Is it possible to put linoleum on a wooden floor. How to put linoleum on wood floors

Anton Tsugunov

Reading time: 4 minutes

A modern interior implies the creation of a beautiful and original finish on all surfaces. This also applies to gender. Linoleum is a time-tested material that can transform any room. It is actively used by professional designers and ordinary citizens who independently repair their homes. They often have different questions about the use of this coating, for example, how to lay linoleum on a wooden floor.

There is a certain technology for laying linoleum on a wooden base. It is quite simple, does not require special building skills. However, it is possible to note moments in it, the knowledge of which will allow you to carry out the work correctly and enjoy the result for a long time.

The technology of laying linoleum on a wooden floor includes several important steps:

- measurements, calculations and acquisition of the main material and related components;

- ground preparation;

- the actual laying of the coating.

Each of them has its own characteristics.

Acquisition of linoleum and related components

In addition to linoleum, you will need funds for which it will be attached. The flooring can be glued to a wooden base with special glue or construction tape. For additional fixation, a plinth is used. It will also hide the gap against the wall.

In order for linoleum to lie flat and serve for a long time, different substrates are used. In the case of a wooden base, this is especially true. Natural cork is used as a layer between the boards and the floor product. But it is expensive, so you can get by with a cheaper polyurethane foam backing.

Methods for preparing a wooden base

Natural wood is a living material. Therefore, the wooden base may lose its stability, deform during operation. Before laying linoleum, it is important to properly prepare it in order to get a good result.

Preparing the old foundation

If the wooden floors have been laid for a long time and a replacement of the finishing layer is required, first of all, the condition of the entire structure is examined. In many houses, the old coating is enameled or oil-painted boards or linoleum. Depending on this, further repair work is being built.

Painted boards are cleaned of color coating with a grinder, sandpaper or liquid compounds that dissolve the components of the old paint. With full confidence that the wooden floorboards are well preserved and free of defects, the paint layer can be left. But then there is no guarantee that the adhesive composition will not react with the previous floor covering. In order not to test the new coating, it is better to remove the old paint.

Linoleum, which has severe damage, cuts, gusts must be removed. Old faded, but whole canvases can be left, but before laying new material on it, the wooden base is carefully checked. Therefore, in any case, the coating that has served its time will need to be twisted.

When the wooden floor-base acquires its original appearance and color, it is carefully examined. It is important to see all the defects in order to avoid damage to the coating later. After the inspection, measures are taken to eliminate defects:

- rotted floorboards are carefully removed and new ones put in their place;

- small cracks are covered with putty on wood;

- on large ones - inserts are stuffed or filled with rope bundles soaked in an adhesive mixture;

- the protrusions are cleaned, smoothed and leveled;

- dents on the boards are filled with special putty;

- protruding nail heads are driven flush;

- lastly, they pass over the entire surface of the base with a grinder, creating an ideal canvas.

Linoleum flooring and fixing

To properly lay a new linoleum on a wooden floor, you need to prepare a simple set of tools:

- sharp clerical knife;

- putty knife;

- heavy roller;

- drill and screws for mounting the plinth.

The linoleum purchased in the store is brought into the apartment, unfolded over the entire surface and left for 2-3 days in this state. He must "lie down" and straighten out. This is especially true for insulated and thick commercial and semi-commercial products. After the “addiction” process, the canvas is folded and transferred to that part of the room from where the installation will begin.

When using the substrate, it is first laid and attached to the boards. To do this, use glue or masking tape. The edges of the canvases are combined and connected with adhesive tape.

There is no fundamental difference from where to start laying linoleum. After laying, you can move freely along it, and the pattern and color of the entire product are the same.

It is necessary to glue the canvas on a wooden surface in stages. They smeared a section of the floor with glue, distributed it evenly with a comb spatula and turned away the edge of the canvas. When it connects to the base, you can coat the next strip and unroll the roll further. So they reach the end of the room. The resulting excess cloth is cut off with a sharp knife. After that, it will be correct to walk on the new floor, roll a heavy roller or any object similar to it on it. Lastly, a plinth is attached around the perimeter of the space. It will additionally fix the coating and close the joints at the wall.

When using adhesive tape, they act differently. Masking tape is glued around the perimeter and in several places on the floor. Next, gradually unfold the linoleum and remove the top protective layer of adhesive tape. At the end, they also walk on the surface, trying to ensure that under the weight of all the elements are thoroughly fastened together, and mount the plinth.

HELPFUL INFORMATION: Floor screed repair: elimination of cracks and potholes, preparation and work procedure

You can, of course, nail linoleum to wooden boards with carnations. But it is outdated and not aesthetically pleasing. This is what they did in the last century.

Linoleum is the best coating for non-professional work. To properly lay it on a wooden floor, you need to make a minimum of effort and skill.

There are many types of floor coverings, and they can be laid on a variety of substrates. Now we will talk specifically about how to lay linoleum on a wooden floor.

At first glance, it may seem that there is nothing simpler, but in fact, in such work there are some that you need to know about so that the linoleum lies evenly, beautifully and without defects.

Linoleum is a material that is suitable for all types of rooms, except for wet ones. That is why it is very popular.

For example, it is not advisable to lay linoleum in a bathroom or shower room, as it can succumb to distortion, and the moisture that gets under it will be an excellent environment for mold to develop. And for rooms and offices - this is one of the best and most affordable coatings.

If you want to lay linoleum on a floor made of wooden boards, first of all, you need to think through everything, take measurements and buy materials.

To the obtained floor dimensions, it is necessary to add 10% for the remainder.

This is the most common option. It has excellent elasticity, is quite durable and not very expensive.

Foam-based PVC would also be a great option. Such linoleum will additionally provide sound insulation and heat.

Some manufacturers produce ready-made linoleum with thermal insulation material. These models are relevant for laying at home, they are useless in the office.

Material without underlay

In such premises, where it is necessary to create a uniform structure of the floor covering, it is better to use linoleum without underlay. It is durable and highly resistant to aggressive external factors.

For a wooden base, it is better to choose linoleum from natural and environmentally friendly components. This coating is completely anti-allergenic and does not emit harmful toxins.

Actual for laying in nurseries, bedrooms and living rooms, as well as in apartments where residents are prone to allergies. The disadvantage of such linoleum is not so long service life.

As for the thickness of the PVC coating, 4 mm is best for laying on a wooden floor. It is durable and will last a long time.

Defects will not be so clearly distinguished on it, if suddenly the floor begins to deteriorate over time. Well, when laying with such material, it is easier to work - there are much fewer gaps.

When choosing linoleum for a room or office in a store, start from interior design to decide on a pattern. Even if the carpet lies on top, the coating should still harmoniously fit into the interior.

Pay attention to heat and sound insulation qualities. Also ask to unroll the roll and check for defects on the material.

When buying multiple rolls, pay attention to the color. Sometimes it happens that at first glance the design is identical, but if you look closely, the color may differ slightly.

Preparatory stage

Linoleum is the most common floor covering. It has many advantages such as high wear resistance, durability, easy maintenance, environmental friendliness and affordable price.

Due to its flexibility, the material duplicates all the irregularities of the surface on which it lies. If you lay it on a wooden floor, without prior preparation, it will repeat all the defects - cracks, bulges, bumps and hats from the hardware that attaches the boards.

Cooking the floor

In order to achieve a perfectly even base, you need to assess its condition and carry out repair and preventive measures:

- eliminate the creak of the floorboards (attach the boards to the base with self-tapping screws more firmly)

- make sure that the boards are not affected by fungus and mold (in which case, replace)

- with differences of more than a centimeter, it is necessary to additionally lay plywood on the damaged areas

- carefully putty the gaps between the boards, then sand and apply the primer

- if the paint on the floor is cracked, it is better to remove it

When the floor is perfectly flat, you can start processing it before linoleum flooring. First you need to hammer in all the nails so that the hats do not stick out.

Then make a primary sanding, and then patch the cracks. To do this, all joints must be filled with acrylic putty.

It is elastic and when the temperature changes, it will help to avoid deformation of the wood and the surface coating. When the material is completely dry, the entire surface must be carefully sanded, removed all dust and primed.

Never lay linoleum or other floor covering on a damaged wood floor, as this will greatly reduce the life of the new material.

If the old floor is very crooked, and the boards are not level, it is necessary to make a bedding from. It will provide a perfectly flat surface and provide water resistance, thereby extending the life of the old floor for many years.

Installation of plywood substrate

Tip: If the original floor is too damaged, consider replacing it. Overhaul and elimination of all defects will take more effort, time and investment. A new floor is a guarantee of quality and protection against decay.

First you need to measure the plywood and cut the panels to the desired length.

It is best to do this with a circular saw so that the cut lines are even and smooth.

You need to retreat one centimeter from the wall.

All sheets are fastened with screws to the beams and the old one.

Hardware must be driven into the wood so that there are no protruding hats, otherwise they will later appear under the linoleum. When the floor is ready, the joints are puttied, sanded and covered with primer.

Linoleum preparation

Even before choosing and buying linoleum, you should take measurements of the floor, take into account all the recesses where the material will have to be cut. Linoleum is sold in rolls of a certain width.

If there is no suitable size, then you will have to mount and make joints. If you have this situation, please note that the joint should be placed parallel to the long wall in the middle. When calculating the material, take into account the margin for fitting the pattern, in case of a joint.

When you have already purchased the required footage of the coating, be sure to lay it out in the room where it will spread, and leave it for 24 hours. This is necessary so that the elastic linoleum takes shape depending on the temperature and evens out after the roll.

We lay linoleum

When the base and linoleum are ready for laying, you can proceed. Some roll coverings require gluing, and for some it is enough to fix the linoleum around the perimeter.

This is especially true in small rooms, where the square is not more than 10 meters. In the event that docking is provided, glue is required.

Tools:

- roller for linoleum

- square

- sharp knife

- roulette

- seam roller

- scraper or spatula

Before laying, you need to roll out the roll and cut off the necessary piece. Count so that the material is 8 centimeters. At the end, when it straightens and settles, the excess is cut off half a centimeter from the wall.

This gap will later be closed with a plinth. Use a very sharp knife for cutting, otherwise the coating may be damaged.

If you decide to fix it completely with glue, then roll back part of the linoleum and apply glue to the floor. The same operation must be done with the other side of the piece.

If you rarely use the cottage, then you don’t need to spend much money on expensive coverage models. It is enough to buy one of the cheapest materials and ennoble your house. But this does not mean at all that the old, crooked and rotten floor does not need to be restored.

How to properly lay linoleum - shown in the video:

When installing linoleum on a wooden floor, you need to take into account a few tips from experts in order to do the job well:

- When laying the material, it is better to leave gaps around the perimeter of the room, 8-9 mm in size. As a result, this residue will be hidden by the plinth. But in the event of a temperature drop or an increase in humidity, linoleum does not deform or swell.

- The basis under linoleum has to be ideally dry. Even as a result of a drop of moisture, mold can develop and lead to decay.

- If the room is not more than 10 sq. meters, then the material can not be glued if it does not have to be joined.

- When laying on a wooden floor or plywood, a layer of insulation can be laid under the linoleum.

- Joints can be cold-welded, hot-welded or carefully glued. To make the joint perfectly even, the coating must be glued with an overlap, and then cut through with a sharp knife to remove excess pieces.

- If the joints are glued with glue, then it must be applied to the edge at least 5 cm wide on both connecting pieces. When pressed, the remaining adhesive will come out. You can not rub them until completely dry. Only then carefully cut with a knife.

- If during the process of laying on the glue, an air bubble has appeared that can no longer be corrected, then it is necessary to carefully pierce the linoleum with a needle and release the air.

- Complete drying of the adhesive material on which the linoleum is held occurs in two days. It is not recommended to open windows at this time and create a change in moisture and temperature. Also, you can not walk on the floor, so that the coating is completely dry and not deformed.

- The skirting board is an integral part of the final flooring installation. Firstly, it will give a beautiful look to the room, and secondly, it will additionally press the linoleum.

Now you know how to lay linoleum on a wooden floor from planks. If you follow all the rules and advice, then everything will work out.

The material will lay flat, without bends and waves, and the joints will be almost invisible. The main thing is to choose the right material and carefully level the floor.

If this is not done, after a while all the errors will be visible through the linoleum, since the material is quite thin and plastic. Do not forget that wood is prone to decay. Therefore, make sure that moisture does not get between the materials, otherwise such a floor will not last long.

Laying linoleum on a wooden floor is one of the construction tasks that people can do without special training, and in order to properly lay the material, it is enough to familiarize yourself with all the nuances and rules for performing this work. What does a person who decides to change an old wooden floor for a new beautiful coating need to know? First you need to learn as much as possible about such a practical coating as linoleum, and then how best to lay it.

There are many types of linoleum

Linoleum: advantages, types, classification

Linoleum is made mainly from natural raw materials: tree resin, jute fabric, linseed oil, cork flour, limestone powder. This flooring is almost universal - it is optimal for apartments, residential buildings, offices and even industrial premises. The material is ideal for flooring in areas with high traffic, such as kitchens, corridors, living rooms.

The popularity of linoleum is due to its many advantages:

- strength;

- water resistance;

- wear resistance;

- elasticity;

- ease of installation and maintenance;

- a wide range of;

- acceptable price.

Depending on the raw materials from which it is made, linoleum is divided into the following types:

- Polyvinyl chloride, made from polymeric material. It is produced on various underlays: foam, heat-insulating, fabric, and also without underlay.

- Alkyd linoleum. It contains alkyd resins, mineral fillers and pigments. It is made on the basis of both synthetic and natural. It is produced in one-color, multi-color, with a pattern. It is characterized by high heat and sound insulation properties, resistant to abrasion, but rather fragile, prone to the formation of fractures and cracks.

- Rubber linoleum or relin. Product thickness 3 mm. Its bottom layer is made of a mixture of bitumen with crushed recycled rubber, and the top layer of the coating is made of colored rubber. It is characterized by high water resistance and elasticity. It is used mainly in industrial and industrial premises.

- Colloxyl linoleum, as a rule, is a baseless coating, which contains nitrocellulose. The material is characterized by moisture resistance, elasticity, fire safety, has a peculiar luster.

In accordance with the manufacturing technology of linoleum, the pattern applied to the base is covered with a protective layer on top, the thickness of which determines its wear resistance and, of course, the cost.

According to wear resistance, linoleum has a separate classification. It is divided into:

- domestic;

- semi-commercial;

- commercial.

Domestic linoleum has a fairly low wear resistance, it is usually used in residential areas.

semi-commercial linoleum is characterized by medium wear resistance, therefore it is recommended as a floor covering in rooms and offices with medium traffic.

Commercial Linoleum has a very high wear resistance. This characteristic also determines its use in rooms with high traffic.

The use of linoleum according to the classification is advisory. However, the selection of flooring in accordance with the purpose of the room and its degree of load is the key to its successful operation and long-term use. For laying on a wooden floor, it is better to choose linoleum with high sound and heat insulation properties. Having decided on the choice of linoleum, we proceed to its flooring.

Step by step instructions for laying linoleum

Linoleum is laid without fail only on a perfectly flat surface. Why? The fact is that if there are irregularities and flaws on the surface of the base, they will also appear on linoleum. In other words, the better the floor is prepared, the more beautiful the new coating will look and the longer its service life will be.

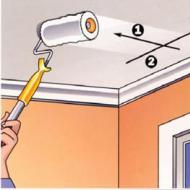

Wood surface preparation (plywood flooring)

The plank floor is deformed and damaged during operation, therefore, experts recommend that when preparing floors for linoleum, laying plates from fiberboard, chipboard or plywood. If the quality of the wooden floor is not bad, the thickness of the slabs can be 5-8 mm. In the presence of large differences, their thickness should be at least 15 mm. Next, we perform the work on preparing the floor in the following sequence:

- We remove the old paint from the painted floor with a spatula, preheating it with a building hair dryer.

- Using a hammer and a beard, we hammer nails into the boards to a depth of 6-7 mm. Boards that creak when walking are additionally nailed to the lags.

- We level the surface with a planer (manual or electric), or a parquet grinder.

- If you decide to lay linoleum on the old base, in this case you need to vacuum it, wash it thoroughly and dry it.

- If, nevertheless, it is decided to lay plywood, for this you will need PVA glue or glue for laying parquet, in which filler is added to increase viscosity. Sheets of plywood are glued with an offset of half a sheet.

- Next, we attach the glued plywood additionally to the floor with nails. We putty the gaps between the sheets of plywood with the same mastic that glued the plywood to the floor. We grind the joints.

- We impregnate dried plywood sheets with hot drying oil.

The surface is ready for laying linoleum. The work is painstaking, but it will pay off in the future with beauty and durability.

To lay linoleum on a wooden floor, it must first be left for a couple of days in this room to stand and straighten out at room temperature. Its surface should be perfectly flat, without a single kink or crease. If you notice the presence of any bend, it should be straightened by pressing the linoleum with boards, books, and other objects.

Linoleum should stand and straighten out a couple of days indoors

If too much crease or folds are found on the material, it is better to replace it, since it will create additional difficulties during installation, and after installation the floor will be uneven and, accordingly, impractical.

Important! Linoleum flooring on a wooden floor should be carried out at a room temperature of at least 16ºС and humidity in the range of 40-60%.

We calculate the amount of material needed:

- measure the length and width of the room and add 10 cm each;

- we take into account the protrusions (the space under the door, window, closet);

- if there is a pattern, we take into account the margin for 1 pattern repeat in both directions.

Important! If the linoleum is cut incorrectly, leaving allowances, it may later happen that it will form waves.

Before laying, we choose the correct direction of the linoleum to hide the seams. Marble and plain linoleum must be placed along the line of light. If there are drawings, they are placed in the longitudinal direction to match. If linoleum is laid on a wooden floor, then the joints are made in the middle of the board.

We prepare the tools necessary for laying:

- well-honed knife;

- steel notched trowel;

- spatula made of wood;

- short and long lines;

- glue, compound for welding seams

- double-sided adhesive tape.

Linoleum flooring methods

Without gluing . This method is the fastest, but it is suitable for low-traffic areas of no more than 12 m2. With such a flooring, the coating wears out faster and there is a high probability of wave formation.

Glueless linoleum installation

Attaching with double sided tape . This method will protect the linoleum from rapid wear. And if necessary, it can be peeled off without difficulty, although traces of adhesive tape may remain on the floor of the room.

Sticking linoleum with double-sided tape

Bonding with glue . This method does not have the disadvantages of the first two. If the area of the room exceeds 20 m2, then this is the only acceptable way. In this case, the service life of linoleum increases significantly. But laying the coating in this way is a rather laborious process.

Laying linoleum with glue

The process of laying linoleum

We spread the linoleum on the floor, while not forgetting to leave a margin on the baseboards (5-10 cm).

We smooth the coating with our hands from the middle to the walls, and so that it fits better to the walls, we make small cuts in the corners.

If we put the linoleum without gluing, cut off the excess along the plinth with a sharp knife, then fix it in the doorways with metal rails.

If we glue it on double-sided tape, then first we stick the tape around the entire perimeter of the room without removing the protective layer. We unfold the roll, bend one half to the other. Now we remove the protective paper, spread the linoleum, smooth it with our hands from the center to the walls.

We do the same with the other half. Cut off the excess along the plinth. We fix it in the doorways with rails-sills.

If we are laying on glue, then after bending one half of the linoleum, we apply glue to the floor and distribute it with a roller or notched trowel. Leave for 20 minutes, then unfold the folded part of the coating, carefully smooth it with your hands.

We do the same operations with the other half. We cut off the excess linoleum, press the edges near the walls with a plinth, put rail-thresholds in the doorway.

The edges of the linoleum are pressed with a plinth, metal slats are placed at the doorways

If, suppose, for some reason, it is necessary to lay more than one strip of linoleum (a large area of \u200b\u200bthe room, or it was not possible to find linoleum of the required width in the store), but several, then they will have to be joined. This is done in the following way:

- We lay the coating strips so that they overlap one another by about 10 cm.

- We bend one strip, apply glue on it and glue it to the floor. We do the same with the other strip.

- With a sharp knife, cut off both layers of linoleum at the overlap, remove the trimmings and carefully glue both edges so that the resulting joint is as inconspicuous as possible.

- After the glue dries, we glue the joints using a special liquid for cold welding of seams. Pre-glue the adhesive tape on the seam. After a few hours, when the seam begins to weld, the tape must be removed.

After gluing the linoleum, we press it tightly with a roller or a special roller. Until the coating is completely dry, do not step on it and do not walk on it.

Do not walk on glued linoleum until it is completely dry.

Having familiarized yourself with the intricacies of choosing linoleum and the process of laying it on a wooden floor, there is no doubt that it will be easy for you to do it yourself. You can safely get to work. And after a dozen or two years, when you want to update your floor, it will not be difficult to change the coating to another if the base has been prepared to last.

Is it possible to lay linoleum on a wooden floor? Detailed analysis of the issue

It is no secret that, in the modern world, linoleum is considered popular. This coating is made from natural materials: cork flour, jute fabric, linseed oil, tree resins, limestone powder. Since this material is universal, it is quite clear that it can be laid on any surface, providing the room with an attractive appearance and saving the owners from troublesome cleaning. However, the installation method that is most beneficial in a given situation depends on the type of PVC coating and the floor material of the room. Let's take a closer look at the order of flooring on linoleum.

Linoleum advantages:

- Strength;

- Elasticity;

- Not demanding in care;

- wear resistance;

- Waterproof;

- Democratic price;

- Large selection of patterns and colors;

- Relative ease of installation.

Varieties of linoleums

Depending on the materials used in the manufacture, there are several types of linoleum:

Polyvinyl chloride (PVC)

Made from polymer. The base can be foamed, heat-insulating, fabric. Sometimes the base is not used at all.

Also read articles:

- Four-layer linoleum is usually located on a foam base. Its thickness is four millimeters. The bottom layer is foamed vinyl. Fiberglass follows above, then PVC, and the last “slice” of such a “sandwich” is the top one, which is a protective layer made of transparent PVC. This coating has excellent heat and sound insulation. It can be laid in any room, regardless of their humidity. This type of material also has many variations of decor.

- 2-3 mm thick has a sound and heat insulating multilayer coating. The lower part is a felt of synthetic foam covered with fiberglass. The top layer is two or three layers of PVC film. This product also has many colors and patterns.

- The fabric base consists of only two layers. The lower one is fabric, the upper one is protective. The thickness of such a coating does not exceed five centimeters. Polyvinyl chloride linoleum with a fabric base is plastic, water-resistant, and resistant to abrasion.

- No foundation. Tyk also differs single-layer and. Its maximum thickness is three millimeters. The material has high electrical resistance, good fire resistance and abrasion resistance. The structure of the coating is one-sided, so neither the color nor the texture of the linoleum will change during use. That is why it is most often placed in rooms with high humidity and traffic - in the bathroom, in the kitchen, in the pool, etc.

Relin or rubber linoleum

It is usually a multi-layer coating with a thickness of three millimeters. The lower layer is a mixture of bitumen with crushed recycled rubber or synthetic rubber, the upper layer is a layer of colored rubber. Relin is monophonic and multi-ton. Its main qualities are elasticity and water resistance. Suitable for use in industrial and industrial premises.

Alkyd linoleum

The thickness of alkyd linoleum ranges from two and a half to five millimeters. Alkyd resins, mineral fillers and pigments are used as raw materials for the manufacture of the material.

Alkyd linoleum can be multi-color, plain, and also decorated with various patterns. It is resistant to abrasion, has high heat and sound insulation properties, but is very fragile and can break.

colloxyl linoleum

In the form of a baseless coating, colloxyl linoleum is presented. Made from nitrocellulose. Shine, flexibility, moisture resistance, fire safety and elasticity are its main advantages.

Linoleum classification

Linoleum is divided into types and depending on its wear resistance. Guided by manufacturing technology, manufacturers cover the image, which is previously applied to the PVC base, with a protective layer on top. The wear resistance of the material depends on the thickness of this layer. The thicker the "shield", the more expensive the coating.

- Household linoleum, which is low in terms of wear resistance, is usually laid in residential premises;

- The semi-commercial type material belongs to the average level of wear resistance, which is why it is laid in rooms with medium traffic: hallways, kitchens, offices. One is quite hard, which is why there are no traces of heavy pieces of furniture and other objects on the surface.

- Commercial linoleum is endowed with increased wear resistance. For this reason, it is laid in industrial premises, as well as in areas with high traffic.