What is made from felt? What is felt and where is this material used? Important characteristics and varieties

The word “felt” comes from the Turkic “ojlyk”, and literally means “bedspread”. This type of material is a dense textile mass made by felting wool, which is produced using a non-woven method. Felt products have been serving people for many thousands of years, and until now this material has not lost its relevance and popularity.

Advantages of felt

Felt has long been used to make carpets, clothing and shoes. At the same time, the material has several useful qualities, among which are the following:

- The ability to retain heat, that is, low thermal conductivity.

- The material allows air to pass through quite well and does not allow a large amount of moisture to linger inside the products.

- High level of sound and noise insulation of the material.

- Wide possibilities of using felt for the manufacture of various types of products.

- Felt is made from natural raw materials and is an environmentally friendly material.

Types of felt

As a rule, felt is made in the form of panels of various sizes, which also have different thicknesses. Depending on the type of products for which it is intended, felt is divided into several main types:

- Felt- a type of felt made from the finest goat or rabbit fluff.

- Velours- a type of felt covered with thick, but soft and short fibers.

Based on the composition of the raw materials used to make the material, felt is divided into three main types:

- — contains only natural animal hair. Depending on the degree of softness and level of processing of the wool, there are fine-wool, coarse-wool and semi-coarse-wool types of felt.

- — 100% consists of artificial, synthetic polyester fibers.

- Technical felt- is a coarse wool material made from low-grade, inexpensive natural wool with the addition of plant fibers (no more than 2.5 - 3%) and mineral impurities (no more than 0.2 - 0.5%). The dense and rough structure of the material, as well as its significant thickness, make it possible to use technical felt for the manufacture of products with a high degree of protection of metal parts during friction and vibration.

The history of felt

The art of felt making is based on the unique property of wool to mat and stick together when wet and shaken. This quality of wool became known to cattle breeders in ancient times, and they began to use it for practical purposes. Thus, felt products appeared long before the invention of spinning. This convenient and affordable material was used to make carpets, home coverings, shoes and clothing.

Felt was especially popular among nomadic tribes because they had herds of cattle, whose wool served as the raw material for the production of the material. In addition, felt products (coverings for yurts or carpets) were relatively light in weight, and if necessary, they could be easily moved to another place.

The process of making felt was quite simple, but at the same time it required certain knowledge and practical skills. The animal wool selected for felting was carefully combed, carefully selecting various particles of weeds, debris and mechanical impurities.

All collected wool was then sorted by hair thickness. Afterwards, selected wool of one type was treated with boiling water in order to remove sebum and lard, as well as various contaminants.

In this way, a loose fabric was obtained, which had to be rolled and unrolled several times so that the individual wool fibers gradually fell off, combining into a homogeneous, solid mass.

Depending on the thickness of the selected wool hairs and the duration of the felting process, the craftsmen received thick or thin felt, which was intended for the manufacture of various types of products.

Thick wool produced a more durable material, which was suitable for the production of carpets, home coverings, and also for the production of shoes. But comfortable clothes were made from thin types of felt, which were generously decorated with embroidery.

To increase the strength of the felt, a little thick wool was added to the thin wool. The resulting felt panels were decorated with embroidery, which at the same time increased the strength of the garment.

Often, before felting, the wool was bleached, and then a pattern of wool dyed in different colors was laid out on a white background. Similar carpets continue to be made in our time, and they fit perfectly into modern apartments.

The production of such products was carried out by special specialists who were called sherstobits. They constituted one of the oldest and most respected groups of artisans, and their art remains in demand to this day.

Felt products

From ancient times to the present day, people have learned to make many types of felt products. Among the most famous and popular among them are the following:

- Felt boots- a type of winter footwear, the production of which has long been common in Russia. According to the design features, felt boots can be either the simplest (but at the same time practical, warm and comfortable), or generously decorated with embroidered patterns or appliqué.

- Carpets- very beautiful, easy to use and durable products that fit harmoniously into, made in oriental style.

- Felt hats- one of the fashionable and popular accessories of a modern person. Felt hats are worn by both men and women.

- Burka- a sleeveless raincoat made of felt in white, beige, red, brown or black. It is the national men's clothing of the peoples of the Caucasus.

- Syrmak- a Kazakh carpet made of felt and generously decorated with national patterns. A special feature of this type of carpet is its manufacturing technology. Syrmak is made from separate pieces of felt of different colors (most often a combination of white and black is used).

When forming a pattern, a mosaic technique is used, in which the pattern is cut into the base at the level of its surface, after which this composition is applied to another piece of felt and carefully quilted, and then stitched along the patterned contour with colored cord.

- Shirdak- is a product of Kyrgyz folk craft. Shirdak is one of the most complex carpet-making techniques. In the process of making shirdak, patterns are also cut into felt of different colors and then combined into a single colorful composition.

Kyrgyz shirdak

Kyrgyz shirdak - - a special type of national headdress among the Kyrgyz and Kazakhs. It is made of thin high-quality felt and embroidered with national patterns.

- Cover for yurt- is a type of portable dwelling on a frame base, covered with felt on top. This type of structure is typical for Turkic and Mongolian nomadic peoples.

Thus, felt has faithfully served people for centuries, and is acquiring new forms of use in various fields. Felt is also used as insulation under floor coverings. This simple technique will help bring an atmosphere of warmth and comfort to every home.

Felt - ancient and modern

The art of textile making is one of the most ancient skills of mankind. The raw material for it among agricultural peoples was plant fibers, and among pastoralists - wool, mainly sheep. The first woolen materials were non-woven, they were produced by felting the fibers into a homogeneous mass. This was facilitated by the structure of sheep fleece, the hairs of which have scales on the surface and are covered with lanolin. Various types of felt were produced in Iran, Mongolia, Kazakhstan and other regions, and the methods for making them have survived to this day. At the same time, new types of this material have been invented relatively recently. Synthetic felt made from polymer fibers is used both for technical purposes and for artistic creativity.

The oldest method of producing this non-woven textile is that the wool is laid out in a thin layer, exposed to hot water or steam, and then compacted in one way or another.

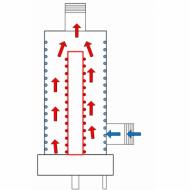

Currently, felt fabric is produced using the following sequence of operations:

- loosening of raw materials using pinching and scattering equipment;

- oiling and mixing;

- combing using a carding machine;

- base compaction;

- impregnation with acid solution;

- felling on felting devices;

- drying.

A special type of felt is felt, which is produced by rolling wool with the addition of fluff. Thick or thin felt made from natural raw materials has the following properties:

- resistant to tearing and abrasion;

- warms while allowing air to pass through;

- protects against high temperature, splashes of molten metal, and electric shock;

- absorbs sound waves;

- absorbs moisture and other liquid and gaseous substances well;

- plastic;

- can be draped;

- relatively inexpensive.

The positive qualities of this felted material also have their downside. First of all, wool fibers are usually coated with lanolin, which causes allergic reactions in some people and gives the material a specific smell. The presence of lanolin attracts moths, which irreparably damage natural felt. However, high-quality wool materials do not smell and are supplied with a special pest-repellent impregnation. You should also remember about the high hygroscopicity, due to which wet felt takes a long time to dry and can become deformed.

Modern varieties of felt are divided into technical, household, and fine-wool. A separate group is made up of felt, which is produced by heat pressing. Technical material is most often made from coarse dark wool up to 25 mm thick and is used for:

- various insulating, insulating and vibration-damping gaskets, filters, substrates, seals, etc.;

- workwear, safety footwear, protective equipment;

- electrical insulation (thin up to 6 mm);

- horse harness and when transporting expensive products (saddlery).

For economic and domestic needs, shoe felt, thin fabric for bath accessories, and traditional woolen fabrics of various thicknesses for yurts, carpets, and national clothing are produced. In the manufacture of modern wardrobe items, warm and indoor shoes, hats, as well as various accessories, they often use synthetic ones.

Areas of use

Among ancient cattle breeders, felted wool material was universal: it was used to make the walls of temporary dwellings, it protected in battle, kept warm in winter, and was used for decorative purposes, and our ancestors could not imagine themselves without comfortable and warm felt boots and hats. Since the middle of the last century, felt, felt and other traditional materials began to be gradually forced out of everyday life, but were still widely used in production, agriculture and even in various sports.

However, in recent decades there has been a real boom in all kinds of felt products. Instead of reliable but clumsy felt boots, beautiful and waterproof shoes are produced, which quickly became fashionable for all ages. Consumers also appreciated the comfort and healing effect of felted indoor slippers, the convenience and reliability of bath accessories, the stylish appearance and warming properties of clothing for the cold season. And finally, felt has become a popular material for making bags, decorative cases, various art products, and toys.

Features of care

All these accessories require constant care and protection from moths. In addition, the absorbent properties of felt contribute to its rapid contamination, and it needs to be regularly dried and cleaned from dust and lint deposited on the surface using a brush or vacuum cleaner. Minor dirt can be removed with a soap solution. If necessary, felt products can be washed. This is done manually, using a lukewarm aqueous solution of wool detergents (containing lanolin). Things do not rub or wring; if necessary, you can use a brush. After washing, the moisture is lightly squeezed out, then the flat product is laid out horizontally on an absorbent mat, and the bulk product is stuffed with lumps of paper, changing them as they get wet. Drying is carried out away from the sun and heat sources.

Felt is a fibrous material that has high tensile and bending properties. It tolerates high temperatures well and does not stretch. Hats, bags, and insulation are made from it.

History of origin

Felt is one of the few materials that have been used since ancient times. The mention of its receipt occurs at the time of the Flood. It turns out that the first fabric was made by sheep. Noah gathered the animals in one place for a long time.

While the flock rubbed and trampled in the cramped ark, the wool fell to the floor and gradually became denser. As a result of physical pressing, felt was obtained. This is one of the very first methods of obtaining natural material. True, the principle of such a process itself is very lengthy.

Recently, production technology has changed little. Felt is a non-woven material obtained by felting wool fluff.

Why does the material compact?

Felt is made from natural wool due to long-term compaction of the fluff. The process is significantly accelerated if the material is pressed while wet. High density and tear resistance is obtained due to the special structure of wool fibers.

The felt flakes hold each other tightly with their edges. The entire process of fabric production consists of striving to hook the scales as tightly as possible. Felting is the most successful way to mix fluff particles. Wet material increases slip and the fibers enter the lock without much resistance, which cannot be separated without damaging the fabric.

Only felt has a scaly structure. The photo shows an example of the interlocking of the edges of the fibers - the cuticle. During the felting process, fluff is exposed to hot or cold steam.

Physical properties of the material

Felt is made from the hair of only domestic animals. In wild sheep, the structure of the fibers is strikingly different and it is impossible to make high-quality material from their wool. Felt fabrics have received a wide range of applications due to the unique properties of the material.

Its important advantage is its natural composition. Nothing is added to it except the fluff of a sheep or other animal. Hence the high degree of thermal insulation. The material is suitable for the production of winter clothing.

Along with its high thermal conductivity, felt quickly absorbs moisture and passes it through itself. Thanks to this, it makes ideal winter shoes (felt boots, widely known to everyone), in which your feet do not sweat. They are very warm and easy to walk in. The material also has an antibacterial property, which prevents the development of microorganisms during prolonged wear of the product.

Felt hats and shoes are worn for years. The material has high wear resistance and the products are practical. However, stronger materials are used to protect the sole, which increases the service life of the fabric.

Application area

Recently, felt bags have become popular. They often make coats, hats, furniture, and cases for smartphones and laptops. Due to its natural composition, the fabric is suitable for the production of children's toys and carpets.

You can find felt insoles and linings on sale. Often the material is used in the production of upholstered furniture as various inserts to give an unusual appearance. This type of felt is called needle-punched felt.

Fabric for outerwear is made from rabbit and goat fluff. The felt is thin and at the same time quite warm. It is also called felt.

Industrial use

Low quality material or synthetic felt is used for various purposes. It turns out to be especially durable, with low thermal conductivity. This allows it to be used for insulating building facades. During construction, sheets of such material are laid under plaster for sound insulation, under linoleum.

In mechanical engineering, synthetic material is used as gaskets and oil seals. Thin fabric is widely used in electrical engineering as a dielectric. Another material is involved in the manufacture of saddles.

The engine compartment of cars is upholstered for sound insulation and heat retention in cold weather. It is also placed on the floor in the cabin and trunk. For similar purposes, it is used to upholster the walls of trailers for shift workers to live in in the North.

Fabric care

Felt can be cleaned from dust and dirt with a vacuum cleaner. It is advisable to process it dry. Some fabrics become damaged after washing, an unpleasant odor appears and is difficult to remove. The ideal cleaning tool is a vacuum cleaner.

Special liquids for caring for felt products are available for sale. Only with their help can you clean the material from stains, and you won’t have to worry about the appearance of a persistent unpleasant odor. It is not recommended to use heat sources to dry washed items. The fabric may change in size: shrink or, conversely, stretch. There is a possibility of wrinkles forming, which are not easy to remove later.

To clean stubborn dirt on felt boots, it is recommended to use lanolin. Before washing, pre-soak shoes in cold water. At the end of the procedure, perform a gentle spin. Before drying, the material is given the position in which the product will be used in the future.

How to make fabric at home?

You can make felt with your own hands. To do this, you will need natural wool from an animal, necessarily domestic: goat, sheep, rabbit, ram. You will need several components:

- Time – the duration of the procedure determines the strength of the tissue.

- Warm soapy water will speed up the felting process. The scales will more easily enter the lock with their cuticles.

- Two hands - we will use them to carry out all mechanical work.

You can roll small balls from wool and make beads from them. Some knock down layers of material to make a rug. You can give the product your own shape, make a toy. It is better to dry the finished item in a warm room.

Some craftsmen have learned to make felt from old woolen items. You need to take, for example, an old woolen sweater. We put it in the washing machine. Felting will take place according to the program with the maximum temperature. You will need a tennis ball, which also needs to be placed in the drum to increase the efficiency of making the material.

After a few washes, the size of the item will almost halve. After this, we start the drying mode. The result should be a felt material that needs to be steamed with an iron. This fabric can be cut and shaped into desired shapes. It should be dense and durable. Of course, the quality will be lower than when felting natural wool. But it is quite suitable as a material for toys or insulation.

Felt belongs to non-woven materials, the manufacturing tradition of which dates back more than five thousand years. If fabric made from plant fibers is associated with farmers, then the nomads and pastoralists of Eurasia, whose main source of livelihood were sheep herds, learned to felt sheep's wool. To this day, in Mongolia, Afghanistan, Iran, Buryatia and other places, wool felt is made in the same way as thousands of years ago. This dense and warm fabric does not lose its popularity, as evidenced by the real “felt boom” of recent years.

What is felt for?

To this day, felt occupies a very important place in the everyday life of many Asian peoples. Temporary housing (yurt) and almost its entire interior are created from it, protective armor and household supplies were made from it, thin felt was and is used for shoes, hats, and as the main fabric of winter clothing.

They say that the smell of sheep's wool drives away karakurts. Therefore, natural felt was considered a magical and healing remedy (however, the latter is not refuted by modern medicine), it was carefully finished and decorated. To this day, three main methods of decorating felt products have been preserved:

- Felting of an ornament, in which colored wool is laid out on a base in accordance with the pattern, after which felting begins (Turkmen felts).

- An application that is widely used these days.

- Embroidery (Buryat and Mongolian felt).

Russia and other Slavic peoples adopted this woolen non-woven textile from Asian peoples, evidence of which is the Turkic origin of its name (ajlyk - bedspread). Felt has become the material for the widespread felt boots, which are indispensable in frosty and snowy winters..

This fabric also spread to Europe, primarily in the form of thin felt, which is made by rolling a mixture of wool and down between rollers.

Currently, not only woolen felt is produced, but also especially durable artificial felt from synthetic fibers, which is used mainly for technical needs.

For technical use, the following types of felt are produced:

- coarse wool (6-12 mm), which is used for thermal and sound insulation, substrate for linoleum, various gaskets, seals, filters, etc.;

- thin technical (2.4-6 mm), which is used in electrical engineering;

- furniture, which is relatively soft and is used in the manufacture of upholstered furniture and mattresses.

For use in everyday life and wardrobe, the following types of non-woven material are classified:

- shoe, from which various shoes, insoles, soles are made;

- under-clamp and sweat-plate - for saddlery products;

- for yurts;

- felt (for shoes, hats, decor, accessories).

Since the end of the twentieth century, the use of felt in everyday life has sharply decreased, but in recent decades its demand has increased significantly. The production of felted wool shoes has increased, the models of which have become more beautiful and comfortable; bags, other accessories, as well as decorative items are made from felt. Paintings and panels, as well as other types of artistic works and crafts made from this material, have become a current trend.

Properties and care

Felted wool fabric has received such wide and varied use due to its many useful properties.

- Ecological cleanliness and the ability to partially neutralize harmful substances.

- Hygroscopicity and the ability to remove moisture to the outside.

- Antibacterial properties.

- High thermal conductivity.

- Light weight.

- Strength.

However, it should be remembered that felt is highly damaged by moths, and appropriate preparations should be regularly applied to it.

In addition, wool fibers absorb impurities and become dirty, so felted fabric needs constant and regular care. Its rules depend on the type of felt item, but in any case it must first be dried, then vacuumed well or the dust beaten out.

In addition, wool fibers absorb impurities and become dirty, so felted fabric needs constant and regular care. Its rules depend on the type of felt item, but in any case it must first be dried, then vacuumed well or the dust beaten out.

Felt– dense non-woven material made of felted wool. This is the oldest material obtained by people. Accordingly, the first man-made household items and clothing were created using the felting technique.

Story

The appearance of the first felted products dates back 8,000 years, and one of the legends tells that the first carpet was felted in Noah’s Ark. Being in a cramped room, the sheep, without knowing it, matted their wool with their hooves. And when the sheep left the ship, a felted carpet remained on the floor.

Ancient people found animal wool and tried to felt the first things. Then pets appeared, and since then, for many centuries, felt has occupied an important place in people's lives.

Properties of wool

The only material from which felt can be made is wool. Moreover, the wool of a wild sheep falls very poorly, since it does not have a scaly layer. Domestic sheep has a top layer, the cuticle, which allows the fibers to adhere to each other when exposed to hot water and steam.

Basic properties of wool:

- It consists of proteins and keratin, just like our skin. Therefore, products made from natural wool are very useful.

- Wool contains lanolin, which is widely used in cosmetology in the manufacture of creams and ointments.

- It allows air to pass through well, allowing the skin to breathe.

- Does not allow fungi and bacteria to multiply.

- Wool is also hygroscopic, it absorbs water well.

- But most importantly, it is good for health, helps with joint pain, lumbar pain, and poor circulation.

Sleeping under a wool blanket is both healthy and warm.

Application

Felt is still widely used, especially among nomadic peoples. What household items and things were made from felt before the advent of spinning wheels?

- Carpets. For many years this was the only way to insulate a home.

- Yurts. Similar technology is still used in nomadic tribes.

- Mattresses. This much-needed household item was light and soft.

- Pillows. A person who spends many hours sleeping needs a good pillow.

- Hats. They were especially warm and easy to care for.

- Shoes. The well-known felt boots are an example of the warmest footwear in cold weather.

Wallow

Natural wool is pleasant to work with. She is alive, warm and surprisingly pliable. The skill of felting wool was especially well developed in Asian countries, Russia, and Finland. In Kyrgyzstan, felt is called kiyiz, and the manufacturing technology is strictly subject to certain requirements. For example, sheep are sheared only at strictly designated times. For the Turkic peoples it was simply a necessary thing in everyday life, a mat or a large felt carpet. It was easily transported, it could be cleaned, and, of course, it had an excellent heat-insulating effect, which is important for the eastern peoples. After all, they spend most of their time on the floor - eating, communicating, sleeping on soft mats.

Creation

But felt served not only utilitarian purposes. It was also a vast field for creativity - craftswomen applied original patterns and ornaments, showing individuality and creativity. From the drawing one can determine both the status and nationality of the author or owner of a felt product, and different colors and shades helped to look at the world more brightly and cheerfully.

Decoration of felt products

Felt products are decorated in various ways:

- Application. It can be made from felt or other suitable materials, such as leather or fabric.

- Embroidery. Felt is decorated with beads and beads. And for embroidery, wool threads are used, which can be of various thicknesses and textures.

- Felt painting. You can use natural dyes, because wool holds the dye well, the color is bright and long-lasting.

- Felt inlay.

Felt today

Felting is experiencing a rebirth, and from a forgotten technique is turning into an exciting and useful activity, gaining more and more adherents and admirers. With this simple technique you can make wonderful things - unique and original. Felting is organic, filled with the energy of ancient traditions, and the items are easy to care for.

An unusual, natural color gives felt products creativity and, at the same time, practicality, which is important for modern design.

Links

- Felt: help for a beginner, forums of the handicraft portal Hobbyportal.ru