Preparing concrete: proportions in buckets. What kind of concrete is needed for the foundation of the house Mixing for the foundation

The stability and durability of any structure directly depends on the strength and reliability of the foundation - the foundation of the house. For its construction requires special knowledge and the availability of qualifications and experience from the master.

As a rule, the design for the foundation of any building is selected depending on the soil of the land on which it is planned, the material for the walls, the climate, the conditions and the nature of the structure itself. There are several types of foundations that are used for construction.

Types of concrete foundations

The most basic types of concrete foundations are columnar and tape, but there are other subtypes and varieties:

- Tape. It is installed as a continuous band, which consists of reinforced concrete, laid under all the load-bearing walls of the structure. The depth of the base of the building is formed depending on the level of soil freezing plus an additional 20 cm.

From the indicators of soil quality and climatic zone, two subtypes can be used:- intermittent;

- continuous.

As a material for this type of base is used:

- Booth, which has excellent strength. The material is not affected by low temperatures and flowing groundwater. A buta stone of the same fraction is used. The construction process requires a lot of labor and money, so it is used very rarely. The depth of the bookmark does not exceed 70 cm, and its durability is about 150 years.

- Rubble concrete, which includes a combination of cement mortar and filler (crushed stone, rubble stone of small size, brick fragments). In terms of strength, it has qualities no worse than rubble, but it is much easier to build and more affordable. It is used to build structures made of heavy materials or consisting of several floors.

- Concrete. This type of house foundation is better known as a flood foundation, since the material is mixed in a concrete mixer, after which the formwork is filled with it. The period of operation of the material is over 50 years, and its cost is much higher due to the large volumes of cement used. Most often, this option is used in construction for the construction of walls made of difficult materials, as well as the construction of country cottages and houses.

- Columnar, which is used for the construction of light-type structures (for example, baths, garden houses, sheds). This version of the base includes sets of support posts located at the corners of the structure and in places experiencing increased load. The pillars are formed from pipes, concrete, rubble and reinforced concrete. This foundation is used on solid soils.

- Ribbon-columnar. It is somewhat cheaper than the strip type of foundation and combines only the best qualities of both types of foundation.

Proper selection of material and type of foundation allows you to make the structure more durable and durable. It is possible to buy material for the foundation in a ready-made version, in the form of mixtures at industrial-type enterprises. But it is much better to make a concrete solution yourself, which can save a lot of money.

Foundation concrete composition

You can prepare a concrete solution for a foundation support yourself, for this you only need to know what concrete is and what characteristics it has.

The solution itself consists of a combination of binders (cement), filler and various additives that impart characteristic qualities and properties to the entire mass of the casting. Then the formed solution is diluted in the required proportions with water.

The composition of the foundation mortar has been used in construction for more than a year, and every day it is improved and the quality and strength indicators increase.

Each individual component is responsible for the specific quality of the concrete solution. Therefore, the final quality of the material depends on the proportions of its components used. In order for the final performance of the solution to ideally match the building, it is necessary to take into account the place of construction and its purpose.

The composition of concrete for the foundation proportions in buckets

Important! If the proportionality of the concrete solution is determined by buckets, then it is necessary to take into account the brand of cement. If it changes, then the proportions in the creation of the solution change.

The main components in the composition of concrete:

- Cement- binds together fillers.

- Fillers. These include: gravel, crushed stone, sand, loose additives.

- Water.

There are several ways to mix a proportional concrete solution. The most common option is concrete mixers, into which the required number of buckets of sand, gravel, cement and water is loaded, and then the device thoroughly mixes the materials together.

Forming a solution with buckets is relevant in several cases:

- For construction work less than 4 m 3 solution is required.

- Failure to deliver concrete from the plant due to location problems, for example, the production company is far away, and the cost of transporting the material is too high.

- The foundation is being poured with interruptions, for example, when several tiers of the structure are formed.

- At the facility under construction there is no access to the installation of mixers and concrete mixers.

Proportions of concrete on the foundation in buckets

As a rule, measuring with buckets is used for small amounts of work.

Weight dimensions of the components for the manufacture of concrete mortar:

- cement - 1;

- sand - 3;

- crushed stone (gravel) - 5.

Each component of the concrete solution has a different volumetric weight, for example, the mass of one bucket of sand is 19.5 kg, cement - 15.6 kg, and gravel - 17 kg. Therefore, in practice, a convenient option for the proportions of cement, sand and gravel is 2: 5: 9. In some situations, gravel is changed to crushed stone.

If the construction of the structure is carried out by hand, then a ready-made sand-gravel mixture (PGS) is used. The ratio of concrete for the foundation to the mixture is approximately 1 bucket of cement to 5 buckets of ASG.

In what proportions to make concrete?

In most situations, for frame-type buildings, a columnar version of the foundation is used, which does not require a concrete mixture with increased strength indicators. For this type, concrete M 200 is suitable, which is made from cement M 500, sand, crushed stone and water.

For one cubic meter of the mixture you need:

- 300–350 kg of cement;

- 1100–1200 kg of crushed stone;

- 600–700 kg of sand;

- 150-180 liters of water.

Such a ratio of materials is formed by their qualities, for example, crushed granite has a high level of strength, in comparison with crushed dolomite or limestone, so it can be used in smaller quantities.

To create a mixture of concrete of the required consistency, it is best to use washed crushed stone, and only purified river sand, in which there are no various impurities of clay.

If you use sand with a low level of quality, then holes and potholes may form in the base.

When choosing cement, initially pay attention to the manufacturer. As a rule, the more famous the organization, the less likely it is to purchase low-quality goods.

Water should also be used clean, so that it is free of impurities and salts. If construction is carried out in the cold season, then water, like other components of the concrete solution, should be heated to +60 0 C in order to give the solution the necessary consistency and strength.

How to mix concrete correctly?

For preparations of a small volume of solution, a bucket is used as a measure of the weight of the components. The proportions are calculated in accordance with the fact that the components have different volumetric weight. Based on this fact, when preparing the 1st 3 solution, you will need a ratio of 9: 5: 2 (gravel or crushed stone, sand and cement).

The production of concrete M 200 is carried out according to the rules in order to achieve a high quality mixture as a result.

Rules for mixing concrete for the foundation:

- Mix well first. between sand and gravel, so that there are no lumps later when adding water. Furrows are made on the surface into which cement is poured. The mixture should be mixed until a completely uniform color is obtained.

- Shape the mixture into a cone and add water in small portions, mix everything thoroughly.

When deciding which is the best way to mix the solution, needs and financial capabilities should be correlated. The best option would be to use a concrete mixer, but it is not profitable to buy it for a small building, so it is better to use manual production.

Preparation of concrete mix for strip foundation

For this type of foundation, you will first need to calculate the amount of material needed. The parameters of one tape (length, width and depth) should be multiplied by their number.

Example. Length 20 m, width 0.5 m, depth 1 m. We multiply these values and get, on one side of the foundation it is necessary to prepare 10 cubic meters of concrete solution.

Having prepared the required amount of the mixture, it is poured into the formwork. It is carried out in layers, for example, if the depth of the base is one meter, then there should be four layers, each 0.25 cm each. After laying each of them, it is necessary to compact. Then, in order to release excess air, reinforcement should be slowly stuck into the solution every meter or two.

Preparation of concrete for a columnar foundation

Calculations in this type of foundation correspond to the tape version. The difference is that the concrete solution is not poured in stages, but immediately, after which it is rammed.

Necessary properties of foundation concretes

The concrete base of the house has different properties and characteristics. They directly depend on what materials and their initial components are used in terms of quality. Also, the properties of concrete depend on the proportions of its components, which are used for the construction of various types of structures.

Required strength of foundation concrete

The strength of a concrete foundation is a key indicator that determines whether the foundation can withstand the planned load on it. It is measured in kilograms per square centimeter.

You can calculate this indicator by calculating the exact degree of load that the structure will exert on the base. To do this, you need to sum up the total weight of all structures and communications, as well as indicators of the payload and possible load that is created by climatic conditions. Then the result should be divided by the area of the entire foundation.

The final strength of concrete should be several positions greater than the planned load on it.

The degree of strength of concrete is indicated in its brand, which means the maximum degree of load on the foundation in kg / cm 2.

According to the calculations obtained, a concrete solution with the appropriate characteristics should be prepared.

The required proportions of the material can be found in the tables:

Concrete from cement brand M 500, sand and crushed stone

Concrete from cement brand M 400, sand and crushed stone

Giving concrete special properties

If additional requirements and special properties are imposed on the structure being erected, for example, water tightness or frost resistance, then additives and special concrete of exposure class XD, XF, XM or XA should be used.

To give the concrete mortar special properties, various additives are added to it, which can enhance and improve certain qualities of the material.

Concrete with high frost resistance requires the addition of an appropriate additive, which increases the level of frost resistance of the concrete base.

The addition of this type of additive ensures that the foundation can withstand a large number of freeze and thaw cycles.

If, in addition to frost, the structure is exposed to salts, additives with high frost resistance and resistance to thawing salts acting on the base are used.

Additives are also used that can increase the plasticity of the solution. As a rule, they are used in formwork mortars with frequently repeated metal reinforcing mesh. This additive contributes to a better distribution of the mixture around the entire perimeter of the formwork.

Additives are also used that increase the degree of stability of the foundation of the structure to being washed away by groundwater (waterproof concrete). It is almost impossible to do without them in places where the soil is too saturated with moisture. A solution of a denser consistency is used for buildings with a thickness of 10 to 40 cm, so that the depth of water penetration does not exceed 0.6, and for structures with a greater thickness - 0.7.

Number of components per cube

As we already know, the main components for the preparation of concrete are water, sand and crushed stone. To prepare the appropriate consistency of the mixture, proportions must be observed.

To obtain the 1st 3 concrete solution, you will need the following amount of materials presented in the table

Approximate proportions for the formation of 1 m 3 concrete

If you are preparing a solution for the first time, then initially prepare a trial version. When the sand is wet, it is better to use less water than indicated.

Based on these data, you can prepare the necessary concrete solution yourself.

Each building, regardless of its purpose, needs a strong support; the reliability of the building and its durability depend on its quality. The foundation can have a different shape and consist of various materials. However, in any case, the main component of the base is concrete.

Proportions of concrete for the foundation

Foundation concrete is a combination of binder, filler, water and various additives.

The binder is almost always cement, which, depending on the withstand load, can be of several grades: M200, M300, M400, M500 and M600.

Sand and gravel are used as filler. Sand is best used river sand, while it should not contain clay impurities. The size of grains of sand for high-quality concrete should not exceed 5 mm. it is better to take from crushed granite, as it is characterized by high strength. The size of the fraction should not exceed 2 cm.

Additives are necessary to give the concrete the required characteristics. A mixture of dry ingredients is diluted with water to the desired consistency. Each component of concrete has its own function, so it is very important to choose the right proportions of the components.

Water for the preparation of concrete must be clean, so it is recommended to take it from the water supply. If this is not possible, then it is allowed to use water from natural reservoirs, but with preliminary purification.

You can knead the concrete solution in a concrete mixer or manually using a certain number of components. However, weighing materials is not always possible, so buckets are used for convenient measurement.

- Cement - 1 part.

- Sand - 3 parts.

- Crushed stone - 5 parts.

In other words, for high-quality concrete, 3 buckets of sand and 5 buckets of crushed stone are taken for 1 bucket of cement. As for water, the estimated amount of this component is determined depending on the amount of cement, most often they take 0.5 parts of water per 1 part of cement. However, there are many factors that affect the amount of water to one degree or another. For example, the use of wet sand significantly reduces the amount of water required to prepare a solution of the desired consistency. In addition, it is necessary to visually control the consistency of the concrete. The main thing is that it is thick and plastic, can keep its shape and not spread.

The proportions of the components for the preparation of 1 cubic meter. concrete

Concrete for the foundation has several grades, which are determined by the type of future structure, its weight and purpose. For the preparation of each brand of concrete, a certain brand of cement can be used. In general, these two factors determine the number of components needed to prepare one cubic meter of concrete.

In most cases, concrete grade M 200 is used for the construction of foundations, it has sufficient strength and can withstand freezing and thawing many times. For the manufacture of such a solution, cement grade M500, crushed stone of the middle fraction and water from the water supply are used.

The preparation of one cubic meter of M200 grade concrete requires the following number of components:

- Cement - 300-350 kg.

- Crushed stone - 1100-1200 kg.

- Sand - 600-700 kg.

- Water - 150-180 liters.

To convert the indicated values into volume in buckets for more convenient measurement, it is enough to know the approximate mass of each component in one bucket. For example, a 10-liter bucket holds 15.6 kg of cement, 19.5 kg of sand and 17 kg of fine gravel. Therefore, to mix a concrete mass of 1 m 3, you will need about 20 buckets of cement, 30 buckets of sand, about 70 buckets of crushed stone and 15-20 buckets of water. As you can see, it is not so difficult to calculate the proportions of concrete for the foundation in buckets.

Features of concrete mortar

The strength of the foundation largely depends on the right components, each of which is designed to perform its assigned task.

For example, the main components of concrete are cement and water, their mixture forms a cement stone. However, despite the solidity of the structure, this stone is easily deformed, shrinking 2 mm per 1 meter. The result of this process is the formation of microcracks, invisible during visual inspection, but significantly reducing the quality of the cement. In the future, to analyze the quality and condition of the foundation.

Fillers help to reduce the degree of deformation of the cement stone. Most often, sand, crushed stone, gravel or expanded clay are used for this. The filler forms a special structure that takes on the stress of the concrete during shrinkage. Therefore, the addition of filler to cement allows several times to increase the strength of concrete.

Manual preparation of concrete mix

To prepare a high-quality concrete mortar for the foundation, it is best to use a concrete mixer. However, this possibility is not always available. Sometimes the purchase of a concrete mixer or its rental is not available due to the limited budget for construction. There are situations when it is not possible to connect to the power supply network. It is possible that the use of a concrete mixer is not rational due to the small amount of work. You can solve the problems of such a plan by manually mixing the concrete mixture.

To work you will need the following:

- Two buckets: one bucket for cement, the other for other components and water.

- Two shovels, one of which is also used only for cement, the other works with sand and gravel.

- Wide container with high sides for easy mixing of ingredients.

The process of manual mixing of the concrete mix is as follows:

- Sand and gravel are poured into the container, mixed well and grooves are made on the surface.

- Cement is poured into the resulting recesses and the whole mixture is mixed until homogeneous.

- A mixture of dry ingredients is collected in a cone, on top of which a hole is made.

- Pour a small amount of water into the recess of the cone and begin to mix. In this case, the kneading is carried out directly at the top of the cone, so that the dry mixture is poured into a hole with water.

- When the filled water is absorbed, a cone is again formed with a recess in the upper part and more water is added. The steps are repeated until the desired consistency of the concrete mass is obtained. It is very important not to pour all the water at once, as its excess can reduce the quality of the prepared solution.

The preparation of concrete for the foundation is a very important stage, on which the strength and durability of the foundation and the entire structure depend. Therefore, it is very important to choose the right components for mixing the concrete mass and calculate their proportions as accurately as possible.

The composition of the foundation is not only the presence of all the required elements, but also the selection of the appropriate concrete for pouring. Its proportions, the calculation of the volume for the foundation will vary greatly for each base under the house.

For the foundation, cement with a brand of at least M200 should be taken.

Today, various types of foundations are used, among them it is necessary to single out the structures of slab, pile, strip foundations. Sometimes combined options are used.

What should be the composition of the strip foundation?

The most commonly used construction of a strip foundation, which is simple and economical. This design consists of a shallow concrete strip, which is arranged around the perimeter and under the load-bearing walls of the house.

In some cases, ready-made concrete blocks, bricks can be used for it. In this case, the duration of the work does not depend on the curing time, only the time for the masonry mortar to dry is taken into account. But it is also required for its preparation.

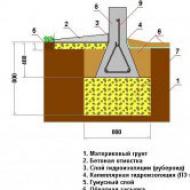

Cake for the tape base of the house includes:

- sand and gravel pad at the bottom of the trench;

- removable formwork from a conventional edged board (removed after the concrete has hardened);

- concrete tape running along the perimeter and under the bearing walls;

- waterproofing the upper part of the strip foundation.

In manufacturing, such a base is considered one of the simplest; it can be erected on almost any type of soil.

To calculate the material, you only need to know such tape parameters as height, width and overall length. In some cases, the foundation is reinforced before pouring with metal reinforcing bars, which enhances its strength and bearing capacity.

Back to index

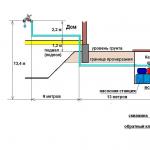

What does a pile foundation include?

The pile foundation for the house is a foundation in the form of special support pillars. This option is used when building on difficult soils, on slopes, on swampy or sandy soils. The house in this case exerts uniform loads on the ground due to the features of this design.

To prepare such a base, not so much is needed, the design pie consists of the following elements:

- sand and gravel pad at the bottom of the well;

- support pillars, which are poured with concrete after installation;

- for grillages, a special belt is used, which is used as a base for the house.

There is a type of pile foundation, which is a combination of tape and support (piers are erected between the pillars to a small height). It doesn't take much time to prepare.

Back to index

Slab foundation and its composition

A slab type of base for a house is a base, which is a monolithic, reinforced slab made of concrete. The recipe for such a base is simple, but very reliable. The slab base pie includes:

- base of sand and gravel;

- plate (can be of several types: ordinary solid, lattice);

- waterproofing on the top.

The slab itself is reinforced with special metal fittings. may include reinforcing polymer additives that enhance strength, resistance to various loads. But there are also disadvantages here. To lay the foundation, a large consumption of materials is required. In addition, during the construction of a slab base, it is impossible to arrange an underground garage, a spacious basement.

Back to index

Foundation concrete: application features

For the construction of the base, concrete of various grades is used in a variety of proportions. Everything here depends on the type of foundation itself, the requirements for it. One of the most important issues with are the proportions of the ingredients. When choosing what will be the composition of concrete for the construction of a slab monolithic, pile (columnar), strip foundation, the following features must be taken into account:

- for must exactly correspond to the expected loads and construction conditions. In this case, the design will be strong and very reliable.

- The base for the house can be of various designs (slab, pile or tape). To arrange it, blocks, support posts or a liquid mixture for pouring can be used. But in any case, it is recommended to use only factory concrete mixes, which are of high quality. It is not recommended to make slabs or poles from a dry mix at home.

- The composition of concrete includes: cement of the selected brand, fillers (gravel or crushed stone, sand, granite sand), water. Plasticizers, special reinforcing additives are often used. The proportions of such a mixture depend on what kind of cement will be used, what brand of concrete should be obtained in the end.

- For the foundation, it is necessary to take cement, the brand of which is not less than M200.

- The strength of the concrete mix for the foundation largely depends not only on the right proportion, but also on the quality of the fillers. It is recommended to use different-grained materials that will evenly fill all voids.

- After preparation, concrete can only be used for two hours, after which it begins to dry and lose its qualities.

- Water plays a big role in the preparation of concrete. You can not make the mixture too liquid or too thick, in its consistency it should resemble thick sour cream.

Back to index

The composition of concrete mixtures for the foundation

The composition of concrete, as already mentioned, includes components such as gravel, sand and water. The base takes on the load from the structure, so it is very important to take into account all factors when calculating the mixture. The proportions will differ depending on which brand of concrete will be used. For example, to build a house, you need to use concrete grades from M200, but for ordinary garden paths, M100 is also perfect.

Consider the proportions and volumetric composition of concrete for various grades:

- M200, mass composition - cement 1 kg, sand 2.8 kg, crushed stone 4.8 kg, volumetric composition for every 10 liters of concrete (sand / crushed stone) - 25:42, the amount of concrete for every 10 liters of cement - 54 liters.

- M250, mass composition - cement 1 kg, sand 2.1 kg, crushed stone 3.9 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 19:34, the amount of concrete for every 10 liters of cement - 43 liters.

- M400, mass composition - cement 1 kg, sand 1.1 kg, crushed stone 2.5 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 11:24, the amount of concrete for every 10 liters of cement - 31 liters.

- M450, mass composition - cement 1 kg, sand 2.8 kg, crushed stone 4.8 kg, volumetric composition for every 10 liters of mortar (sand / crushed stone) - 10:22, the amount of concrete for every 10 liters of cement - 29 liters.

The higher the brand of concrete for the mixture, the greater the amount of cement will be contained in the composition. Therefore, it is important to correctly determine which brand is needed in order to. The M300 and M400 are optimal, which are quite enough to build a foundation even for a massive country house.

Concrete is one of the modern materials that are used to create strong and durable structures. It consists of sand, some fillers and a binder. When the concrete mortar completely hardens, it becomes a stone. It is impossible to imagine any construction event in which concrete would not be used.

However, the material must meet certain requirements. Only in this case it is possible to build a solid structure from it that will last for more than a dozen years. To make the material as durable as possible, it should be made using a special technology. The proportions of concrete for the foundation of various structures are selected in accordance with the strength requirements for the structure.

Cement

Cement always acts as a binder when creating a concrete mix. It is made in different variations. The choice of a particular brand of cement depends on the final destination of the concrete product and the conditions for its use. The quality of binding is one of the main characteristics of cement.

When choosing cement, it is important to consider its technical data. They affect the maximum load that the finished product can experience. This indicator is measured in megapascals. When designating a brand of a domestic product, the letter D (impurities) is added. For example, if M400-D20 is written on the bag, then a concrete product made from such cement will withstand a load of up to 400 MPa, and the percentage of impurities in the powder is 20%.

For domestic purposes, Portland cement grade 400 is often used. It has good strength and is suitable for low-rise construction. For industrial purposes, cement grades from 500 are chosen. When erecting structures that will experience serious loads, cement powder of a higher grade should be chosen.

Cement powder has such a characteristic as an expiration date. After a certain time, the material begins to lose its useful properties. If the cement is fresh, it is friable, does not have seals and lumps. When various seals are in the powder, cement should not be used in the work. Such a powder has already absorbed a certain amount of moisture, which is reflected in its binding properties.

Sand selection

Sand can have different characteristics. The strength of the final result will depend on how well it is selected. During the preparation of concrete mortar, different types of sand are used. One of the main conditions is the absence of dust or clay particles in it. If there are quite a lot of such inclusions, the mixture will turn out to be of poor quality. This can be especially attributed to fine sand, which contains a high percentage of dust particles. It cannot be used to make concrete.

How not to miscalculate when choosing sand? After all, only when choosing a quality material can you make the most durable concrete. It is better to choose river or sea sand. He is the purest. Quarry sand should not be used to create a concrete mixture without prior cleaning. Usually it contains a lot of tree roots, leaves and bark. Quarry sand must be washed and settled.

If any organic inclusions get into the concrete, it will lose a certain percentage of strength. This is due to the formation of voids in the finished solution when mixing concrete with dirty sand.

Another important factor is the moisture percentage of the sand. Even if the material is dry, it can contain up to 2% water, in wet sand up to 10%. If you use too wet sand for the mixture, the strength of the finished product will be significantly reduced. The exact proportions for the preparation of concrete are selected in accordance with the requirements for the final result. The differences between concrete of different grades are analyzed in the table:

gravel and crushed stone

Gravel and crushed stone are often among the main fillers for concrete. This material is a rock that is crushed to a certain size. It can be classified according to the size of individual elements. Crushed stone can have a rough or smooth texture.

Crushed stone can be:

- very small - individual components have a size of 3 to 10 mm;

- small - stones differ in diameter of 10-20 mm;

- medium - such crushed stone has a size of 20 to 40 mm;

- large crushed stone differs in diameter of 40-70 mm.

To make concrete that will last for many years, it is necessary to choose such crushed stone so that the size of its individual parts is no more than 1/3 of the thickness of the finished product.

In addition, it is important to take into account another indicator - the voidness of the filler. It is determined by the amount of empty space between the stones. It is quite easy to define it. To do this, you need to fill a 10-liter bucket with crushed stone and see how much water is needed to fill the remaining space. When using 3 liters of water, we can say that the voidness of the filler is 30%.

This indicator affects the amount of sand and cement that will be used to create concrete. The smaller the void, the less other components will have to be used to create a mixture.

To fill the voids as much as possible, crushed stone of different fractions is used. Stones are taken as small, as large and medium in size. It should be borne in mind that the elements of the fine fraction must be used at least 1.3 of the total amount of crushed stone.

In addition to gravel and crushed granite, depending on the purpose of using the concrete product, expanded clay and blast-furnace slag are used. Other fillers may also be used. If lightweight concrete is being prepared, wood shavings are chosen as the filler. When creating ultralight types of concrete, gases are the filler. However, in the manufacture of such concretes, certain requirements must be observed. Otherwise, the finished product will not meet standard standards. Table of general requirements for concrete:

Fillers for concrete mixes can be dense or hollow. Natural materials have a lower radiation background than artificial ones. Granite rocks have the lowest index. However, finished products with any fillers will not be sources of radioactive contamination, so this indicator is often not taken into account.

Water

Water is one of the most important components of the solution, which must also meet certain requirements. If the water quality is poor, it will adversely affect the strength of the concrete product. The main rule in the manufacture of the mixture can be considered such a condition - if water can be used for cooking, it is also suitable for mixing the concrete mixture. It is not recommended to use swamp water.

Each element of the solution has a certain moisture index. Moisture that is present in building materials is excess water that can spoil the finished concrete mix. To figure out how to prepare concrete, you will need to determine the necessary properties of the finished product.

The volume of water used affects such an indicator as the ductility of concrete. The plasticity of the solution is usually determined "by eye".

To determine this indicator, you should take the solution on a shovel. If it slides off a horizontally placed tool, it has high ductility. When concrete slips in the case of a slight inclination of the shovel, it can be considered medium-plastic. Concrete has low plasticity, which will not roll, even if the shovel is strongly tilted.

Strength set

Concrete acquires a certain strength only after a certain time. After a week, the finished material gains a certain strength (up to 40%). However, only within 28 days from the date of pouring concrete can become as strong as possible. Special requirements for this indicator are imposed when creating concrete for the foundation.

The calculation of the composition of concrete must be carried out taking into account certain data. Among them should be highlighted:

- brand of cement powder;

- characteristics of the granulometric composition of crushed stone and sand;

- plasticity of concrete to be achieved;

- required brand of ready-made concrete.

The composition of concrete can be calculated by the mass of its components or their volume. Cement is always taken as a unit. Other components of concrete are calculated as a certain part of the volume of cement. Determine which proportions of concrete to choose for the foundation should be according to the required indicator of the brand of the finished product.

Calculation by weight

The calculation of the composition can be carried out according to certain standards. The main goal is to obtain a solution of medium plasticity.

At the beginning of work, it is necessary to determine what the water-cement ratio will be. For this, the W / C indicator is determined. It represents the ratio of water and cement. The determination of such a characteristic is carried out empirically or according to a special table.

To measure the amount of materials that make up concrete, a 10-liter bucket is usually used. It is used as a measuring vessel. For ease of calculation, it should be mentioned how much a 10-liter bucket contains certain materials:

- about 13-15 kg of cement powder;

- from 14 to 17 kg of sand - this figure depends on the percentage of moisture in the material;

It should be understood that the methodology for such a calculation is somewhat inferior to the methods used by professional builders. However, this method is still good for domestic purposes. In addition to using proportions by weight, proportions of the composition of the mixture according to volume are also used. This method is less accurate.

Proper concrete mixing

Concrete can also be kneaded by hand, but mixers or concrete mixers are more often used for such work. In the first case, the finished mixture is obtained in a small volume. To properly knead the solution, you need a container of a certain volume. Usually a tin trough is chosen for this purpose.

The proportions for the preparation of concrete of medium plasticity grade M400 should be as follows:

- cement - 1 part;

- crushed stone - 2.7 parts;

- sand - 1.2 parts.

With 10 liters of cement, 31 liters of water must be used. Manual mixing is the most popular when creating concrete products in home gardens. The number of components used can be calculated using the table:

Preparing concrete by hand is quite simple. Sand is poured into the trough. Then a strip is drawn in it in the middle. Cement is poured into the groove. Then these ingredients must be thoroughly mixed. After that, crushed stone is added. The resulting mixture is kneaded until each stone is covered with a solution. At the same time, water should be added a little at a time. Its quantity regulates the plasticity of concrete. When the mixture is homogeneous, the concrete can be poured.

During manual mixing, it is important to pour the finished solution as quickly as possible. If there is a momentary delay, the concrete will begin to delaminate. In this case, water begins to appear from above the solution. It is better to mix concrete in a concrete mixer.

Using a concrete mixer

When using a concrete mixer, cement powder is first poured into the device and water is poured. Then you need to add sand. Then the solution should be kneaded, adding water along the way. When a homogeneous solution is obtained, filler is poured into it.

The advantage of this method is that the concrete will not delaminate. It can be in the mixer for about 1 hour without losing its properties. The device should not be placed far from the place where the concrete is to be poured. This condition must be observed so that the concrete does not lose its properties during delivery to the place of laying. If you follow these simple rules, you can get a reliable and durable design.

In private construction, the foundation is usually poured on their own, without ordering kilotons of concrete in a mixer. Because imported concrete is much more expensive, given the small volumes. If, for example, you pour a strip foundation for a garage or a masonry fence, the cost of a mixer will not be justified in any way. Therefore, in such cases, concrete is prepared with a hand-made shovel in a convenient, sweet trough. If, of course, they know the proportions and technologies ...

Composition and material

Concrete is not a masonry mortar, so the presence of aggregate must be taken into account. The composition will certainly include crushed stone or other crushed material, small red brick breakage, gravel. The ratio of materials is taken depending on the purpose and the required brand of concrete. The more irregularities on the surface of the aggregate, the better its adhesion coefficient. Pellets (river gravel) are not suitable for concrete preparation!

Sand is better to take medium-grained, mined in quarries, and not washed along the banks of rivers. River sand, in addition to having a fine fraction, also contains a large percentage of clay particles, which is an aspect that worsens performance for high-quality concrete.

It is optimal to choose crushed stone or another type of aggregate with a fraction of 5-20 for pouring the formwork or 20-40 for pouring the foundation “on the ground”.

Lightweight concretes (containing a minimum of gravel, granite or other heavy crushed stone) are not suitable for pouring the foundation. The same applies to the masonry mortar prepared according to the technology without aggregates at all.

The standard ratio of cement / sand / crushed stone for concrete grade M200 and cement grade M400 is 1 / 2.8 / 4.8 (proportions are indicated by weight, not by volume). To prepare M250 concrete from the same grade of cement, you will need to mix the solution in proportions by weight of 1 / 2.1 / 3.9. To prepare M300 concrete, mix the components in a ratio of 1 / 1.9 / 3.7.

Pay attention to the mixing method! This is not a masonry mortar, and mixing all the ingredients before adding water will be very problematic, unless you had a worthy nickname "excavator" in your childhood. Therefore, first mix the sand and cement, as in a normal mortar, and gradually add water and crushed stone, achieving the desired consistency in the end result. It should be noted that in order to fill a strip foundation without formwork, “in the ground” to the level of the upper soil layer, a more liquid consistency is always prepared.

So, you will need materials:

cement brand M400 or M500;

river or quarry sand;

aggregate;

additives, hardeners, additives, softeners and others - only with the subsequent use of the prepared concrete in non-standard conditions (high humidity, constant rain, air temperature less than + 5 ℃, the need to quickly load a freshly poured foundation and other circumstances).

Prepare your tools:

electric or manual concrete mixer;

large capacity (trough) for manual stirring;

10-12-liter bucket for transporting components, water;

shovel;

the sieve is capacious enough for sifting sand from weeds. "Handicraftsmen" often use a metal mesh from an old spring bed set at an angle of 45 ° and above.

It is worth noting that the purchase of a concrete mixer for one-time use is also unprofitable, as in the case of ordering a mixer with ready-made concrete for small volumes of construction. The foundation for an ordinary garage will be much cheaper to prepare in the “old-fashioned” way, stirring the components in a trough. It will take a little more time. Proven by time and billions of private developers.

Construction technologies used in everyday life provide for the formation of a concrete solution directly at the construction site. Making concrete for the foundation with your own hands is not a particularly difficult task.

Most often, domestic construction work is carried out precisely in the use of self-made concrete solutions. The formation of a concrete mixture of proper quality provides for the presence of the following components: aggregate, cement, lime, additives, water.

Aggregate concrete

The manufacture of mortar for construction purposes most often involves the use of fine sand or crushed stone. It is also possible to use large crushed stone or gravel. The preparation of mortar for plastering or masonry work is carried out using fine sand. Stucco with a special, non-smooth texture can be made from coarser sand.

As a rule, the sand offered by manufacturers is of river or ravine origin. The first is considered medium-grained. Its cost is high, but the quality matches. The second type of sand can be fine-grained, but the presence of impurities and clay particles in its composition makes it not the best choice for making good concrete, but mortars can be made with such material.

The manufacture of high quality lightweight concrete mortar involves the use of sand exclusively as a filler. Gravel and crushed stone are used to make stronger concrete.

The best option is a combination of a mixture of crushed stone of different fractions, such a composition contributes to the formation of a minimum number of voids. All kinds of contaminants such as soil, glass, peat and plants are unacceptable in the composition of the solution.

Cement - characteristics

Such a common name is given to substances of a powdery texture, made on the basis of clay and calcareous rocks with the use of various additives to them.

The most applicable is Portland cement. This type of material contains a large amount of calcium silicates. There are two types of this substance:

- Type 1 - the content of additives does not exceed 5%;

- Type 2 - additives reach 35% in the composition.

Domestic cement is marked with the letter D, to indicate the presence and amount of additives in its composition. For example, the inscription on the packaging of PC 300-D20 informs the buyer about the presence of 20% additives in this product.

When buying cement, you should check for proper labeling on the package, as well as check the absence of moisture in the package itself.

As a rule, this can be understood in appearance or simply felt with your hands. Stale cement is not the best purchase for construction repairs or work.

Lime - why is it?

Lime can improve the properties of the solution and ensure its high-quality laying. Previously, it was required to “extinguish” it before adding it to the solution. Now slaked lime (fluff) packed in bags is available for sale. You can use both a dry mix and a water-based lime paste. Lime is added to make plaster or masonry mortars.

When working with lime mortars, it is necessary to observe safety precautions:

- wear protective gloves and avoid getting lime on your skin or eyes. This composition has strong corrosive properties. In case of contact, rinse with water.

Additives - nuances of application

To improve or improve the properties of the cement mortar, additional additives are included in its composition.

- plasticizers. They improve the flow properties of concrete. The use of such substances allows you to create concrete structures of various shapes and generally improves the laying properties of concrete.

- Superplasticizers or thinning additives help reduce water in the solution. Also, such elements make the concrete structure frost-resistant and waterproof;

- additives that promote rapid hardening;

- additives that allow working with concrete at temperatures from -10 to +35 degrees;

- Aerating or air-entraining components. Serve to increase resistance to frost and reduce the moisture content in the finished product;

You can buy additives at a hardware store, checking for dosage information on the package. They are sold already in finished liquid form, adding them to the solution should not exceed 2% of the total mass.

In some cases, additives can be made independently. For example, the manufacture of plasticizers from soap or soap solutions is common.

Compliance with the dosage when using such substances is of key importance, a violation of the proportion can lead to a decrease in the quality of the solution.

And, of course, water for concrete mix

The choice of water for the preparation of a mixture of concrete must be carried out in accordance with GOST. Water requirements include the absence of impurities, sugars, oils or acids.

It is recommended not to use water from dubious sources, such as a lake or river, but to take a liquid suitable for drinking. If, nevertheless, it is planned to use water from a reservoir, then it is better to check its suitability in a special laboratory.

Proportions and composition of the solution

Parameters such as the composition of the concrete mixture and the proportions of the components used depend on the purpose of this solution. When making concrete for the foundation with your own hands, it is better to take high-density concrete, which has sufficient strength.

- The manufacture of elements such as the base for the fence can be made of concrete of a lighter grade. It is better if the concrete for self-production of the mixture corresponds to the M300 or M400 grades.

- The proportions of the components necessary for the manufacture of high-quality mortar: 1 part of cement, 3 parts of sand and 5 parts of crushed stone. The weight of the added water should be half the weight of the dry mixture.

- Components can be added during mixing. When forming a solution of too thick consistency, you can add water.

- The use of wet sand requires less fluid to be added.

- The consistency of the solution should be such that mixing it with a shovel is not carried out with excessive effort.

- Works with concrete, performed in conditions of negative temperature, should be carried out with heating of the material itself and water. If this condition is not met, then premature solidification of the mixture is possible and, as a result, a violation of construction technology.

- It is better to mix the components in a purchased concrete mixer, but it is also possible to use home-made devices.

The implementation of recommendations for the manufacture of concrete contributes to the improvement of the quality of work performed. The right choice of material brand, components and additives will allow you to create a solution that is optimal for the implementation of each specific task.

Be sure to observe safety precautions in the process of work, as well as the use of high-quality tools and devices.