How to finish an iron staircase. Finishing stairs with wood: metal cladding and cladding, do-it-yourself wooden frame and steps

The combination of metal and wood is considered the most spectacular design solution for interior design. External attractiveness and amazing strength, variety of stylistic and color solutions, a sense of extraordinary grace and elegance determine the incomparable success of metal stairs decorated with wood. An endless flight of fantasy and a true work of art.

Wooden staircase on a metal frame: the main figure of a modern interior

The modern staircase design can be safely called the key final figure of a private or country house and a bright, expressive accent of the chosen stylistic direction.

Metal stairs, decorated with natural wood and forged elements, undoubtedly, give the interior a noble, respectable look. Countless configurations, modern manufacturing techniques and a harmonious combination of durable metal and natural wood open up wide scope for designers to bring ideas to life.

Metal staircases with wooden elements have excellent performance and longer service life compared to wooden counterparts, while the weight, due to the design of natural wood, is noticeably less than that of all-metal or concrete structures.

In designs of this kind, the main advantages that metal and wooden stairs are endowed with are surprisingly combined. Full of grace, the metal staircase structure with original wooden steps is light and swift, at the same time it is reliable and able to withstand enormous loads during the entire service life. Metal gives the structure increased strength and durability, and wooden steps - safety and comfort of movement, ease of descent and ascent of absolutely everyone for family members.

Traditionally, light but strong grades of metal with a characteristic increased resistance to corrosion act as a material for the manufacture of a metal base. Depending on the design project and the wishes of the customer, the technology for creating stairs on a metal frame with wooden elements can involve both full and partial wood cladding of metal surfaces.

Finishing a metal staircase: the choice of materials

Facing a metal staircase with a natural array is a very ambivalent process in many respects: facing can be the most budget option, or, conversely, the most expensive. It is the material that you will use for facing the structure that determines the final result - whether it will be a very modest, cozy staircase or whether you like a graceful and respectable structure.

Depending on the developed design project and the estimated budget, you can veneer with wood either only the steps, or the steps together with the risers.

At the same time, it should be noted that choosing a natural array for facing, you will not lose. No other material can bring more warmth, natural freshness and harmony into the interior than natural wood. Among other things, wood is famous for its increased sound and heat insulation, impact resistance, durability, and, finally, visual appeal.

The most important parameter that is taken into account when choosing wood is moisture, the degree of which has a direct impact on the performance properties of wood. Excess moisture significantly reduces the strength of wood, therefore, before the production of elements and parts for your staircase, the wood should be dried until the moisture level is within the acceptable range, otherwise you may experience swelling of wooden products during operation.

The humidity of a freshly cut tree is 35-100%. But if facing work is to be done, then the moisture content of the wood should not exceed 12%.

So, how to finish a metal staircase?

The most popular for cladding work are walnut, oak, beech, pear, cherry, ash, mahogany wood.

oak wood attracts with increased strength and durability, rich colors: from pale yellow to red-brown tones. When facing a metal staircase with oak, one feature should be taken into account: over time, the oak array darkens a little, acquires a deep noble color.

Ash solid wood as strong as oak. The wood has a pronounced texture and a noble grayish tint.

Beech symbolizes elegance and sophisticated style. Beech wood is distinguished by visual appeal, uniform texture and durability. Excellent for imitation mahogany.

Great effect can be obtained when using exotic woods - wenge, teak, merbau. Incredible color palette: lemon yellow tones, deep purple, deep red, brown and black! Even the richest imagination will not convey the variety of color shades that nature has bestowed on trees growing in exotic corners. In addition to color superiority, stairs lined with exotic species are highly durable and durable.

For the manufacture of risers, experts recommend using pine, spruce and fir.

Pine it is characterized by good performance properties and, due to its low density, it is easy to process it. The cost of structures lined with such material is much lower than hardwood analogues.

After decorating the stairs with wooden elements, they can be tinted in any color, or you can simply process them with a special compound, which will prevent wood cracking and rotting in the future.

However, you can, on the contrary, emphasize the natural texture and relief of the material, natural shade. It is enough just to use some decorative techniques: for example, using a grinder with a metal brush, you can “comb” wood with soft and hard fibers. In the process, the soft fibers are removed with a brush, while the hard ones form an interesting embossed pattern.

Then, using special paints and varnishes, the steps are given the desired shade and the surface is carefully cleaned with a grinder. This should be done delicately to slightly emphasize the special texture of the wood. As a result, the paint remains exclusively in the recesses.

Features of sheathing metal stairs with wood

The creation of stair structures on a metal frame is a creative process, which, in addition to skill and knowledge, requires a highly artistic taste. The most popular and common way of cladding is to fasten wooden steps to a metal staircase.

The remaining visible details of the metal frame are to be painted in a suitable color, so that the finished staircase design harmoniously fits into a private or country house.

If the design project involves the implementation of a full sheathing of a metal frame, then you have to perform a whole range of works on sheathing with a natural array of steps and risers, under-stair space, to imitate a bowstring made of wood or a braid.

After such a disguise, your metal staircase will become visually indistinguishable from a wooden counterpart.

Ladders on a metal frame, lined with wood, are unpretentious in installation and operation. Experts distinguish between several installation methods. If you decide to build a wooden staircase on a metal frame yourself, then pay attention to the stairs from ready-made prefabricated modules. Such structures are separate elements assembled into flights of stairs and fixed to each other in accordance with the attached instructions. Typically, such modules are manufactured in the factory in accordance with the rules and regulations of GOST for metal and wooden stairs.

It should be noted that the guarantee of the safe operation of any ladder structure is a periodic inspection for the timely identification and elimination of possible problems.

Wood finishing technology for metal stairs

Metal stairs sheathed with wood are not only a highly artistic element of the interior, but also a stylish architectural structure, for the manufacture of which it is necessary to strictly comply with all technological standards. Turning to specialists with high qualifications and experience, you can get real masterpieces of design art that will delight you for decades. However, you can do the finishing of a metal staircase with your own hands, having carefully studied the technology of the process, with a little perseverance and diligence.

To sheathe a metal staircase with wood, you will have to perform several steps:

1. choose the design of the future staircase structure and the method of cladding the metal frame with wood: whether only steps will be sheathed, or steps with risers, wooden railings and balusters;

2. decide on the type of wood for sheathing;

3. prepare the elements and details of the skin. To do this, you will have to adjust the array to the dimensions of the frame, excluding the occurrence of cracks. After careful measurements, cut out the wooden parts of the steps and number each one;

4. choose the most suitable type of balustrade. Fences on the steps, in addition to their protective function, are also quite an effective decorative element of the staircase structure. Since railings can have different sections, you should choose the most convenient and comfortable shape for your palm. To ensure the safety of moving up the stairs, it is extremely important to consider the location of the balusters. Usually the interval between them is 90 mm, 130 mm or 220 mm;

5. fasten the wooden elements. Armed with a screwdriver, fix the steps at the top. Then press the risers as tightly as possible into the frame and secure them. Follow the same steps along the entire length of the ladder structure.

Steps on which wooden elements slightly protrude beyond the metal surface look great. Use only hard woods for overlays. Chamfering around the entire perimeter of the wood panel and creating a rounded shape in the corners will help you avoid chipping of the cladding.

Place balusters along the edges of the steps from the beginning to the end of your stairs. After checking the verticality, fix the balusters with special pins and fix the railings on them;

6. Completely sew up the frame. With a wooden panel cut in advance in the form of steps, sheathe the side of the stairs. After sheathing the risers and steps, proceed to the design of the marches of the rear of the metal structure. To do this, you will need drywall sheets. At the end of the work, apply varnish or paint to all wooden elements.

So, a metal staircase, sheathed with wood, is considered universal, but far from the only architectural solution for private and country multi-level houses. For example, a wooden staircase with metal balusters can refresh the interior of a room.

In the manufacture of staircases, metal and wood can be successfully combined in the most unexpected combinations. And you just have to choose the most suitable option that will fully meet the aesthetic, functional and financial requirements.

You can learn more about how to sheathe a metal staircase with wood by watching a video on youtube.

A metal staircase is one of the varieties of such structures, which is distinguished by its strength, reliability and durability. Such structures are installed both outside buildings and inside a residential building, providing a comfortable lift to the second floor, attic or attic. Ladders on a metal frame today are presented in various configurations, because thanks to modern technologies, any, even the most complex shape, can be made from metal.

However, without finishing, such structures cannot be considered complete. A bare frame is not yet a full-fledged staircase. On the modern market there is a large selection of finishing materials. Wood has gained the most popularity. It is this natural material that is in perfect harmony with cold metal, opening up the widest scope for designers to bring their ideas to life.

Design features

The metal frame is a strong base for the stairs. For its manufacture, light, but at the same time durable metal alloys are used that are not subject to corrosion, wear and deformation. Such structures can be of any shape, the most common are marching and screw models.

Before you opt for this particular type of staircase, you should familiarize yourself with their main features and weigh all the pros and cons:

- Stairs on a metal frame are only slightly more expensive than similar wooden ones, but cheaper than concrete monolithic structures.

- The metal base can be combined with other materials, and wood paneling is the best solution.

- You can also note the absence of creaking steps. For these models, metal acts as a supporting support, the frame elements are tightly connected by welding.

- Unlike completely wooden stairs, metal structures last a long time. The elements are not exposed to moisture, and the connections do not become loose from intensive use.

- Making an iron staircase with your own hands is carried out in two stages: installing a metal frame at the stage of construction of the building and finishing with wood after the interior decoration of the whole house.

Frame sheathing material

To finish the metal staircase with your own hands, you can use different types of wood. From the specific choice will depend on what kind of design you end up with - a budget option or an expensive interior element. Also, the choice of wood largely determines the performance of the future product - whether it will be a modest staircase for infrequent use or an impact-resistant model with high heat and sound insulation.

Sheathing stairs on a metal frame can be made of such types of wood as:

- Oak. Renowned for its strength and durability. It is presented in a wide range of colors: from light yellow to red-brown shades. This wood also has one feature - over time, the array darkens a little, acquiring deep and noble tones.

- Ash. Not inferior to its predecessor in terms of strength. It has a grayish tint and a unique fibrous pattern, the structure of this wood is more porous than oak.

- Beech. The rock is hard and dense, but easy to process. It has a beautiful and clear texture with veins. Figured and bent elements are most often made from beech.

- Coniferous breeds. Cedar, pine, larch are often used for sheathing stair structures. Pine is the cheapest, but it does not have high performance. Such materials are used for sheathing only in those places where there is no need to use more expensive and durable wood.

- exotic breeds. These include wenge, teak and merbau. Their main plus in a variety of colors: from lemon yellow to deep purple, rich red and black tones. In addition to aesthetic appeal and decorativeness, they are durable and have a long service life.

For tinting wood sheathing, wood stain is most often used. If you want to save money, choose any of the affordable options. The main thing is that it should be a light wood species.

Criteria for choosing a metal staircase finish

Facing an iron staircase structure with wood is, to a greater extent, a decorative design of the frame. However, it is still necessary to choose such finishing materials that would significantly improve the technical characteristics of the future product. At the exit, you should get a strong, comfortable and safe staircase in operation.

To choose a quality facing material, you should pay attention to the following criteria:

- The maximum allowable moisture content of lumber should not exceed 12%. Poorly dried wood is often the cause of deformation of the staircase or its elements.

- There should be no cracks, chips or other defects on the surface of the material. Choose only smooth wood, one that has been sawn on good machines.

- There should not be too many knots in the tree structure. Otherwise, the material will be difficult to process, and this is a lot of labor.

- The choice of sheathing also depends on the location of the metal staircase - in the living room, occupying the central part of the room, or in the utility part. After all, the aesthetic characteristics of different breeds are not the same.

Choose only high-quality and well-dried wood

Choose only high-quality and well-dried wood On the video: how to choose the material and accessories for the stairs.

Steel structure sheathing technology

When you have decided on the wood and purchased lumber for cladding in the right amount, you can proceed with the installation. But before that, it is necessary to make accurate calculations and prepare tools, without which it is impossible to finish the stairs.

Required tool

To sheathe a metal staircase with wood with your own hands, you will need the following list of tools:

- perforator and screwdriver;

- electric jigsaw for sawing material;

- planer, file, sandpaper;

- hammer, rubber mallet, pliers;

- tape measure, building level;

- set of wrenches, self-tapping screws.

Preparatory work

To sheathe a metal staircase, it is not enough just to acquire the necessary tools. From correctly performed preparatory work will depend on how reliable, durable and easy to use the design will be.

So what needs to be done:

1. Using a tape measure, measure each step of the iron staircase, as well as its side parts and the length of the march.

2. Write down the data obtained on a piece of paper and mark up the necessary details on the lumber.

3. Cut out all the necessary blanks of suitable sizes, process rough edges with a file, and sharp corners with sandpaper.

4. Number the elements for sheathing steps, given that you will carry out the finishing process from the bottom up. It is better to do this in places that will not be visible after installation.

5. Using sandpaper, grind the planes to perfect smoothness. You can use a grinder, so the work will go faster.

6. In conclusion, it is enough to treat all wooden elements with an antiseptic and wait for them to dry completely.

Metal frame cladding

When all the details are carefully processed and ready for installation, we proceed to the lining of the frame. The whole process looks like this:

1. We begin the work with finishing the steps from the bottom up. To do this, we lay wooden treads and fix them with self-tapping screws. Hats of fasteners should be deepened into the boards by half a centimeter.

2. Installing risers. They should fit snugly against the frame, for their fastening we also use self-tapping screws with a drill for metal.

3. We proceed to the assembly of the elements of the fence. Balusters are installed on the steps along the edges, on the reverse side of the step we screw in self-tapping screws. It is desirable to arrange the supporting elements with an interval of 15-20 cm. Next, we attach the handrail to the installed balusters.

If desired, it is possible to sheathe with wood the parts of the frame that remain in sight. But this finishing option is needed only if the metal structure has any defects.

Rear mounting

The peculiarity of this method of sheathing is that the wooden parts are laid on top of the frame, and the screws are twisted from its back side. First you need to drill holes in the metal itself in the right places for fasteners. Just prepare a container with cold water in advance to cool the drill - often the metal in such frames has a thickness of 5-7 mm.

The diameter of the holes should be such that in the future the self-tapping screws can easily pass through them.

Next, we proceed to the installation of each step. Everything is very simple here. First you need to make a plywood backing and fix it to the frame with a filling effect mounting adhesive. Just do not use mounting foam instead of glue - it dries out over time, which will lead to unpleasant squeaks.

We lay treads on top of the substrate and attract them from the back side with self-tapping screws through the holes made in advance in the metal. As for the risers, the technology for their installation is no different from the process described above.

External decoration of the stairs

At the final stage, it remains to sheathe the back side and finish the side part of the staircase structure. This can be done using sheets of chipboard, drywall or lining. First, we prepare the parts of the desired size and sheathe the side face like a bowstring, for this it is better to use wooden panels. We close the lower part of the flight of stairs with drywall. Fastening is carried out using self-tapping screws.

After sheathing a metal staircase with wood, do not forget about the finishing touch, on which the final result will depend. We cover the additionally lined parts of the stairs with paint on wood or open them with varnish, tinted or transparent - whatever you like.

Sheathing of the metal frame and installation of balusters (3 videos)

The most common stair cladding option is wood cladding. This is one of the most practical and win-win options. Such a staircase fits perfectly into any interior, and can not only fulfill its main tasks, but also serve as a separate interior object. Stylish, thoughtful design staircase will decorate any room. What are the methods of cladding, and most importantly - how is the sheathing of a metal staircase made of wood? After reading this article, you will find answers to all these questions.

Combination of metal and wood

Experts say that the choice and design of stairs should be taken with all seriousness and responsibility, because this is an object that connects two floors, so it must be as durable as possible, with a high service life, and most importantly, reliable.

Important! If we talk about strength and reliability, then in this case the undisputed leader is a ladder on a metal base. It fully complies with all requirements and is designed to serve for more than a dozen years.

A staircase on a metal base is much more advantageous than concrete structures, due to its:

- lightness;

- reliability;

- durability;

- elegance;

- high variability.

However, everyone knows that metal is a very cold material, devoid of comfort. Since the ladder is used for ascent and descent and implies the presence of height, it is worth mentioning the injury risk of metal. All these disadvantages are eliminated very simply - by sheathing a metal staircase with wood.

Important! Wood, unlike metal, is a warm and cozy material. Wooden stairs go well with any style of interior, you just need to choose the right design. Sheathing the stairs with wood, you reduce the risk of injury to the structure, create additional comfort of movement, while maintaining the strength of the structure and not reducing the service life at all.

Metal and wood are a great combination and absolutely the right decision when choosing the material from which your stairs will be made.

Cladding material

If, after long deliberation, you still opted for wood cladding, then you should figure out what kind of wood is better to sheathe the stairs. One of the materials for cladding is MDF panels, they are pre-cut according to a given template, then they are mounted on a metal frame . However, this is not the best option. The best material for the house is natural wood, because it is environmentally friendly and safe.

When choosing a tree, you should understand that depending on the variety, it differs in its density, durability and texture. What kind of wood to choose for lining a metal staircase with wood is not such a difficult question. Knowing the characteristics of a particular type of wood, as well as based on your requirements and preferences, you can easily choose the right array.

Here are the most popular types of wood and their features:

- Oak. This wood is particularly strong and durable. Depending on the place of growth, it can differ significantly in color. It has an incredibly noble color.

Important! Oak may darken over time, this should be taken into account when choosing an oak array.

- Beech. It is in no way inferior to oak in its characteristics, but has a more uniform texture, so it is easy to tint. It is distinguished by incredible elegance and aesthetic appeal. One of the most sought after materials for cladding.

- Ash. Along with oak and beech, it is very durable, its distinctive feature is a characteristic grayish tint.

- Exotic tree species such as wenge, teak, merbau, abash. These types of wood have an extensive choice of shades, an attractive appearance, while they are incredibly durable. The palette of colors is striking in its exoticism, unusual shades for the wood of our region.

- Coniferous arrays, such as spruce, pine, fir, cedar. Such wood is not durable, rather soft, and does not stand out for its high performance characteristics. Experts advise using pine exclusively for trimming risers and side cladding.

Important! Do not use pine as a step material as it is soft and has low wear resistance. Use solid coniferous trees only for cladding of risers, decorative cladding of the side. They work well and are affordable.

Ways of facing the stairs

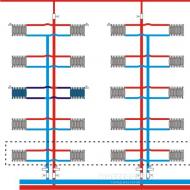

Depending on the design of the room and the design of the stairs, there are two main ways of facing the stairs. These include:

- The full sheathing of the stairs is a sheathing of a metal frame on all sides. The steps, risers, side and back sides of the stairs are sheathed with wood. As a result, a complete imitation of a wooden staircase is obtained, but the metal frame inside makes it stronger and more durable.

- Partial sheathing, when only treads are made of wood, and the entire structure remains unsewn. This method is typical for stairs on the stringer.

Deciding on the method of cladding is not so difficult. It is enough to proceed from the general design concept, to understand what will fit into your interior more: a wooden staircase without visible metal elements or a combination of metal and wood.

Methods for mounting wooden steps

In order to sheathe a metal staircase with wood, it is necessary to attach wooden blanks to a metal frame. This can be done in several ways, which are determined based on the method of sheathing, frame design and your personal preferences.

There are the following ways of mounting steps, depending on the design of the stairs:

- Mounting on stringers. One of the most common mounting methods. A platform for fastening steps is welded to the stringer and the tree is fixed to it with self-tapping screws or bolts. There are stairs on one or two stringers. If a side stringer is used in the wall, then fixation is made on the studs coming out of the stringer. In this version of fastening the steps, it is enough to bait on the studs.

- Installation using filly. The filly is attached by a channel to a metal base and has the shape of a triangle with a right angle. For its manufacture, parameters such as the height of the riser and the width of the tread are important. The wooden step is attached to the filly.

- Bolts installation. With this method, there is no central base and the steps are attached to the bolts in the wall. On the reverse side, it is possible to fasten the steps with bolts to the ceiling.

- Screw mounting. With this method, metal plates are attached to the helical pipe, which serve as the basis for the steps. The steps are screwed around the pipe.

- Modular method, when the ladder consists of identical modules, fastened together and having a pipe installed vertically for support. Steps are attached to the finished structure for each module.

In turn, the installation of steps can be done using:

- self-tapping screws, screws using an electric screwdriver;

- mounting glue and a gun for it;

- bolts, nuts using an open-end or box wrench or socket heads;

- hairpins.

The order of work on the lining of the stairs

After you have decided on the type of staircase design, it is worth starting to sheath it with wood. The most common option for fastening steps to the metal base of the stairs is fastening to metal plates or a frame.

How to sheathe a metal staircase with wood with your own hands, what order of work should be followed. In general, the algorithm of actions can be summarized as follows:

- To begin with, based on the interior design and your idea, determine the type of stairs, which cladding option you will use - full or partial.

- Decide on the type of wood, and if you have already decided how to sheathe a metal staircase, you need to calculate the amount of material needed, purchase it. It is desirable to carry out cladding with material from the same batch, so that there are no visual differences in the structure of the wood, it had the same degree of humidity.

- Based on all measurements, make blanks for steps. It is necessary to accurately fit each step in size, number each of them.

- Fasten each step, starting from the top, based on the chosen method of fastening. Ideally, the tread should protrude slightly forward from the base.

Important! When securing each tread, check the evenness of the fastening using a building level.

Frame stairs are becoming more and more in demand and popularity. Undoubtedly, this is due to the fact that in addition to strength and durability, they can be made in countless different shapes and designs. This article will be of interest to those who set out to make not just a typical staircase, but a real highlight of their home.

Choosing wooden stairs on a metal frame, you make a choice in favor of practicality, reliability and modernity. A huge advantage of the frame technology is its adaptive properties, first you can make the frame of the stairs with your own hands with the expectation that it will fit into the overall design idea of the room, or you can build a draft version of the frame, and later, cover it with a suitable material.

The combination of metal with wood is one of the most successful interior design solutions. Due to the successful combination of beauty and strength, wood and / or metal structures are popular with builders and owners of country cottages. This is one of the rare moments when builders and owners, relying on their tastes and preferences, clearly agree on one thing, the choice of wooden stairs on a metal frame.

A metal staircase with a wooden finish will create an original atmosphere in the house and an interior in a classic or old style. The possibility of decorating with forged and wooden elements is a real work of art that will give any room a true noble and respectable look.

An elegant metal staircase, decorated with wooden steps, looks swift and light, while remaining a reliable and durable structure that can withstand significant loads over many years of operation. Metal is the strength, durability of the stairs, and steps made of wood are comfort and style. The metal ladder and wooden steps guarantee the convenience of descending and / or ascending for all members of your family, including the elderly, children and pets.

Wooden stairs on a metal base are made of light or durable grades of metal, an important indicator of which is corrosion resistance. The technology for building wooden stairs with a metal frame involves partial or complete sheathing of visible metal surfaces with wood.

Having set a goal to independently design and build a staircase, it is important, first of all, to perform an accurate calculation of the metal frame of the staircase, so that unpleasant moments do not arise in the future.

The main indicator from which all calculations of the ladder frame are based is based on the width of the human step.

On average, this figure is 57-64 centimeters. Based on the above indicated indicator, the ratio of the step and the riser is determined.

- S is the width of the step,

- P is the riser height.

The formula will be:

- S + 2P = 57 - 64

In addition, it is necessary to calculate the formula for the ease of use of stairs:

- S - P = 12 cm.

As well as the formula for the safety condition:

- S + P = 46 cm.

All quantities cannot be taken into account separately from each other, it is important to grow, taking into account all design parameters, and for this it is necessary to make a clear analysis of the initial data.

Sheathing the metal frame of the stairs with a tree with your own hands

The most popular way of finishing at minimal cost is the installation of wooden steps to the frame of a metal staircase. And the remaining visible parts of the structure are simply painted in a suitable color, as a result, the metal staircase looks quite harmonious and natural.

If we talk about the complete sheathing of the metal frame of the stairs with wood, then the process includes finishing:

- understair space,

- steps,

- risers,

- imitation of a wooden string.

After such a "disguise", the metal frame becomes invisible, and the staircase is visually indistinguishable from the wooden one.

For the design of exclusive stairs, precious wood is used:

- cherry,

- cedar.

The above tree species have high aesthetic and operational properties.

The hardness of oak wood is several times higher than the hardness of pine wood, and is compared with the hardness of metal alloys. This natural material is unique and resistant to mechanical damage and wear. When choosing oak, the service life of the steps is equal to the resource of the frame itself.

Do-it-yourself installation of the metal frame of the stairs

As for installation and operation, wooden stairs on a metal frame are practically unpretentious. There are several options for installing them. If the owner decided to independently install the metal frame of the stairs in the house, he should take a closer look at the structures from prefabricated and prefabricated modules.

They have the appearance of a designer, and are represented by separate parts that are easily assembled into flights of stairs, connecting to each other in accordance with the attached instructions. Such modules are produced on industrial equipment according to the established state standards for wooden and metal structures of stairs. It is important to remember that such ladders require frequent maintenance and special maintenance to eliminate the occurrence of possible backlashes, tightening connections.

All stair structures are subject to periodic inspection and testing to ensure their safe operation.

Fastening wooden steps to a metal frame.

Basic moments:

- In each step of the metal frame, a mark is made for two mounting holes, every 15-20 cm, we retreat from the edge of the tread by no less than 2 cm.

- If the steps are fastened to the frame with ordinary self-tapping screws, then the holes in the metal frame are drilled into the "tip".

- To compensate for stresses when tightening parts, fasteners with washers are used.

Even the highest quality metal frame can have slight height differences between the parts. In order for the wooden linings to adhere qualitatively to the surface, a substrate is laid on it. For fixing, which is used with ordinary mounting adhesive with a filler effect. It fills voids and forms a durable layer that is resistant to crushing.

The use of mounting foam in this option is absolutely excluded, the dried foam is capable of wrinkling, which leads to corrosion, loosening and creaking of the steps. The most reliable and popular material for the substrate is plywood.

Summing up, it is worth saying that a hand-made wooden staircase with a metal frame is the perfect combination of important points: the durability of a metal structure and the aesthetics of a wooden staircase. No other material has such warmth and attractiveness as wood. In addition to the aesthetic appeal, a wooden staircase pleasantly surprises with the availability of the financial side. You will not find materials cheaper and more reliable.

Stairs on metal frames are increasingly replacing traditional wooden structures from residential interiors. This is facilitated by a number of advantages of metal stairs.

However, the appearance of a steel staircase, harmoniously combined with the interior of a production or storage facility, hardly fits into the decoration of a residential area. Of course, if you are planning a high-tech home interior, then chrome-plated metal will be there, as they say, “in the subject”, but in most cases, metal structures look like alien inclusions in traditional interiors and need to be disguised. Let's look at the main ways to finish stairs on steel frames with your own hands.

Wood paneling (photo) is perhaps the most common way to disguise a metal frame in private cottages. A significant advantage of this method is that wood and metal complement each other favorably - the metal does not bend under weight, and the wooden covering of the steps, due to its fibrous structure, practically does not "tread down". In addition, wooden panels are not slippery, which is important for outdoor stairs.

The solid wood has sufficient strength to serve as a material not only for finishing, but also for the manufacture of the entire step. The wooden step is inserted into the groove of the bowstring or superimposed on the steel riser from the corner or channel.

Also, wood is widely used as a material for handrails for railings. Strict aristocracy will give the interior a combination of wooden handrails with forged metal platters.

If desired, you can sheathe a metal staircase with solid wood panels, which will create the complete illusion of a solid wood staircase, as in the photo.

Laminate finish

With all its undoubted advantages, the solid wood is expensive and difficult to process, it is better to entrust the work with solid wood panels to professionals. For do-it-yourself staircase sheathing, a more inexpensive option is better - laminate.

A multilayer high-strength wood-fiber material finished with a decorative film that mimics the look of a solid wood, which is called a laminate, is much cheaper, lighter and easier to process than a solid wood. Of course, you had to pay for this with some decrease in quality, but this can be considered a completely reasonable compromise - it is unlikely that hundreds of feet will be walking on the steps of your house.

Fiberboard even has some advantages over solid wood. In particular, better sound insulation (in some brands, a separate layer is responsible for sound insulation), which is especially important when sheathing metal structures. In addition, the tree begins to creak over time, this feature is fought by laying a sheet of plywood between the solid wood and the frame. Laminate is devoid of such a disadvantage initially.