prepare concrete for a strip foundation

It is better to count each line (tape) of the foundation separately, and then add everything up. The length of the tape is multiplied by the height, then by the width. Let's say one foundation tape has the following values: length - 10 m, height - 1 m, width - 0.5 m. It turns out 5 m 3 of concrete per tape.

If you count each tape along its full length (from corner to corner), it turns out that the volume of each corner is counted twice. This is correct, since it is better to make more concrete than required. The foundation pit is not jewelry smooth.

It is desirable to pour concrete into the formwork in layers. For example, if the height of the foundation is 1 m, then it can be concreted in 4 layers of 25 cm each. During the pouring of each layer, it is advisable to compact it with a vibrator or at least by tapping with a hammer / shovel. After pouring each layer, air must be released from it, sticking reinforcement every 1-3 m (not very quickly). Also, each layer of concrete must be leveled with a board. For clarity, in the formwork, you can mark the height of each layer.

In the same way, the calculation, preparation and pouring of concrete into the grillage is performed.

How to prepare concrete for a slab foundation

Dimensions: length and width of 10 meters, height 25 centimeters. 10 times 10 times 0.25. Total: 25 cubic meters of concrete for a slab monolithic foundation.

The slab foundation must be rammed on every square meter of area. Since this type of foundation is a solid area, all the concrete must be poured at once. After pouring, it is better to do alignment, starting from the smaller side of the perimeter, and move to the opposite side with a snake. For leveling, you need a wide board with a handle for convenience. Be sure to release air in many places.

How to prepare concrete for a columnar foundation

Concrete for a columnar foundation is calculated according to the volume formula, it is poured all at once and rammed, followed by piercing the mixture to release air.

Preparation of concrete for a pile-rammed foundation

Compared to columnar foundations, only the calculation formula for cylindrical columns of stuffed piles changes. You need to multiply the height by the radius squared and by the number "Pi" (3.14). Calculation example: multiply the height of 1 m by 0.0625 (radius 0.25 m 2) and multiply by 3.14. It turns out 0.19, rounded up to 0.2 cubic meters. This calculation is for one pile column.

After pouring any foundation, you need to cover it with a protective film from precipitation. On the day of pouring, pour plenty of water over the foundation at night, otherwise it may give small cracks in the morning, because the top layer dries quickly. Moisten the foundation every few hours for the first week. From the second week you can once a day.