How and how to level walls for wallpaper: materials and stages of work. How to level walls with your own hands Leveling old walls with your own hands

In old Soviet-built houses, the walls, unfortunately, are not always particularly even. In most cases, their surface is covered with bumps and pits, has cracks or chips. Moreover, their plane itself often deviates significantly from the vertical or horizontal. Of course, rooms with such walls do not look very attractive. Before wallpapering, painting or, for example, before finishing with decorative plaster, the surfaces of enclosing structures in such apartments have to be adjusted. How to level the walls? Of course, many homeowners would like to know the answer to this question. Surfaces with defects can be corrected using different materials.

Two main techniques

There are two main ways to level indoor walls these days:

- dry;

- raw.

In the first case, leveling walls for wallpaper or decorative plaster is most often done using plasterboard. Also, dry correction technology may involve the use of plywood, lining or PVC boards. When using the raw leveling method, different types of plaster are usually used.

What types of mixtures are there?

Such materials for leveling walls are usually supplied to the market in dry bags. Before use, they must be diluted with water in the amount specified in the instructions for use. Plaster can be used to level the walls:

- plaster;

- cement;

- clay;

- acrylic;

- silicate.

Advantages and disadvantages of gypsum compositions

The initial mass of materials of this type is a very fine powdery dry mixture. The answer to the question of how to level the walls in an apartment is that gypsum plaster is a very good answer. It contains, among other things, various types of plasticizers. And therefore it lies on the walls very smoothly.

Using this plaster, concrete or brick walls can be leveled. Such mixtures are generally not used only in very wet rooms - saunas, bathrooms, swimming pools, etc. It is also not allowed to use gypsum to level the facades of buildings.

The main advantages of this type of plasters are:

- high degree of elasticity;

- excellent adhesion to the treated surface.

Craftsmen also include its fine texture as an advantage of gypsum plaster. Leveling walls under wallpaper using such mixtures has the advantage that in this case it is not necessary to use finishing putty at the final stage. Another undoubted advantage of such plasters is their rapid maturation. If necessary, you can start gluing walls lined with gypsum mixture within a week.

The disadvantages of compositions of this variety include, first of all, their high cost. Leveling walls with gypsum plaster is usually quite expensive. Products of this variety cost approximately one and a half to two times more than cement ones. Also, the disadvantages of mixtures of this type include a very short viability period. The prepared gypsum mixture must be used within an average of 45 minutes. Of course, such a short “life” makes working with this type of plaster not particularly convenient.

The best brands of gypsum mixtures

Of course, when choosing this type of plaster, like any other, you should first of all pay attention to the manufacturer’s brand. The most popular gypsum mixtures in our country are:

- "Osnovit". Plaster of this brand can remain viable for up to 90 minutes. It costs about 250-300 rubles. per bag.

- "Knauf". This manufacturer supplies the Russian market with very high-quality Rotband gypsum mixture. A bag of this plaster costs about 400 rubles. Leveling walls with “Rotband” is not a particularly complicated procedure. This mixture can remain viable for one and a half hours. In addition, it has a high degree of plasticity.

- "Eunice". After preparation, such mixtures must be processed within 50 minutes. They cost about 300 rubles. per bag.

Pros and cons of cement compositions

It is this material that most often serves as the answer to the question of how to level the walls inside or outside the room. There are two main types of such plasters on the market today. To level surfaces, either a cement-lime mixture or a cement-sand mixture can be used.

Both of these types of plaster work on walls no worse than plaster. At the same time, the cement leveling mixture is much cheaper. This type of plaster is the best answer to the question of how to line the walls in the bathroom. It is perfect for wet rooms.

The only thing in which cement plaster is inferior to gypsum plaster is its not too smooth texture. After using such a mixture, it is usually necessary to additionally apply a finishing material. Another disadvantage of cement plaster compared to gypsum plaster is the long maturation period. You can begin the final finishing of walls leveled using it only after about a month.

The best manufacturers of cement mixtures

Compositions of this type, like gypsum, are supplied to the domestic market by many companies. But the most popular plasters in our country are:

- cement-lime "Osnovit Starwell-21";

- cement-lime Polimin ShV 1;

- cement-sand “Vetonit TT”.

The Starwell mixture can be used to level walls not only indoors, but also outside. This plaster costs about $5.9 per bag weighing 25 kg. Polimin ShV 1 mixtures are only allowed to be used indoors. The permissible maximum thickness of the leveling layer when using both of these types of plaster is 20 mm. The price of Polimin ШВ 1 mixtures is approximately $3.6.

Vetonit TT compositions can be used for leveling indoor walls and facades. They can be applied to the surface in a layer of up to 3 cm. This plaster costs about $9 per 25 kg.

How to level walls outside: acrylic compounds

Building facades are thus most often leveled using cement plaster. However, acrylic mixtures are sometimes used for this purpose. Such materials are more expensive, but they provide a much more durable leveling layer. This finishing composition is made based on an aqueous solution of acrylic. The main advantages of this type of plasters are:

- elasticity;

- good degree of heat and sound insulation;

- frost resistance;

- ease of use.

The disadvantages of this type of plasters, as well as gypsum plasters, include a short pot life. Also, this mixture has not earned very good reviews from consumers and for its not particularly high degree of vapor permeability. Unfortunately, walls covered with this type of plaster simply stop “breathing.” One of the disadvantages of mixtures of this variety is that after drying they can accumulate static tension and attract various types of debris.

The best brands of acrylic mixtures

The most popular manufacturers of such plasters in Russia, as well as gypsum plasters, are Osnovit, Vetonit and Knauf. Ceresit brand plasters are also often used to level facades. Such mixtures are usually supplied to the market in ready-made form. There is no need to dilute them with water. It is convenient to work with them, but plasters of this type are also more expensive than gypsum and cement. Therefore, they are usually used only for correcting walls that have only minor defects.

Advantages and disadvantages of silicate mixtures

Leveling walls for painting or any other type of decorative finishing using such material can be done both outside and inside the room. But most often, silicate plaster, like acrylic plaster, is still used for finishing facades. Such materials are made based on silicone resin. They also contain liquid potassium glass, a water-repellent agent and mineral fillers. Like acrylic, silicate plaster is expensive. And they use it, accordingly, only for leveling walls that have minor defects or as a finishing touch after a cement-sand mixture.

The advantages of silicate plasters include primarily:

- elasticity and good adhesive properties;

- high degree of strength;

- resistance to various types of atmospheric influences.

The main disadvantage of such mixtures is their short pot life.

Raw wall leveling technology: main features

Acrylic and silicate plasters, therefore, in most cases are applied to the walls in a thin layer using conventional technology - with a spatula or using a sprayer. Cement and gypsum mixtures are usually applied to the surface in a thick layer. Therefore, when working with them, among other things, special guides are used - beacons. The use of such additions allows you to obtain the most even surfaces. In this case, work is carried out in several stages:

- First, the old plaster layer is removed from the wall (if necessary).

- The surface is primed. Depending on what type of plaster is intended to be used in the future, a gypsum- or cement-based product is used to treat the surface.

- Beacons are installed. To level the walls, a special profile is usually used, which can be purchased at any construction hypermarket. Beacons are attached to the wall using cement or gypsum mortar according to the level. The distance between them should be slightly less than the length of the rule.

- The plaster itself is laid between the beacons. The wall can be treated with the solution either manually or, for example, using a sprayer.

- The mixture is carefully leveled using a rule.

After the composition dries, the beacons are removed from the wall. To level the walls (seal the grooves remaining after the profile), a little more gypsum or cement plaster is added. At the final stage, the surface is treated with a paint float and covered with a thin layer of fine-textured mixture.

Finishing putty: varieties

Compositions of this type can be:

- cement (based on very fine sand or lime);

- plaster;

- silicate;

- acrylic.

For wet rooms and facades, depending on the budget, cement, acrylic or silicate plasters can be chosen. To decorate the inside of rooms, gypsum is usually used. Also, in some cases, cement can, of course, be used for this purpose. Putties of this type are applied over plaster, often using a special reinforcing painting mesh.

Drywall

Plasters are, of course, just an excellent answer to the question of how to level the walls. However, such means, unfortunately, can be used mainly only for removing holes and bumps from the surface. More serious defects in the form of deviations from the plane using a crude technique are quite difficult to correct, and sometimes even impossible. After all, applying plaster compositions to surfaces is only allowed in a not too thick layer.

Some disadvantage of the raw technology is that it can be used to level mainly only concrete or brick walls. For wood, such materials are usually not used.

Therefore, the raw method is not suitable for eliminating serious wall defects, as well as for leveling paving or chopped surfaces. In this case, another correction method is usually used - dry. With this technology, the walls are simply sheathed along the frame with some kind of sheet material. In this case, different types of finishing can be used. But most often plasterboard is used for this purpose.

Actually, the gypsum board sheets themselves for wall correction can be used in two main varieties:

- ordinary;

- moisture resistant.

The second type of gypsum board differs from the first primarily in color. Moisture-resistant sheets have a greenish tint. They are, for example, an excellent answer to the question of how to line the walls in the bathroom. Nowadays, fireproof gypsum plasterboard is also produced by industry. Sheets of this variety can withstand not only very high temperatures, but even open fire (for an hour). Such drywall is very expensive, and therefore it is mainly used only for leveling the surfaces of stoves and fireplaces.

The best brands of drywall

The leading manufacturers of gypsum boards in Russia are:

- Lafarge.

- Rigips.

- Giproc.

All these brands of drywall are of good quality. But Knauf sheets are still the most popular in our country. This company supplies three main types of gypsum boards to the domestic market:

- wall thickness 12.5 mm;

- ceiling - 9.5 mm;

- arched - 6.5 mm.

If desired, today you can purchase both regular sheets from this manufacturer 2500 x 1200 mm, and non-standard ones. The width of the latter can be 600-1500 mm, length - 1500-4000 mm, and thickness - 6.5-24 mm.

Plasterboard finishing technology

No special preparation of walls is required when using gypsum boards. In this case, the surfaces are usually simply cleaned of dirt and dust. Next, a special aluminum or steel profile is mounted on the wall using a level. Actually, the drywall itself is attached to it using dowels of a special design with plastic wide heads. GKL sheets are fixed during installation so that cross-shaped seams do not form between them.

At the final stage, the plasterboard surface can either be covered with wallpaper or treated with a thin layer of plaster. Of course, gypsum board and finishing putty are often used for finishing.

Lining, plywood and plastic panels

Such materials are also usually used when surfaces have large deviations from the horizontal or vertical. In addition, this finish can also be used when the walls need to not only be leveled, but also insulated.

In the latter case, timber is usually used to assemble the frame under the material. It can be mounted on the wall either vertically or horizontally. Actually, for insulation between the beams of the frame, slabs of mineral wool or expanded polystyrene are subsequently installed. Then a vapor barrier film is sewn on top, and the leveling material itself is installed on top of it.

Anton Tsugunov

Reading time: 9 minutes

A major renovation of an apartment is rarely complete without such a procedure as leveling the walls. Even new buildings, not to mention old houses, do not have ideal room geometry. If a couple of decades ago this was not given due attention, today smooth walls are a prerequisite for quality repairs. At first glance, this is a complex operation, but with patience, accuracy and following step-by-step instructions, even a beginner can handle it.

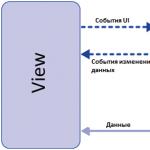

Wall leveling methods

To straighten crooked walls in an apartment, you can choose one of two main methods:

- applying the plaster mixture;

- plasterboard cladding.

Both methods have their advantages and disadvantages.

Pros of plastering

Plaster leveling technology has been used for a long time. Gypsum or cement based mixtures are used.

The main advantage of plastering is the minimal reduction in the volume of the room.

Other important advantages of the method:

- You can plaster walls in any room, regardless of its purpose and internal microclimate.

- The material holds tiles and other finishing coatings well.

- If necessary, partial leveling is applied by applying the solution only to the required location.

Minuses

When choosing a leveling method, you need to keep in mind that the plastering method also has significant disadvantages:

- It is recommended to use plaster mixtures to level walls with minor differences. Otherwise, you will need to apply too large a layer of material, and this is expensive, time-consuming and labor-intensive.

- Plastering work requires specific skills. A beginner will have to develop them during the repair process.

- The applied solution must dry before finishing, which takes at least a week (the time depends on the thickness of the layer).

Note! The entire plastering process is accompanied by the formation of a large amount of dirt and dust. You will have to remove furniture from the room and cover already finished surfaces with film to protect them from contamination.

Advantages of leveling with plasterboard

Due to the inconvenience when working with plaster, today most people prefer to level crooked walls using drywall. Its use has the following advantages:

- It allows you to relatively easily and quickly correct flaws in even a very crooked wall.

- Plasterboard can be used to level walls made of any material: brick, concrete, gas blocks, wood. Plaster does not have sufficient adhesion to all surfaces.

- When using the frame method, it is possible to additionally insulate the walls or improve their sound insulation properties.

Minuses

Disadvantages of using drywall:

- Reducing the internal volume of the room.

- GCR does not tolerate prolonged contact with water. Even moisture-resistant drywall loses its properties over time in such an environment.

- Careful preparation is required before finishing. This includes reinforcing the seams with sickle mesh or paper tape and sealing them with putty, priming, puttying and grouting the plasterboard surface.

It is important to know! If the seams are processed insufficiently and the technology is violated, cracks often appear at the joints of the sheets.

Leveling with plaster

Before leveling the walls yourself, it is advisable to find out the prices for this service from professionals. It is quite possible that the cost of plastering work is not so high and there is no point in bothering with it yourself, risking wasting time without achieving the desired result. In addition, specialists have the opportunity to use a mechanical method of applying the plaster composition, which is practically inaccessible to a single master. By the way, machine plastering will cost 30–40% less than manual plastering. Approximate prices for work in Moscow and St. Petersburg. - at the end of the article.

To avoid unpleasant surprises and get the desired result when contacting professional builders, it is important to draw up a contract correctly. It specifies not only the price, but also GOST tolerances when performing wall leveling work. When drawing up a contract, you can rely on the requirements of SNiP 3.04.01-87.

If you decide to edit the walls yourself, then at the first stage you should assess the scale of the work ahead:

- If the unevenness of the wall does not exceed 5 mm, then it is quite possible to get by with just putty.

- Differences of up to 5 cm can be leveled with either gypsum or cement plaster mixture.

- The layer of cement-based plaster can reach 10 cm when using reinforcing mesh.

The use of gypsum-based plaster is also limited by the microclimate of the room: it cannot be used in rooms with high humidity, such as the bathroom, toilet and even the kitchen.

- If the wall is completely crooked, a very large layer of plaster may be required. In this case, a more economical way would be to use a frame structure made of plasterboard.

It is important to choose a high-quality dry mixture for the job from a well-known leader. The Knauf company has proven itself well in the Russian market. The Rotband gypsum plaster produced by it is ideal for renovation of apartments in terms of price/quality ratio.

Preparing the base

To perform plastering efficiently, the following preparatory work is carried out:

- From the base plane: wallpaper, poorly fixed areas of old plaster, knock down protrusions.

- De-energize and then disassemble the sockets. The wires are hidden in grooves or enclosed in cable channels.

- All elements used to fasten suspended structures are removed from the wall: nails, screws, hooks.

- Deep cracks are widened using a chisel, filled with cement mortar, and then sealed with putty.

- The entire surface of the wall is cleaned of dirt and dust.

Primer

A mandatory operation is carried out to improve the adhesion of the mortar to the wall. It is recommended to use a deep penetration primer with antiseptic properties: it will not only strengthen the base and improve adhesion, but also prevent the appearance of mold or mildew.

Secret from the pros. Works well with quartz sand. However, you need to remember that it is only used under gypsum plaster. It is not suitable for subsequent application of cement mortar, since due to the properties of this material it only worsens adhesion.

The composition is applied in a continuous layer using a roller. It’s better to coat the corner with a brush, it’s more convenient.

The primer is applied in two layers. Between their application, you must take a pause to allow the composition to dry. Its expiration date is indicated by the manufacturer on the packaging.

Displaying beacons

It is recommended to plaster walls using. Their role is most often played by a metal profile with a T-shaped section. You can also use wooden slats. This is the simplest method that does not cause any particular difficulties even for beginners.

The beacons are mounted on the wall by pressing them into scattered “cakes” made of cement or gypsum mortar. Until it sets, level the profiles using a level so that they are in the same plane.

It is important to choose the right distance between the beacons: the rule should move freely in the vertical direction, resting its edges on two adjacent profiles.

For the convenience of leveling the mixture, the outer beacons are not attached to the corners of the room, but retreat from them at least 30 cm.

Having taken the necessary tool, perform the plastering operations step by step:

- The mixture is diluted in a container, following the manufacturer’s recommendations. For mixing, use a construction mixer or a drill with a special attachment.

Plaster, especially gypsum, hardens quite quickly. Therefore, you should not mix a large volume at once: it is difficult to work with a thickened solution, and some of it may simply disappear.

- Using a spatula or trowel, spread the plaster between two beacons so that it protrudes slightly above their surface.

- The most important and time-consuming stage: the rule is to level the plaster from the bottom up, pressing it tightly with your hands to the beacons. At the same time, smooth turns of the tool are made to the right and left, evenly distributing the mixture throughout the entire filled volume.

- If there are small depressions left on the surface, carefully add the solution to them and smooth them out with a spatula.

- So, step by step, all the niches between the beacons are filled with plaster.

- After allowing the solution to set, remove the profiles or slats that serve as beacons. Then the holes from them are leveled and smoothed with a grater.

Some craftsmen prefer to leave beacons in the wall, covering them with a thin layer of mixture on top.

All stages of applying plaster are shown in detail in the training video.

A complete step-by-step guide can be found.

Alignment of walls according to the rule (visual alignment)

Often it is not at all necessary to plaster the entire surface of the wall. It is much more effective to simply level out problem areas in the form of depressions. The advantages of this method are significant savings in time and material.

When leveling “by eye”, special attention is paid to visually significant places. These are corners, doorways, joints of walls and ceilings. The entire rest of the plane is aligned according to the rule: it is pressed against the wall, and with its help the locations of the depressions are determined. After filling them with plaster mortar, the excess is removed as a rule. And so on until the tool is adjacent to the plane without gaps.

As a result, even if the wall has a slight slope, it is almost impossible to notice. All decorative elements, such as baseboards or baguettes, are positioned perfectly evenly.

The visual alignment method is quite complex and, as a rule, is used by experienced builders.

After completing the plastering work, the surface is treated with finishing putty and sanded.

A step-by-step method for leveling with plaster without beacons is described.

How to level the walls in an apartment with plasterboard

Due to its complexity, plaster leveling is increasingly losing its position to gypsum boards. It is used for those surfaces where too much plaster is required or its use is completely impossible. For example, if we are talking about a wooden frame.

Drywall is mounted using frame and frameless methods. Each of them has its own area of application and technology.

Installing drywall using the frame method

It is advisable to install the lathing in case of significant curvature of the walls, and also if it is planned, along with leveling, to insulate the room or increase its sound insulation. Wires are hidden in the space under the plasterboard surface, enclosing them in fireproof corrugations or cable ducts.

The leveling technology is as follows:

- Minimal surface preparation is carried out: wallpaper and poorly adhering parts of the old coating are removed.

- A line is drawn on the ceiling indicating the outer edge of the future wall surface.

- Using a plumb line, it is transferred to the floor.

- The locations of vertical posts and attachment points for direct hangers, which serve to adjust their position, are marked on the surfaces. The racks are placed in increments of 60 cm: this way, each sheet of drywall will be fixed on three racks - two are located at the edges, and the third is in the middle. The suspension mounting step is 60 cm.

- Vertical racks are installed. They are cut 1–2 cm less than the distance between the floor and ceiling, inserted into the guides and fixed with metal screws. Some craftsmen prefer to use a cutter for this purpose.

- Controlling the position of each rack with a level, it is secured to straight hangers with self-tapping screws. The protruding parts of the suspensions are bent to the sides.

- If necessary, horizontal jumpers are installed. They are required in places of horizontal joints of sheathing elements. In addition, jumpers will add rigidity to the frame.

- GCR is cut into pieces of the desired shape and size. Holes for sockets and switches are drilled, and chamfers are made at the joints with a plane at an angle of 45˚.

- The drywall elements are screwed to the frame with self-tapping screws in increments of 25–30 cm. The heads of the screws are slightly recessed into the material.

For this operation, it is very useful, designed for fastening drywall. It will prevent you from turning the screw too deeply and denting the surface of the gypsum board.

Detailed instructions for assembling the frame, installing gypsum boards and pre-finishing are in this.

Fastening gypsum boards with glue

Used if the wall is relatively flat. Installation of drywall is faster and easier than with the frame method, but requires careful preparation of the surface.

The operating procedure is as follows:

- The wall is cleaned of old coating. The cracks expand and are sealed with repair mortar, the protrusions become knocked down.

- A layer of deep penetration primer with antiseptic properties is applied to the entire base surface.

- Drywall sheets are cut.

- The gypsum board is attached with special glue. It is not necessary to lubricate the entire surface with it: just draw stripes around the perimeter and make several “cakes” inside it.

- The fragment is pressed against the wall. After adjusting its position using a level, hold it for about a minute until the adhesive mixture sets.

The most crucial moment is the installation of the first sheathing element: it is along it that all subsequent ones will be aligned.

- This is how drywall fragments are glued sequentially. To reduce the load and prevent sheets from slipping, a rail is screwed from below. It will hold the fragments in place until the glue dries and provides reliable adhesion. After this, the rail is dismantled and the area is covered with a plinth.

Read more about options for attaching gypsum boards with glue for different wall curvatures.

Finishing gypsum plasterboard

Before final finishing, for example, wallpapering, the final preparation of the plasterboard surface is carried out:

- The seams are glued with reinforcing mesh and sealed with putty.

- After it dries, grouting is carried out using fine sandpaper.

- At the final stage, the surface is primed in two layers, applying the second after the first has completely dried.

- Then the entire surface is puttied. This must be done before painting; it is highly desirable for wallpaper; however, putty is not required before gluing tiles or decorative stones.

Leveling prices

To decide whether to do the work yourself or turn to a professional, it’s useful to get acquainted with the prices for leveling from professionals.

Average cost per sq. m.:

- Plaster without beacons – 350 rub. in Moscow, 250–300 rubles. in St. Petersburg.

- Plastering on beacons – 450 rub. in the capital, 420 rubles. in St. Petersburg.

- Plastering beacons using a mechanized method – 250 rubles. in Moscow, 200 in St. Petersburg.

Leveling walls with your own hands is not a simple process, which even a beginner can handle with effort. First you need to decide on the desired result and method of work. There are several ways to level walls with your own hands; in each case there is an optimal option.

Types of alignment

Based on the operating technology and material, a distinction is made between dry and wet leveling. Dry leveling is advisable to use in rooms with large surface errors, in wooden houses. Wet leveling is used for both minor and noticeable deviations. Let's take a closer look at how to properly level walls using each technology.

Dry leveling

Dry leveling, also known as frame leveling, significantly saves costs compared to plastering a falling wall - this is an important advantage.

To begin work, the necessary material is calculated:

- the guide profile is purchased in double the perimeter size;

- rack profile - the quantity is equal to the ratio of the perimeter of the room to the width of the drywall (standard 1 m 20 cm), multiplied by two, plus 4 corners;

- anchor wedges or dowel nails - divide the perimeter by 50 cm and multiply by 2;

- screws for metal - multiply the number of rack profiles by 4;

- GKL - divide the perimeter by 1 m 20 cm;

- self-tapping screws for gypsum board - divide the perimeter of one sheet by 60 cm and multiply by the total number of sheets;

- serpyanka - the number of rack profiles is multiplied by their height;

- deep penetration primer - 150 ml per 1 sq. m.;

- putty for seams - consumption varies depending on the manufacturer;

- putty on gypsum board.

Frame alignment allows you to create the ideal geometry of the room; it is suitable for any type of finishing.

Using a laser level, the frame of the structure is marked, the guide profiles are attached with anchors or dowels along the marked marks on the ceiling and floor.

Rack profiles are cut at the ends, petals are created through which self-tapping screws are screwed. They are inserted into the guides and fastened at a distance of 60 cm from each other.

Sheets of plasterboard are screwed to the finished frame in 0.6 m increments, and the heads of the self-tapping screws are sunk in.

The seams are rubbed with a special putty; it is more elastic. To prevent cracks from appearing, sickle is embedded into the putty.

To finish leveling the surface, putty is used: a mixture is prepared and spread over the entire surface. In order to save processing time and the cost of the finishing layer, it is worth choosing gypsum boards with beveled edges, then the difference in height will be insignificant. You can cut the edges yourself.

In addition to plasterboard, other materials can be used for frame leveling: fiberboard, chipboard, PVC panels, plywood, lining and the more modern OSB board.

Advice! The choice of alignment method depends on personal preferences and financial capabilities. Therefore, before starting repairs, it is worth describing all possible types of finishing, their cost, and then making a decision.

Wet leveling

Leveling walls with a mixture is a more labor-intensive and messy process. But it allows you to save space, and in some cases, finances - with minor deviations, the consumption of mixtures will be less. The alignment method depends on the requirements for the final result.

There are two ways to do the work: by beacons and by rule. Perfect alignment of wall corners is impossible without beacons and corner elements. This labor-intensive process is relevant for the bathroom and kitchen. Here the geometry of the room is very important; when installing furniture of the correct shape, minor errors become noticeable. Leveling recommendations from professionals:

In practice, two methods are often combined: walls with windows and doors are aligned using beacons, and other walls are aligned according to the rule. Also, rooms with external corners require careful alignment according to the beacons.

The choice of mixture for leveling the walls depends on the finishing coating. This could be wallpaper, paint, decorative plaster.

The alignment of walls under wallpaper depends on its type:

- for a light thin coating you need a light base without the slightest error;

- glass wallpaper and vinyl wallpaper with a dense texture can hide minor imperfections in the base;

- Liquid wallpaper, depending on the grain size, requires a perfectly flat surface or allows small flaws.

Leveling walls for painting always requires a perfectly flat surface. Involves several stages of puttying and the use of a high-quality mixture. The choice of polymer putty allows you to prepare the surface for painting in one stage of puttying without sanding and re-plastering.

Coarse-grain decorative plaster does not require puttying of the walls; plastering is sufficient for a smooth base; smoothness does not matter.

Important! Regardless of the number of layers and finishing coat, each stage ends with a primer. It is necessary for better adhesion of layers and saving material.

Difficult cases in alignment

How to level walls in a wooden house? For this case, it is permissible to use both methods of work, but the frame option is preferable. The technology of work is the same as described above.

An important point is the height of the cladding material in a non-settled house; it should be 5-10 cm less than the walls. Leveling with a mixture is a more labor-intensive process: it requires careful treatment of the walls with an adhesive compound, attaching shingles or mesh to hold the plaster. Preliminary cladding for plastering looks like this.

Even in modern new buildings you can find clay walls. This material is characterized by low cost, good hygroscopicity - ideal for use in residential premises. How can you level rare clay walls?

In fact, nothing complicated: leveling occurs by plastering and filling with lighter or more balanced mixtures. Gypsum or clay mixtures are suitable for this.

Aligning the outer corner of a wall with your own hands becomes much easier if you use a special perforated corner. It can be narrower or wider, depending on need. The corner creates perfectly even sides and remains in the plaster. For puttying, it is convenient to use a special corner spatula, which will require a minimum of skill and effort.

Aligning corners in a room of irregular geometric shape with your own hands is a very labor-intensive process. Using drywall will take up more space than plastering, but will go faster. In any case, the corner elements are installed perpendicular to each other. Then, in line with them, beacons are attached to the alabaster wall along the wall. The laser level simplifies the process of aligning beacons and corner elements. The most crucial moment has been completed; all that remains is to fill the space between the beacons with plaster.

Material selection

For high-quality finishing, its speed, and ease of work, material and tools are important. You shouldn't skimp on them.

Mixtures for leveling walls are available in different grain sizes and whiteness. The more expensive the mixture, the less hassle it will be. Particularly convenient are ready-made compositions of plasters and putties, which are ready for application without dilution with water. Such mixtures are characterized by long-term retention of properties even when opened, which is very important for beginners - after all, ordinary solutions dry quickly and are inconvenient to apply. Ready-made formulations are sold in buckets; after use, leftovers can be stored in a bucket until the expiration date.

White putty saves painting costs and is necessary for light-colored wallpaper. Therefore, when choosing, it is worth specifying the color of the mixture if you need to align the walls in the apartment with wallpaper.

High-quality drywall does not crumble or chip - its processing will be much faster. The presence of factory chamfers (image above) on the sheet saves the overall consumption of the finishing mixture and time for finishing. The same applies to profiles - rigid profiles create a strong frame and are not subject to deformation during installation.

Advice! When choosing cheap material, you should not count on quick repairs; such savings will require more patience and skill in work.

It's nice to improve your home yourself, but the wrong approach can spoil the mood. Before starting repairs, you need to soberly assess your strengths and study the necessary information. You can always entrust the work to professionals.

Every owner of an apartment or private house who has decided to undertake a major renovation of their home has many different questions about carrying out certain construction or finishing works. One of the most common: what methods of leveling walls that can be done independently exist, and which one to choose in a particular case.

We have to admit, with regret, that the walls not only in private houses, but also in modern high-rise buildings, are rarely perfectly smooth, and therefore even the most expensive finishing on them will not look properly. Therefore, no matter what decorative coating is planned for the finishing of the premises, it is necessary to put the walls in order, giving them the necessary evenness, in almost any case.

Methods for determining surface roughness

Before choosing an alignment method, you need to determine how much the wall is curved. This can be done in several ways using different tools.

To determine the degree of deformation of surfaces, a long rule, levels of different designs and plumb lines are used.

- The rule, in this case, just like one of the building levels, must have a length of at least 2000÷2500 mm, since it is required that the tool rise vertically to almost the entire height of the wall, and also that it can be easily rotated along diagonals. As a rule, if it is not in the home “arsenal”, a perfectly straight slate can be used. But it should not be too thin, bending when force is applied, otherwise accurate measurements will not be possible. Its size in cross section 20x50 mm will be sufficient.

A batten, level or rule is applied to the wall surface vertically, horizontally and diagonally. They monitor the size of the gaps formed between the wall and the tool, which will show the degree of surface unevenness.

- Another simple and affordable way to check the verticality of a wall that does not require expensive tools is to use a plumb line. Even if the farm does not have such a device, it is easy to quickly make it yourself. To do this, you will need a thin but strong cord about three meters long, as well as a load weighing 150÷200 grams, best of all, a balanced, symmetrical shape.

Using a plumb line is not difficult: to do this, a nail is driven into the wall, under the ceiling, at a distance of 25÷30 mm from the joint, onto which the cord is attached, and the weight tied to it is freely lowered vertically along the wall. The load should hang freely, not reaching the floor by 10÷15 mm. When the load calms down and does not move, you can see how distorted the surface is - measure the gaps at various points in height - and compare the results.

- In addition to the evenness of the walls, it is necessary to check their perpendicularity, that is, the corners of the room must be straight.

A construction square will help in determining this parameter, which is applied in several places along the entire height of the joint and the necessary marks are made. True, the square must be quite large in order to accurately identify possible deviations.

If there is no large square, then it is better to apply the “Egyptian triangle” rule. To do this, two legs are laid from the corner along the walls, multiples of 3 and 4, and the hypotenuse should be a multiple of 5. For example, 1.5 m (0.5 × 3) is measured along one wall, 2 m (0.5 × 4), and the distance between these points in a straight line should be 2.5 m (0.5 × 5). If this is not the case, then the angle is clearly different from the straight one, and it is necessary to look for the cause and a way to eliminate it.

Prices per building level

building level

- Probably the most optimal and accurate option is to use a laser plane builder.

This device sets perpendicular vertical planes, projects lines in space, along which, by simple measurements and comparisons of clearance values, it is easy to identify unevenness of wall surfaces, their correspondence to the vertical plane and mutual perpendicularity.

Having determined the deviations of the walls from the required plane, the location of irregularities - depressions or convexities, their approximate height or depth is immediately assessed.

— In the case where surface defects or deviations from the vertical plane are 8÷15 mm or more, it will have to be done by plastering along beacons or by installing plasterboard sheets.

— If the differences do not exceed 5÷8 mm, then you can correct the surface by applying a thin layer of plaster or putty mortar.

Preparing surfaces for leveling

In order to understand what stages the wall leveling work consists of, it is worth considering these processes in more detail. However, before moving on to a brief description of each of the alignment methods, a few words need to be said about the preparatory activities common to all technologies.

The preparatory stage can be complex and tedious, but you should not ignore it, as this guarantees the quality of the leveled surface and its operational durability. It is necessary to approach the preparation of walls under especially carefully, but drywall also requires its own special approach.

So, preparing walls for further leveling includes several important operations, which include the following:

- The first step is to completely clean the walls from the decorative coating, if there is any on the surfaces - remove the old paint or. These processes are carried out in different ways, which are described in detail in a separate article.

- After the walls are freed from the old finish, the plaster layer will be exposed, which requires the most thorough examination. Such an inspection is necessary, since cracks may have appeared on it during operation, or peeling, partial or complete, cannot be ruled out.

Depending on the extent of damage to the old plaster layer, it will have to be completely removed or proper repairs made. If this layer is thick enough, low-quality material is used for it, and its surface is uneven, then it is better to get rid of it completely.

If the wall has large protrusions, they will have to be knocked down, and small protrusions will have to be sanded or cleaned off with a wire brush.

- If “wet” work is expected on the wall, then to ensure electrical safety the room will most likely have to be de-energized. Usually in such cases it is planned to replace sockets and switches, which means that the old ones must be dismantled and then the exposed wires must be insulated.

- Having cleaned or repaired the wall surface, it needs to be primed several times - this is to strengthen and remove dust from the surface and to create conditions for reliable adhesion between the surface and the new leveling solution.

Careful preparation of walls is the key to the quality and durability of future finishing

This seemingly simple to understand, but labor-intensive stage has many nuances. A special publication on our portal tells more about all operations.

- After the primer has completely dried, you can proceed to applying putty, plaster, or installing special beacon profiles, along which the surfaces will be leveled.

- If you plan to level wooden walls with plaster, then they are cleaned of dust and primed with an antiseptic wood primer. After this, the dried walls are sheathed with wooden slats - shingles, which will create good adhesion between the mortar and wood.

Methods for leveling surfaces

The choice of method for leveling the walls directly depends on their condition, that is, whether they have significant curvatures, or whether it is simply necessary to eliminate a slight surface relief that can appear through layers of paint or pasted wallpaper.

In fact, there are not many technological techniques for leveling walls. They have been used for decades, but with the advent of new building materials, they are constantly being improved.

Plaster prices

plaster

So, leveling the walls is carried out in the following ways:

- Plastering, that is, applying a leveling layer of a special mortar to the surface. In turn, this method can be divided into two types - leveling the walls using beacons and without using them.

- Installation of plasterboard sheets that determine the desired evenness of the wall surface (often also called “dry plaster”). This leveling option is also divided into two different approaches - fixing sheets to a frame, or frameless fastening of gypsum fiber boards directly to the wall.

- Leveling walls with putty This method of putting the surface in order is used in combination with the other two mentioned above, or independently. If the walls have a smooth surface without major geometric distortions, but there are small unevennesses on it, then putty will help bring them to ideal smoothness.

Plastering walls

A few words about leveling solutions

Currently, construction stores offer a very wide range of ready-made building mixtures intended for plastering work. They can be on different bases

- Cement-based plasters are used for exterior work, as well as for rooms with high humidity levels

- Gypsum mixtures are suitable for walls made of almost any material, but their scope is limited only to interior decoration.

However, many craftsmen and homeowners prefer to prepare plaster solutions themselves. And the basis for this, in addition to cement or gypsum, can also be lime or clay.

Lime and cement-lime mortars have proven themselves well for external and internal finishing, and clay-based plasters are generally inexpensive (if free raw materials are available) and are suitable for leveling wooden, clay or brick walls.

If you want to try your hand at plastering walls with a homemade solution, then the “recipe” for the preparation can be found in the table below:

| Name of solution | Components | Proportions of solutions, depending on the specific layer | ||

|---|---|---|---|---|

| "spray" | "priming" | Covering or “washing” | ||

| Cement | Cement: sand | 1: (2.5÷4) | 1: (2÷3) | 1: (1÷2) |

| Lime | Lime paste: sand | 1: (2.5÷4) | 1: (2÷3) | 1: (1÷1.5) |

| Clay | Clay: sand | 1: (3÷5) | 1: (3÷5) | 1: (3÷5) |

| Cement-clay | Cement: clay: sand | 1:4:12 | 1:4:12 | 1:4:12 |

| Cement-lime | Cement: lime paste: sand | 1: (0.3÷1):(3÷5) | 1: (0.7÷1):(2.5÷4.5) | 1: (1÷1.5):(1.5÷2) |

| Lime-clay | Lime paste: clay: sand | 0.2÷1:(3÷5) | 0.2÷1:(3÷5) | 0.2÷1:(3÷5) |

| Lime-gypsum | Lime paste: gypsum: sand | 1:(0.3÷1):(2÷3) | 1:(0.5÷1.5):(1.5÷2) | 1:(1÷1.5) |

Plastering walls without installing beacons

Leveling walls with plaster mortar without beacons is possible in cases where the wall is relatively flat, without serious deformations, depressions and depressions, and to put it in order it will be enough to apply a leveling mixture of relatively small thickness. It must be said right away that this method of tidying up the surface is much more difficult than plastering using beacons, since leveling has to be done by eye, and this is not at all easy to do without proper skill. Therefore, if there is no experience in this work, then it is better to entrust it to professional craftsmen.

The process of plastering walls without beacons can be divided into several stages - these are “spraying”, “soil” and “washing”.

- "Spray"- this is the first layer of mortar applied to the wall when leveling it. The mixture for this stage should have the consistency of thick sour cream.

When applying the mortar to a brick or stone wall, its layer should be 10÷12 mm, on a shingled wooden surface 15÷18 mm.

“Spraying” is carried out with a trowel, onto which the solution is scooped up and, with a little effort, applied to the surface. If the surface of the wall is relatively flat and does not require the application of a thick layer of plaster, then sometimes craftsmen “spray” it even with a wide brush. When applying the solution with a brush, you should not make a large sweep with your hand, otherwise, part of the mixture will be splashed around the room.

You can apply the first layer of plaster using the “spreading” method. In this case, you will need a spatula 200÷250 mm wide, with which the solution is taken from the container and evenly distributed over the surface of the wall in strokes. Perfect alignment of this layer is not required, as it will become the basis for further work.

- "Priming"- this is the second layer when plastering walls without beacons, and it is applied only after the “spray” has completely dried. To apply the “soil”, a thicker solution is used - it is thrown onto the surface, starting from the bottom of the wall, filling in the areas not covered by the first layer, thus bringing both layers to approximately the same thickness.

Having applied this solution to a section of the wall 350÷400 mm high, it is leveled using a rule, collecting excess mixture, which is sent back to the container, since it can still be used in further work.

When leveling, unfilled areas may additionally appear, which must be immediately filled with solution and then the rule must be passed over this area.

Sometimes, instead of the rule, a special tool is used to level this layer - a grater.

A trowel is also used to level the solution, simultaneously collecting its excess and filling the identified voids.

- The “wash” or top layer of plaster consists of a liquid solution and is intended to eliminate all the flaws remaining on the surface of the wall after applying the “primer”. The thickness of this layer should be no more than two millimeters, so it is very important to maintain the correct consistency of the plaster solution.

In this regard, if the mixture is prepared independently and not purchased ready-made, all materials used in it must be sifted through a sieve with cells no larger than 0.5 ÷ 1 mm. The solution is kneaded until smooth, as there should not be even small lumps left in it.

Prices per rule

Next, the surface of the wall is moistened with water and a thin layer of liquid solution is applied to it using a spatula and a trowel. Then, the wet solution is rubbed in with circular movements, which are made counterclockwise. Therefore, this stage of work is often called surface grouting.

When choosing this method of leveling the wall, during each stage of work it is necessary to control the verticality and required evenness of the surface using a rule and a level.

Leveling walls with plaster according to beacons

Leveling walls with plaster mortar using beacons is a more popular method than without installing them, since these elements greatly simplify the work and result in a perfectly flat surface. However, in order for the work to be successful, there is no need to rush when performing them, especially if the process is being performed by a master for the first time.

Leveling Beacon System

As beacons for leveling surfaces, special perforated metal profiles are most often used, having a protrusion, the height of which can vary depending on the required thickness of the plaster layer.

The beacons are installed vertically on the wall surface, at a distance from each other, ensuring convenient operation with the rule of the available length (approximately 200÷300 mm less than the length of the rule). For beginners, an installation step of no more than 1000÷1200 mm is usually optimal. Fastening of profiles is most often done on slides of quick-drying mortar laid out along the line.

Sometimes improvised devices are used to set up beacons, for example, pieces of plywood, drywall or ceramic tiles, which are also glued to the solution along pre-marked marks and a plumb line.

However, leveling across entire profiles is much easier, since they are fixed vertically from floor to ceiling and do not allow deviation from the intended level.

The conclusion suggests itself that the most important thing in the process of aligning walls with beacons is their correct alignment, which is done in compliance with certain rules.

Basic techniques for setting up a beacon system

Installing leveling beacons is not as simple as it seems at first glance, since there are some nuances that must be constantly remembered. A professional view of the technology of this stage is presented in an article on our portal.

If we talk about the accessible method of placing beacons in a few words, very simplified, then this process is carried out as follows:

- The first step is to set up the outer profile elements, that is, those located closer to the corners of the room.

- Then, between them horizontally, in three or four places, cords are stretched, which will serve as a guide for the installation of intermediate beacons.

- The required level of the beacons relative to the wall can be achieved by recessing the profiles into the mounds of mortar on which they are fixed.

There are several interesting, accurate and at the same time accessible technologies for placing beacons. This is discussed in detail in other publications on our portal.

The process of plastering walls

Work is usually carried out in sections with a height of 450÷500 mm. Experienced craftsmen can afford large areas, but it is better for a novice plasterer not to rush into this - there will be an opportunity to identify and correct mistakes.

- A solution of medium density, with a height that should exceed the level of the beacons by 15÷20 mm, is applied to a certain section of the wall using the “spray” method (or application and distribution with a spatula, if spraying has not yet worked out). This thickness is necessary so that when the mixture is leveled as a rule, as few voids as possible remain on the applied layer.

- Next, the applied solution, starting from the bottom of the coated section of the wall, is leveled with a rule, which is rested with an edge against the metal beacons and driven along them, as if on rails. In this case, excess solution is usually collected, which is regularly removed with a spatula, sent back to the container and used for the next spray. When leveling, the rule is mixed progressively upward, but at the same time slightly moved horizontally in one direction or the other, which helps fill all the voids in the layer and make the most of the entire applied solution.

- Most often, several such passes will usually have to be made, with the identified cavities being filled using a trowel or spatula. The result should be a flat surface, flush with the guides of the beacon system.

- After plastering the wall, when the mortar has set slightly, the beacon profiles are carefully removed from the thickness of the plaster. The remaining grooves are sealed with mortar and leveled over the common surface.

- Next, the still wet surface of the plaster is rubbed with a special construction float. The work is done in a counterclockwise circular motion.

- To refine the internal and external corners of the wall, a special corner spatula is used.

- External corners, especially in cases where a thick leveling layer is applied, are recommended to be reinforced with metal perforated corners, which are pressed into the wet mortar and adjusted to the building level.

Let's learn to align walls using beacons!

On the pages of our portal there is a detailed publication dedicated to. In it, special emphasis is placed on the creation of beacon systems of various types - from ordinary profile to mortar and string.

Leveling walls with plasterboard (dry plaster)

Since drywall became available for free sale, and at a price accessible to everyone, it has become the most popular material used to level walls. The fact is that any homeowner is quite capable of working with sheets of this “dry plaster” without resorting to the help of a construction team. Moreover, there are two ways to fix it to the surface - with construction glue and with frame sheathing. Therefore, you can choose the option that is more suitable for a specific room and for ease of installation.

Installation of drywall without frame

So, you can level the wall with plasterboard by fixing its sheets with glue made on a gypsum base. Moreover, using this method, even a strongly curved surface can be made smooth. However, if the wall is severely deformed, you will have to seriously work on it, since you will need to create unique beacons against which the sheet of finishing material will rest. The frame for the support points can be self-tapping screws with wide heads or slate nails, which are driven into the wall with the ends of the heads brought out into a single plane, which can be aligned in any available way. The adhesive composition is applied to these beacons in slides, and then a plasterboard sheet is carefully pressed to these points.

1 – old wall surface to be leveled;

2 – screwed-in self-tapping screws, the ends of the heads of which are aligned in the same vertical plane. The pitch between the screws is 200÷300 mm;

3 – slides of gypsum-based construction adhesive;

4 – sheet of drywall.

It is much easier to install drywall on a more or less flat wall by preparing it with a primer. To do this, the adhesive mass is applied pointwise in slides to the sheet itself or to the surface of the wall.

Next, the drywall is lifted and pressed against a vertical surface, and then, if necessary, its verticality is adjusted by gentle tapping. In order not to damage the sheet, the adjustment can be carried out with the edge of the rule, which immediately covers the entire width of the sheet.

When fixing the sheet to the wall, the correctness of its position must be checked with a building level. The second and all subsequent sheets are adjusted to the first finishing sheet fixed on the wall. After the glue has dried, the seams between the drywall are sealed with a sickle mesh or special tape, and then filled with putty.

Quickly and reliably - plasterboard on the wall without creating a frame

The main steps of this method were listed above, however, this installation technology still contains some nuances, which are also good to know about when getting started. Therefore, it is recommended to pay attention to the article on our portal.

Frame method of installing drywall

The frame method of leveling walls has its advantages and disadvantages, and at the same time is even more popular than fixing sheets with glue.

The disadvantage of this technology is that the frame system significantly reduces the area of the room, since the sheathing itself, and plus a sheet of plasterboard, make up a total thickness of at least 50 mm, that is, the room will be reduced on each side by this distance.

There are many more advantages to such leveling, therefore, if space allows, then this method will be an ideal option for transforming a room.

An obvious “advantage” of this installation is the ability to insulate and soundproof the wall by installing a layer of appropriate material in the space between it and the cladding. This is especially true for apartments located in panel buildings.

Another positive aspect is that the frame system does not require “super-thorough” preparation of the walls.

- They need to be cleaned of the decorative coating just to make sure that there are no deep cracks in the wall. Small surface defects will not interfere with installation work.

- It is necessary to prime the walls before fixing the profiles, and for this purpose an antiseptic solution is used, which will protect the surfaces from the appearance and development of mold.

After the primed surface has completely dried, you can begin marking and installation work.

Profiles are usually installed in increments of 600 mm (along the axes), since the width of all plasterboard sheets is 1200 mm. Thus, each vertically installed sheet will be fixed along three lines. In addition, this is convenient from the point of view that the overwhelming majority of insulation materials are produced in mats of exactly this width - 600 mm.

To achieve ideal evenness of the walls, it is necessary to carefully align the metal profiles vertically, thereby setting the future plane of the surface being created.

Since the profiles are fixed in special brackets - straight hangers, with perforated side “wings”, it is possible to accurately adjust their distance from the wall. The hangers are fixed along the line using dowels or self-tapping screws (depending on the wall material) in increments of 500÷600 mm.

The protruding ends of the side shelves, after fixing the racks in them, easily bend back, so they will not interfere with the further fixation of the drywall sheets.

To make it easier to cope with the alignment of the frame, first the outer posts are accurately aligned vertically and relative to each other and secured. Then cords are stretched between them, which will indicate how far the intermediate profiles should be extended from the wall.

If the ceilings in the room are high enough, then horizontal crossbars are sometimes mounted between the vertical posts, which will give the system additional rigidity and strength.

The sheets are secured to the frame using special black self-tapping screws TN25 (3.2×25 mm), the heads of which must be recessed into the plasterboard by 1÷1.5 mm. In the future, these remaining holes from the caps will need to be puttied.

It should be noted that sometimes plasterboard sheets are mounted in two layers - in this case, the created wall covering will have higher strength. The sheets of the outer layer must overlap the joints of the sheets of the lower one.

After the wall is leveled with the plasterboard system, they proceed to sealing the joints, and after the solution has dried, the wall is primed and puttied. The putty layer should completely hide the joints. The final stage of work is the application of a decorative coating - paint or wallpaper.

Universal material - drywall

Modern finishing work in houses and apartments is difficult to imagine without the use of plasterboard. – this is far from the only way to use it. For example, this material allows you to quickly and efficiently build indoors.

Leveling walls with putty

Bringing the surface of the walls to perfection with putty can be called the final stage for any chosen method of leveling them during interior decoration. In addition, putty, as the only leveling layer, is used if the wall itself is already quite smooth, but has small errors in the form of small depressions or minor roughness, which can appear through decorative finishing - wallpaper or painting.

The putty has a finer mixture structure, and when mixed, it acquires high plasticity, is easily applied and distributed on a prepared, primed surface, masking flaws and making the wall perfectly smooth.

This leveling layer is applied using spatulas (trowels) of various widths, but in large areas a wide spatula is always used, with a working surface of 400 millimeters or more.

Puttying walls is a rather complex process that requires some experience, since you need to achieve smoothness of the walls, and a spatula in inept hands with its edges almost always leaves grooves of varying depths on the surface of the raw plastic mortar, and this must be avoided. If they have formed, they must be leveled immediately, since after the putty mixture has set, this will be difficult to do.

As a rule, two (or even more) layers are applied - one leveling, and the second, finishing, bringing the surface to perfection. Accordingly, different types of putties can be used for different stages.

The final stage of putty work is always grinding the surface to the desired degree of smoothness. This final stage of leveling the walls is carried out using a special grater, onto which mesh attachments or sandpaper of the required grain size are installed. There are also special electric tools - grinding machines of various operating principles, which can speed up this rather labor-intensive process.

Many craftsmen, in order to achieve an ideal result, use portable lighting when performing sanding work, which perfectly reveals poorly leveled areas of the wall, down to the smallest surface defects.

How to learn how to putty walls correctly?

This technological operation is quite complex, and the first results may not be encouraging. It’s okay, the skill will develop, the main thing is to listen to the advice of experienced finishers. A good selection of such recommendations, with step-by-step illustrated instructions, is posted in the article on our portal about.

So, based on everything said above, we can conclude that even if you have no experience in leveling walls, it is possible to choose a method that will be within the capabilities of even a novice builder. By taking on these works, you can not only save a decent amount, but also be confident in their quality - after all, it is done, as they say, “for yourself.” Therefore, when starting an apartment renovation, you need to carefully weigh your financial and creative capabilities, and boldly get down to business.

At the end of the publication there is a short video sketch, which should also help the reader in choosing a method for leveling the walls.

Video: Which method of wall leveling should I choose?

A beautiful apartment with high-quality renovation, tastefully selected modern furniture and a comfortable interior is the dream of any person. But all this splendor fades in rooms with uneven walls. Very often people try to hide a small blockage and cover it with furniture or resort to other tricks. In vain, since uneven walls need to be leveled, not masked. For example, furniture only emphasizes such a drawback. Therefore, in this article we will talk about how to level the walls and achieve the desired result.

The reasons for uneven walls can be different. Ceilings and walls in old houses often leave much to be desired, but in many new buildings they are also not ideal. Most panel houses have crooked walls due to the fact that the panels are slightly uneven. But only not to such an extent that the house cannot be put into operation - this aspect does not affect its reliability in any way. During the installation itself, the stove could turn around a little. For a more visual representation of the situation, you need to find a landscape sheet of paper and put it on the table. The sheet is even, but if you take it by the ends diagonally, and then pull one end up and the other down, you can see an interesting picture. What happens to the leaf? A concrete slab can bend using the same principle. This deviation is insignificant, but it is enough to block the walls and violate the geometry of the corners in the room.

Determination of vertical deviations

It is quite possible to level the walls with your own hands, but first you need to determine where there is a blockage. To do this, you should pay attention to the corners, if there is an assumption that some wall is uneven, then you need to check the correctness of your thoughts. This is done in an elementary way: a heavy object is tied to one end of a thin but strong rope, and the opposite end must be attached to the corner of the junction of the upper ceiling and the wall. Well, are the line of the wall and the rope parallel? This means that the walls are even, and if deviations are observed, that is, there is a blockage and it needs to be eliminated.

Important: it is advisable to carry out this check together - one person holds the cord, and the second, from a distance of several meters, assesses the parallelism of the lines.

There is another option for assessing the condition of surfaces. For this process you will also need a homemade plumb line with a weight that does not rotate. In each corner you need to perform the so-called hanging. To do this, the plumb line is attached to a nail driven into the wall.

Important: the nail is driven near the ceiling, so that the plumb line is located near the wall, but does not touch its surface.

A similar operation must be carried out on the other edge of the wall. The next step is to pull the cords along the four beacon points; as a result, you can get an accurate picture of the condition of the wall surface.

Determining the verticality of walls

If there is a slight deviation of 10 mm during repairs, it will be necessary to carry out putty work using gypsum and cement mixtures for leveling. And with more significant vertical deviations, you will need to resort to leveling the walls with plasterboard.

Start - surface preparation

How to properly align the walls, that is, what order should you follow? First, the surface is prepared: a solid base and the absence of crumbling areas are important. It is also necessary to remove the remnants of old wallpaper and dilapidated plaster. Next, the prepared wall is carefully primed with a roller, brush or spray. The primed base should dry for about 12 hours, so this work is best done closer to night, so as not to waste time waiting.

Ways to level walls

Depending on the materials used, there are 2 ways to level the curvature of the walls. The first is wet (using building mixtures) and the second is dry (installation of structures). Both methods are good, but only if all processes are strictly followed. And each has its own characteristics, advantages and disadvantages. Basically, leveling with plaster is used for small differences (30-50 mm). Of course, it is also possible to use them for surfaces with greater curvature. But these are additional financial costs for both work and materials. Therefore, the best option in such cases is to install a frame and cover it with plasterboard.

Leveling with plaster using beacons

So, if the unevenness has already been identified and the surface of the walls is prepared, you can proceed to direct leveling.

Important: do not forget about electricity - you should turn it off first. And when cleaning the walls, act carefully so as not to damage the electrical wiring elements that are hidden in the wall.

To firmly fix the plaster, the walls must be primed. This process prevents extremely undesirable delamination of materials and also increases moisture resistance. For cement mixtures, cement laitance is used, consisting of cement, water and sand.

Installation of beacons before “wet” leveling with plaster

When leveling with wet plaster, it is best to use the “beacon” technology. This is a special metal element made of flexible aluminum. The lighthouse is embedded in a curved wall, and it is along it that subsequent alignment takes place. For greater clarity, we can give the following example: if the wall is blocked at the top, then you can understand that the lighthouse must be rested against the wall from below, and some material, for example, a rotbow, will be placed on top between the wall and the lighthouse - this will eliminate the unevenness.

Beacon installation process

The installation of beacon slats begins with the installation of profiles on opposite walls. The verticality of each lighthouse is checked with a plumb line, and such profiles are mounted on the wall with building plaster. Plaster is applied to the rail at several points while maintaining a distance of 50 cm. Then a cord is pulled through the lower, middle and upper profiles. The following slats are also mounted on the wall, but so that the cord barely touches them.

Important: the distance between the beacons is selected based on the size of the tool that will be used to apply the plaster.

It is also possible to attach the beacons with self-tapping screws. This slows down the work a little, but then makes it much easier. Even a non-professional can easily adjust the verticality of the lines by tightening or unscrewing the screws.

What is the best way to level a wall?

The leveling composition depends on the maximum thickness of the leveling layer, as well as on the type of binding component - cement or gypsum. The cement mixture is most suitable for wet rooms (bathroom, kitchen), and the gypsum composition is preferably used in living rooms, because it perfectly maintains the microclimate of the room.

Leveling "wet"

When the display of beacons is completed, little remains to be done. Now you need to dilute 10-15 liters of plaster and apply it between the beacons. The mixture should have a certain consistency, it should not be too liquid (it will slide) and too thick (it will be difficult to apply). If gypsum compositions are used in the work, then their quantity should be such that the mixture is produced within an hour.

After applying the mixture, take the rule of the required length and press it against the beacons, and then level the surface with movements from bottom to top, or vice versa, whichever is more convenient for you. If in some places there is not enough mixture, then you need to add it and apply the rule again. These steps are repeated until the wall becomes perfectly flat.

When the applied layer of plaster dries, you will notice the roughness of the wall. For this reason, it is necessary to treat it with finishing putty and sanding with fine sandpaper.

The advantages of this leveling method are that the usable area of the room is not taken away, but the disadvantages are that preliminary cleaning of the walls is necessary and this is a rather labor-intensive process, after which a lot of debris and dust remains.

Plaster square - a device for forming ideal angles

A separate point in the alignment process is the corners. How to align the corners of the walls, since these are the most problematic areas? In this work, it is advisable to use an angle trowel, a level and other auxiliary tools. Aligning corners is a painstaking task and requires experience and knowledge. To make the solution set faster in the corners, you need to add a small amount of gypsum to the mixture.

How to eliminate significant irregularities?

How to level the walls in an apartment with large differences and terrible curvature of the walls? In this case, it is rational to resort to installing specific structures and then covering them with plasterboard. This method has the main disadvantage of “eating up” the usable area, but it is also characterized by positive aspects: there is no need for preliminary work, and communications can be hidden inside the constructed frame and sound- and heat-insulating materials can be laid.

This method has the right to life. First, the frame is mounted, which is subsequently covered with plasterboard. It is possible to level the blockage, but still the blockage does not disappear anywhere, but simply hides under the casing. If the apartment is small, then such machinations will make the living space even smaller.

Preparing the walls for wallpaper

If repairs have begun in the apartment, then the question will surely arise, how to align the walls under the wallpaper? Wallpaper and other decorative coverings require a smooth surface to be prepared.

If the unevenness is minor, you can safely treat the wall with regular putty. For this purpose, you need to use a spatula, which is designed for opening cracks and then puttingtying them. The most convenient option is to use two medium-sized spatulas.

Perfectly smooth walls - a beautiful room

For a large amount of work, you can dilute the putty in a basin so as not to constantly jump up and down. And for small holes and crevices, a small vessel is used.

Important: if the volumes are large, then it is better to dilute the mixture using a drill with a special attachment.

And if the layer is thick, then the surface must first be treated with starting putty. With the right technology, the putty is applied in several stages, but only when the previous layer has dried. Usually three layers are used, the last one is finishing putty to finish the job. Then the entire surface is cleaned with sandpaper.

The bathroom is no exception to the rule.

The most common reason for leveling bathroom walls is the type of future finish. If it is a tile, then you need to know how to align the walls under the tile. It should be noted that working with tiles is a responsible and serious process that requires a competent approach, and uneven walls are no exception. This means that before starting the main process, you need to think about how to level the walls in the bathroom, adhering to technology.

Laying ceramic tiles is only possible on flat walls, since if this issue is ignored, the result can be disastrous: the masonry will stick out with bumps and the appearance of the room will be spoiled. The most common alignment method is the same beacons.

Alignment beacon installation diagram