Heating cable operating principle. Heating cable: types and applications

Water pipes located at a depth, at a minimum temperature, are subject to freezing. This leads to disruption of the functioning of the entire plumbing system. To minimize the likelihood of such a risk, you can install a heating cable for the water supply. This element can be located inside or on the surface of the pipes. The possibility of using a heating cable of different lengths allows heating the entire system or a separate part of the water supply system located in the freezing zone.

How does a heating cable work?

The heating of the cable occurs due to the action of the passing current. This heating element is positioned as the main component of the system that provides reliable protection of pipes from freezing. Its operation is based on the conversion of electrical energy into heat.

Heating cable for plumbing is not a carrier of energy. Its main characteristic is the specific heat release. The overall length of the product may vary depending on the needs of the consumer. The cable is distinguished by the presence of a hermetic sheath of a seamless type, which is highly resistant to negative chemical effects and makes it easy to endure the influence of minimum temperature indicators.

The main heating element of the cable is located inside the protective sheath. In the event of a decrease in the ambient temperature, it is connected to the network, and the pipe is heated. With a subsequent increase in temperature, the power is turned off and the heating stops. This method of heating the plumbing system has a number of advantages:

- profitability;

- safety;

- ease of operation;

- versatility.

Economy . Using a heating cable for plumbing, you can focus on the ambient temperature and coordinate the operation of the entire system. The ability to adjust the heating power allows you to minimize the level of electrical energy consumption.

Safety . The insulation system protects the heating wire very well from various negative effects of mechanical, chemical and thermal types.

Ease of operation . To start functioning, simply turn on the power to the network and press the button. The ultimate ease of operation of the entire system contributes to the expansion of the range of consumers.

Versatility . The design features of the product make it possible to use this pipe heating cable for heating any plumbing system located underground and on the surface.

Design features

The main functional element of the cable is the inner core. To protect it, a polymer material is used. The overall sheath is made of PVC. It provides reliable protection of components.

Cheaper cable variations are single-core. Such products are characterized by extreme structural simplicity. At the same time, single-core cables do not have an additional conductive core, which is present in two or three-core products.

The heat cable for the water supply is presented in the form of an electric guide of the tape type. The two-layer structure of the product provides additional dielectric strength, as well as protection against abrasion and impact loads.

Heat Cable Variations

The classification of such products is carried out according to various criteria. The cable can be resistive and self-regulating. There is also another type of product with mineral insulation. Heating of pipes with a cable can be carried out using any of the named product variations.

Resistive cable

The heating of the water supply through the use of such a cable is realized on the surface or inside the pipes. Temperature sensors are installed outside the plumbing system. If the temperature drops below the set level, then the heating is switched on. After reaching a certain temperature threshold, the system turns off.

Resistive type heating cable can be of linear or zonal design. In the first case, we can talk about the sectional design of the product. The zone cable is characterized by the presence of two conductive elements arranged in parallel. The top layer of such a product is presented in the form of a spiral of small diameter.

Mineral insulated cable

The basis of such a cable is a copper core. The top layer is in the form of a magnesium oxide insulator. This ensures stability of operation in the widest possible range.

Self-regulating cable

Self-regulating heating cable for plumbing in a constructive way has much in common with the resistive variation of the product. At the same time, it is distinguished by the fact that there is no insulating coating. Such a heating cable for pipes is able to locally change the amount of heat generated.

Features of the installation work

Heating pipes with a cable minimizes the risk of freezing of the water supply system. Installation work is carried out in two ways, which differ in the location of the main heating element.

Heating cable outside the pipe

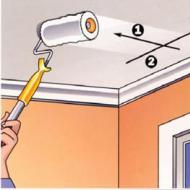

The heating cable on the outside of the pipe can be arranged in a linear manner or in a spiral. In the first case, it is best to place it in the lower zone of the pipe. This position will help protect the entire heating system from mechanical damage.

Installation of a heating cable for water supply must be carried out according to certain rules. In particular, it is necessary to ensure the most reliable and tight fastening to the pipe. For these purposes, you can use adhesive fiberglass tape or plastic clamps.

Advice! Before direct installation of the heating cable, it is recommended to carry out foil insulation of the pipe. This will ensure the longest and most reliable operation of the entire system.

Heating cable inside the pipe

The internal connection of the heating cable for the water supply is a more laborious procedure. Manufacturers provide a complete set of additional attributes necessary for high-quality installation.

The heating cable is inserted into the pipe through the use of special glands. It is strongly recommended to refrain from laying the cable through the stop valves. Also, before installation, care must be taken to remove all sharp edges and threads on the fittings.

The section of the water supply that will be heated by the cable is most expedient to mount with a minimum number of connecting elements. In order to ensure efficient operation of the cable and uniform distribution of heat, it is recommended to take care of high-quality pipe insulation.

There are many ways to heat water in water pipes. One of the most common of these is heating with a self-regulating heating cable. This device is highly efficient and economical. In addition to heating the water supply, a self-regulating cable is used to organize a "warm floor" system in the house.

Principle of operation

Such devices are commonly used not only in everyday life, but also on an industrial scale. The main goals which allows you to achieve a self-regulating cable are:

- All-the-year-round protection of all pipes against freezing.

- Ensuring safety on roofs and gutters. With a self-regulating heating cable, you can eliminate the risk of injury from icicles.

- Constant maintenance of the set temperature.

- Implementation of the "warm floor" system.

Some craftsmen also use self-regulating heating cables to heat sofas and armchairs.

The device itself is quite simple. It consists of 5 elements: copper wires, shielding braid, outer protective sheath, semiconductor matrix and internal insulation. The semiconductor matrix is designed for heat dissipation of the wire. It allows you to adjust the heat output.

The device itself is quite simple. It consists of 5 elements: copper wires, shielding braid, outer protective sheath, semiconductor matrix and internal insulation. The semiconductor matrix is designed for heat dissipation of the wire. It allows you to adjust the heat output.

When the ambient temperature drops to a predetermined level, the middle of the wire shrinks by a micron value. After that, the cable starts to generate additional heat, raising the ambient temperature.

An important role is played by the design features of the self-regulating heating cable. The highest quality will be those models that contain all 5 elements mentioned above. The store should carefully check the fixtures for various damage and marriage. In addition, it is recommended to consider the following indicators:

For greater security, it is recommended to ask the seller about the availability of all necessary certificates. If you plan to use the device for domestic heating of pipes, then it is best to purchase a system of small size, which will do the job perfectly and save you money.

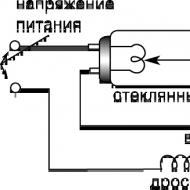

Wiring diagram

There are different methods of mounting a self-regulating heating product.. Each of them is suitable for different applications of the device. Linear installation is used for water and sewer pipes. It involves the installation of wire along the pipe. In addition to linear, you can use the spiral installation method. This will require a large length of material. In some cases, internal installation along the pipe is performed, but this method requires serious efforts to implement.

There are different methods of mounting a self-regulating heating product.. Each of them is suitable for different applications of the device. Linear installation is used for water and sewer pipes. It involves the installation of wire along the pipe. In addition to linear, you can use the spiral installation method. This will require a large length of material. In some cases, internal installation along the pipe is performed, but this method requires serious efforts to implement.

When the device is fully installed, it is necessary to connect it to the mains using the power cord. You should also read the recommendations of experts:

- During installation, the ambient temperature must be at least 15 degrees.

- The bend of the device must be equal to the sum of six of its diameters.

- Upon completion of the installation procedure, you need to check the resistance indicator.

Popular brands

As for the price of a self-regulating heating cable, it is somewhat higher than the cost of a standard fixture. However, during the period of operation, it manages to justify itself.

As for the price of a self-regulating heating cable, it is somewhat higher than the cost of a standard fixture. However, during the period of operation, it manages to justify itself.

The cost of such cables varies from 100 to 1 thousand rubles per 1 meter of material. Cheap devices are offered by domestic manufacturers. In addition, it is necessary to take into account the fact that the longer the wire the buyer needs, the lower the price for each meter.

If you believe the reviews written by the supporters of such products, the most popular brands of heating cables are Raychem, Lavita, Ensto and Devi.

Products from Ensto and Lavita are distinguished by a high-quality internal coating of the product. The most expensive products come from Denmark under the Devi brand. Budget options include Ensto and Lavita brands. In terms of service life, Ensto is not inferior to expensive devices from Devi. In this regard, most consumers prefer heating devices from Ensto.

If you study in detail the principle of operation and the device of a self-regulating heating cable, you can find a fairly effective use of such a device at home.

In regions with cold winters, plumbing may freeze slightly. The consequences will not keep you waiting: the lack of water in the house and the break of pipes will bring a lot of trouble. But there is a way out - a self-regulating heating cable. If his choice from the entire nomenclature is made correctly, he will not let the water freeze. Mount it both inside the pipes and outside.

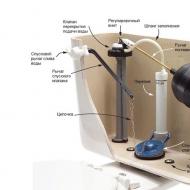

Heating cable device

Heating cables for plumbing are far from new. Previously, they were actively used to heat industrial communications. Currently, the use of such systems is common in private and communal households, since it is not always possible to lay water pipes below the soil freezing level.

Heating cable device for water supply

Self-regulating cable for heating pipes of communications multilayer, consists of:

- two current conductors - copper conductors;

- polymer matrix connecting the cores;

- two layers of seamless insulation;

- copper screen - heat reflector;

- external insulating cover.

The kit of the self-regulating water heating system also includes a repair kit with parts for sealing the cable when connected.

The principle of operation of a self-regulating cable

The polymer matrix connecting the conductive wires is the main heating element. Its heating is carried out continuously. A cable with such “insides” can be cut into separate fragments from 20 cm long. The main feature of the matrix is a spontaneous change in heat transfer depending on the external temperature. How it works? With an increase in external temperature, the resistance of the matrix polymer increases proportionally, and heat transfer, accordingly, decreases.

Heating cable

The property of self-regulation is manifested in various sections of the pipeline. So, the underground part of the pipeline, under favorable conditions, will not heat up, without preventing the heating of open sections of the pipe by the same cable.

Advice. Such technical characteristics completely exclude cable burnout from overheating, and normalize the power consumption for its operation.

To turn on the heating of the water supply when the temperature drops, just plug the cable into the socket. They turn on the cable when it gets cold up to + 5 °, in order to be prepared for sudden night frosts.

The heating cable is very easy to use. With proper installation, its service life is unlimited. Reliable protection against overheating makes the cable absolutely safe.

Advice. For drinking water supply, the use of such a cable is quite acceptable.

Heating cable selection

The choice of a self-regulating heating cable should not be spontaneous. Manufacturers have clearly defined the characteristics of the cable for various conditions of its use.

The first thing you need to pay attention to is the power of the cable. For private houses, a cable with a power of 5 to 25 W / m and above is used. Moreover, the parameters are determined for each specific case:

- underground water supply with internal heating installation - a power of 5 W / m is enough;

- underground water supply with external heating - a cable is required, with a power of 10 W / m;

- open water supply - a cable with a power of less than 20 W / m will not cope with pipe heating.

Advice. In private homes, the use of a self-regulating cable with a power higher than 50 W / m is not advisable. Energy will be wasted despite the fact that the cost of such a cable will be considerable.

Such a parameter as the operating temperature, in the case of choosing a heating cable for the pipeline, is always unchanged. Use only low-temperature (up to 65 °).

Depending on the area of application, the heating cable is classified into food and technical.

Attention! Inside the domestic water supply, only a food cable can be installed. Outdoor mounting allows the use of any cable.

Mounting inside the pipe

Inside, the heating cable is often mounted when the water supply has already been laid and is in operation, and its thermal insulation cannot cope with low temperatures.

Attention! A cable with a fluorine-containing polymer is laid inside the pipe. It must have a certificate confirming food approval for use.

The cable entry into the pipe from above does not require any additional clamps, while the bottom connection must be securely fastened to prevent the heater from slipping.

Scheme: connecting the heating cable

The procedure for installing the heating cable inside the pipe is as follows:

- Measure the section of the pipeline that needs additional heating.

- Dissolve one end of the tape (cable) according to the instructions and install the sleeve with glands for sealing.

- Securely insulate the second end of the cable.

- Lower the cable with the insulated edge into the pipes. This must be done with extreme caution so as not to damage the cable insulation.

- Connect the cable with the sleeve to the power supply using a plug or directly to the junction box.

- The section of the pipe with the cable is marked with an inscription in a bright color.

Attention! Passing the cable through stopcocks and other nodes is strictly prohibited.

Cable installation outside the pipe

External installation of the water heating system is quite simple. The cable is attached to the pipe with aluminum tape or special adhesive tape according to the following schemes:

The choice of installation scheme depends on climatic conditions and the method of laying pipes. It should be understood that the larger the area covered by the cable, the more intense the pipes will warm up.

Before installation, the heating tape must be wrapped with foil. So the pipes will warm up more evenly and not waste heat in vain.

The cable fixed on the pipes is again wrapped with profile tape from above in a continuous layer. It will serve not only as cable protection, but also as an additional layer of cable insulation from insulation.

Attention! The use of plastic tape as an alternative to aluminum tape is prohibited when installing a self-regulating cable.

A pipe with a securely fixed cable is insulated. To do this, use foil, tightly wrapping the pipes with it. The connection to the power supply of the heating external cable is carried out in the same way as for internal installation.

A self-regulating cable for pipeline heating will certainly be an excellent solution where it is not possible to provide reliable thermal insulation of pipes. Its installation will not cause difficulties. Such a cable can also be used for additional protection of sewers and drainage systems or roof heating.

Heating cable for plumbing: video

The use of a heating cable in the plumbing system: photo

During severe frosts, water can freeze in sewerage and water supply systems, which often leads to a number of unpleasant consequences: from stopping the water supply to rupturing pipes.

To avoid such troubles, it is recommended to use a heating cable for plumbing, which can be resistive or self-regulating. Installation of such a wire will help prevent the formation of ice plugs in pipes, maintain the supply pressure at the technological level, and when laying a new water supply system, the use of a cable will reduce its depth in the ground.

Resistive heating cable for plumbing.

The resistive heating cable system works according to the following principle: a cable is laid along the entire length of the pipe (on the surface or inside), the temperature sensors installed on the pipe determine the ambient temperature, and the control thermostat is sensitive to any change in relation to the specified parameters. If the temperature drops below, the heating system automatically turns on: current flows, the conductor begins to generate heat, heat the pipe and the water in it. When the required temperature level is reached, the system automatically turns off.

The cable consists of a metal core enclosed in insulation. Its heating occurs evenly along the entire length and, if you do not monitor the temperature regime, it may burn out. In order for the operation of such a heating system to be most efficient, it is necessary to provide the pipeline with very good thermal insulation - this will significantly reduce energy costs and reduce heat loss. Any materials with a low thermal conductivity, such as mineral wool, can be used for thermal insulation.

Based on the capacity, the heating cable can be laid on the pipe in one or more parallel lines, in a spiral or in waves. Laying is easy, without tension, attached to the surface with adhesive tape made of aluminum. To increase the contact of the cable with the pipe and ensure better heat distribution over the surface, you can wrap the pipe with the cable with several layers of aluminum foil.

Self-regulating heating cable for plumbing.

The self-regulating heating cable for plumbing was developed as an alternative solution to the resistive system, and it worked out perfectly. The cable has excellent performance and technical characteristics, it can be successfully used in various anti-icing systems. Such systems, for example, are installed on the roofs of buildings to prevent the formation of ice icicles.

A self-regulating heating wire is a pair of insulated conductors enclosed in a polymer that is sensitive to the slightest change in temperature and changes its resistance depending on this. The lower the temperature drops, the more the resistance decreases and, accordingly, the current strength and the amount of heat generated increase.

Response to temperature changes occurs at any point along the entire length of the wire, so the amount of heat generated in different places may differ. This feature allows the material to be used with great efficiency. In addition, it is highly economical and safe to use, as it is equipped with very reliable insulation. The scope of its use is truly unlimited, and the service life, with constant use, is at least 40 years. To mount the cable, you can cut it into pieces of any length - the work efficiency will not decrease from this.

How to make a heating cable with your own hands.

You can buy heating cables in the distribution network, but you should be aware that their cost is quite high. But, with some skill and some technical skills, you can try to make a heating cable with your own hands, using an alternative material for this.

Experienced craftsmen argue that the most suitable replacement for a branded heating cable is the so-called "field worker" - a power telephone cable intended for a military field communication device, its official marking is P-274M. It is thin, strong enough, rigid, has good and reliable insulation, can be used in a humid environment.

Naturally, a homemade heating cable system will lack some qualities, for example, it will not have special food insulation and there will be no self-regulation function. If it does not work constantly, but only periodically (for example, it occasionally turns on in a country house where they do not live permanently in winter, but only come from time to time) and the cable is laid not inside the pipe, but outside, then it is quite possible to do without the above benefits.

When installing the "field worker" inside the water pipe, so as not to expose the core at the end, it is better to unravel it into two wires. Then bend the single wire in half and twist it in half again. At two open ends, it is necessary to provide for a sealed wire entry; it can be built from a flange from a flexible water supply. The input must be really tight and not let in a drop of moisture, for this, the fitting, with the wires threaded inside, must be filled with epoxy glue and slightly flattened, the union nut will allow you to tighten the connection well.

If the cable is supposed to be laid over the pipe, then it is not necessary to unravel the "field worker", but simply connect the wires at the opposite end of the heated area. The connection must be carefully insulated.

Attach the wire to the surface very tightly. First, the pipe with the cable must be wrapped in foil, and tape must be wound over it, which, in fact, will press the cable to the heated base. Then wrap it all with a heater, for example, mineral wool.

In this way, heating can be arranged not only for water supply, but also for sewage. The strength of the current passed through the "field worker" should not exceed 9A.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion :)

Recently, cable heating systems have been very popular, which are being installed in various buildings and structures. A self-regulating heating cable is needed to solve the problem of heating a pipeline, floor or roof. Using it, interesting architectural solutions are easily implemented, and the arrangement of the premises becomes a simple task. In the article, we will consider how it works and what features a self-regulating heating cable has.

Cable features

The main quality of the heating cable is its flexibility, which allows it to be laid in almost any place, effectively and evenly creating heating. There are other positive aspects of its use:

- If you correctly calculate and install the element, it will function for a long time and reliably;

- Universal wiring. With the help of a self-regulating cable, street and underground pipelines are heated, a popular "warm floor" system is created, the roof is heated and much more;

- Environmental friendliness. Heating using wiring is environmentally friendly;

- The wire is easy to install and does not cause difficulties in the process.

At the moment, many companies are engaged in the production of samreg cables. Choosing the right element is not difficult, since they work on the same principle. All that is needed is to clarify what characteristics the wiring has.

Important! A self-regulating heating cable heats up as a result of an electrical current passing through it. Its main characteristic is the specific heat release.

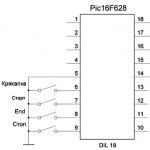

The design of self-regulating wires is as follows:

- Copper strands. The alloy has a high electrical resistance, on which the specific heat release depends;

- Self-adjusting semi-conductive sample matrix;

- The presence of internal insulation, for the execution of which polyester is used;

- Tinned copper wire as braid;

- Polyolefin is used for external insulation, it allows to protect the cable from external influences.

Self-regulating cable in its composition contains from one to several cores, each covered with a protective sheath. The simplest and cheapest are those elements that contain one core, but they most often fail, as they are subject to third-party electromagnetic radiation. To ensure protection against interference, manufacturers have provided a protective foil screen. Based on this, elements are either shielded or unshielded. The former are more expensive, as they are manufactured using complex technology.

Self-regulating cable - universal wiring, since it can be used to heat the roof, water supply systems, pipelines and various containers with liquid. It has a key feature - the ability to independently regulate the power and intensity of heat supply. For example, if the temperature drops below the specified value, the wire will start to heat up without outside help.

The principle of operation of such wiring is simple and boils down to the fact that the conductor has the ability to reduce or increase the current strength (depending on the resistance). If you increase the resistance, then the current will decrease, resulting in a decrease in power. Now let's look at how everything functions when cooled. Due to the drop in resistance, the current strength increases, and the wire begins to heat up.

Self-regulating models have the following advantage - their work is "zonal". In a word, the wiring is able to independently distribute the “labor force”, that is, the wire thoroughly warms up where it has cooled down and maintains the optimal degree in areas where strong heating is not needed.

Note! This type of wiring operates in a constant mode, which is very convenient in the cold season. But, when the thaws come in the spring, it is irrational to keep it on.

On a note. For complete automation of the equipment, it is recommended that the system be equipped with a thermostat “linked” to the outside temperature.

Features of cable insulation

There are various types of wiring used for one purpose or another. Regardless of this, the cables require insulation. Thermal insulation should be installed not only on top of the system itself, but also on water pipes. That is, water pipes with a heating cable should be placed in a kind of sealed "cocoon" so that heating does not go in all directions.

Reliable and effective insulation - expanded polystyrene and foamed polyethylene. These materials are not afraid of moisture, in addition, they are able to create protective cushioning for pipes. Despite this, they require additional protection, so the "pipe in pipe" design is often involved.

Note! The heat-insulating layer has a different thickness, which depends on external factors. For example, if the installation is carried out in the ground, then an insulating layer with a thickness of 20 to 30 mm is sufficient. In the case of above-ground execution, a thickness of at least 50 mm is required.

Positive traits

The heating cable and at the same time self-regulating has the following advantages, due to which it has become widespread:

- Able to automatically maintain the required temperature in the system;

- Without losing characteristics, the wiring of the required length is cut off;

- Even if there is a self-intersection of elements, they will not overheat and will not burn out;

- Due to the flat design, reliable thermal contact is ensured;

- Due to the fluoropolymer shell, it is often mounted in places where corrosive chemical solutions and vapors occur;

- Can be used in areas with increased explosion hazard;

- Power is connected from one end;

- Never burns out and does not heat above +65 degrees Celsius.

Due to the positive properties described above, samreg cables are widely used in various fields of human activity. It can be industrial frost protection, heating of roofing elements, pipelines. In addition, with its help, the “warm floor” system is heated, like any other track: the cable is simply poured into concrete or laid in the ground, resulting in a heated track on the site.

Heating cables are widely used due to their unique properties that allow them to be used in a wide variety of applications. These are both industrial and residential facilities. All that is required for effective use is to determine the technical characteristics of the wiring and correctly mount it, taking into account all the requirements and standards.

Video