Device of a blast freezing chamber. Refrigerator cabinet - storing vegetables at home Technical characteristics of Electrolux refrigeration equipment

The process of intensive cooling of various types of products for long-term storage is called. Chambers with this freezing method are widely used in household refrigerators. What are they? Read this article about what types of blast freezing refrigerators there are.

How it all began

For quite a long period of time, food was stored in simple refrigerators and village cellars. A man dreamed of a food paradise. It has become possible since blast freezing refrigerators appeared. Its author is the American natural scientist Clarence Birdseye. The discovery took place at the beginning of the last century. The scientist noticed how the inhabitants of Labrador store fish. The island's fishermen laid out their catch on the ice. The fish was frozen in a matter of minutes. This was facilitated by the Arctic wind. When the scientist tried a dish of fish frozen on ice, he was pleasantly surprised. It turned out that it quickly retained its taste, aroma and beneficial properties.

Since that time, scientists began to actively work on creating installations for freezing food. They have proven that the quick freezing method is the most effective for preserving food while preserving vitamins, essential oils, perishable proteins and other beneficial properties.

Traditional cooling technology

Low-temperature refrigeration chambers, with which the Russian user is familiar, at temperatures from 18 to 24 degrees below zero. This requires at least two and a half hours. Depending on the temperature inside the product, three ranges are distinguished.

The task of the first stage is to cool the product, the second is to transform the liquid into a solid state. Rapid heat transfer occurs with a slight decrease in temperature. The product begins to freeze, that is, 70% of the liquid crystallizes. At the last stage, it freezes. The temperature decreases in proportion to the work done by the refrigerator.

Blast freezing

In this process, a key role is played by the speed of freezing, that is, reducing the temperature environment to 30-30 degrees below zero at a rapid pace. This is ensured due to the accelerated movement of the coolant, the role of which is played by air. Its movement occurs due to the ventilation of the evaporator. The product is thus exposed to a very strong flow of cold air. The freezing process is carried out in three stages:

- First, the product is cooled to three degrees Celsius or to zero. Crystallization of moisture occurs on the surface of the product. Moreover, the cooling rate is such that many harmful bacteria do not have time to develop.

- Freezing is the process of transition of a product from the liquid phase to the solid phase. It occurs when the temperature drops to five degrees. Speed is also important, as the fluid inside the cells quickly turns to ice, creating small crystals that prevent the tissue structure from breaking down.

- Freezing occurs when the temperature quickly drops to a thermometer mark of 18 degrees below zero. The structure of the product is fixed and it is stored for a long time.

What foods can be frozen?

With chambers for blast freezing, it prepares products for long-term storage. At the same time, their quality is not lost. Fish, minced meat, meat, fruits, vegetables, mushrooms and much more can be frozen.

The equipment allows you to cool finished products: first and second courses, side dishes, vinaigrettes and salads, bread, desserts, pastries. After several hours of freezing, it can be successfully transferred to a simple freezer, and, if necessary, transported to any place.

What are the benefits of blast freezing units?

This type of freezing technology has its advantages. Using the method of forcing three modes - cooling, freezing and pre-freezing, blast freezing refrigerators preserve the tissue structure of the product and reduce the activity of the environment in which bacteria, different types of which live in different temperature zones, can develop.

Sagi refrigeration devices

This Italian-made equipment, the development of which began in the 80s of the last century, has received recognition throughout the world. It has become indispensable in food industry enterprises and catering establishments. The Sagi blast freezer has high performance and low energy consumption.

All production processes are controlled by a computer system. It determines the “smart” properties of the product. The technology does not allow surface freezing; the temperature is evenly distributed over all points of the product. The blast freezing system is suitable for semi-finished products and various dishes. There is a convenient control panel to configure it.

Sagi freezers come in different models. Some have 5 levels of containers for loading products, others - 10. For 5-level chambers, the body and internal space are made of stainless steel. The legs can be adjusted in height. The freezer is easy to clean, as its corners are rounded and there is a hole through which condensation drains.

The panel protecting the fan opens. The door has a device to automatically stop the system when it is opened, which does not waste energy. In addition, the chamber has thick walls, up to 70 mm. They are protected by polyurethane foam. This allows you to save electricity. A household or industrial blast freezing refrigerator operates stably at ambient temperatures up to 32 degrees.

Electrolux refrigerator

The chamber is designed to quickly cool and freeze food. The Italian-made Electrolux blast freezer refrigerator has various models, one of which is RBF201. The chamber houses 12 gastronomic containers. Water is removed using drainage or poured into a container. In this refrigerator model, the evaporator has anti-corrosion protection. All corners of the design are rounded, making it easy to clean.

Technical characteristics of Electrolux refrigeration equipment

The chamber is capable of cooling 64 kilograms of food from 90 to 3 degrees above zero. It only takes 90 minutes. In this chamber you can freeze 56 kilograms of food up to 18 degrees cold in 240 minutes. There are cooling modes here, there are three in total. With the help of soft cooling, the air temperature is reduced to minus two degrees, strong - to 12 below zero and shock freezing - 35 cold.

In addition, the camera is equipped with a storage mode function. It turns on automatically immediately after the product has been frozen to 18 degrees below zero. Blast freezing refrigerators are equipped with a temperature probe that automatically determines the appropriate mode. Using this installation, you can set the cooling temperature and time yourself. Operation of the equipment is possible in an environment with an air temperature of 32 degrees Celsius.

Cooling and storage of products is carried out using effective ventilation. The walls are protected by thermal insulation made of polyurethane foam. The blast freezer is equipped with an air cooling system. The characteristics of the device allow it to be placed above the camera itself. Stainless steel is used to finish the body and interior of the cabinet. Tightness when closing the door is achieved through a magnetic insert.

The refrigeration device has a height of 2.3 m, a width of 80 and a depth of 83 and a half cm. The weight of the refrigerator is 235 kilograms. The thickness of the walls reaches 60 mm.

Usage

Blast freezing refrigerators are very popular today. For the home, this type of household appliance is indispensable. But, having decided to buy, you should know that in addition to the refrigerator, you will also need a combi oven. With its help, frozen foods are heated. Moreover, their original appearance does not change. Instead of this unit, you can use a microwave oven. To store frozen foods, the following conditions must be observed:

- Repeated freezing of the same product is not allowed.

- The freezer should be defrosted every month.

The blast freezer is a household appliance for constant use. Its purpose is to cool food in a short period of time while maintaining hygiene, economy and quality.

Blast freezing refrigerators are widely used in industrial production. Their need is due to the preservation of semi-finished products, which are produced in large volumes. These units are used in the kitchens of sanatoriums, hotels, large and chain restaurants. No exception are establishments where the throughput is not very large. For any enterprise, it is important that freezing equipment not only works, but also makes a profit. This is achieved through cost-effectiveness when using blast freezers.

Blast freezers will help preserve fresh food for a long time. Vegetables, berries, and herbs are placed in the cold from summer to winter. Scientists have noticed that if sharp cooling is carried out, then after thawing the products taste fresh.

Positive aspects of the storage method

Blast freezing devices are widely used due to the preservation of important properties of products after thawing. Other methods do not provide optimal product quality. The taste and smell change. Structural changes often occur.

Blast freezing devices also preserve:

- appearance;

- physical qualities: elasticity, cell integrity;

- and, most importantly, all the vitamins and beneficial microelements.

In terms of quality of food preservation, instant freezing ranks higher than other methods. In comparison, common canning changes the appearance and many vitamins are lost. And with prolonged cooling, structural changes often cannot be avoided.

Using a blast freezer, it is impossible to maintain the original freshness of food. But this method provides the most harmless storage known to date. Many manufacturers often use it to move vegetables, meat, and berries over long distances without losing their quality.

Cooling principle

The blast freezer is often used to preserve summer vegetables. Everyone loves to eat them in late autumn, winter and early spring. This device is installed in the sales areas of catering establishments and restaurants.

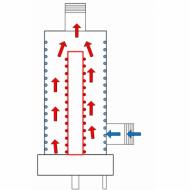

The blast freezing chamber has a powerful cold emitter and fans. As the name suggests, the process takes no more than a few minutes. Due to this, more than 90% of the beneficial properties of the products are preserved.

When slowly cooled, the water molecules of vegetables, berries and other fresh foods are transformed into large crystals that practically break the microstructures. This does not happen with blast freezing. The particles freeze in small forms and melt without changing the composition of the cells.

Models of devices on sale

Most often, equipment for blast freezing is professional. Manufacturers offer volumetric chambers from 80 kg and above. In domestic conditions such capacity is not required. After all, this is comparable to the volume of the entire refrigerator. Whereas it takes up a third and rarely half of the used space.

Equipment is divided according to the principle of operation:

- tunnel - products move along a conveyor system;

- standard - in the form of an ordinary closed chamber.

Within 15 minutes, vegetables and fruits are frozen at a temperature of minus 40 degrees. This method has been used since ancient times by the Eskimos. True, for them this is the only method of storing meat and fish.

Now blast freezing is used by fast food manufacturers. Chilled products are heated for 3 minutes, they look perfect and taste the same as fresh ones. This technique has been successfully used since 1925 by manufacturers around the world to produce frozen food products.

Optional equipment

The standard version includes a chamber where freezing directly occurs. Additionally, ultraviolet emitters for disinfection are built into the equipment. Some models may be equipped with a stainless steel baking tray.

The control can be manual or with automatic adjustment of the cooling temperature. The devices can be supplemented with transportation lines. To track the quantity of products at the entrance and exit, weighing equipment is installed.

The freezing process can be fully automated. To do this, you will need to equip the equipment with a programmable controller. Accordingly, each additional item increases the cost of the final equipment.

Quality control

Shock-frozen products can be found on sale. However, it is necessary to check the quality of the purchased product, which may have been damaged during transportation or under inappropriate storage conditions. You can determine proper freezing by touch - vegetables or berries should not be stuck together inside the bag.

Ice floes and lumps should not form with proper shock freezing. If we assume that the main cooling was successful, but there are still lumps, then unexpected thawing has occurred in the warehouses. All these shortcomings will later affect the taste of berries, vegetables or meat.

When touched, a quality product should be crumbly, each piece should have standard sizes, and there should be no pieces of ice present. Shock freezing produces microscopic crystals. It is impossible to probe them. The hard vegetables in the bag should be identified by hand.

To implement a simple business idea, a blast freezer is the best choice. The price of the simplest freezer starts from 100 thousand rubles. There are cheaper options, but their performance is too low for industrial use.

According to consumer reviews, the cost of a normal cabinet is about 200 thousand rubles. - the optimal method of preparing carrots, cabbage and other vegetables for storage. The quality of products is affected by the reliability of the freezer. Therefore, you should trust positively proven equipment suppliers.

General principles for preparing food before refrigeration

Before blast freezing, vegetables must be processed. Several stages of cleaning must be carried out. The ideal shape is cubes with a diagonal of no more than 2 cm.

The vegetables are scattered in an even layer through a chamber with a temperature of minus 40 degrees. With this thickness it is possible to achieve high performance without increasing the cooler power. According to buyers, it is more convenient to use small pieces immediately during the cooking process without wasting additional time on pre-defrosting them.

Beetroot, broccoli, and green beans are processed this way. Carrots and mushrooms are frozen in the same way. You can also find more exotic root vegetables and berries on store shelves. Thanks to the shock cooling method, it is now possible to deliver various products from distant countries practically fresh.

However, strict requirements are imposed on the storage conditions of products. One defrosting and the quality of freshness will be lost forever. The shelf life, while maintaining the technology parameters, is limited to a year from the moment of freezing at a temperature not exceeding -18 degrees.

Some models

There are refrigerators with quick-freezing chambers for home use. One of these is the device Liebherr model CN 3913. This option is suitable for storing berries and vegetables in a chamber with a volume of 150 liters. The temperature rises to -38 degrees. According to customer reviews, this is one of the most frequently purchased models. It is also convenient to use because the main camera is separated from the general space.

But for the convenience of quick freezing, many advise purchasing a separate cabinet and storing frozen berries in a regular freezer. There are more economical options for refrigerators with a similar function on sale. Eg, Electrolux EUF 23391W. According to consumer reviews, this device does a good job of preserving fresh berries and fruits.

The freezing temperature drops to -35 degrees. To prevent bacterial growth, it is recommended to periodically defrost such freezers and treat the internal surfaces with antiseptics.

It is impossible to imagine the windows of modern grocery stores and supermarkets without departments with Manufacturers of semi-finished products subject various types of food products to special processing, which allows them to preserve their gastronomic qualities for a long time. For the producers themselves, blast freezing is beneficial, first of all, for economic reasons. And this is exactly the case when the financial feasibility of using new product processing technologies completely coincides with the needs of the consumer.

Description of blast freezing technology

The freezing process involves several stages during which the product is exposed to temperature influences in different modes. The first stage involves cooling in the range from 20 to 0 °C. It is important to note that the decrease in the temperature of the product occurs in proportion to the amount of work aimed at collecting its heat. The second stage involves the transition from a liquid to a solid state. In this case, the temperature can drop to -5 °C. At this stage, shock freezing also provides heat extraction, but at the same time crystallization of liquid fractions in the product is performed. This stage can be called freezing. The final stage ensures freezing at temperatures down to -18 °C. And again, the decrease in degrees occurs in proportion to the efficiency of the main function performed by the refrigeration unit.

Features of the technology

In its classic form, shock freezing is carried out using low-temperature refrigeration machines in an average of 2.5-3 hours. It is the high speed of the freezing process that is the main distinguishing feature of the technology. The increase in cooling dynamics is not only due to the desire to optimize the process. According to research, the speed of freezing affects the formation of ice crystals, as well as the quality of enzymes and the structure of products. Speeding up the stages of cooling, freezing and freezing is ensured by increasing the rate of heat intake. At the same time, blast freezing units must operate with optimal acceleration of the coolant. The fact is that deviation from the optimal temperature reduction intensity indicators can lead to unjustified power losses and, most importantly, to product deformation. Therefore, in the process of performing blowing and cooling effects, it is very important to maintain uniformity and balance, maintaining moderate

Benefits of blast freezing

Subject to compliance with technological rules and nuances, the manufacturer can count on high quality of the final product. And this is not to mention the advantages that shock freezing implies from a financial and logistics point of view. In particular, the payback period of the enterprise is reduced by almost 20%, the need to use large areas for organizing the processing process is eliminated, the time for freezing is reduced, etc.

The advantages of this approach are most obvious when comparing it with traditional freezing technologies. For example, conventional techniques for ensuring such processes require much more time. Thus, a blast freezing conveyor serves an average batch of dumplings in 20-25 minutes, while traditional means of similar processing perform the same operations in 2 hours or more. It is obvious that savings affect both productivity indicators and the profitability of the enterprise in general.

Blast frozen products

The range of food products that can be frozen this way is quite wide and varied. Of course, the most popular are meat and fish semi-finished products, but this range has expanded significantly in recent years. Today, frozen vegetables, fruits, nuts, herbs, melons, all kinds of juices and desserts are produced. Blast-frozen products in the form of ready-made soups and main courses are presented in a separate category on the market. It should be noted that manufacturers strive to completely exclude the presence of inedible elements in the product, not counting the shell itself with packaging. Particular attention is paid to the stages of packaging, dosing and portioning. All this makes the products convenient for the consumer in terms of handling and further consumption.

Technical support

To implement the blast freezing process, several groups of refrigeration equipment are used. The most effective are quick-freezing fluidization units, which are used when working with crushed or small-piece fruit and vegetable products. The features of such devices include high freezing speed with minimal drying. The most popular type of equipment in this niche is the blast freezing conveyor freezer, which is used to process about 80% of the entire range of semi-finished products. A special class of such equipment is represented by spiral devices, which ensure freezing of portioned dishes and breaded semi-finished products.

Manufacturers of blast freezing equipment

There is no shortage of specialized equipment for blast freezing, since the market is represented by a wide range of manufacturers of different levels. The segment leaders include Nemox, Liebherr and Polair. In the families of these manufacturers you can find quick-freezing cabinets designed for different volumes and capacities. Irinox installations are also in high demand. Blast freezing on devices of this brand allows you to get quick results with maximum preservation of the original properties of the product. In addition, Irinox equipment differs from competitive offerings in its multifunctionality. For example, the additional ability to perform heating operations.

Installation of equipment

Setting up a production site does not require a lot of space or special requirements for communication support. To install the cameras, it is enough to use heat-insulating panels with a paint coating. This cladding of the equipment serves as a supporting structure and at the same time provides moderate thermal insulation. Depending on the modification, the blast freezing device may include elements of a supporting frame as standard. For example, there are devices on special frames that can be simply placed indoors or even outdoors if the device has a remote condenser. If you plan to install a high-performance conveyor, then it makes sense to initially pay attention to quick freezing complexes, which provide for the combination of several chambers in order to minimize the cost of the project.

Conclusion

The advent of blast freezing has opened up new opportunities for manufacturers, raising the level of development of the food industry to a higher level. In particular, technology makes it possible to delay implementation in time. In a sense, blast freezing is a means of transport, allowing distributors to distribute products without being tied to specific regions and harvesting seasons. This is also beneficial for the consumer, since he has the opportunity to purchase a fresh product of any origin, regardless of the time of year. Most importantly, the quality remains quite high. Of course, there is no talk of a complete comparison of the gastronomic characteristics of frozen products with fresh analogues, but modern technologies are constantly reducing this distance.

The product freezing process consists of three stages: freezing from +20 to 0°C, from 0 to −5°C and from −5 to −18°C. At the stage from +20 to 0°C, the product is cooled, and its temperature decreases equal to the amount of heat given off.

At 0 to −5°C, the cooled product passes from the liquid phase to the solid phase. Heat removal occurs more strongly, but the temperature decreases slightly, and crystallization of 70% of the product fractions occurs. This is the initial freezing stage. At the last stage, the product is cooled from −5 to −18 ° C, which is the final freezing.

An example of standard freezing technology are low-temperature ones, capable of cooling the product from −18 ÷ −24°С. The freezing period in them starts from 2.5 hours or more. The most important factor is time, since there is a close relationship between the quality of the product and the freezing period. The size of ice crystals, enzymatic and structural changes in products also depend on time. It is based method of heat extraction from a product by lowering the ambient temperature to −30 ÷ −35°С. The chamber plays the role of air, which intensively blows the product. It is worth noting that further lowering the temperature does not make sense, since this leads to increased deformation of the product and unjustified power consumption.

Unlike conventional freezing, shock freezing has the following advantages:

- reduction of the freezing period by 3-10 times;

- reduction of product losses by 2-3 times;

- reduction of production area by 1.5-2 times;

- reduction of production personnel by 25-30%;

- reduction of the payback period by 15-20%.

- tissue structure. When blast freezing a product, the high cooling rate allows for a rapid transition from the liquid phase to the solid phase. In this case, small ice crystals are formed, as a result the shape of the product remains practically unchanged, which is not observed with other freezing methods.

- bacteriological frequency. Due to the high freezing rate, the period of activity of the bacteriological environment is reduced. Bacteria of various types have their own temperature zones for life. With slow freezing, they can leave traces of their vital activity, but shock freezing does not leave them time to develop;

- ecology and biochemistry. In the absence of thermal and chemical treatment, in order to maintain an unchanged protein composition, rapid freezing is performed using a method that does not have a harmful effect on the biochemistry of the product and its environmental purity;

- shelf life. Quick-frozen products have a longer shelf life than those frozen in regular freezers. Blast freezing technology also ensures the preservation of the taste of the product, leaving other storage and preparation methods far behind in this regard;

- nutritional value and taste. Since the product is not subject to drying out when quickly frozen, it better preserves its nutritional and aromatic properties;

- weight. During normal freezing, liquid evaporation (shrinkage) is about 5-10% of the product weight. The forced freezing mode reduces weight loss to 0.8%, thereby increasing the economic effect;

- quick defrost products. Convenience foods, ready meals and other quick-defrost products are very popular in countries such as the USA, Japan, Germany, Sweden, Switzerland, Great Britain, Denmark, Finland and France. In them, the average consumption of such products per person is 40-100 kg per year. Moreover, their number is constantly growing by 5-7% per year.

The range of products that can be quickly frozen is very large. Each country has its own products that are specific to that particular area. Lately most often quick freezing The following types of products are suitable:

- ice cream, desserts, juices, etc.;

- meat and fish semi-finished products;

- ready-made first and second courses and bakery and confectionery products;

- fruits, vegetables, berries, herbs, melons and combinations thereof.

- taste qualities are maintained at natural levels;

- have virtually no inedible components;

- waste-free (except for packaging);

- dosed (portions, packaging);

- do not require special storage conditions and preparation time.

It should be noted that in Russia the frozen food market was initially focused on foreign products. Now the developed priorities are gradually changing, but the share of imported fresh frozen fruit and vegetable products still remains quite large. According to unofficial data, the share of imports of vegetables and products is 40-60%, and most of them are imported illegally.

Blast freezing technology has undeniable advantages that allow you to recoup the costs of equipment in the shortest possible time. Now it is becoming a kind of standard for most manufacturers, who without it would not be able to sell a large number of products.

Blast freezing equipment

In order to produce various types of semi-finished products, ready meals and other frozen products, the following types of equipment are used:- fluidization freezers. They are used for freezing small-piece or crushed raw materials: fruits, berries, soup mixtures, stews, French fries. Mushrooms, shrimp, small fish and other seafood are also frozen. These devices have minimal shrinkage, maintain high quality products and have a high freezing speed. The product frozen in this way is well packaged and retains its crumbly structure;

- cradle freezers used for freezing semi-finished products from fish, poultry, meat - cutlets, meatballs, hamburgers, steaks, sausages and confectionery. Products in such devices are frozen in thickness up to 80 mm in length and in width - up to 200x150 mm.

- conveyor freezers used for fish, meat, dairy, flour semi-finished products and ready-made dishes, including baked goods, puff pastry, pancakes, cutlets, hamburgers, sausages, steaks, dumplings, dumplings. Here the thickness of frozen products reaches 25 mm. These devices are used to freeze 80% of known products. They are also used to freeze plant products - strawberries, peaches, mushrooms, apricots;

- spiral freezers used for freezing fish, meat, portioned dishes, vegetables, fruits and breaded semi-finished products.

Freezing vegetables at home is a great way to get a lot of nutrients and vitamins in winter. Of course, when frozen, some of the vitamins are lost, but the remaining beneficial substances are much greater than, for example, in pickled vegetables or jam.

Home freezing of vegetables has become possible thanks to the spread of more modern freezers, which prevent food from turning into a block of ice covered with frost.

How to properly freeze vegetables?

They freeze everything: greens, zucchini, peppers, corn, cabbage, peas, raspberries, cherries, etc. Only completely watery berries, such as watermelon, and some types of salads cannot be frozen. To prevent vegetables and fruits from turning into ice-cold porridge and, after defrosting, into mush, you must follow the basic rules that describe how to properly freeze vegetables:

- Only whole vegetables and berries are selected for freezing, without damaging the skin.

- Before freezing, products must be thoroughly washed and dried, and all seeds and seeds are removed. So, the pepper is cut, peeled and cut into cubes or slices. The exception is berries. For example, cherries are washed, dried and frozen in an intact state. If you remove the pits from a cherry, it will lose its elasticity and the berries will stick together after freezing.

- Some vegetables are blanched, which means they are boiled for several minutes. Boiling kills microbes and substances that promote oxidation. Vegetables last longer after blanching.

- Frozen vegetables and fruits do not spoil for 12 months if stored at a temperature no higher than -18ºС, and about three months at a higher temperature.

Types of freezing

Basic recipes for freezing vegetables suggest two options: dry freezing and shock freezing.

Shock freezing of vegetables involves the rapid freezing of washed and dried vegetables: the water contained in the fruits, during rapid freezing, does not have time to form large crystals, the structural lattice of vegetable cells is not damaged, and after defrosting they retain their shape and color, as well as up to 90% of useful vitamins . Dried vegetables are placed in bags and placed in the freezer. Blast freezing can be carried out at home, using a regular freezer and the “fast freezing” function, which is found in most modern refrigeration devices.

Dry freezing of vegetables proceeds a little differently: first, washed and peeled vegetables are placed in an even thin layer on a board, which is placed in the freezer. After the vegetables have frozen, they are poured into small bags. It is especially convenient to freeze berries this way. Sometimes dry freezing is understood as the no frost function of a refrigerator, because it is this function that ensures freezing without moisture accumulation, that is, without the formation of ice. Watermelon and salad are not at all suitable for shock and dry freezing: due to the large amount of water, preserving these products without marinating is impossible.

What are the most convenient vegetables to freeze for the winter?

First, tomatoes: they are used to make borscht, beloved by many.

Secondly, peppers: if you don’t cut them, in winter you can make stuffed peppers from tasty foods full of vitamins. Some housewives prefer to stuff the peppers in advance and freeze them ready-made.

Thirdly, cucumbers are an indispensable attribute of any salad. In winter, a salad of summer vegetables that retain their juicy taste is especially healthy.

Greens are certainly not a vegetable, but they are also great for freezing. Cooking traditional dishes with cilantro in winter? It’s easy if you prepare cilantro for the winter in advance. It is enough to wash and dry the greens, chop them finely and scatter them into bags.

Frozen vegetable mixtures are useful for nutrition for athletes

With the onset of winter, many vegetables and fruits are available to people through freezing.

In the Soviet years, methods were used to preserve summer fruits - sugaring, salting, drying, drying, but now new technologies have come to the rescue.

The advantage of frozen summer fruits is that the berries retain most of the beneficial mineral vitamins. It is through quick and dry processing that frozen vegetable mixtures retain their nutrients.

You can prepare vegetables for the winter at home, preserve them, and put them in the freezer of the refrigerator. After three to four months, various dishes can be prepared from them.

Fruits can be frozen in the freezer at minus 18 degrees. In factory production, “shock” freezing is used - at minus 30-40 degrees. The quality of industrial freezing becomes better than home freezing, this is determined by vitamin C, which is the most sensitive during processing.

Endocrinologist, Candidate of Medical Sciences Elena Pyankova I am sure that frozen fruits and vegetables are no worse than fresh ones, because this is the best way to preserve them for the winter.

During industrial freezing, the loss of vitamins is no more than 15 percent.

Carrots, cauliflower, beans, green peas, other vegetables and fruits - all these frozen products are supplied from the warehouse Yuzh company http://natural-mors.ru/ city of Odintsovo, Moscow region. The company is a manufacturer of bases for fruit drinks and jams, so there is confidence in the quality of the products, which is confirmed by a special certificate. To make jams from raspberries, cranberries, and lingonberries, high-quality berries grown in ecologically clean regions of Russia are used.

Many customers prefer packaged products in transparent packaging, ice cream, and semi-finished products. These products go to stores and wholesale customers. On the company website natural-mors.ru It is noted that wholesale supplies of frozen mushrooms, forest and garden berries, and vegetables are carried out. The service covers all regions of Russia.

Experts have already learned how to freeze certain varieties of fruit so that they practically do not lose their taste properties. The fries are so beautiful and look frozen in the bag because they are a special variety that has little water and a lot of starch.

When purchasing frozen fruit, shake the bag first. Each berry in the bag should be separate from each other, and not a sticky mess. With high-quality storage, even tender strawberries look tasty and beautiful.

It is worth looking carefully at the date of manufacture. If the release of the product coincides with the harvest, then the manufacturer has indeed provided a quality product by freezing the fruit immediately after harvest.

Vegetables should have their usual appearance, cabbage should not be yellow, and potatoes should not be dark. The main rule when welding frozen foods is that they cook twice as fast as usual. Add a minimal amount of water so you retain more of the nutrients in your vegetables and fruits.