The order of laying flexible tiles on usb. Do-it-yourself flexible tile laying

Practicality, functionality, durability - all these advantages of soft tiles distinguish it from other roofing materials.

What features this material has, how to prepare a base for it and what technology to mount it with - you can find out below.

First of all, consider the pros and cons of flexible tiles.

The soft tile has many benefits:

- Aesthetic appearance. The line of soft roofs is distinguished by a variety of colors and shapes, which allows you to decorate the roof in any style. In our country, the brand is very popular, with which you can create rectangular, oval, hexagonal and many other geometric shapes of roofs.

- Resistance to mechanical damage, dirt, water, mold and temperature extremes. The operating temperature range is from -45 to 110 0 C, which is great for Russian frosts.

- Durability. With, operation and periodic maintenance, a soft tile roof will last more than 50 years.

- . In the event of a breakdown, any structural element can be easily replaced without rearranging a whole row. At the same time, the surface of the tile does not fade and does not peel off over time, which eliminates the need for regular touch-up.

- Easy installation. With the appropriate skills and tools, installing a soft roof will not take much time. And this is not to mention the minimum waste during the process.

Unfortunately, the coverage is not without some shortcomings:

- Strict requirements for conditions and temperature during installation. Tiles can be laid at a temperature of + 5-10 C. The same applies to climatic conditions: it is strictly forbidden to lay tiles in rain or high humidity, since the base of the material will begin to rot.

- high cost, which is not particularly felt due to the service life of the coating.

- Difficulty of installation. Soft roofing needs reinforced beams and walls for installation. Therefore, specialized companies use the generally accepted frame technology.

Positive qualities of tiles

Composition and technical characteristics

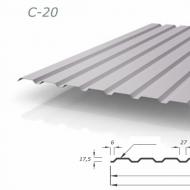

Tiles are produced in the form of individual plates, which have width within 0.3 - 0.45 m, thickness 3 - 5 mm and length up to 1 m. Composition of soft tiles:

- front part: ceramic granulate made of basalt or mineral wool;

- multilayer construction of bitumen and the base material - non-woven polyester or fiberglass;

- rear end: self-adhesive type bituminous layer, protected by a polyethylene film. The film is removed before installation.

The main material from which the tiles and the insulating carpet under them are made is non-woven polyester, fiberglass with bituminous impregnation. The first one is distinguished by high tensile strength, due to which it is used in areas where there is a maximum load among the entire structure - these are skates, valleys and other junctions.

The structure of flexible tiles - photo

Fiberglass coating is cheaper than polyester models, and therefore it is used as the main coating and in places without requirements for increased strength. More details and characteristics .

Statistically, more than 30% of heat escapes through the roof, which forces a responsible approach to the choice of insulation.

Preparation as a guarantor of durability: roofing cake for shingles

Before installing soft tiles, it is necessary to carry out a number of preparatory work for:

- provide;

- mount;

- apply waterproofing (this stage can be combined with vapor barrier);

- create a system.

After that, you can proceed directly to the laying of shingles.

NOTE!

When arranging a roofing pie, it is necessary to strictly follow the sequence described above. However, the insulation step can be skipped if planned attic with a cold roof limited to the installation of a waterproofing layer.

roofing cake

Flexible tiles - preparation of the crate

The crate acts as structural strengthening and provides ventilation to the roof. During installation, the bars of the counter-lattice are first laid, and on them - the main part of the crate. It is they who form the gaps included in slope ventilation system, which provides air circulation, condensate drainage and minimizes rotting of the rafters.

For flexible tiles use solid plywood sheathing, oriented strand board and other smooth materials without joints. Before installation, it is recommended to make sure that the humidity of the plates is less than 20%.

The plates themselves are installed "in a run" with a gap no more than 2-3 mm. When choosing the pitch of the rafters and battens, they are repelled by the possible load that the roof will experience. It depends on climatic conditions, precipitation, temperature, wind and the general design of the building.

Soft tiles are suitable for arranging the roofs of private houses and cottages, as well as country baths and other structures.

Lathing for soft tiles

Warming

If necessary, an insulated room or attic is used for insulation for flexible tiles. Recommended by specialists based on basalt or glass wool. They are easy to install and are suitable even for hard-to-reach places. At the same time they do not form cold bridges and well protected from temperature extremes.

CAREFULLY!

Minimum material thickness - 150 mm, and for regions with severe frosts - 200 mm or more.

Laying and installation of the coating

For a sloping roof, it is necessary to use, which will perform the functions and. For roofs with steep pitches the angle of inclination is more than 20 0 it is possible to not completely lay the layer. It will be enough to get by with insulation on the ridge, panels at the ends and cornice overhangs.

For a sloping roof, it is necessary to use, which will perform the functions and. For roofs with steep pitches the angle of inclination is more than 20 0 it is possible to not completely lay the layer. It will be enough to get by with insulation on the ridge, panels at the ends and cornice overhangs.

The most important stage of work during installation is the installation of cornice tiles and the first row. It is necessary to strictly follow a clear direction along the entire row and observe equivalent distances. The tile is fastened with the help of special holes that are made in the factory.

Complete installation takes seven steps:

- A special carpet is laid on the covering of the crate in areas where the structure experiences the maximum load. These are the ends of the roof, valleys, overhangs and junctions. The carpet is spread over the base along the eaves, the resulting seams are sealed and glued. After gluing, there are edges that fixed every 20 cm. When laying in valleys, it is necessary to leave the carpet at a distance of 7 cm, and then glue the resulting edges with a width of at least 10 cm after cutting. To avoid damage to the carpet when cutting tiles, it is recommended to place a thin plank or piece of plywood under the tiles.

- Installation of metal cornice and front strips. This will protect the structure from decay and moisture, fix the carpet more firmly along the cornices and frontal joints. The cornice-type plank is fixed with nails, which are located in a checkerboard pattern with a step of 10 cm. Also, on the cornice overhang, it is necessary to equip a 2 cm thick entry. Gable strips are subsequently mounted according to exactly the same principle.

- Arrangement of valleys. An important stage of work, since in these areas the roof made of soft tiles is especially susceptible to destruction from moisture. For sealing, a carpet is laid in the valleys, and its edges are fastened with nails. Step between nails - 10 cm. To ensure water resistance, a waterproofing carpet is used, which is installed in 10 cm increments. The color of the carpet should be matched to the appearance of the tiles.

- Eaves tiles: installation on overhangs. This element is mounted on top of the metal protection, cornice and carpet. The protective film is removed from the shingles, then the tiles are laid to the eaves and nailed in the perforations. The next step is the laying of ordinary tiles, the sheets of which will overlap the places where the cornice is attached.

- using our online calculator.

- Installation of ordinary tiles. It is laid on top of the cornice row. This type of tile has curly cutouts that form the roof pattern and special recesses for precise joining of tiles. Start laying from the center of the slope, moving towards the ends. For even installation, it is recommended to make horizontal markings with chalk. It will especially help in cases where the roof has places with broken geometry. All tiles are nailed in 2-3 cm increments, four nails are needed per tile. If the slope is 45 0 or more, then six fasteners will be needed. Subsequent rows of tiles are laid in such a way that the lower edge of the petals is flush with the grooves of the tiles of the previous row.

- Installation of tiles on skates. For installation in skates, it is necessary to separate special sheets of tiles (they have a size of 0.25-0.33 m) and perforation lines. After separating the sheets, the fragments of the tile are laid on the ridge, and then they are nailed with two nails on each side. Each row of tiles must overlap the previous one. with an overlap of 2-5 cm. It is necessary to cut the tiles along the ridge so that the waterproofing layer is open by 7.5 on both sides. As for the roof at the place of trimming, it must be treated with glue for at least 10 cm and glued.

- Installation of tiles on valleys. In places where a roof made of flexible tiles adjoins vertical surfaces, a triangular block of wood is installed. This will reduce the risk of shingle deformation at the folds. At the same time, ordinary tiles, together with the lining carpet, should go over it. Next step - installation of valley carpet 30 cm high above the vertical surface and the roof slope. Its edges are coated with adhesive, and its upper edge with silicone-based sealant. After that, everything is covered with a metal bar.

The first example of a soft tile roof - photo

The second example of a shingle roof - photo

With pitched slopes with an angle of 30 0, roofing strips are also used from metal. They are installed at the junction, end (wind slats) and eaves (drip slats).

Soft tiles are a durable and stylish roof that will allow you to take care of the roof of the building for many years. It remains only to correctly prepare the design and carry out the installation.

Useful video

Answers to questions about flexible tiles in the following video:

A reliable, inexpensive and easy-to-install roof is one of the most cherished wishes of the developer. Simplicity, the possibility of arranging with your own hands without the help of third parties - laying soft tiles differs in all parameters. Affordable technology, democratic cost of the material, no need for special skills and tools make laying out easier. And we will tell you how to install soft tiles with your own hands.

A preliminary calculation of the material, additional elements, fasteners is the key to a high-quality arrangement of the roofing carpet. Approximate costs are:

- The number of shingles in a box can be different: from 1.5 to 3 m2. It all depends on the size of the elements (including overlap). All parameters are indicated on the box, the material should be bought with a margin of 5-7%.

- Mastic in quantity: 200 g/m2 for valley carpet, 100 g/m2 for ends, 750 g/m2 for junctions, nodes.

- Nails 30 mm long, galvanized with 3 mm shank and 9 mm head, 80 g/m2.

All calculations are averaged standard. You will also need tools:

- Knife for trimming bituminous shingles, substrates;

- Scissors for metal (or others) for trimming planks;

- Hammer for fasteners;

- Brush for bituminous mastic.

Advice! If the laying of flexible tiles with your own hands is done in the cold season, a burner will come in handy for heating the bituminous layer. Despite the possibility of carrying out work up to -5 ..-7 degrees, it is better to equip the roofing carpet in warm, dry, not the hottest and calm weather. In the cold, the flexibility of shingles decreases, the risk of cracking increases, in extreme heat, bituminous materials heat up excessively and melt.

Roofing cake for shingles

With the arrangement of a roofing pie for soft tiles, a large stage of work begins. Depending on the purpose, the attic can be warm or cold. The purpose of the under-roof space affects the arrangement of the roofing pie, however, the part above the rafters is always the same:

- a layer of waterproofing material;

- bars with a thickness of 30 mm;

- crate in the form of a continuous flooring.

Important! Additional elements: junction slats, cornice overhangs, pediment slats are made of special steel.

Laying out waterproofing

Membrane materials can be one-, two-, three-layer.

- Single layer waterproofing- an affordable and cheap option that performs the task of preventing humidity from entering the room and not preventing fumes from escaping to the outside.

- Two-, three-layer materials- more durable and practical. They have an absorbent layer that absorbs condensate, as well as a layer of reinforcing material, which gives greater tensile strength.

Advice! Three-layer waterproofing membranes are shown in the case of mineral wool insulation. The material is afraid of getting wet and with an increase in humidity, even by 10%, it loses 56-60% of its quality characteristics. In the case of arranging a cold attic, it is better to use a two-layer membrane sheet: the price is slightly more expensive than a single-layer one, but the strength is much higher.

Advice! If the slope angle is more than 18 °, waterproofing membranes should be placed parallel to the end and cornice planes. The junction points have an increased risk of leaks, therefore the layout is carried out with an overlap. The same is true for the skate area. If necessary, the ridge area is covered with another lining carpet. Work is carried out from the bottom up, fastening is carried out with nails with an increased cap size. Mounting step 20 cm.

Ventilation

Roof ventilation made of soft tiles is usually arranged by means of a ridge. It is laid out on a ribbed profile. In case of insufficiency of this method, ventilation elements are laid on the roof surface. This is the name of profiles with ribs located at a distance of 20 mm from each other. Structures are attached to the base with nails.

Sheathing and flooring

Immediately after laying the waterproofing, the lathing strips are stuffed on top. Thick timber elements create the necessary ventilation gap. The crate is made from a bar of coniferous wood. The thickness of the elements is at least 30 mm; before installation, the wood is treated with impregnations against decay and fire.

Important! The length of the boards for the crate is a distance equal to two spans of rafters. Fastening is carried out above the rafter legs.

Do-it-yourself installation of flexible tiles is carried out on a solid flooring. It is made from OSB3, sheets of moisture-resistant plywood, tongue-and-groove or edged boards 25 mm thick, with a moisture content of not more than 20%.

Important! The layout of solid elements is carried out with gaps - compensators for thermal expansion of the material. For plywood or OSB, the gap width is 3 mm, for boards 1-5 mm. Sheet dies are fastened in the way of running up the seams so that the joints are not continuous. Mounting on self-tapping screws or ruffed nails.

Arrangement of flooring next to chimneys with a width of more than 0.5 m often requires the construction of a mini-roof. After installing the flooring, it is necessary to check the evenness of the coating plane, dimensional parameters - the slope must be perfectly aligned.

Laying shingles

When purchasing a product, you should carefully review the instructions from the manufacturer. It necessarily indicates how to lay flexible tiles. Often it is enough to follow the step-by-step instructions to do the roofing work correctly, however, preliminary familiarization with the procedure helps to allocate time.

Advice! Installation of bituminous tiles requires caution: no kinks, no creases. Unnecessarily, you should not walk on the coating.

Now the installation technology:

- Strengthen the overhang. A drip bar is mounted to protect the structure of the rafters and battens from moisture. Place one edge of the dripper on the deck, close the overhang with the second. Fastening with galvanized nails. Pitch 200-250 mm, checkerboard pattern, layout with an overlap of 30 mm. The gaps are smeared with bituminous mastic, sealant.

- Attach hooks for drain pipes.

- Lay waterproofing carpet. The adhesive underside facilitates the installation process. Start from the valley section. From the point of inflection, an overlap of at least 0.5 m is left on both sides. It is better to do without joints, but if necessary, leave an overlap of 150 mm. Laying from bottom to top, the junction is pre-treated with bitumen-based mastic. Along the cornice overhang, the free residue of waterproofing material is 0.6 m.

Advice! Before laying, the waterproofing carpet is rolled out, cut, then the protective film is removed and only then glued onto the substrate. Additional fixation along the edges with stainless steel nails will help to secure the sheet of material more firmly. The points of joints and overlaps are additionally sealed with bituminous mastic, crimped.

- Carpet lining. The product also has the form of a roll with an adhesive base protected by a paper layer. The layout option depends on the profile of the selected tile shingles, the shape of the roof, the angle of the slope. In the case of choosing Jazz, Trio coverage, an underlayment is a must. If the roof slope is 12-18 °, the lining is mounted around the entire perimeter of the roof. Installation should be carried out from below, overlaps of at least 150-200 mm, lubrication of the joints is required. The top edge is additionally fastened with galvanized nails. If the slope angle is from 18 °, the lining is needed at the kinks, at the points where the gable line adjoins the wall panels.

- Gable plank needed for arranging side cuts. The additional element already has the desired shape, is mounted on the lining or waterproofing flooring and fastened with nails in 150 mm increments.

Advice! When starting to lay out shingles of tiles, it is better to first mark the slope. Mesh markings will help to place the roofing material, taking into account centering, joints. It is easier and smoother to make markings with a regular paint cord.

- First strip of shingles as a rule, ridge-cornice or ordinary ordinary with cut petals. The sheet is laid out on the edge of the slope so that one edge of the shingle goes to the gable bar. The lower edge of the shingle should lie on the drip with a 150 mm indent from the fold of the additional element. Fastening at the corners with a gap from the edge of 20-30 mm.

Advice! Often sheets in packs have some differences in color background. So that the laid shingles do not differ much, you should open several packs in advance and lay out the elements alternately.

- How to lay ordinary soft tiles? The first shingle does not reach the edge of the starting strip 10 mm, the sheet is fixed with nails (except for the adhesive base). The number of fasteners with a slope of 12-45 ° steepness per sheet is 4 pieces, and at the junction points of two sheets, the nails are stuffed so that the hat “covers” the edges of both shingles. If the slope angle is greater than 45°, fasteners are driven into each sheet.

After the do-it-yourself installation of tiles along the slopes is completed, it remains to arrange the valley and gables. Flexible roofing has a lot of advantages, one of them is the quick arrangement of the most difficult areas. The roof in the valley area is arranged as follows:

- Designate an area where nails cannot be driven in (300 mm from the middle point of the valley), mark the boundaries of the additional gutter - this is about 5-15 cm in both directions.

- Now hammer the fasteners of ordinary tiles as close as possible to the line, beyond which fasteners are no longer allowed.

- Cut the shingle along the gutter installation line.

- To prevent water from leaking under the edge of the material, the corners of the material are cut (4-5 cm each), the loose edge is attached to bituminous mastic.

It is not difficult to lay roofing material along the gables: the side shingles are cut off with the calculation of the distance to the ribs of 10 mm. Cut the upper corner, as well as the valley elements: obliquely 4-5 cm. “Sit” the edges of the tiles on the bituminous mastic and fix with nails.

The installation of bituminous tiles on the ridge has its own characteristics: a gap is cut along the ridge element, not reaching the ribs of 300 mm. The installation of shingles is carried out before the start of the slot, after which an additional element (ridge profile) is mounted. A long skate may require several profiles, this is normal. Fastening with nails, laying out end-to-end, mating points are smeared with bitumen.

Important! On the ridge, underwind installation is carried out; flexible tiles are laid out towards the wind, with an overlap of at least 30-50 mm.

Installing a soft roof is not difficult, especially if you follow the technological subtleties of the process and perform an accurate preliminary calculation. Work is carried out on a dry sunny day without wind and intense heat. If clarification is required, watch a video from professionals: do-it-yourself flexible tile laying.

The roof made of bituminous soft tiles is easy to use, durable and aesthetic. Its big plus is that self-assembly is quite possible. The technology is not the most complicated, the weight of the fragment is small, it is attached to the adhesive base, additionally fixed with roofing nails. So the installation of soft tiles with your own hands can be done even alone.

Roofing cake for soft tiles

The attic under the roof can be warm or cold, depending on this, the composition of the roofing cake changes. But its part from the rafters and above always remains unchanged:

- waterproofing is stuffed on the rafters;

- on it - bars with a thickness of at least 30 mm;

- solid flooring.

Here we will consider these materials in more detail - from what and how to make, what features each of them has.

Waterproofing

Waterproofing membranes are available in one, two or three layers. Single-layer membranes - the simplest and cheapest, perform only a dual task - do not allow moisture to pass towards the room and release vapors to the outside. In such a simple way, the attic is not only protected from the penetration of condensate or suddenly leaked precipitation, but also excess moisture that accompanies human life is removed from the air. Single-layer membranes are poorly represented on the market. Practically they are produced by one company - Tyvek.

Two and three-layer membranes are more durable. They, in addition to the waterproofing layer, also have a layer that gives greater tensile strength. The third layer, if any, is the absorbent layer. That is, even if a drop of condensate has formed on the surface of the membrane, this layer absorbs it into itself, preventing it from spilling onto other materials. With sufficient ventilation, moisture from this layer gradually evaporates and is carried away by air currents.

Three-layer membranes (for example, EUROTOP N35, RANKKA, YUTAKON) are desirable if your attic is insulated and mineral wool is used as a heater. It is afraid of getting wet and with an increase in humidity by 10% loses half of its thermal insulation properties.

If there is a cold attic under the soft tiles, it is advisable to use a two-layer waterproofing membrane. In terms of strength, it is much better than single-layer ones, and at a price it is only a little more expensive.

crate

On top of the waterproofing film, parallel to the overhang, the lathing strips are stuffed. They are necessary to create a ventilation gap. It will help maintain the normal humidity of roofing materials.

The crate is made of coniferous boards (mainly pine). The thickness of the boards is at least 30 mm. This is the minimum gap that will ensure the normal movement of air in the under-roof space. Before laying, the wood must be treated with an impregnation that protects against pests and fungi; after drying this layer, it is also treated with flame retardants, which reduce the combustibility of wood.

The minimum length of the board for the crate is at least two spans of rafters. They are attached and connected above the rafter legs. You can't connect them anywhere else.

Flooring

The flooring under soft tiles is made solid. Materials are selected based on the fact that nails must be driven into it, therefore they are usually used:

- OSB 3;

- moisture resistant plywood;

- tongue-and-groove or edged board of the same thickness (25 mm) with a moisture content of not more than 20%.

When laying flooring under soft tiles, it is necessary to leave gaps between the elements to compensate for thermal expansion. When using plywood or OSB, the gap is 3 mm, between edged boards 1-5 mm. Sheet material is fastened with a run-out of seams, that is, so that the joints are not continuous. Fasten the OSB with self-tapping screws or ruffed nails.

Using boards as flooring, it is necessary to ensure that the annual rings of the wood are directed downwards. With the reverse arrangement, they will be arched, soft tiles will be lifted, the tightness of the coating may be broken. There is another trick that will keep the wooden flooring even if the moisture content of the boards is above 20%. When laying the ends of the boards, they are additionally fastened with two nails or self-tapping screws hammered close to the edge. This additional fastener will prevent the boards from bending during shrinkage.

The choice of the thickness of the material for flooring under soft tiles depends on the pitch of the crate. The larger the pitch, the thicker the flooring required. The best option is a frequent step and thin plates. In this case, a light but rigid base is obtained.

Another point concerns the installation of flooring for soft tiles around the chimney pipe. With a brick pipe, the width of which is more than 50 cm, a groove is made behind it (pictured). This design, reminiscent of a mini-roof. It separates the rain streams, they roll down the sides of the pipe without flowing into the under-roof space.

After installing the flooring, its geometry is checked. The length is measured, the width of the slope at the top and bottom, the height of the slope on both sides, the diagonals are measured. And the last check - tracking the plane - the entire slope must lie entirely in the same plane.

Soft tile roofing technology

When buying, you will most likely be provided with instructions, to which the installation of soft tiles will be described step by step and in detail, indicating all the exact dimensions that this particular manufacturer requires. These recommendations should be followed. However, it is worth getting acquainted with the order of work and their volumes ahead of time - in order to understand the intricacies of installation and the required amount of materials.

We must say right away that it is necessary to handle soft tiles when laying carefully - she does not like it if she is bent. Therefore, try not to bend or crush the shingles unnecessarily (this is one fragment consisting of a visible and mounting part).

Overhang reinforcement

The drip bar is installed first. This is an L-shaped sheet of metal coated with paint or polymer composition. Polymer coating is more expensive, but also more reliable. The color is selected close to the color of bituminous tiles.

Drip bar installed along the roof overhangs

The task of the drip bar is to protect the crate, sections of rafters and flooring from moisture. With one edge, the dropper is laid on the flooring, with the second it closes the overhang. It is fastened with galvanized (stainless steel) nails, which are hammered in a checkerboard pattern (one is closer to the fold, the second is almost at the edge). Fastener installation step - 20-25 cm.

The drip bar is sold in two-meter pieces. Having laid the first element, the second is fixed with an overlap of at least 3 cm. If desired, the gap can be closed: grease the joint with bituminous mastic, fill it with sealant. At the same stage, it is mounted, in any case, hooks are nailed that will hold the gutters.

Laying waterproofing carpet

Regardless of the angle of the roof, a waterproofing lining must be laid in and along the slope. It is sold in meter wide rolls. An adhesive is applied to the underside, covered with a protective film or paper. Before laying, the paper is removed, the valley carpet is glued to the flooring.

Installation of a waterproofing carpet begins with laying it in the valley. Roll out the material of a meter width, distributing 50 cm on both sides of the bend. Here it is desirable to do without joints, but, if necessary, the overlap of two canvases should be at least 15 cm. Laying goes from bottom to top, the junction is additionally coated with bitumen mastic, the material is well pressed.

Next, a waterproofing carpet for flexible tiles is laid along the cornice overhang. The minimum width of the carpet on the cornice overhang is the size of the overhang itself, plus 60 cm. First, the carpet is rolled out, if necessary, cut, then the protective film is removed from the inside and glued to the substrate. Additionally, they are fixed along the edges with stainless steel or galvanized nails with a large flat hat (step 20-25 cm).

In places of a horizontal joint, the overlap of two canvases is at least 10 cm, in the vertical direction - at least 15 cm. All joints are additionally coated with bituminous mastic, the material is compressed.

Lining carpet

The lining carpet, as well as the waterproofing carpet, is sold in rolls of meter width, the back side is covered with an adhesive. The laying method depends on the slope of the roof and on the profile of the selected shingles.

When using shingles with cuts (such as Jazz, Trio, Beaver tail), regardless of the slope, the lining carpet is spread over the entire surface of the roof.

Underlayment installation often requires undercutting. This is done with a sharp knife. In order not to damage the material below when cutting, enclose a piece of plywood or OSB.

Fronton (end) plank

Gable strips are mounted on the side sections of the overhangs. These are strips of metal bent in the form of the letter "G", along the fold line of which there is a small protrusion. They cover the laid roofing materials from wind loads, from moisture ingress. The gable plank is laid on the flooring over the lining or waterproofing carpet, fixed with nails (stainless steel or galvanized) in a checkerboard pattern with a step of 15 cm.

These planks also come in pieces of 2 m, stacked with an overlap of at least 3 cm.

Slope marking

To make the installation of soft tiles simple, markings in the form of a grid are applied to the lining carpet or flooring. Do this with a painter's cord. The lines along the cornice overhang are applied at a distance equal to 5 rows of tiles, in the vertical - every meter (the length of one flexible tile shingle). This marking makes laying easier - the edges are leveled along it, it is easier to track distances.

Valley carpet

On top of the already laid waterproofing carpet, another valley material is laid. It is slightly wider, serves as an additional guarantee of no leaks. Without removing the protective film from the underside, it is laid, cut at the bottom in the overhang area, and the boundaries are marked. Deviating from the mark of 4-5 cm, a special mastic of increased fixation Fixer is applied. It is applied from a syringe, with a roller, then rubbed with a spatula into a strip about 10 cm wide.

A valley carpet is laid out on the mastic, the folds are smoothed out, the edges are pressed. Stepping back from the edge by 3 cm, it is fixed with nails in increments of 20 cm.

Connection to a brick pipe

To bypass pipes and ventilation outlets, patterns are made from a valley carpet or galvanized metal, painted in the appropriate color. The surface of the pipe is plastered, treated with a primer.

When using a valley carpet, a pattern is made so that the material enters the pipe by at least 30 cm, and at least 20 cm should remain on the roof.

The pattern is smeared with bitumen mastic, placed in place. the front part is installed first, then the right and left.

Part of the side elements is wrapped on the front part. The back wall is installed last. Its parts go to the side.

With proper installation on the flooring around the pipe, a platform is obtained, completely covered with a valley carpet. Before laying tiles in this place, the surface is smeared with bituminous mastic.

The tile from three sides enters the laid carpet, not reaching the walls of the pipe 8 cm.

The upper part of the junction is sealed with a metal strip, which is attached to the dowels.

All gaps are filled with heat-resistant sealant.

Conclusion of round pipes

For the passage of ventilation pipes there are special passage devices. They are positioned so that the lower edge of the element extends over the tile by at least 2 cm.

Having attached the passage element to the roof, its inner hole is circled. According to the applied contour, a hole is cut in the substrate, into which a round pipe is led out.

The back of the skirt of the passage element is smeared with bituminous mastic, set to the desired position, and additionally fastened around the perimeter with nails. When installing soft tiles, the penetration skirt is smeared with mastic.

The shingle is cut as close as possible to the ledge of the penetration, the gap is then filled with mastic, which is covered with a special UV-protective dressing.

starting strip

The installation of soft tiles begins with the laying of the starting strip. Usually it is a ridge-cornice tile or an ordinary one with cut petals. The first element is laid on one of the edges of the slope, going to the edge of the gable plank. The lower edge of the starting strip is laid on the drip, stepping back from its fold 1.5 cm.

Before installation, the protective film is removed from the back, the shingle is leveled and laid. Each section of bituminous tiles is fastened with four nails - at the corners of each fragment, stepping back from the edge or perforation line 2-3 cm.

If a cut from an ordinary tile is used as a starting strip, in some part of it there will be no adhesive composition. In these places, the substrate is smeared with bituminous mastic.

Installation of soft ordinary tiles

There is a flexible tile with an applied adhesive mass, protected by a film, and there is a composition that does not require a protective film, although it also fixes the elements well on the roof. When using the first type of material, the film is removed immediately before installation.

Before laying bituminous tiles on the roof, several packs are opened - 5-6 pieces. Laying is carried out from all packs at the same time, taking one shingle from each one in turn. Otherwise, there will be pronounced spots on the roof that differ in color.

The first shingle is laid so that its edge does not reach the edge of the starting strip by 1 cm. In addition to the adhesive composition, the tiles are also fixed with roofing nails. The number of fasteners depends on the slope angle:

When installing soft tiles, it is important to drive in nails correctly. Hats should be pressed against the shingle, but not break through its surface.

Valley design

With the help of a paint cord in the valley, an area is marked in which nails cannot be driven in - this is 30 cm from the middle of the valley. Then mark the boundaries of the gutter. They can be from 5 to 15 cm in both directions.

The upper corner, which is turned towards the valley, is cut

When laying ordinary shingles, nails are driven in as close as possible to the line beyond which nails cannot be hammered, and shingles are trimmed to the floor of the gutter laying line. To prevent water from flowing under the material, the upper corner of the tile is cut obliquely, cutting off about 4-5 cm. The loose edge of the tile is smeared with bituminous mastic and fixed with nails.

Decoration of the pediment

On the sides of the slope, the tiles are cut so that 1 cm remains to the edge (protrusion) of the end plank. The upper corner of the shingle is cut in the same way as in the valley - a piece of 4-5 cm obliquely. The edge of the tile is smeared with mastic. A strip of mastic - at least 10 cm. Then it is fixed with nails, like the rest of the elements.

If the flooring in the area of the ridge is made solid, a hole is cut along the ridge, which should not reach the end of the rib 30 cm.

It is fixed with long roofing nails. On a long skate, several elements can be used, they are joined end-to-end. The installed metal ridge is covered with ridge tiles. A protective film is removed from it, then the fragment is fixed with four nails (two on each side). The installation of soft tiles on the ridge goes towards the prevailing winds, one fragment overlaps the other by 3-5 cm.

The ridge tile is a ridge-eaves divided into three parts. A perforation is applied on it, a fragment comes off along it (first bend, press the fold, then tear off).

The same elements can be cut from an ordinary tile. It is divided into three parts, not paying attention to the drawing. At the resulting tiles, a corner is cut off - about 2-3 cm on each side. The middle of the fragment is heated with a building hair dryer on both sides, placed in the middle on a bar and, gently pressing, bend over.

Ribs and kinks

The ribs are covered with ridge tiles. A line is beaten off along the bend at the required distance with a masking cord. The edge of the tile is aligned along it. Laying of flexible tiles on the edge goes from bottom to top, each fragment is glued, then stepping back from the top edge of 2 cm, fixed with nails - two on each side. The next fragment comes to the laid 3-5 cm.

It is unlikely that there will be such an owner who refuses to have the roof of his house covered with reliable, but at the same time affordable roofing material. And if you plan your own installation correctly, then the structure will not only be well protected from possible damage and bad weather, but will also significantly save a significant amount of money.

Similar qualities are possessed by an innovative material, which is a flexible tile with a bituminous base (it is also called roofing tiles). Of course, such a roof cannot be called the easiest for self-production. However, it is not the most difficult either. One has only to understand the technological intricacies of installation, and the high-quality performance of such work will be quite real.

innovative material

The flexible tile represents the small sizes flat sheets. This one has one curly edge. Its basis, as a rule, is fiberglass or fiberglass. However, there are types that are made on organic cellulose, that is, felt. The basis of such a roofing material is coated on both sides with an impregnating composition, the main component of which is bitumen.

The front part of the flexible tile is sprinkled with a basalt granulator painted in a certain color. Sometimes mineral chips act as a dye. This or that color of a tile is given by special technologies thanks to which it remains within many decades. The powder present on the roofing tiles gives it a more beautiful look, and also protects the surface from various atmospheric phenomena, increases its wear resistance and neutralizes the negative effects of ultraviolet radiation.

Sometimes it happens that in some places the dressing simply disappears. Such a defect occurs only with materials from the economy segment, moreover, it is easy to eliminate it with glue and mineral chips of the appropriate color.

Positive characteristics and disadvantages

Flexible tiles can be laid on single and multi-pitched roofs. Due to the fact that this material is small in size and has plasticity, it is simply indispensable for the arrangement of roofs of complex shapes (multi-pitched, domed, round). In addition, this coating looks great on buildings of various styles of architecture.

Among the positive qualities of flexible tiles are:

- durability (about 30 years);

- a significant operating temperature range, which allows the use of such material in both southern and northern countries;

- resistance to ultraviolet radiation;

- undemanding to special care;

- ease of installation, which allows you not to involve specialists;

- light weight, which can easily withstand the rafters of a small section;

- a small amount of waste remaining after installation;

- high degree of maintainability;

- good adaptability to the change in the geometry of the building that occurs during its shrinkage;

- the ability to withstand strong gusts of wind (with additional reinforcement by 6 nails);

- good heat-saving and soundproofing properties;

- resistance to acids, as well as to the negative effects of lichens, mosses and fungi.

Among the shortcomings are:

- high price;

- greater consumption of materials required for arranging the crate.

How to get started with roofing?

Soft material for roofs is used for slopes with a slope above 12 percent. If the roof is flatter, then there is a high probability of leakage at the joints. How to lay flexible tiles in this case, if there is a desire to use it?

With small slopes of the roof, it is necessary to spread a continuous special lining carpet on the crate, which helps protect the top layer from moisture.

In recent years, soft material has gained great popularity. However, not all developers know how to lay shingles. The instruction for its installation explains that such material should be placed on the crate, which differs from the usual one arranged for metal tiles or ondulin.

A kind of foundation designed for flexible tiles is Mauerlat. The truss system is based on it.

How to lay flexible tiles? It should be borne in mind that these do not like bumps, height differences, unnecessary bends and protruding nails. In this regard, the Mauerlat bars must be laid strictly horizontally. At the same time, for the lines that connect the ends of the Mauerlats at the ends of the building, an angle of 90 degrees must be observed.

How to lay flexible tiles? For it, it is necessary to prepare either a solid base, or knock down a crate with gaps of no more than 0.5 cm. This is where the difference between this system and any similar one ends. Otherwise, an exemplary roofing pie made of flexible tiles consists of a vapor barrier film laid on the rafters, on top of which a heater follows. Next, a waterproofing film, OSB board and underlayment are placed on the roof. The whole structure is completed with a soft roofing material.

How to lay flexible tiles on an iron roof? To do this, you need to level its surface. Of course, flexible tiles can be laid on top of existing material, but in this case, its crests will be visible visually, and the presence of air gaps near them will reduce the life of soft tiles. Using the option of leveling the surface, a crate of laths or OSB sheets is laid on top of the iron.

The bases for roofing material can be different. Let's consider them in more detail.

Solid crate

This is the first version of the base, which is made of grooved or edged boards, fastened end-to-end or with small gaps. It is desirable that whole boards be laid without splicing. If such an arrangement is not possible, the joints should be located above the rafters with careful fixing of the edges. When solving the question “How to lay flexible tiles?”, height differences should not be allowed. Otherwise, the tiles laid on such boards will accumulate water, and therefore there will be a high probability of its leakage.

Arrangement of plate material

The base for flexible tiles can be done differently. In this case, slab material must be laid on the crate made of unedged or edged boards. It can be moisture resistant OSB, DSP, GVL boards or plywood. The thickness of such sheets should not be less than 9 mm.

How to lay shingles on OSB and other boards? According to the instructions, such a substrate must be fastened so that the seams located in one row must be overlapped by another. In order to compensate for expansion during temperature fluctuations, a small gap (from 3 to 5 mm) can be left between adjacent sheets.

Features of mounting the crate

How to lay flexible tiles? Due to the fact that the material is not affected by mold and fungi, it does not deteriorate or rot. However, it is laid on wood, which is damaged by high humidity. What needs to be done in this regard? All wooden structures must be treated with antiseptic impregnations. However, this is not all.

In order for wood to serve for many years, it must be subjected to natural ventilation. For this, gaps of 5 mm must be left between the waterproofing layer and the base under the roof slabs. Sometimes for this they arrange a counter-lattice, to which the base is attached. In addition, special ventilation holes are made around the perimeter of the roof, placing them in overhangs. To prevent birds and insects from entering such holes, they are covered with nets.

Features of work at different times of the year

How to lay flexible tiles? It must be installed on a clean, dry and level surface. In this case, the work is carried out in several stages. It is desirable to start them in the warm season, when the air temperature is more than five degrees above zero. This will allow the coating to become airtight, which will create certain conveniences in work. It is desirable to comply with such a condition because when sunlight hits the material, the bitumen heats up. This process allows it to fuse with the plates into a single whole. Only in this case, the coating, which consists of individual sheets, turns into a monolith.

How to lay shingles in winter? If it is necessary to carry out work in the cold season, it will be necessary to use infrared heaters or heat guns. Only in this case it will be possible to heat up the material so that the installation conditions are close to summer ones. But you should not lay flexible tiles in severe frosts, even if heaters are at hand. In order to avoid downtime in work, you can do the installation of building structures of the roof, the installation and installation of thermal insulation.

Additional waterproofing

This is the first stage of installation of flexible tiles. A layer of additional waterproofing is laid in valleys, along overhangs, as well as in places adjacent to the building, on ridges and dormer windows. Such a layer will serve as additional insurance against leaks in places where the greatest accumulation of water will be observed.

Fasten the waterproofing carpet with roofing nails in increments of 40 cm. Along the lower edge, this distance should be more frequent (10 cm). The second layer must be laid on top of the first layer. In places where there is an abutment with a wall or pipe, the material should go on them by 5-10 cm.

This task is not faced by those who solve the question "How to put flexible tiles on the gazebo with your own hands?". After all, the pipe in this case simply will not be.

and end strips

This is the second stage of the ongoing work on laying shingles. It is necessary to protect the ends and cornices from water leakage. To preserve the material of the roof, it is necessary to fill the cornice strips along the entire roof overhang. They are fastened with nails, which are hammered every 10 cm. Moreover, one of them should be located at the bottom of the plank, and the second - along its top, and so on. Neighboring planks are stacked with an overlap of 5 cm.

The end strips are arranged according to the same scheme and with the same interval. Their installation begins at the bottom of the roof with a gradual movement towards the ridge.

Laying the valley carpet

In places where the roof slopes are joined (in the valleys), a special protective carpet should be placed. It has a greater thickness than a waterproofing coating, due to the required protection of the slopes, where significant water flows pass. The valley carpet should be rolled out from top to bottom and nailed every 10 cm. Such a coating is also important when the question “How to put flexible tiles on the roof of an octagonal arbor or any other with a multi-pitched roof?” Is solved.

Fixing the eaves

Consider the fourth stage of laying shingles. This material is similar to the main one, but does not have a curly lower part. The cornice strip is the starting one and is designed to form an even lower edge along the entire perimeter of the overhang. The work of this stage should not be missed by those owners who decide the question “How to lay flexible tiles on the gazebo?”.

There is a protective film on the wrong side of the strip. It must be removed and this element placed, stepping back from the bend of the cornice strip 1-2 cm. After laying, the strip must be pressed. Then it is nailed in places of perforation and along the edges.

Installation of tiles

This is the fifth stage of the roofing work. Pre-prepared packages with tiles should be under a canopy or indoors. During installation, they are transferred to the building under construction. It should be borne in mind that the material in different packs, as a rule, is slightly different in color. In this regard, it is recommended to open 4-6 packages at the same time. You need to take sheets from them alternately. In this case, the roof will turn out to be more voluminous, and stripes of different shades will not be particularly visible. This condition must also be met in the case when the question “How to put flexible tiles on a hip roof?” Is being solved.

Laying the material starts from the center, gradually moving to the ends. The lower edge of the first row of tiles is placed on the same level with the cornice strip. The upper edge of the flexible tile should cover such a strip for several centimeters.

Skate

This is the final stage of installation of flexible tiles. The ridge is closed after all the slopes are completely covered with roofing material.

At this stage, either a special tile is used, or an ordinary tile is cut into separate fragments. The second option is cheaper, because the price of a special ridge tile is twice as high as the usual one.

Installation work is carried out in stages, in several steps, each of which is fundamentally important for the quality of the entire roofing system.

Preparatory work

No matter how reliable the soft roof coating is, the roof can “go” or leak if the fastening is done without proper preparation. Therefore, preliminary work before laying the roof is very important and should be carried out by professionals in several stages.

Creating a truss system

The rafters bear the main load from flexible tiles, so you need to make the right calculation, taking into account the weight of the roofing cake, wind and snow exposure.

Advice. Securely fasten the rafter legs, treat the wooden elements with special protective agents to increase the reliability of the structure.

Vapor barrier device

After installing the rafters, it is necessary to lay a vapor barrier film that will protect the roofing cake and insulation from condensation. The film is overlapped, and the resulting seams are glued with adhesive tape.

Warming

In order for the thermal insulation to hold securely, a bar must be nailed between the rafter legs, which will hold the insulation plates. Thermal calculation will help to choose the correct thickness of the insulation. Heat-insulating boards are laid apart, covered with a wind and moisture protective film, which is fastened with a counter beam.

Advice. The counter beam must be nailed parallel to the rafters to create a free ventilation channel to remove excess moisture from the under-roof space.

Installation of bituminous tiles should be carried out only on a flat solid base, which is preferably used as a crate and solid flooring made of moisture-resistant plywood or OSB. Boards are fixed with special galvanized nails.

After laying the base, preparation for the installation of a soft roof is completed - you can proceed to the main work.

Bituminous roof installation: materials used

When installing bituminous shingles, we recommend using high-quality materials of the IKOPAL brand, which are produced in accordance with European standards and are certified according to Russian standards. To install a soft roof, you will need the following materials.

Roof covering includes:

- SBS-modified with fiberglass backing with colored slate topping;

- a ridge-eaves strip of a similar composition for arranging cornices, ridges, ribs;

- valley carpet - a rolled protective material that is used to reinforce soft welded roofing in valleys and other vulnerable places;

- underlayment carpet - rolled waterproofing, the installation of which is an obligatory stage in the installation of the roof.

Advice. The lining carpet is laid over the entire surface of the roof from the bottom up parallel to the cornice overhang. Avoid wrinkling!

Additional components/materials

- Metal junction strips, gable strips, droppers are needed to remove moisture from the edges of the roof, giving it a complete appearance.

- Fastening bituminous tiles is impossible without special galvanized nails with a cap size of 8 mm.

- Mastic and adhesive-sealant "IKOPAL" are used for sealing junctions, overlaps, other knots and seams.

- Elements such as deflectors, under-roof fans or pipe flanges provide ventilation systems to the roof.

- The IKOPAL gutter system, which includes gutters, brackets, funnels, elbows, fasteners, allows you to effectively drain outside water.

vapor barrier

The instruction for the installation of the roof indicates the need to create a reliable vapor barrier layer. As a vapor barrier, it is worth using a durable four-layer reinforced ICOPAL Polycraft membrane, which not only protects against condensate, but also effectively reflects heat, reducing energy costs.

Advice. Lay the vapor barrier with an overlap of 100-150 mm and seal with double-sided tape.

thermal insulation

The installation of bituminous tiles involves the use of such heat-insulating material as non-combustible mineral wool with a density of 30 kg / m3.

Windproof membranes

ICOPAL Monarperm hydro-windproof membranes help to protect the insulation from wind and water, which are laid on top of the thermal insulation without a ventilated gap.

Do not try to save money on bituminous roofing materials, as this will lead to a deterioration in quality and a reduction in the life of the roofing without repair.

Laying roofing material: installation instructions

The preparatory measures have been taken, the base for the roof is ready - which means that you can proceed directly to the installation of flexible tiles.

1. We mount the lining carpet

First, we lay a special waterproof layer on the finished even base - the lining carpet "IKOPAL" K-EL or "Felix". We unfold it from the bottom up parallel to the cornice overhang, fix it to the base along the upper edge every 40 cm, along the bottom - every 10 cm. We seal the overlaps with mastic.

2. We mount the strips

On the lining carpet with roofing nails we nail the eaves and end strips along the zigzag markings. The overlap is 3-5 cm, the step between the nails is 10 cm.

3. We mount the cornice strip

We remove the protective film from the ridge-cornice strip, step back from the bend of the cornice strip 10-20 mm, fix the strip butt-to-butt. In places of perforations and along the edges we nail.

4. We mount the valley carpet

Carpet to protect the valley is mounted in two layers: the top one matches the color of the main coating, and an additional layer of lining carpet is used as the bottom one. It is fastened with nails in 20 cm increments. The valley carpet is laid in the direction of the axis of the valley with the edges fixed every 10 cm.

Advice. In order not to damage the valley carpet when cutting off the flexible tile, a plywood sheet should be placed under it.

5. We mount ordinary shingles

|

|

In order to avoid visual defects during the installation of a soft roof, it is recommended to mix the shingles from four or six packs before laying to balance the shade. After that, you can proceed directly to covering the roof with shingles.

Installation of the roof starts from the middle of the cornice overhang and moves towards the ends. To lay the first row, we retreat 1 cm from the lower edge of the cornice shingles and fasten the lower edge of ordinary petals on this line, having previously removed the lower protective film from the shingles. Fastening is carried out with four or six (with a large slope) nails per shingle.

Advice. When using rectangular shingles, the number of nails should be increased to 5 on flat roofs and 7 on pitched roofs greater than 45 degrees.

With further installation of ordinary tiles, we make sure that the petals of each subsequent row coincide with the cutouts of the previous one. In the area of \u200b\u200bthe ends, we cut the shingles along the edge, glue them to the end plank with mastic, and seal the seams with the appropriate adhesive.

Installation of tiles in hard-to-reach places

Particular attention and control is required for the installation of a soft roof in areas adjacent to a wall or chimney, in the area of openings for laying pipes, communications, and on a roof ridge. Failure to follow the laying technology in these places can damage the tightness and appearance of the coating.

The main rule when installing installation passages or installing a soft roof on lifting strips when installing chimneys is to fix the shingles with bituminous mastic and be sure to seal the seams with IKOPAL glue-sealant.

For the installation of ridge tiles, tiles of the ICOPAL Combi ridge and eaves strip 25 by 33 cm in size are used. The latter is laid parallel to the ridge, bending over the slope, then fixed with two nails on each side.

The overlap when laying ridge tiles should be 5-10 cm and cover the fasteners of each previous element. The final tile is fixed with mastic.

Advice. Dividing the IKOPAL ridge-cornice strip into separate tiles is easy: just break it into three parts in places with perforations.

Summary

Step-by-step installation instructions for flexible tiles will allow you to create a reliable, durable, beautiful roofing that will protect the building from leaks and atmospheric influences for a long time.

Proper laying technology, together with the use of quality materials from the manufacturer ICOPAL, will ensure long-term preservation of the operational and aesthetic characteristics of the roof.